Shell and Tube Heat Exchanger

A technology of shell-and-tube heat exchange and heat exchange tubes, which is applied in the direction of heat exchanger types, heat exchanger shells, indirect heat exchangers, etc., and can solve the problem of different thermal elongation of the shell and heat exchange tubes and equipment damage and other problems to achieve the effect of avoiding adhesion and accumulation, ensuring smooth circulation and avoiding smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

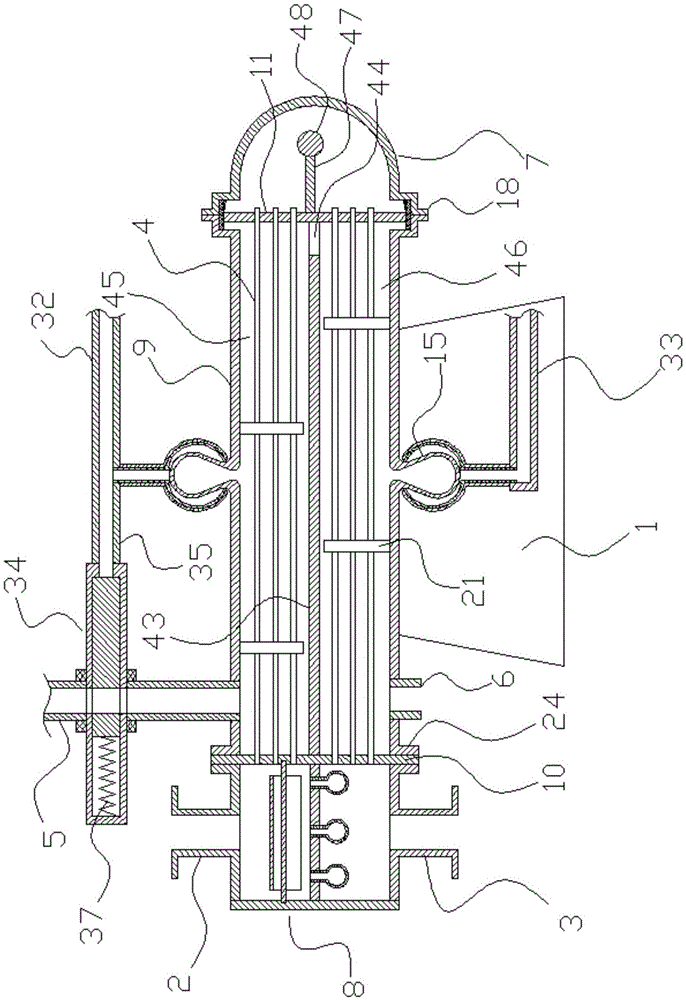

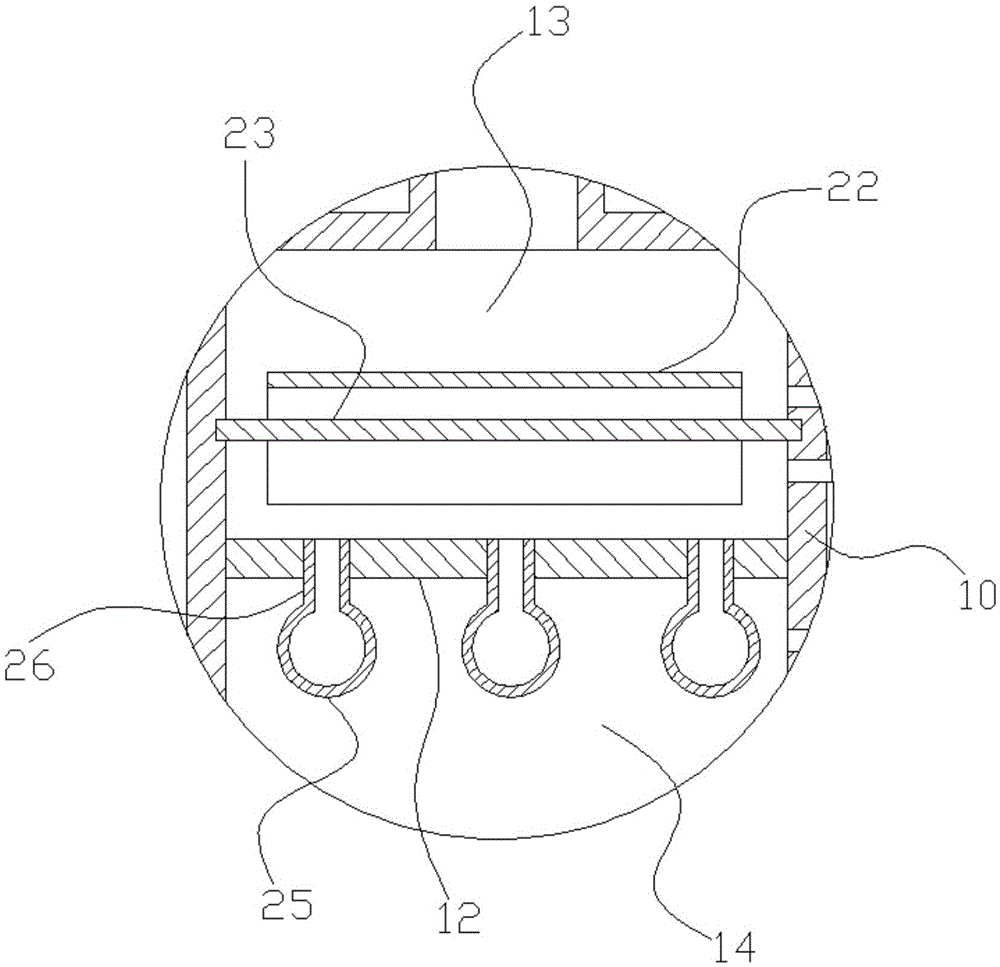

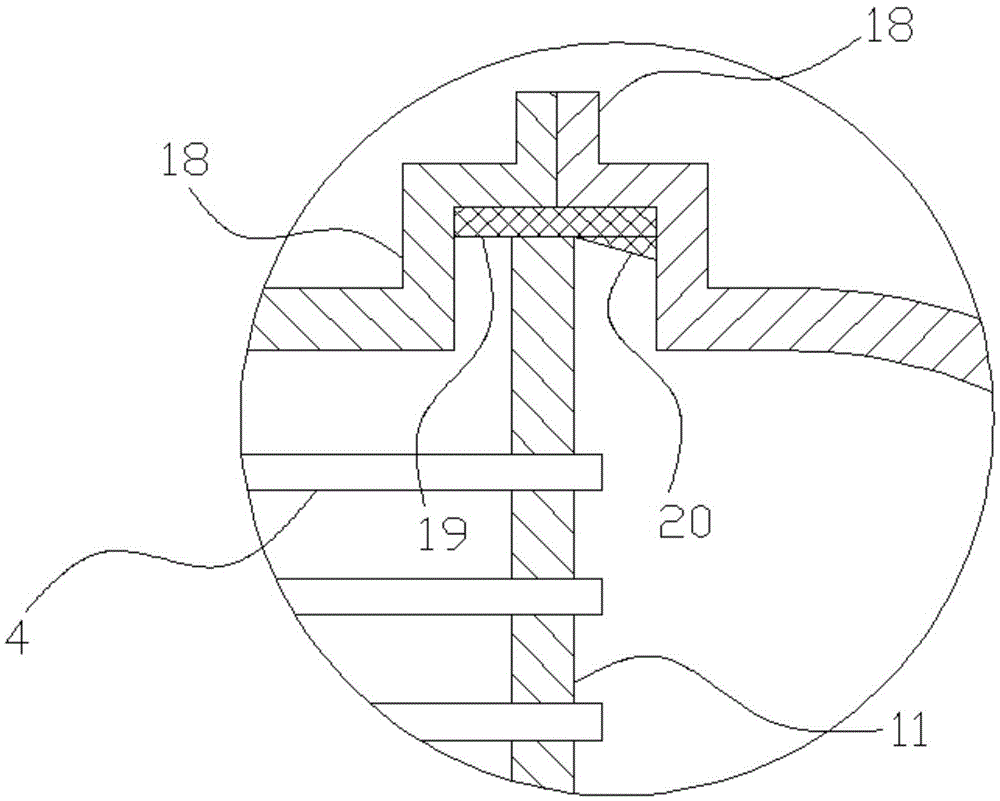

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0026] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7In the shown embodiment, a shell-and-tube heat exchange device includes a tube-side part, a shell-side part, and several brackets 1, and the tube-side part includes a tube-side inlet tube 2, a tube-side outlet tube 3, a plurality of The heat exchange tube 4, the shell part includes a horizontal heat exchanger outer shell, the shell side inlet pipe 5, and the shell side outlet pipe 6, and the heat exchanger outer shell is composed of a head 7, a shell head 8, A tube box 9 with openings at both ends is jointly formed, a fixed tube plate 10 is provided between the shell head and the tube box, and a head tube plate 11 is provided between the described head and the tube box. Both ends of the heat exchange tubes are respectively connected to the fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com