Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Accurate leak detection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

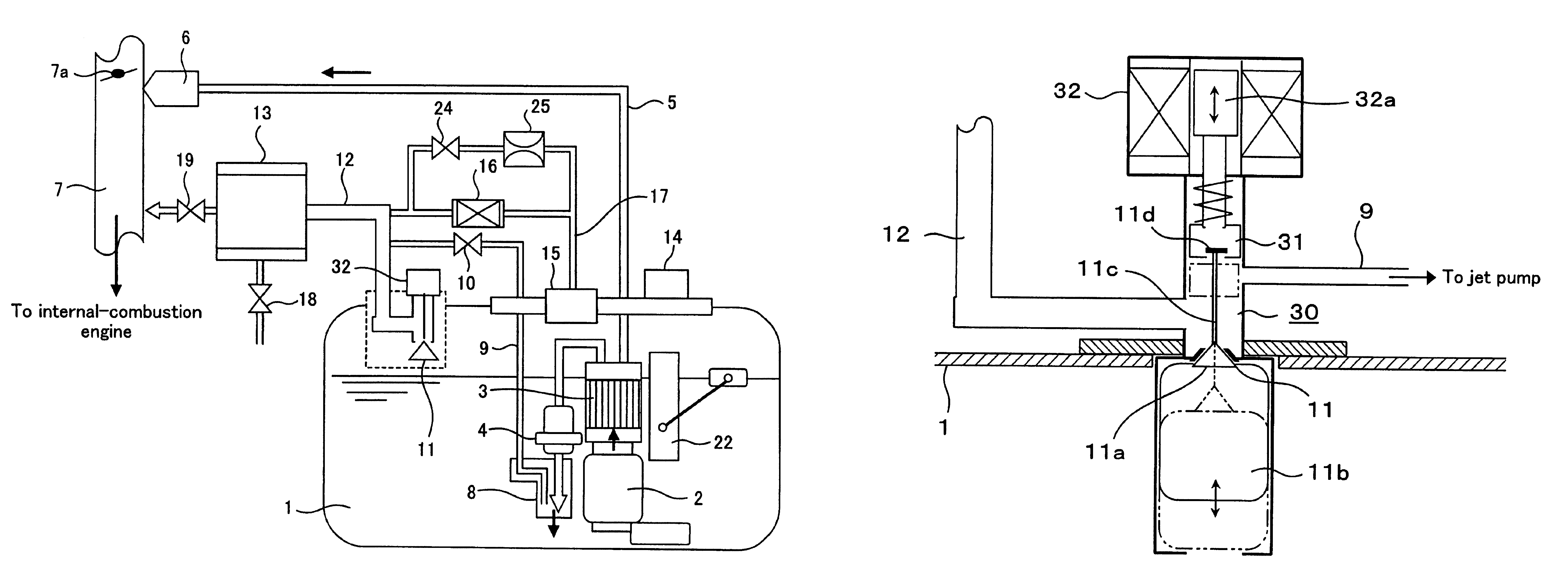

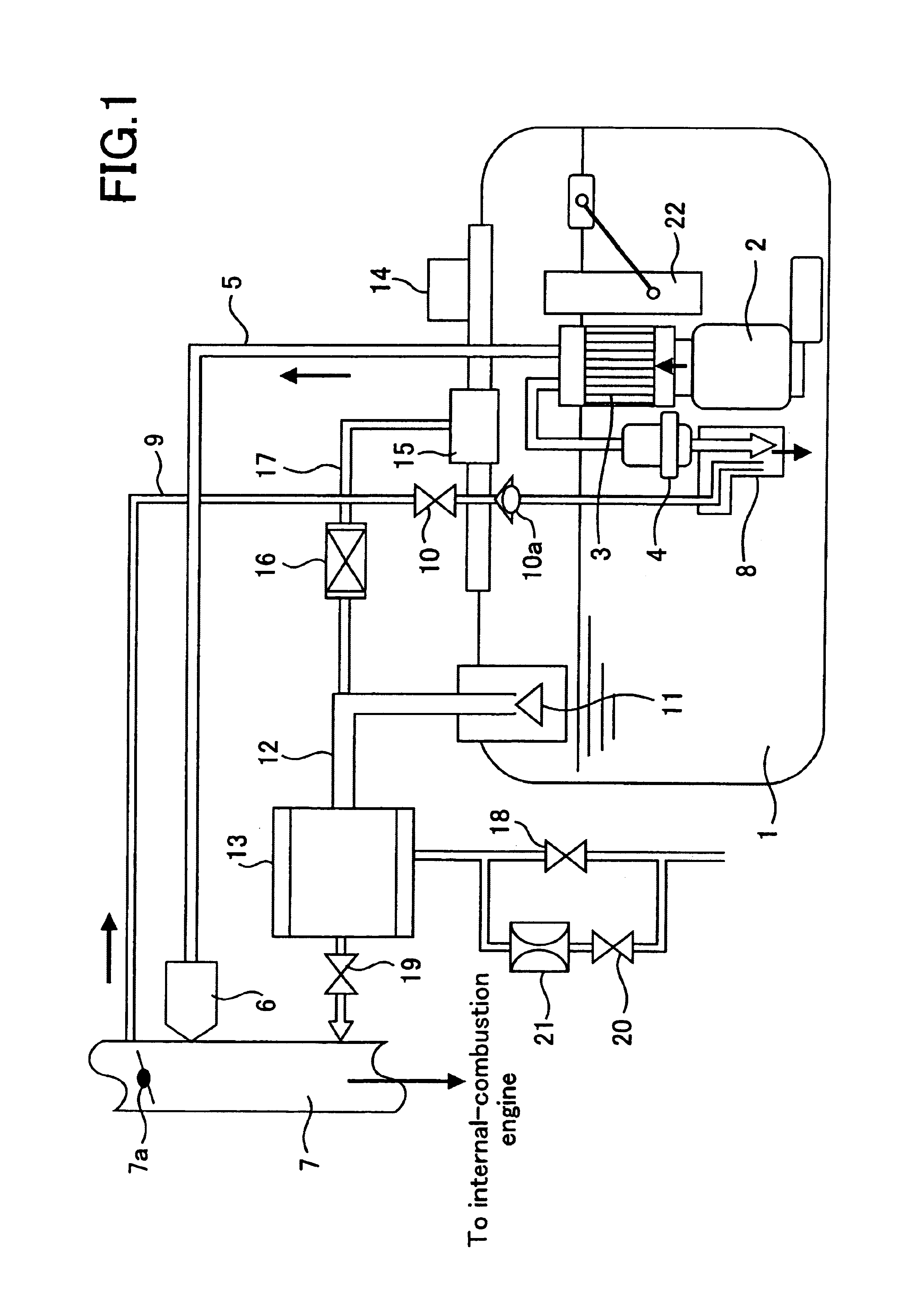

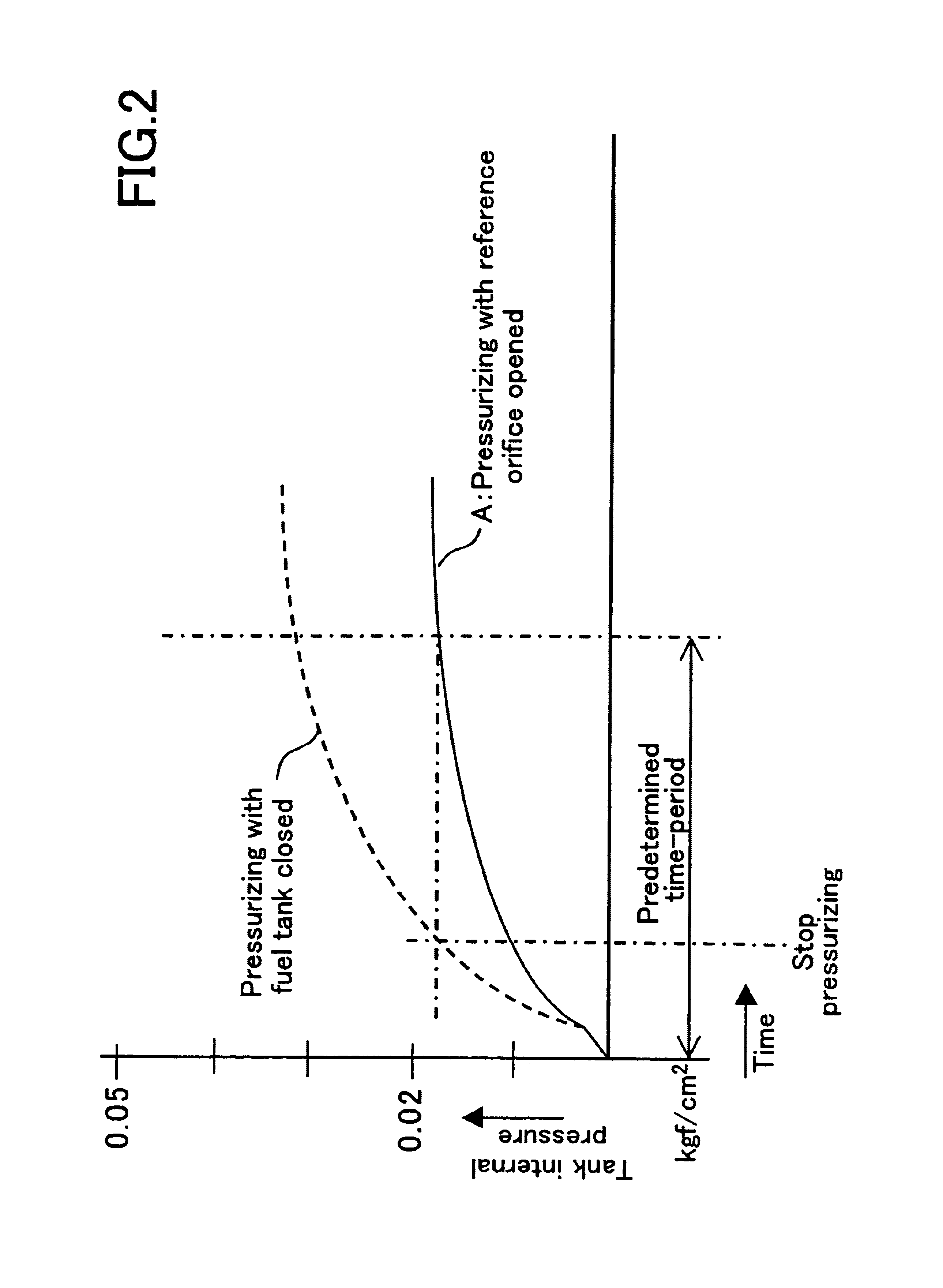

Apparatus for detecting fuel-vapor gas leaks, and vent valve apparatus applied to this apparatus

InactiveUS6986341B2Accurate leak detectionDetection of fluid at leakage pointOperating means/releasing devices for valvesInternal pressurePressure curve

An apparatus for detecting fuel-vapor gas leaks that includes a jet pump (8) that introduces outside air into and pressurizes a vapor purge system including a fuel tank (1) by gasoline flow from a fuel pump (2); an internal pressure sensor (14) for measuring vapor purge system internal pressure, an open / close controllable reference orifice (21) that causes leakage through a reference leak hole; and a storage device for storing as an initial curve pressure changes during pressurization by the jet pump (8) for a predetermined time period, with the reference orifice (21) alone opened. The device can accurately detect leakage even while an internal combustion engine is running because it judges leak presence / absence by comparing a time series in a pressure curve obtained by jet pump (8) pressurization over the predetermined time period while idling with the vapor purge system completely shut-off, with a time series in the initial curve.

Owner:MITSUBISHI ELECTRIC CORP

Pipe joint rapid leak hunting method

InactiveCN1595089AImprove securityImprove reliabilityMeasurement of fluid loss/gain rateEngineeringHigh pressure

This invention provides a pipe joint leak hunting method, especially that of pipe joint of water bottom transmission engineering. It mainly locates the pipe joints into the apparatus full of high pressure gas inside and measure the leak through observing the changes of the high-pressure gas. This method is simple and convenient and quick and solves the main technique difficulty in the field.

Owner:杜广才

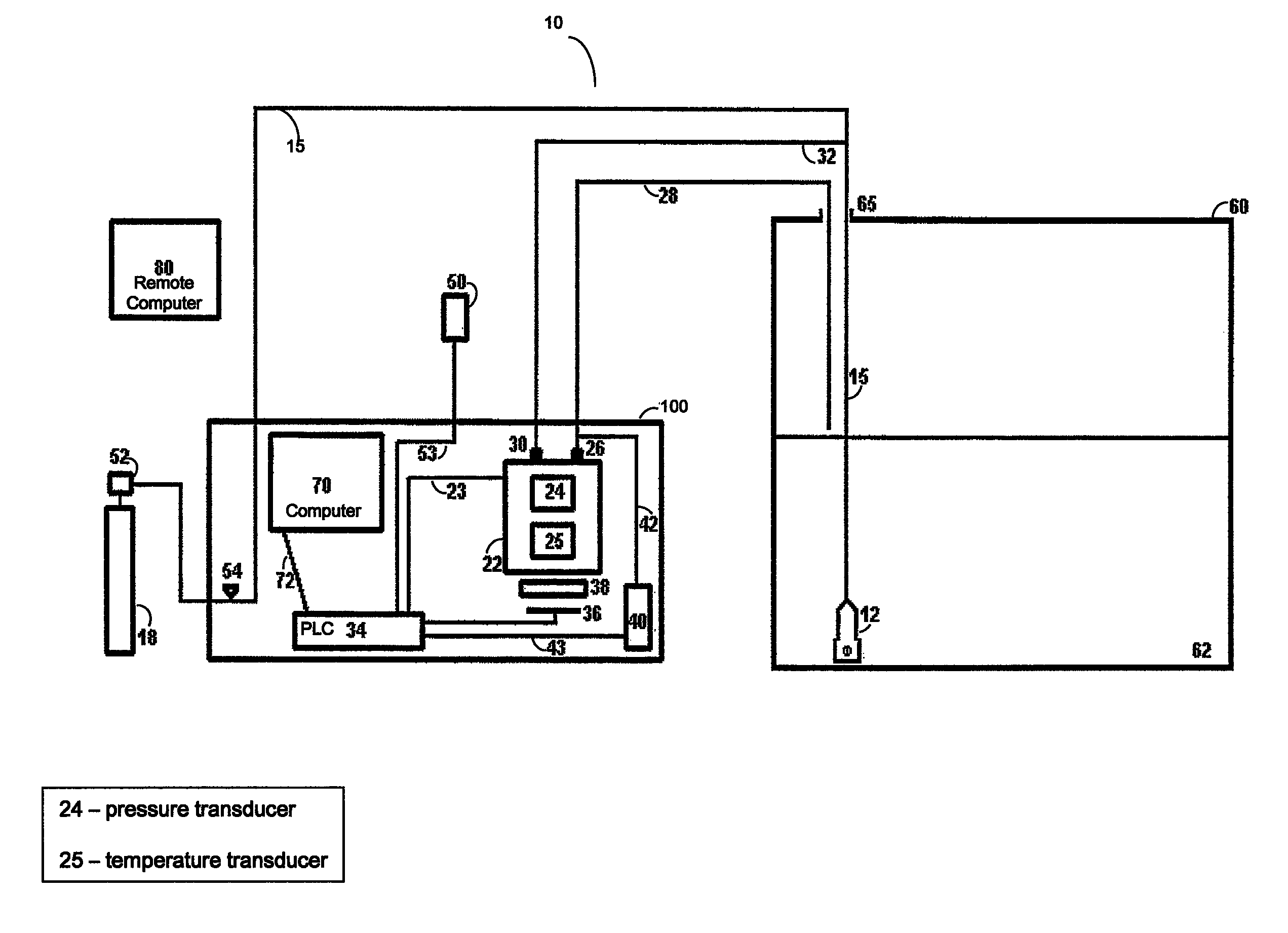

Method and apparatus for leak detection in horizontal cylindrical storage tanks

ActiveUS20100212404A1Low detection thresholdPreserving industrial and environmental resourcesDetection of fluid at leakage pointTransducerHydrostatic pressure

A safe, precise, and cost effective storage tank leak detection system. Embodiments include two highly precise quartz crystal type pressure transducers held at a constant temperature. A bubbler to achieve access to the hydrostatic pressure at the tank bottom and just below the liquid surface. First transducer and bubbler are used to measure fluid mass while second transducer and bubbler are used to measure fluid density then used in combination with data correction and regression techniques to yield a storage tank leak detection system for use in horizontal cylindrically shaped tanks with an extremely low leak detection threshold. The storage tank leak detection system is thought to be most useful for detecting and measuring very small leaks in large horizontal cylindrical storage tanks.

Owner:MASS TECH

Aerosol generator

InactiveCN102069046AAccurate detectionAccurate leak detectionLiquid spraying apparatusPermeability/surface area analysisSpray nozzleLiquid storage tank

The invention relates to an aerosol generator, which comprises a shell, wherein the shell is provided with a compressed air inlet, a spray nozzle, an adjusting valve, a pressure adjusting valve and a liquid storage tank; and the liquid storage tank comprises a plurality of Laskin nozzles. A first cavity is communicated with the compressed air inlet. The adjusting valve is communicated with the compressed air inlet. A second cavity is formed in the liquid storage tank through a baffle plate, and the second cavity is connected with the spray nozzle. The plurality of Laskin nozzles are accommodated in the liquid storage tank; and the nozzles are communicated with the first cavity through a plurality of conduits. The whole generator has simple structure, is convenient to operate, and has more accurate effects on detection of filter materials and finished product filters and leakage detection of filters.

Owner:SUZHOU HUADA INSTR & EQUIP

Leakage detecting method for sealing structure part

InactiveCN102564709AEasy to useLow leak detection rateDetection of fluid at leakage pointEngineeringHelium mass spectrometer

The invention relates to a leakage detecting method for a sealing structure part, which comprises the following steps: 1) connecting a part to be detected into a helium mass spectrometer leak detector; 2) vacuumizing the part to be detected and the helium mass spectrometer leak detector; 3) blowing helium to the part to be detected; and 4) carrying out sealing detection to the part to be detected according to the indication situation of an output meter of the helium mass spectrometer leak detector. In the invention, the leakage detecting method for the sealing structure part, which can directly reflect the omission factor, is accurate to detect the leakage, simplifies the leakage detecting process and is convenient to use, is provided.

Owner:AVIC NO 631 RES INST

Detection method for leakage of buried metal pipeline

The invention discloses a detection method for leakage of a buried metal pipeline. According to the method, the earth surface current distribution state is detected on the basis of an alternating voltage gradient detection method, the distance between a predicted corrosion point and a detection point of the buried metal pipeline is acquired on the basis of the earth surface current distribution state, then the distance is converted into space coordinates of the predicted corrosion point on the basis of the geographical location information of the buried metal pipeline, and on-site hydrocarbon detection is performed on the basis of the space coordinates, so that leakage of the buried metal pipeline can be detected accurately in a nondestructive manner.

Owner:叶雷

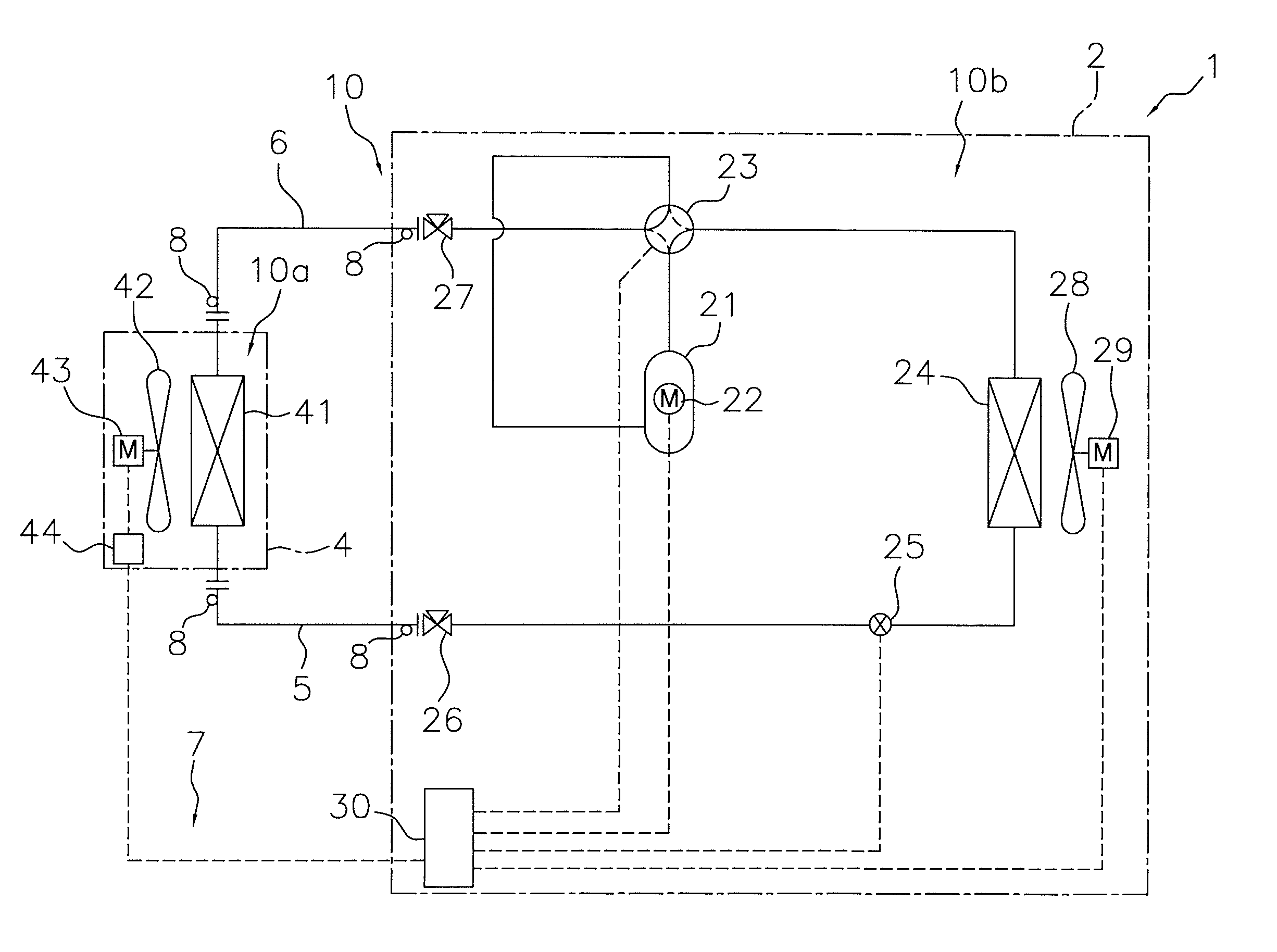

Fluid sensor, refrigerant leakage detection device, refrigeration system, and refrigerant leakage detection method

InactiveUS20100244863A1Accurate leak detectionEasy to detectResistance/reactance/impedenceFluid-tightness measurementMeasurement deviceEngineering

It is possible to detect refrigerant leakage while pinpointing the location where refrigerant leakage is occurring in a refrigerant circuit of a refrigeration system. A fluid sensor (8) is a fluid sensor for detecting refrigerant leakage from a refrigerant circuit (10), wherein the fluid sensor includes a sensor main body (8a) having two electrodes (81, 82) spaced apart, and the fluid sensor (8) is configured such that the fluid sensor (8) is capable of being connected to an impedance measurement device (9) for measuring impedance between the two electrodes (81, 82).

Owner:DAIKIN IND LTD

Online leakage detection method and device thereof for heat treatment furnace radiant tube

ActiveCN102853976ADoes not affect productionLow costMeasurement of fluid loss/gain rateUltimate tensile strengthStreamflow

The invention discloses an online quick leakage detection method for a heat treatment furnace radiant tube. The method comprises that the heat treatment furnace radiant tube is closed; gas flow at positions of any connectors of the heat treatment furnace radiant tube is detected; and leakage points exist on the heat treatment furnace radiant tube if the gas flow is more than zero, and the heat treatment furnace radiant tube is normal and no leakage exists if the gas flow is zero. The device of the method comprises a gas flow meter and a vacuum sampling pump, wherein a gas inlet of the gas flow meter is connected with any connector on the heat treatment furnace radiant tube, which is communicated with the external, and an exhaust port of the gas flow meter is connected with a gas inlet end of the vacuum sampling pump through a gas suction pipe. By the aid of the method, the accuracy and the reliability of detection are improved, the leakage detection can be conducted on a non-oxidation furnace radiant tube in real time accurately, reliably, conveniently and rapidly in the normal production, the operation is simple, the labor intensity is low, the cost is low and the method and the device are suitable to popularization and application.

Owner:武汉钢铁有限公司

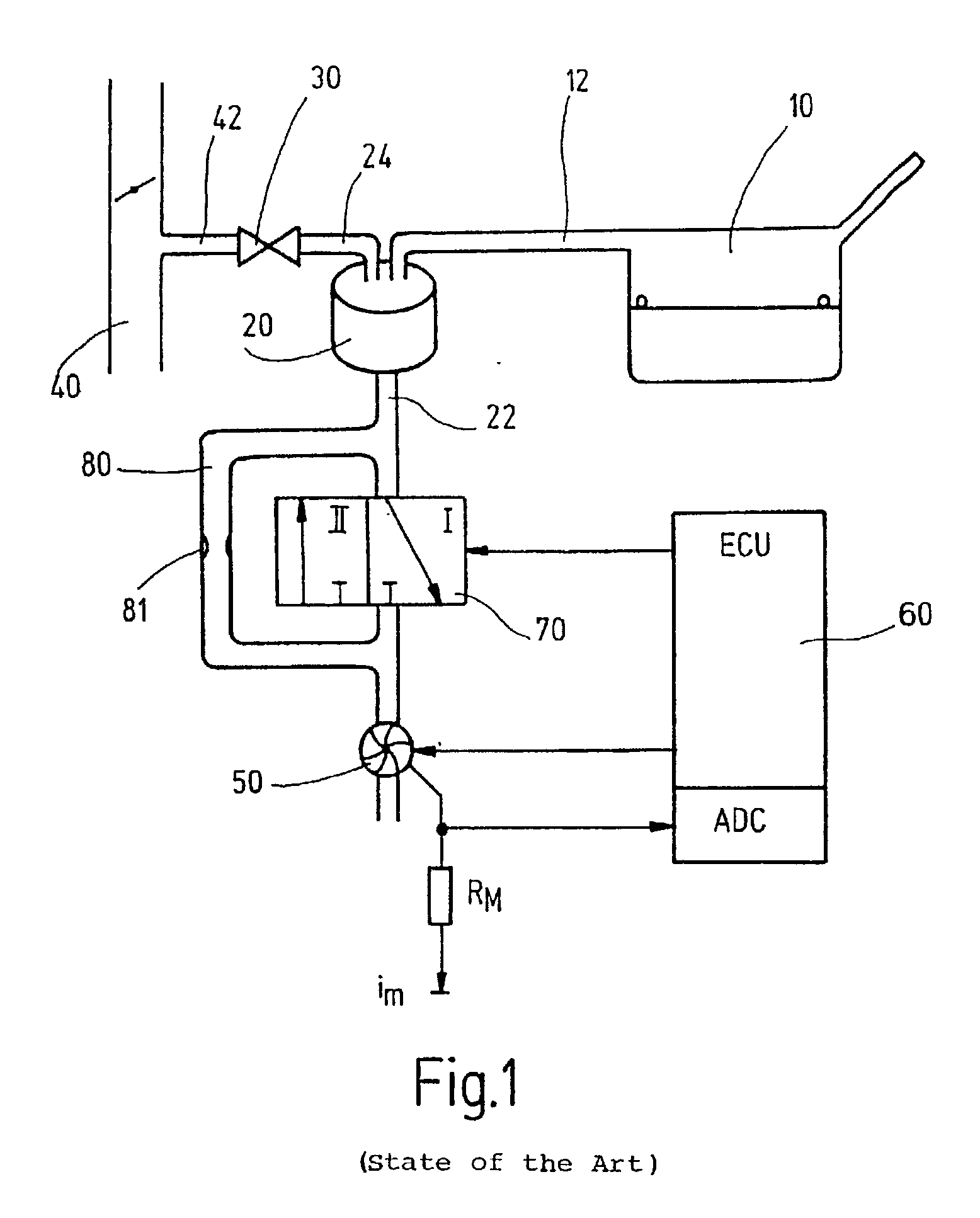

Method for verifying the tightness of a tank system in a motor vehicle

InactiveUS20020157653A1Accurate leak detectionImprove accuracyDetection of fluid at leakage pointMeasurement of fluid loss/gain rateMobile vehicleEngineering

A method for checking the tightness of a tank system, especially of a tank-venting system of a vehicle, wherein an overpressure or an underpressure relative to the atmospheric pressure is introduced into the tank system by means of a pressure source and the time-dependent trace of at least one operating characteristic variable of the pressure source is detected when introducing the overpressure / underpressure up to reaching a first time point or a first pressure level and is compared to a time-dependent trace of the operating characteristic value up to this time point or up to this pressure level (expected diagnostic trace), the time-dependent trace being expected in the case of a tight tank system, and, a conclusion as to non-tightness is drawn when the detected time-dependent trace deviates from the expected diagnostic trace by at least a pregiven value, characterized in that, when a deviation is determined, the overpressure / underpressure in the tank-venting system is further increased up to reaching a second time point or a second pressure level; the operating characteristic value of the pressure source continues to be detected and compared to an expected further time-dependent trace of the operating variable in the case of a tight system (further diagnostic trace) and, a fault announcement is only then outputted when the detected time-dependent trace during the introduction of the further overpressure / underpressure deviates from the further diagnostic trace.

Owner:ROBERT BOSCH GMBH

Leakage-proof detection device for valve machining

InactiveCN111122064AAccurate leak detectionImprove accuracyDetection of fluid at leakage pointMachine valve testingWater trapCoupling

The invention belongs to the technical field of valve machining, especially relates to a leakage-proof detection device for valve machining. For the problem of the detection accuracy, the following solution is presented: the device comprises a transparent detection box motors are arranged on the two sides of the outer wall of the bottom of the transparent detection box, output shafts of the motorsare connected with rotating rods through couplers, stirring rods distributed at equal intervals are arranged on the two sides of the outer wall of each rotating rod, the specifications and sizes of the stirring rods are different, the sizes of the stirring rods are gradually reduced from top to bottom, and an inverted horn-shaped structure is formed. According to the invention, the motors, the rotating rods, the stirring rods and the stirring blades are arranged; the sizes of the stirring rods are gradually reduced from top to bottom, the inverted horn-shaped structure is formed, the uneven stirring rods can form vortexes and water waves with different sizes, water flow impact with different sizes can be conducted on the valve, the situation that the valve is impacted by water flow can besimulated, and leakage-proof detection can be conducted on the valve more accurately.

Owner:广州迅磊科技有限公司

Leak detection fixture and leak detection device

The invention discloses a leak detection fixture and a leak detection device. The leak detection fixture comprises a fixture upper press plate, an airbag support seat, an airbag and a fixture holder. The fixture upper press plate is fixed on the upper end of the airbag support seat. The lower end of the airbag support seat is fixed on the fixture holder. The airbag is arranged in the airbag support seat. The airbag is sleeved on the body of a kettle. The upper part of the airbag is arranged at the joint of the fixture upper press plate and the airbag support base. The lower part of the airbag is arranged at the joint of the airbag support seat and the fixture holder. The airbag support seat is provided with a blow hole which is connected with an air source. The fixture holder is provided with a vacuumizing hole connected with a suction pump. The kettle is arranged in the middle groove of the leak detection fixture. The leak detection fixture provided by the invention has the advantages of simple and practical structure and good sealing property, and can be specifically used for detecting the sealing property of the key part of the kettle (such as the part between the kettle body and the kettle bottom), namely the sealing of the lower part of the kettle.

Owner:FOSHAN GREALT APPLIANCE CO LTD

Online leakage detection method and device for non-oxidation furnace radiant tube containing shielding hydrogen gas

InactiveCN102879155ADoes not affect productionEasy to implementDetection of fluid at leakage pointPhysical chemistryEngineering

The invention discloses an online leakage detection method for non-oxidation furnace radiant tube containing shielding hydrogen gas. The online leakage detection method includes steps of 1), emptying gas in a non-oxidation furnace radiant tube and then closing the non-oxidation furnace radiant tube; 2), opening any one of joints of closed space and leading sampled gas in the closed space to be communicated with a hydrogen analyzer through the joint; 3), analyzing the sampled gas, determining that a leak point of the non-oxidation furnace radiant tube exists if the sampled gas contains hydrogen gas, and determining that no leak point of the non-oxidation furnace radiant tube exists if content of hydrogen gas in the sampled gas is zero. An online leakage detection device comprises a hydrogen analyzer, a gas inlet of the hydrogen analyzer is connected with one end of a gas sampling tube, the other end of the gas sampling tube is used for being connected with any joint, communicated with the outside, on the non-oxidation furnace radiant tube, and an exhaust outlet of the hydrogen analyzer is connected with an exhaust tube. By the online leakage detection method, online quick leakage-detection to the non-oxidation furnace radiant tube can be realized accurately, reliably, conveniently and quickly.

Owner:武钢集团有限公司

Fuel vapor handling system

InactiveUS6854452B2Prevent leak detectionLeakage can not be detected accuratelyInternal-combustion engine testingMeasurement of fluid loss/gain rateHandling systemFuel vapor

In a fuel vapor handling system of this invention, an ECU performs a leak check to check a leak of fuel vapor in a fuel vapor passage when the engine is at a stop. The ECU functions to detect the quantity of fuel during the engine stop. The ECU detects the quantity of fuel at the time of engine starting. Furthermore, the ECU compares the quantity of fuel measured at the time of engine starting with the quantity of fuel measured at the preceding engine stop, to thereby determine whether a filler cap was opened during the engine stop. When the filler cap was opened during the engine stop, a result of the leak check will be cancelled. When the filler cap was not opened, the result of the leak check will be determined.

Owner:DENSO CORP

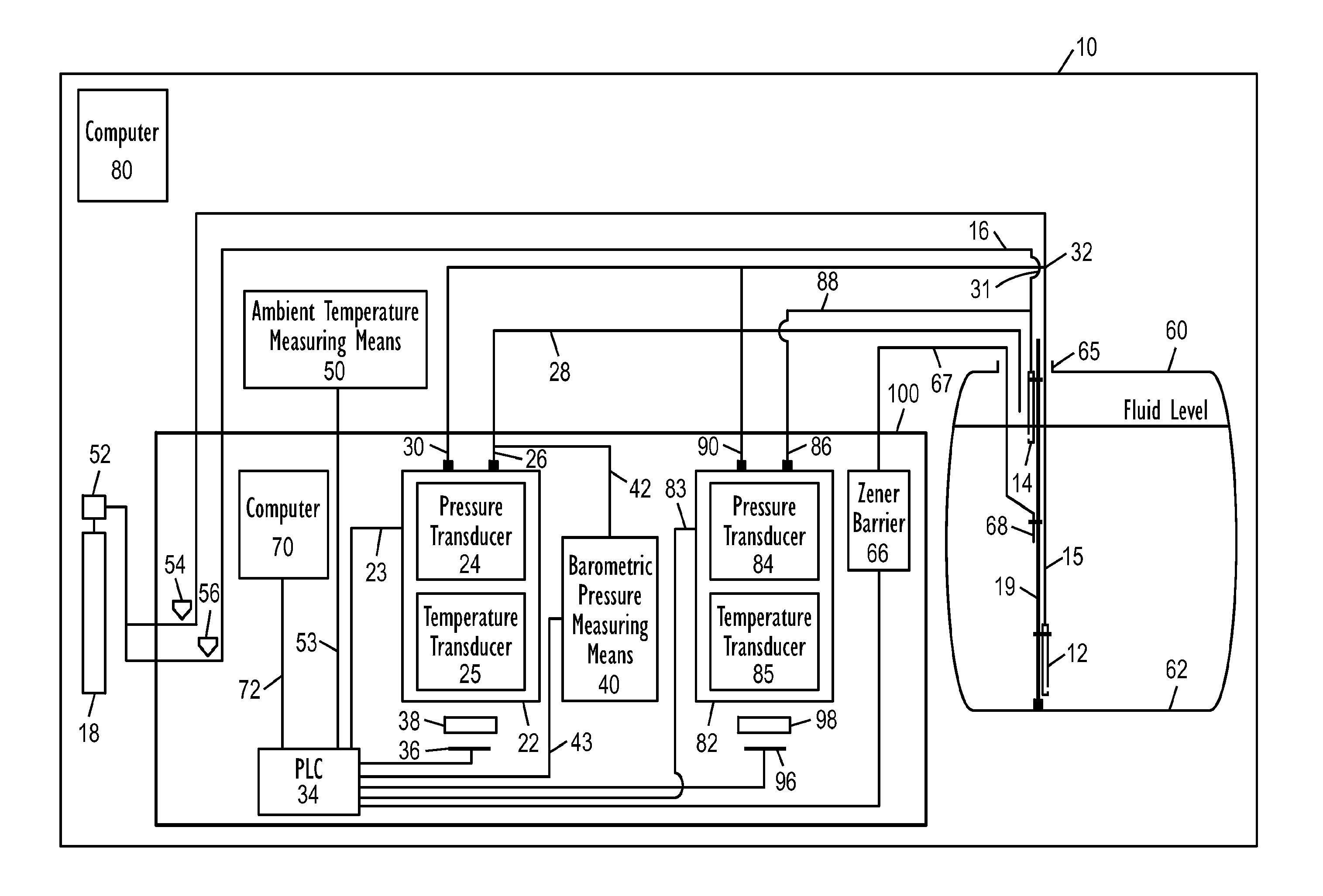

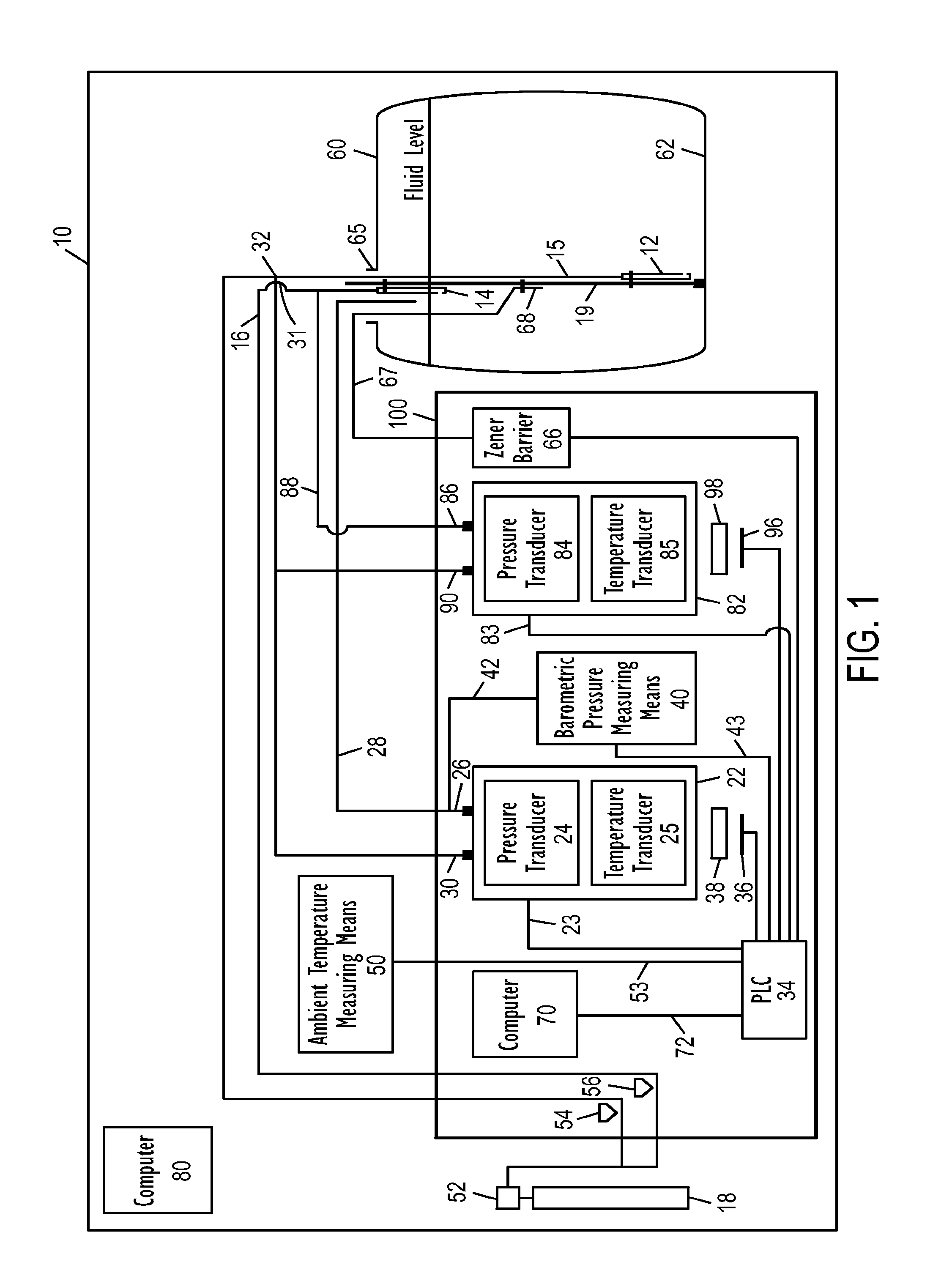

System and method for detecting and quantifying changes in the mass content of liquid storage containers

ActiveUS7739901B2Low detection thresholdPreserving industrial and environmental resourcesDetection of fluid at leakage pointMeasurement of fluid loss/gain rateMeasurement deviceBottom pressure

A storage tank leak detection system, including a quartz crystal type pressure transducer held at a constant temperature, a bubbler-based pressure sensor for reporting tank bottom pressure measurements to the transducer, a fluid surface measurement apparatus to report liquid surface pressure to the transducer, atmospheric pressure measuring apparatus, and a computing system for, based on data reported by all components, effecting data correction (corrected for atmospheric and container physical variations during data gathering) and regression techniques to yield data indicative of changes, if any, in mass content of a liquid storage container, such as a surface storage tank for petroleum and other chemicals.

Owner:MASS TECH

Fluid sensor, refrigerant leakage detection device, refrigeration system, and refrigerant leakage detection method

InactiveUS8350582B2Accurate leak detectionEasy to detectResistance/reactance/impedenceFluid-tightness measurementMeasurement deviceEngineering

A fluid sensor for detecting refrigerant leakage from a refrigerant circuit includes a sensor main body having two electrodes spaced apart from each other. The fluid sensor is configured such that the fluid sensor is connectable to an impedance measurement device to measure impedance between the two electrodes.

Owner:DAIKIN IND LTD

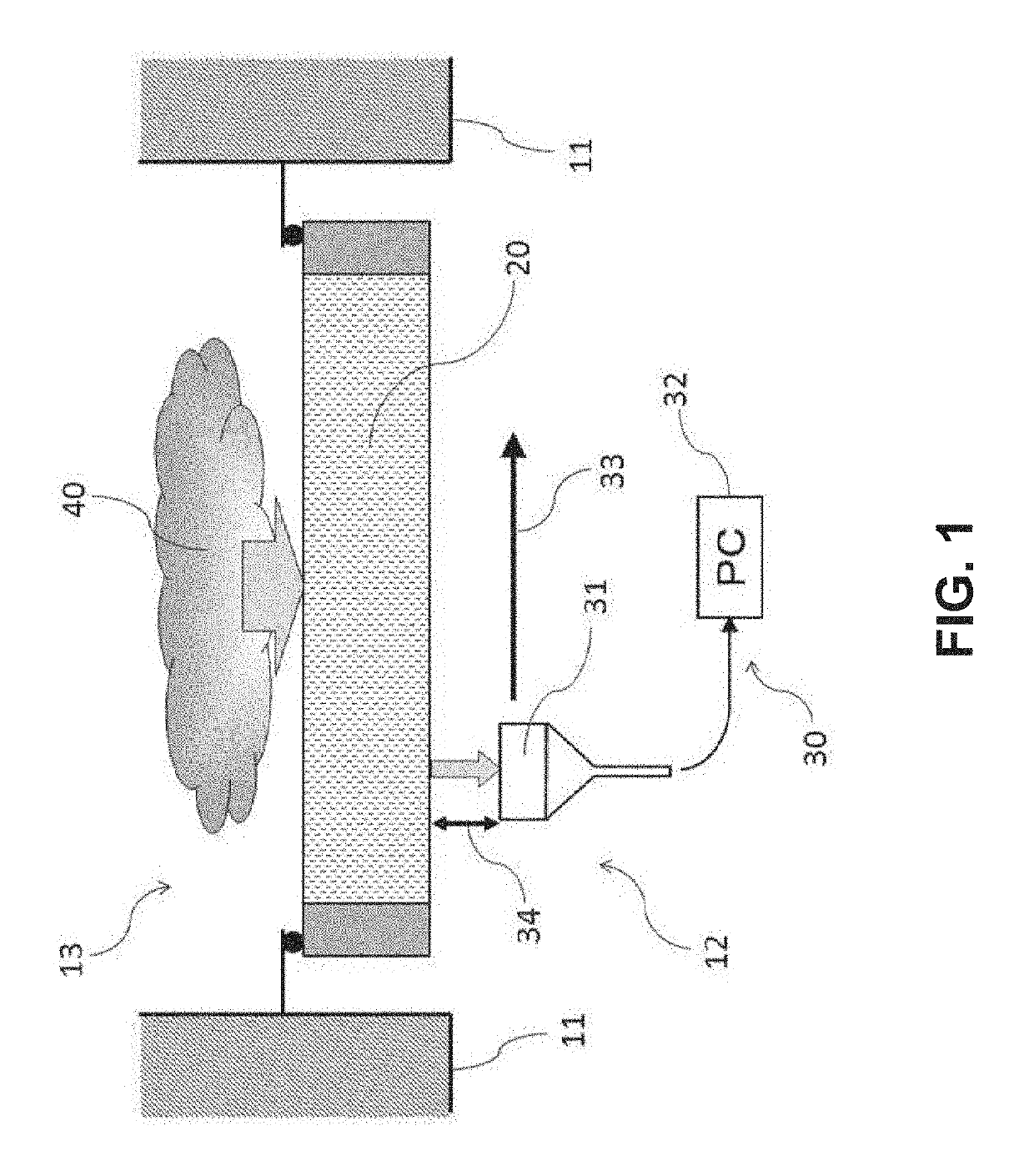

Leak inspection assistance device and leak inspection method using same

ActiveUS20190265122A1Leak inspection can be accuratelyLow costDetection of fluid at leakage pointDispersed particle filtrationCost burdenEngineering

Provided are a leak inspection assistance device and a leak inspection method using the same which enable using a normal leak inspection device in a leak inspection of filters in a clean room, have a small cost burden since a scanning robot, large-scape equipment, an incidental work, and the like are not required, and enable performing the accurate leak inspection with a small number of workers.A projection device which projects a suction point of a suction probe adjunct to a leak inspection device which performs a leak inspection onto a surface of a filter in a clean room in such a manner that the suction point moves in X-Y axis directions orthogonal to each other along the surface of the filter at a fixed interval and a fixed speed is provided, and a worker uses the suction probe for scanning in accordance with movement of the suction point.

Owner:AIREX

Quick helium mass spectrum leakage detecting device for diaphragm inner circle welding joint

ActiveCN109297649AQuick leak detectionAccurate leak detectionDetection of fluid at leakage pointEngineeringHelium

The invention relates to a quick helium mass spectrum leakage detecting device for a diaphragm inner circle welding joint, solves the problem of difficulty in sealing caused by a small inner cavity formed due to a thin wall and welding of the inner circle welding joint, effectively avoids the problem the whole diaphragm box is scrapped due to leakage of inner circle welding joint, and improves theleak detection efficiency greatly. An inner supporting tool, an upper cover and a lower cover, a sealing ring and the like are used for sealing a narrow space formed after the diaphragm inner circlewelding joint is welded, so that quick and accurate helium mass spectrum leakage detecting is realized; compared with the prior art, the inner supporting tool, the upper cover and the lower cover, thesealing ring and the like are used for sealing the narrow space formed after the diaphragm inner circle welding joint is welded, so that diaphragm inner circle welding joint leakage detecting is realized, and the possibility that the whole diaphragm box is scrapped due to leakage of the weld joint of the diaphragm is reduced.

Owner:CAPITAL AEROSPACE MACHINERY +1

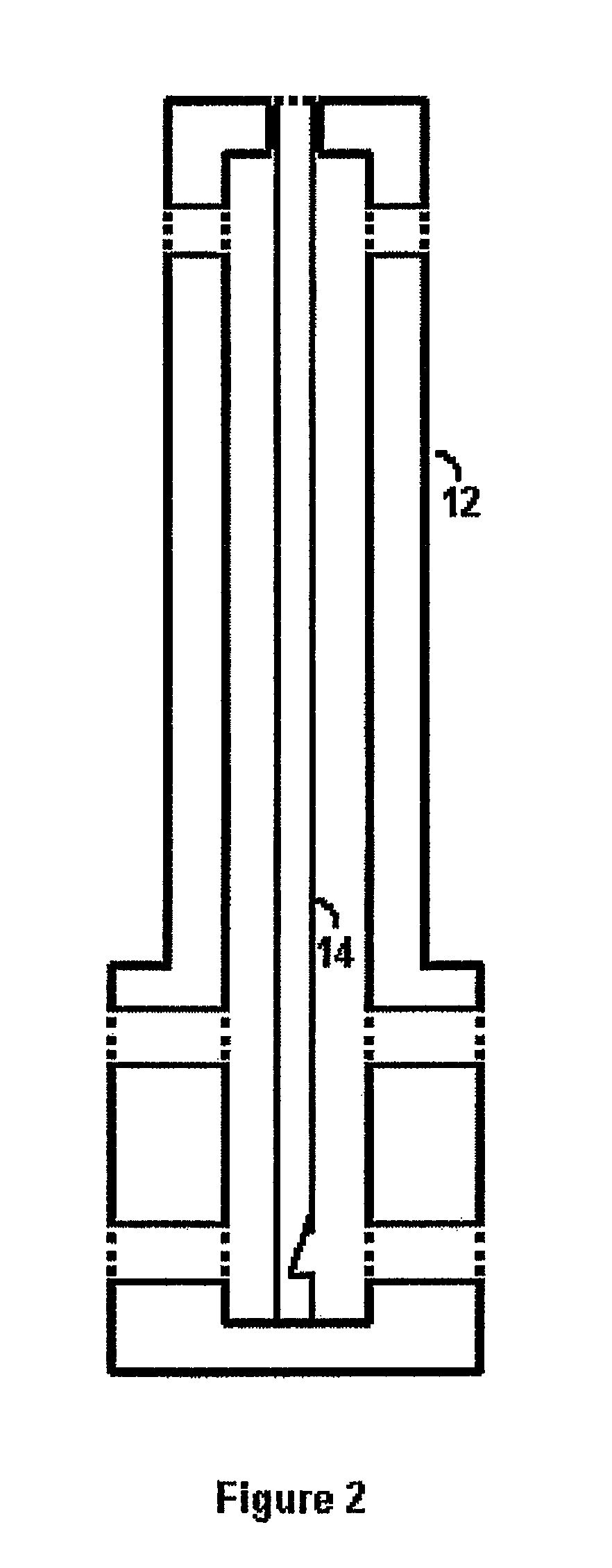

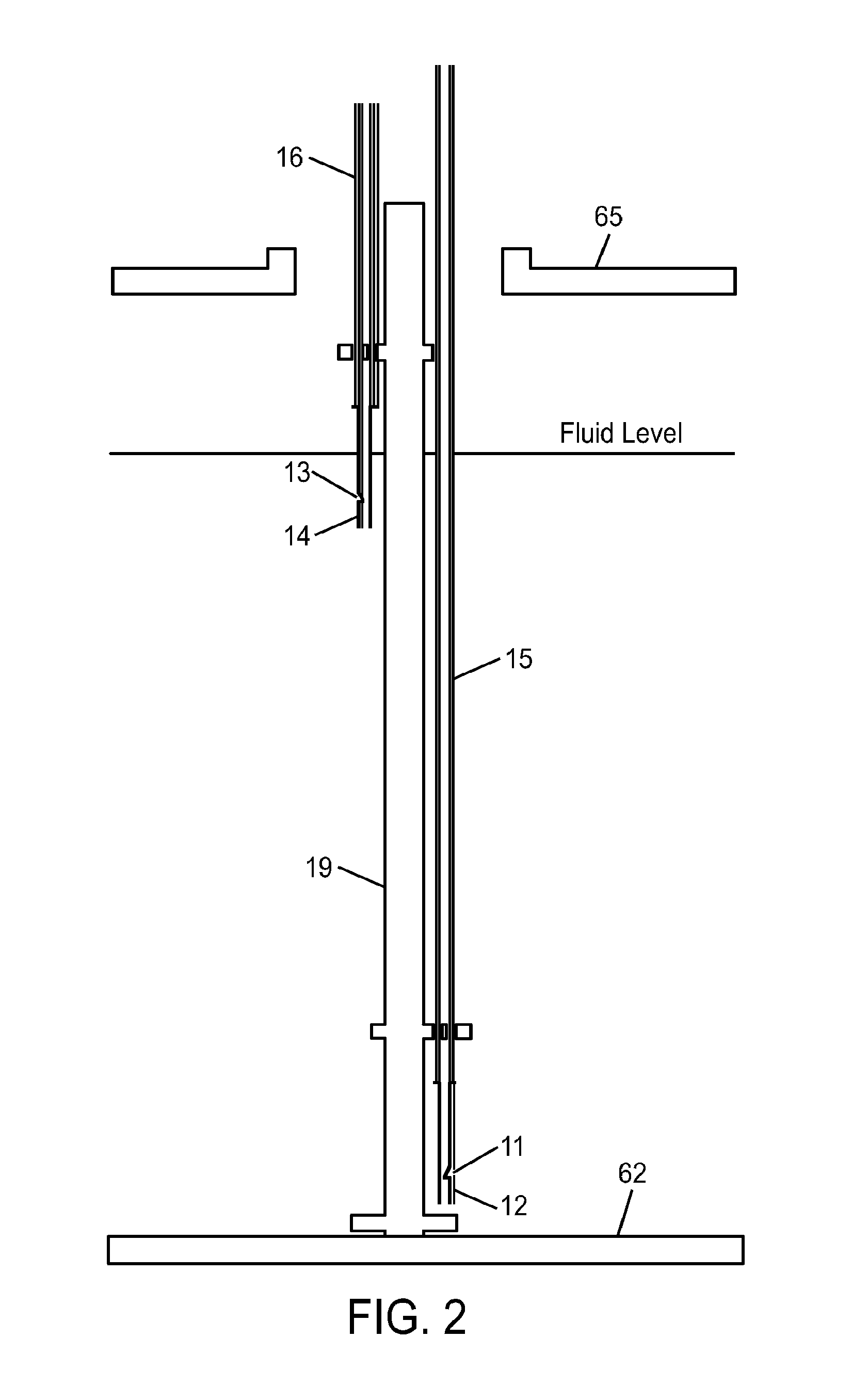

Method and apparatus for storage tank leak detection

ActiveUS7712352B2Low detection thresholdPreserving industrial and environmental resourcesDetection of fluid at leakage pointMeasurement of fluid loss/gain rateIntrinsic safetyTransducer

An intrinsically safe, precise, and cost effective storage tank leak detection system. Embodiments include a highly precise quartz crystal type pressure transducer, secured in a vacuum and held at a constant temperature. Said transducer is used in combination with data correction and regression techniques to yield a storage tank leak detection system with an extremely low leak detection threshold. The storage tank leak detection system is thought to be most useful for detecting very small leaks in very large storage tanks.

Owner:MASS TECH

Concrete impermeability testing device and method

PendingCN114813503AEasy to demouldImprove sealingPermeability/surface area analysisOutfallStructural engineering

The invention belongs to the technical field of impervious performance testing, and particularly relates to a concrete impervious performance testing device and method.The concrete impervious performance testing device comprises a device body, a workbench and a columnar testing mold, and the testing mold comprises a fixed mold integrally connected with the workbench and a movable mold sliding on the workbench; an infrared camera for acquiring an infrared image of a concrete test piece in the test mold is arranged above the test mold; a water seepage table with a water seepage groove in the upper surface is arranged at the bottom end of the test mold, the middle of the water seepage groove is connected with a water inlet pipe and a valve through a water outlet, a first assembly is arranged in the axis center of the water outlet, a channel is formed between the water outlet and the valve, and a second assembly is arranged on one side of the channel and detects the airtightness of the water seepage table and the test mold by using the movable mold to approach the fixed mold. According to the test device, hydraulic equipment does not need to be used for compressing the test piece and the test mold, a large amount of screw tightening work is avoided, and when the test device is used, the test piece is directly put into the water seepage table, and then the fixed mold and the movable mold are fixed.

Owner:CHINA NAT CHEM ENG THIRD CONSTR

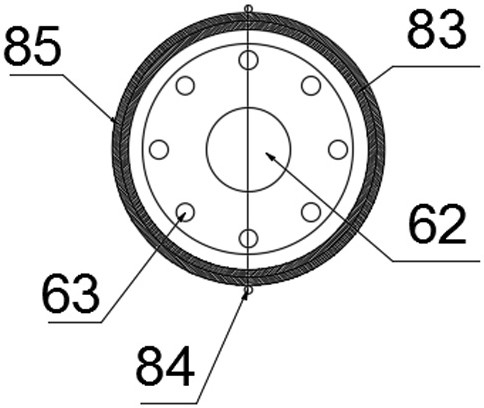

Method and apparatus for leak detection in horizontal cylindrical storage tanks

InactiveUS20130253856A1Low detection thresholdPreserving industrial and environmental resourcesFlow propertiesFluid-tightness measurementTransducerHydrostatic pressure

A storage tank leak detection system for detecting and measuring very small leaks in large horizontal cylindrical storage tanks. Embodiments include two highly precise quartz crystal type pressure transducers held at a constant temperature. A bubbler to achieve access to the hydrostatic pressure at the tank bottom and just below the liquid surface. First transducer and bubbler are used to measure fluid mass while second transducer and bubbler are used to measure fluid density then used in combination with data correction and regression techniques to yield a storage tank leak detection system for use in horizontal cylindrically shaped tanks with an extremely low leak detection threshold.

Owner:MASS TECH

Comprehensive detection device and method for leakage of reservoirs and hydropower stations

PendingCN111811748AAccurately determineIntuitively determinedDetection of fluid at leakage pointMeasurement of fluid loss/gain rateControlled releaseSoil science

The invention discloses a comprehensive detection device and method for leakage of reservoirs and hydropower stations. The device comprises a host machine and a probe, wherein a shell is arranged on surface of the probe; and a tracer agent controller, a tracer agent memory, a tracer agent release device and an image acquisition device are sequentially arranged in the shell. The device enters a water body by controlling release of a liquid tracer agent, a visible movement track is formed along with the flowing of the water body, and the movement track of the tracer agent is recorded and storedthrough a high-definition camera system, so the flowing characteristics of the water body in various states can be conveniently analyzed and researched, a leakage part, a leakage point, a seepage direction and a leakage degree can be accurately and visually determined, and even the movement rule and trend of the water body at each point can be researched by establishing a numerical simulation model. According to the reservoir water station leakage comprehensive detection method, leakage detection is more accurate and more visual; and the detection device can realize leakage detection in various environments such as clear water, muddy water and the like, is not influenced by water depth, and is accurate in detection.

Owner:辽宁省水利水电勘测设计研究院有限责任公司

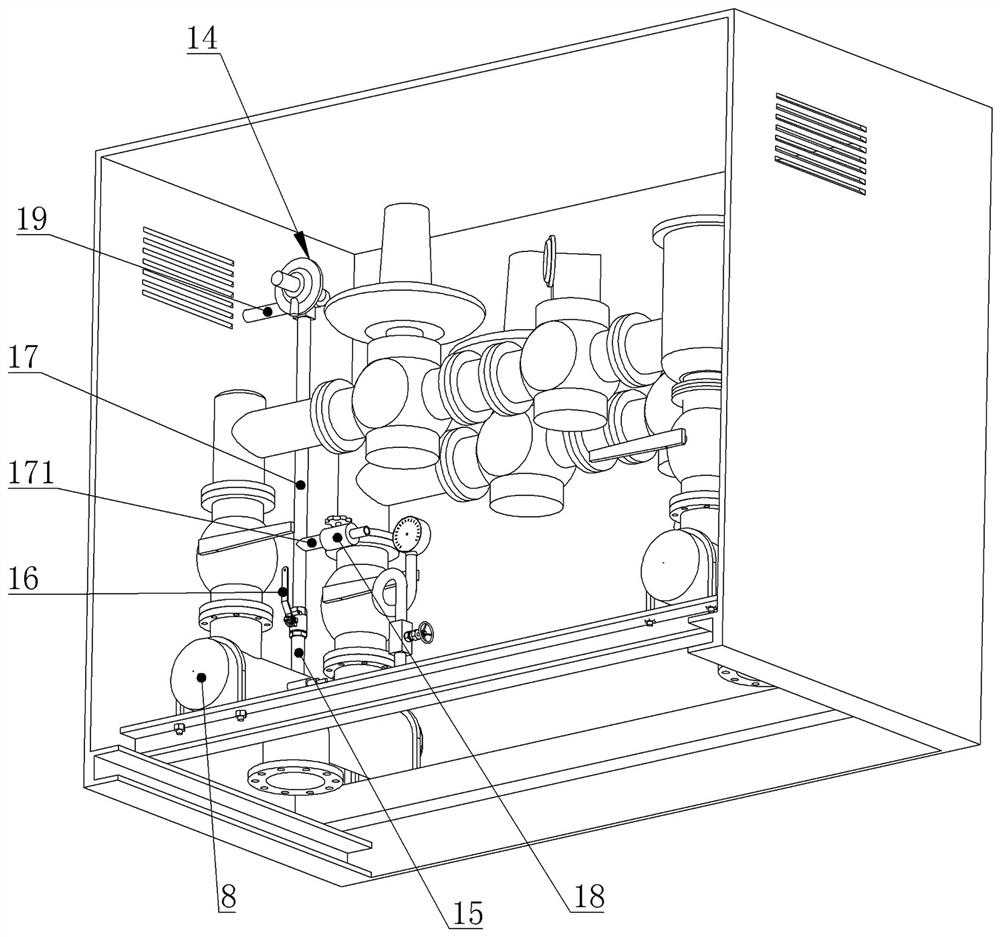

Fuel gas pressure regulating box

PendingCN113483273AAccurate leak detectionThe displayed value is stablePipeline systemsEngineeringMechanics

The invention relates to the field of pressure regulating boxes, in particular to a fuel gas pressure regulating box. The fuel gas pressure regulating box comprises a box body. An inlet manifold is arranged in the box body, the upper portion of the inlet manifold is connected with an inlet ball valve, the upper portion of the inlet ball valve is connected with a filter, an outlet of the filter is connected with a fuel gas pressure regulator through a pipe, an outlet of the gas pressure regulator is connected with an outlet ball valve through a pipe, the other end of the outlet ball valve is connected with an outlet manifold, one side of the outlet manifold is provided with a pressure measuring pipe, the pressure measuring pipe is connected with a needle valve, the needle valve is connected with a pressure gauge through a pipe, and a buffer pipe with the buffering function is arranged in the pipe between the needle valve and the pressure gauge. According to the fuel gas pressure regulating box, the pressure gauge is not prone to being damaged, and displays more stable numerical values, detection on a blow-off valve is short in time and high in efficiency, and online monitoring during operation can be implemented.

Owner:HEBEI YONGLIANG COMBUSTION GAS EQUIP

Fluid Control Device

ActiveUS20210215269A1Accurate leak detectionDiaphragm valvesMeasurement of fluid loss/gain rateFluid controlEngineering

A fluid control device, capable of detecting leaks even if the leaks is slight, is provided. The fluid control device includes a valve body in which the flow path is formed, a diaphragm isolating a closed space from the flow path, a bonnet forming the closed space between the diaphragm and providing a penetration hole connected to the closed space and penetrated to be able to vertically move a diaphragm retainer, the diaphragm retainer vertically moving in the penetration hole to press the diaphragm and providing an increased diameter portion not to be removed from the penetration hole, a pressure sensor detecting a pressure inside of the closed space, and an elastic body interposing between the increased diameter portion of the diaphragm retainer and the bonnet inside of the closed space and elastically expanding and deflating between the increased diameter portion of the diaphragm retainer and the bonnet as the diaphragm retainer vertically moves.

Owner:FUJIKIN INC

Online leakage detection method and device thereof for heat treatment furnace radiant tube

ActiveCN102853976BDoes not affect productionLow costMeasurement of fluid loss/gain rateThermodynamicsEngineering

The invention discloses an online quick leakage detection method for a heat treatment furnace radiant tube. The method comprises that the heat treatment furnace radiant tube is closed; gas flow at positions of any connectors of the heat treatment furnace radiant tube is detected; and leakage points exist on the heat treatment furnace radiant tube if the gas flow is more than zero, and the heat treatment furnace radiant tube is normal and no leakage exists if the gas flow is zero. The device of the method comprises a gas flow meter and a vacuum sampling pump, wherein a gas inlet of the gas flow meter is connected with any connector on the heat treatment furnace radiant tube, which is communicated with the external, and an exhaust port of the gas flow meter is connected with a gas inlet end of the vacuum sampling pump through a gas suction pipe. By the aid of the method, the accuracy and the reliability of detection are improved, the leakage detection can be conducted on a non-oxidation furnace radiant tube in real time accurately, reliably, conveniently and rapidly in the normal production, the operation is simple, the labor intensity is low, the cost is low and the method and the device are suitable to popularization and application.

Owner:武汉钢铁有限公司

Leak hunting device

ActiveCN102230838AImprove accuracyImprove detection efficiencyMeasurement of fluid loss/gain rateElectricityEngineering

The invention provides a leak hunting device, which comprises a first water supply device, a second water supply device and at least one set of irrigation device, wherein the first water supply device comprises a first water tank and a water pump; the second water supply device comprises a second water tank and a first water level switch; the irrigation device comprises a quantifying water hopper, a second water level switch, a water inlet electromagnetic valve, a water outlet electromagnetic valve and a relay; the first water level switch is arranged in the second water tank; the second water level switch is arranged in the quantifying water hopper; the outlet of the first water tank is connected with the inlet of the second water tank through the water pump; the inlet of the quantifyingwater hopper is connected with the outlet of the second water tank through the water inlet electromagnetic valve; the first water level switch is electrically connected with the water pump; the second water level switch is electrically connected with the water inlet electromagnetic valve; the water outlet electromagnetic valve is connected with the outlet of the quantifying water hopper; and the relay is electrically connected with the water outlet electromagnetic valve. According to the leak hunting device, detection accuracy and efficiency of leak hunting are increased.

Owner:HAIER GRP CORP +1

Method and apparatus for leak detection in horizontal cylindrical storage tanks

ActiveUS8468876B2Low detection thresholdPreserving industrial and environmental resourcesDetection of fluid at leakage pointMeasurement of fluid loss/gain rateHydrostatic pressureTransducer

A storage tank leak detection system for detecting and measuring very small leaks in large horizontal cylindrical storage tanks. Embodiments include two highly precise quartz crystal type pressure transducers held at a constant temperature. A bubbler to achieve access to the hydrostatic pressure at the tank bottom and just below the liquid surface. First transducer and bubbler are used to measure fluid mass while second transducer and bubbler are used to measure fluid density then used in combination with data correction and regression techniques to yield a storage tank leak detection system for use in horizontal cylindrically shaped tanks with an extremely low leak detection threshold.

Owner:MASS TECH

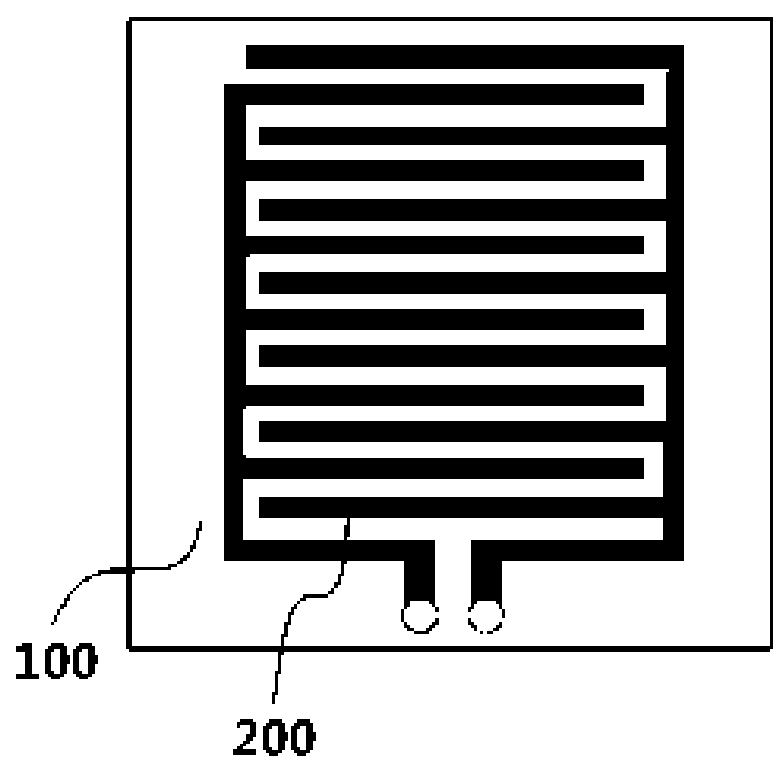

Intelligent flexible water drop detection device for flexible multiple application scenes

PendingCN113432800AReduce volumeReduce the chance of errorsDetection of fluid at leakage pointMaterial resistanceElectrically conductiveMultiple applications

The invention discloses a flexible multi-application scene intelligent flexible water drop detection device. The device comprises a flexible water drop detection device and a main control module, and is characterized in that the flexible water drop detection device comprises five layers of composite materials which are a first insulating layer, a second conductive layer, a third water absorption layer, a fourth conductive layer and a fifth insulating layer in sequence from top to bottom; the first insulating layer, the second conducting layer, the fourth conducting layer and the fifth insulating layer are all provided with uniformly distributed small holes, the second conducting layer and the fourth conducting layer are both provided with wires, the second conducting layer and the fourth conducting layer are matched to form a water drop detection device R1, and two electrodes of the water drop detection device R1 are respectively connected with a power supply Ui and a divider resistor R2; the other end of the divider resistor R2 is grounded; the divider resistor R2 is connected with an input port of the master control module through a cable; and the main control module judges whether water leaks or not according to the acquired sampling voltage value A. The flexible water drop detection device is connected with the main control module, a large amount of labor cost does not need to be spent, and the probability of errors in the detection process is reduced.

Owner:温尚熙

Storage tank bottom plate welding line vacuum test apparatus

InactiveCN107543660AImprove vacuum leak detection progressImprove accuracyDetection of fluid at leakage pointControl valvesStorage tank

The invention discloses a storage tank bottom plate welding line vacuum test apparatus. The apparatus includes a frame body which has the shape of a rectangle. The apparatus is characterized in that the top part and the bottom parts of the frame body are provided with an opening. The top part of the frame body is provided with an observation window. The two elongate side surfaces of the frame bodyare both provided with a vacuum manometer. Each vacuum manometer is provided with a control valve I in the front thereof. The two short side surfaces of the frame body are respectively provided witha vacuum pump interface and an air inlet. The vacuum pump interface and the air inlet are both provided with a control valve II.

Owner:SHANDONG ZAOJIAN CONSTR GRP CO LTD

Flexible sheet-type physical property detecting leak sensor device

ActiveUS9964462B2Detection securityNot to damageDetection of fluid at leakage pointWeather/light/corrosion resistanceTetrafluoroethyleneEngineering

A flexible sheet-type leak sensor device according to the present invention comprises: a flexible base sheet made of a non-conductive fluorine-based synthetic resin comprising ethylene tetrafluoroethylene (ETFE); conductive lines formed on a surface of the base sheet so as to have a predetermined pattern and so as not to meet or cross each other, the conductive lines being formed by depositing on the base sheet surface a carbon black-containing, conductive fluorine-based synthetic resin comprising ethylene tetrafluoroethylene (ETFE); and a conductive material composed of pure carbon black, formed at the bottom of the conductive lines.

Owner:FLUOROTECH

Blast furnace cooling equipment leak detection device

The invention provides a blast-furnace cooling equipment leakage detecting device. The blast-furnace cooling equipment leakage detecting device comprises a connector, a water pipe and a pressure meter, wherein the connector is used for being connected to a cooling water pipeline of blast-furnace cooling equipment, one end of the water pipe is connected to the connector, and the pressure meter is connected to the other end of the water pipe. When the blast-furnace cooling equipment leakage detecting device is used, if the pressure meter relieves pressure, it is shown that the blast-furnace cooling equipment is damaged and subjected to water leakage; otherwise, it is shown that the blast-furnace cooling equipment is not subjected to water leakage. The blast-furnace cooling equipment leakage detecting device can detect leakage easily, efficiently and accurately. In addition, the blast-furnace cooling equipment leakage detecting device has the advantages of being simple in structure and convenient to carry and use.

Owner:DAYE SPECIAL STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com