Gantry type stacking and lifting device based on energy-saving brick production

A lifting device, gantry-type technology, applied in the direction of lifting equipment braking device, hoisting device, transportation and packaging, etc., can solve the problems of easy deposition and adhesion, cumbersome maintenance, lack of awareness of dust-proof sealing protection, etc., to ensure stability , The effect of ensuring cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

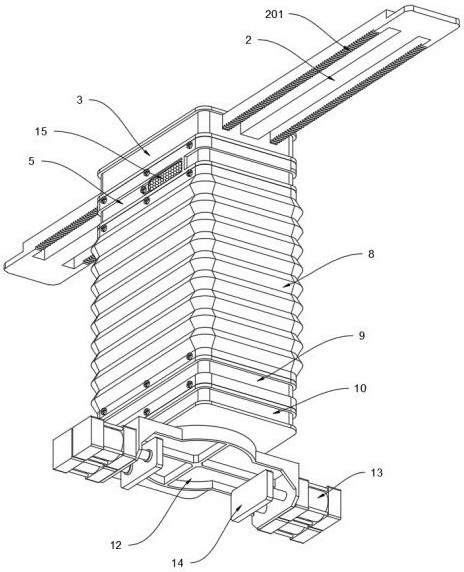

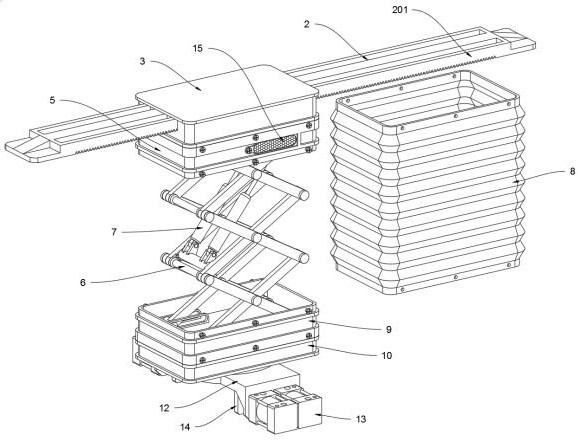

[0032] as attached figure 1 to attach Figure 10 As shown: the present invention provides a gantry-type stacking and lifting device based on the production of energy-saving bricks, including a support rail 2, a top connection seat 5, a dust-proof telescopic shell 8 and a movable base 10; 1 is fixedly connected, and the outer side of the support rail 2 is connected to the mobile top seat 3; the top connecting seat 5 is connected to the bottom of the mobile top seat 3, and the top connecting seat 5 is connected to the bottom connecting seat 9 through the telescopic frame 6, and two lifting hydraulic cylinders 7 It is symmetrically connected to the inside of the telescopic frame 6; the upper and lower ends of the dustproof telescopic shell 8 are respectively connected with the top connection seat 5 and the bottom connection seat 9; A rotating motor 11 is fixedly installed inside the 10, and a driving gear 1101 is installed on the rotating shaft of the rotating motor 11. The bott...

Embodiment 2

[0036] The top end of the dust-proof telescopic shell 8 is fixed on the outside of the bottom of the top connecting seat 5 by bolts, and the bottom end of the dust-proof telescopic shell 8 is set on the outside of the top of the bottom connecting seat 9 by bolts. The shell 8 is located outside the telescopic frame 6;

[0037] With the above technical solution, while the telescopic frame 6 is telescopically adjusted, the dustproof telescopic shell 8 is synchronously telescopically adjusted, and the telescopic frame 6 is sealed and protected by the dustproof telescopic shell 8, so as to prevent external dust and impurities from adhering to the connecting parts of the telescopic frame 6, Affect the smoothness of the telescopic adjustment of the telescopic frame 6 .

Embodiment 3

[0039] Air holes 501 are respectively opened on the front and rear sides of the top connecting seat 5, and the air holes 501 communicate with the top of the dust-proof telescopic shell 8. The right end of the filter mesh 15 is inserted and connected to the outside of the top connecting seat 5, and the left end of the filter mesh 15 is connected to the top by bolts. The seat 5 is fixedly connected, and the filter screen sheet 15 is located outside the air hole 501; adopting the above-mentioned technical scheme, when the telescopic frame 6 is extended and adjusted downward, the air enters the inside of the dust-proof telescopic shell 8 through the air hole 501, and when the telescopic frame 6 is upwardly retracted and adjusted, The air inside the dust-proof telescopic shell 8 is discharged through the air hole 501, and the air entering the dust-proof telescopic shell 8 is filtered through the filter mesh 15 to ensure the cleanliness of each part of the telescopic frame 6.

[0040...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com