Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

98results about "Safety devices for sewing-machines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

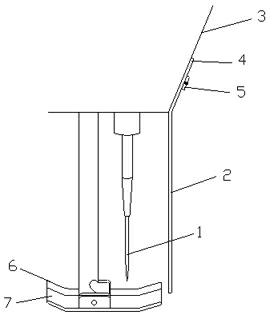

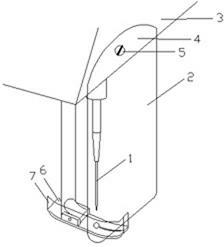

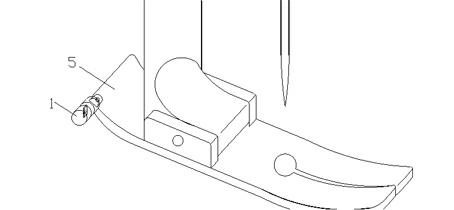

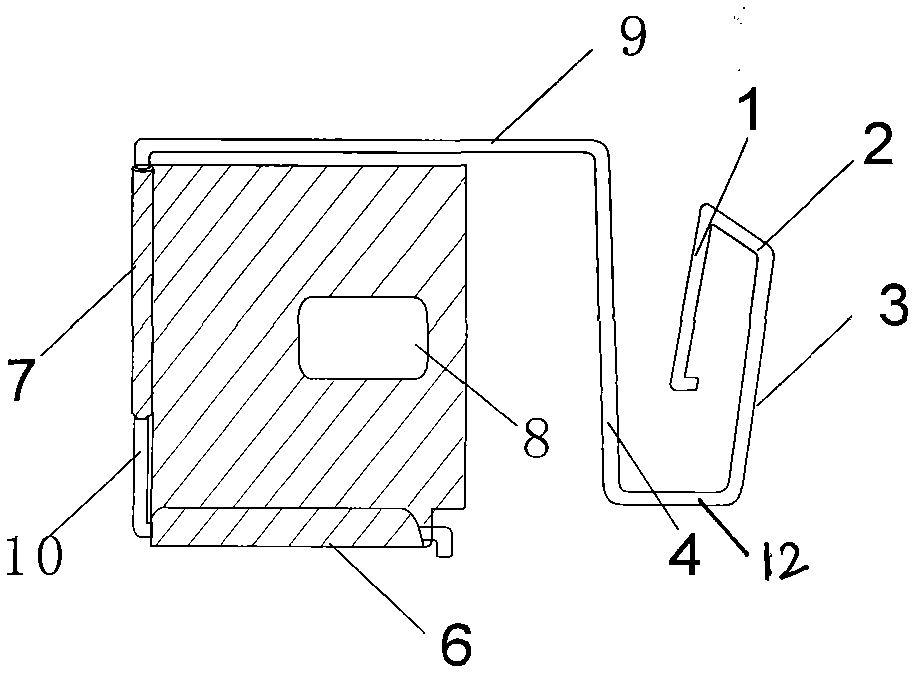

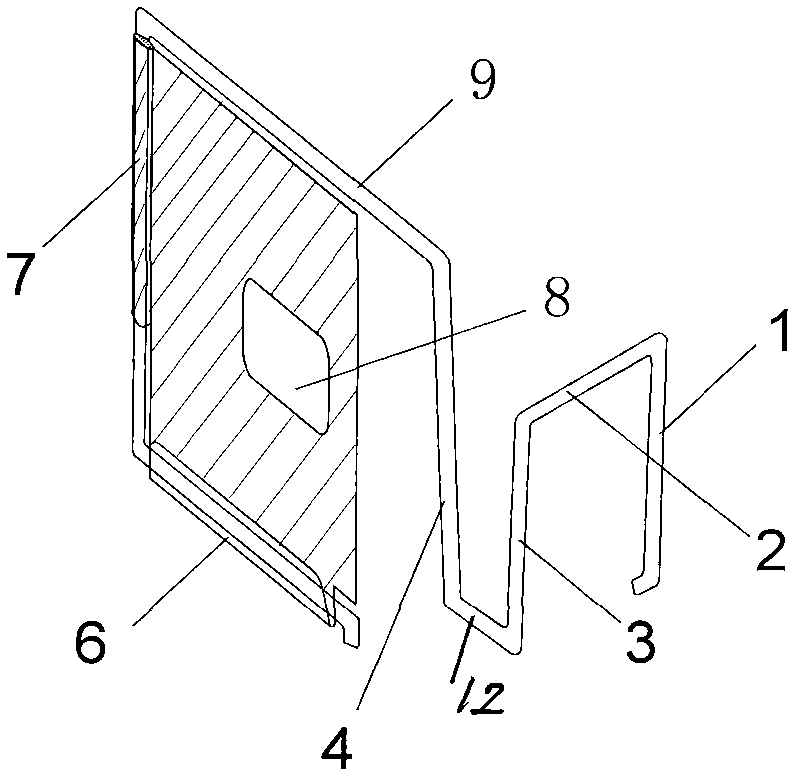

Protection device for preventing broken needle of sewing machine

A protection device for sewing machine includes a presser which has a first end connected to a presser bar and a second end of the presser has a through hole so that the needle reciprocally extends therethrough. A needle cover is connected to a top of the second end of the presser and no gap is defined between the needle cover and the top of the presser. The needle cover protects the user from being hurt by broken needle.

Owner:CHANG TSENG HSIEN

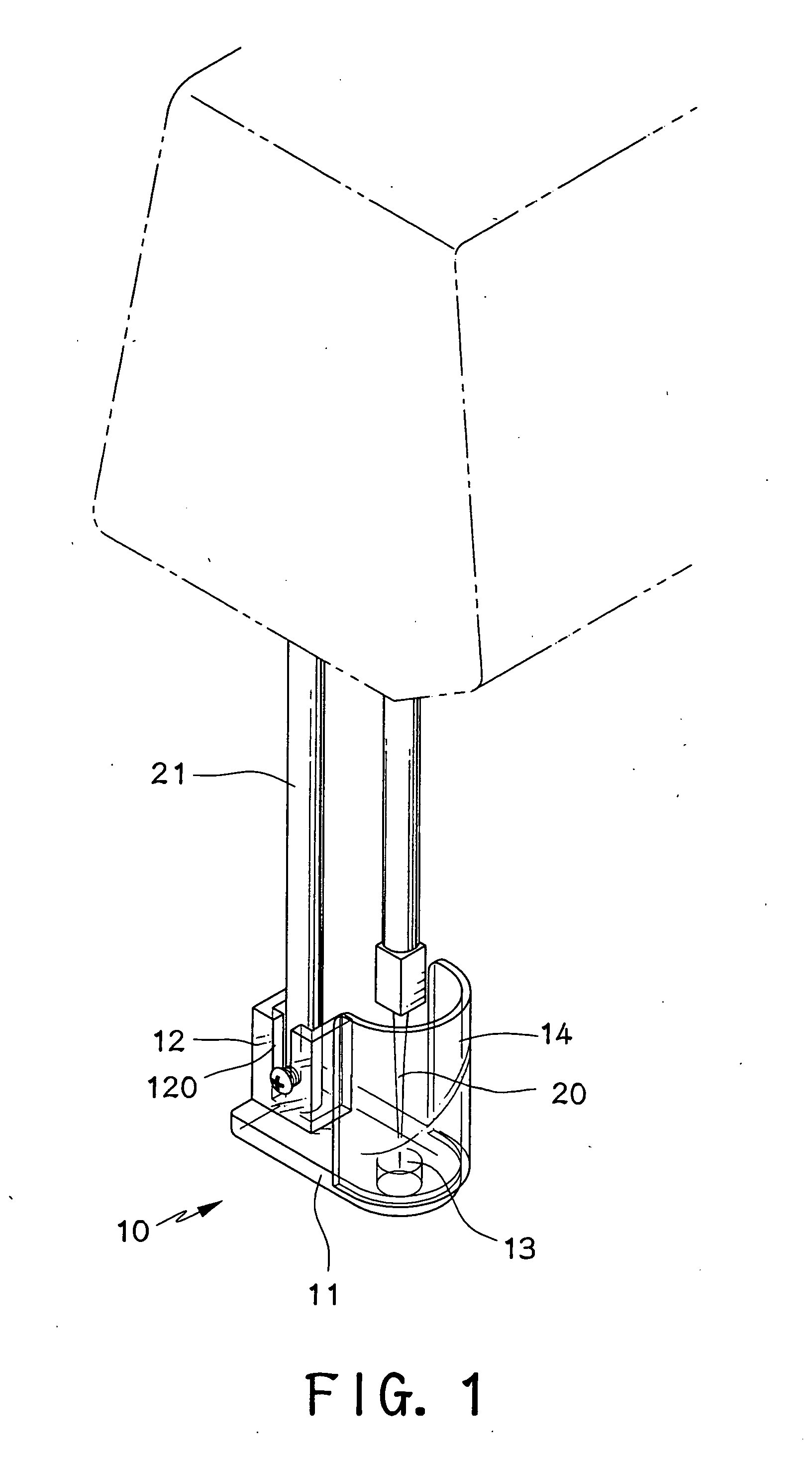

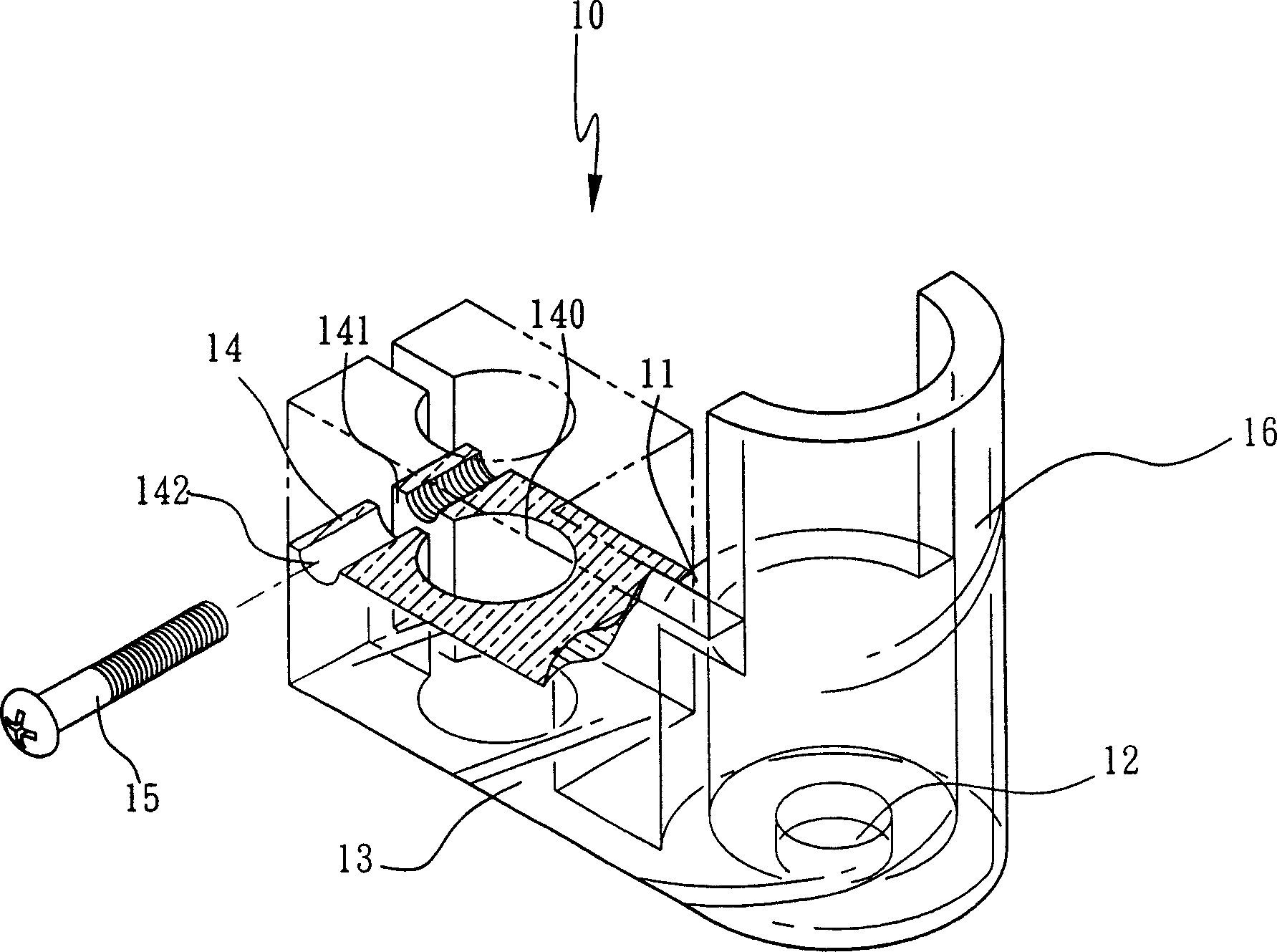

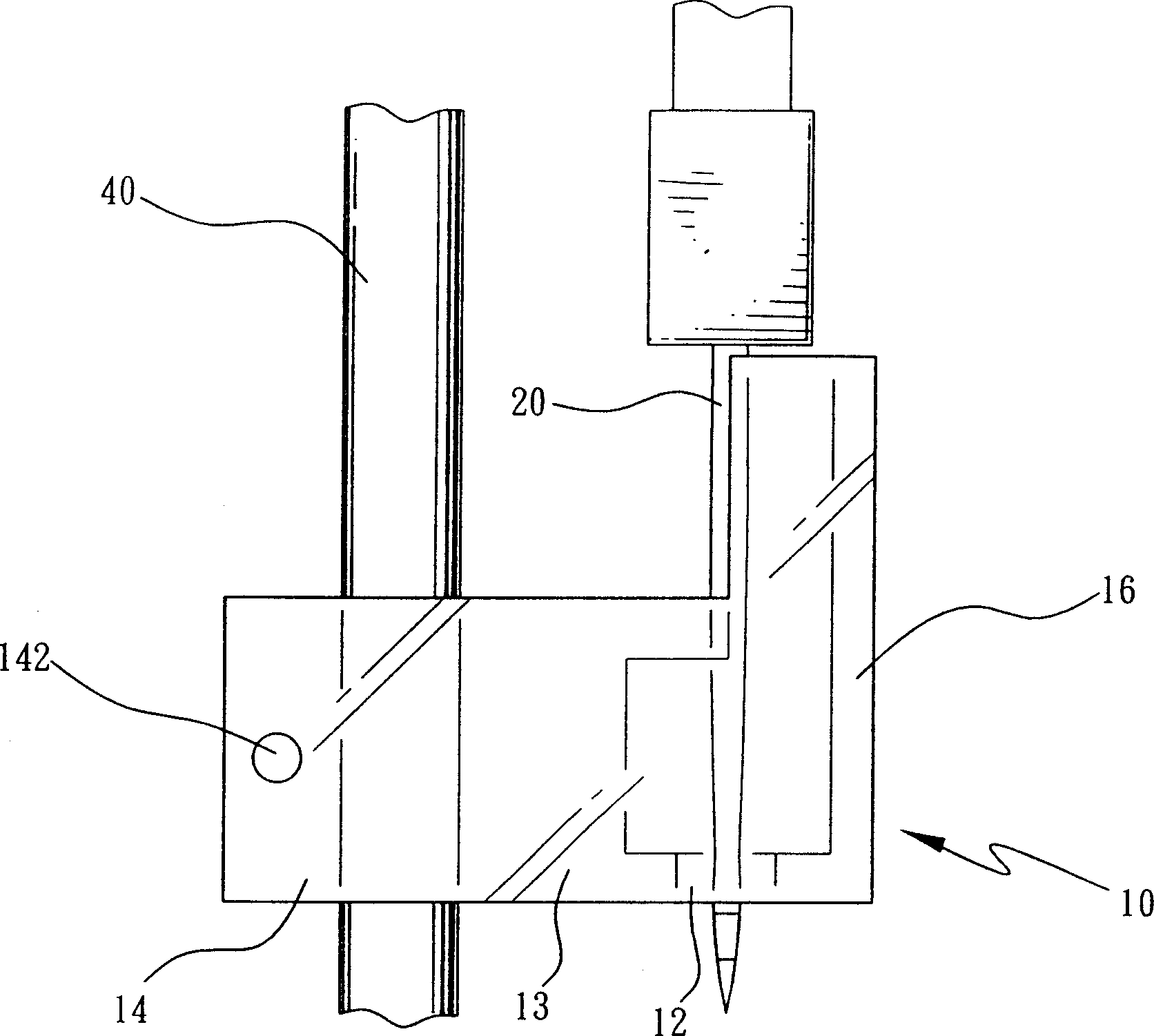

Protector for blocking off on-the-fly of broken needle

InactiveCN1696376AImprove practicalityImprove securitySafety devices for sewing-machinesEngineeringOn the fly

The present invention discloses a protection device capable of preventing broken sewing-machine needle from arbitrarily flying to injure operator. It is characterized by that a transparent protection device is placed around active area of sewing-machine needle and fixedly connected on the supporting rod of presser foot, and said protection device is placed between the sewing-machine and user so as to form protection.

Owner:曾贤长

Sewing machine and security protection device for application of sewing machine

Owner:ZHEJIANG ZOBOW MECHANICAL & ELECTRICAL TECH

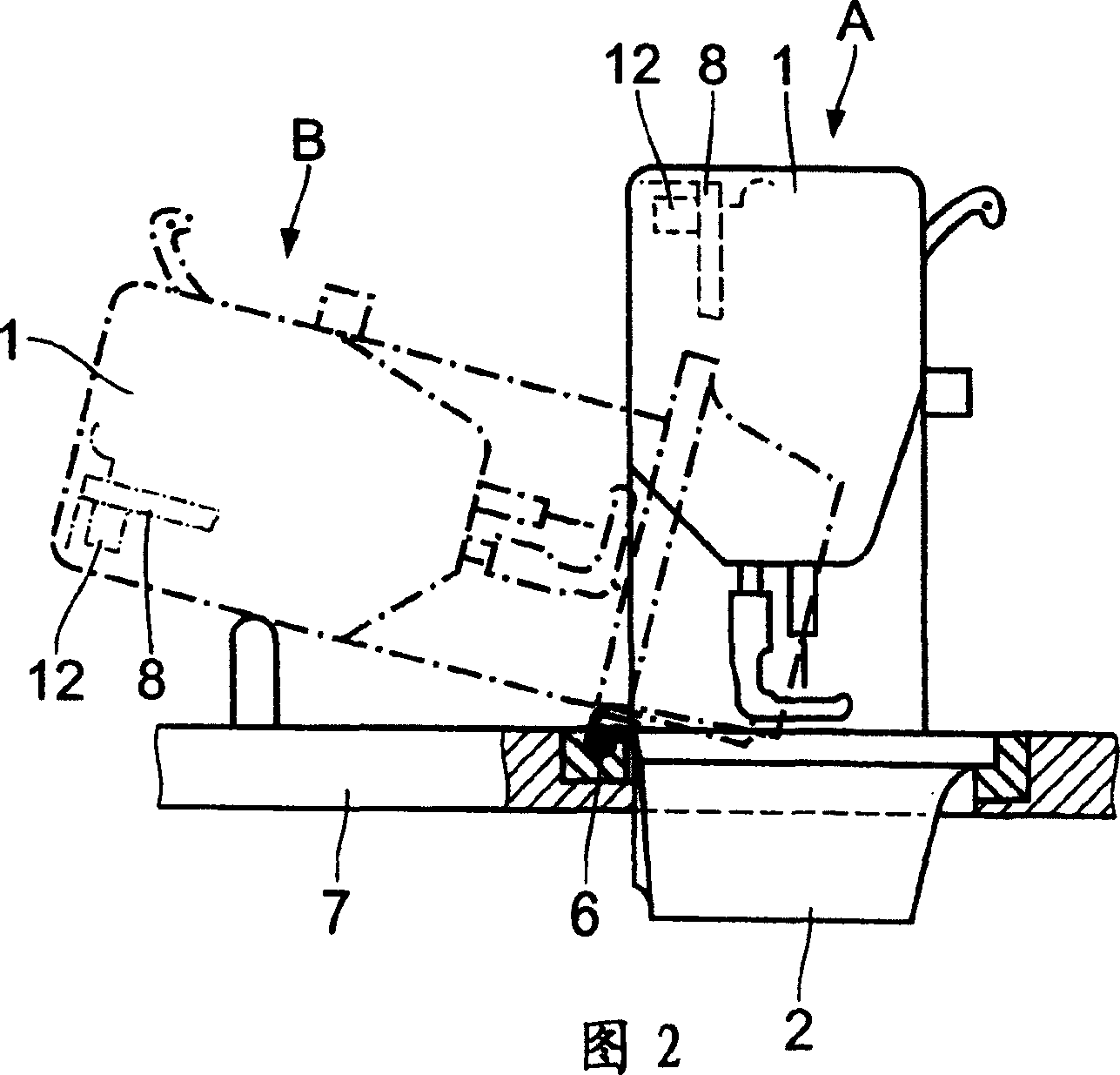

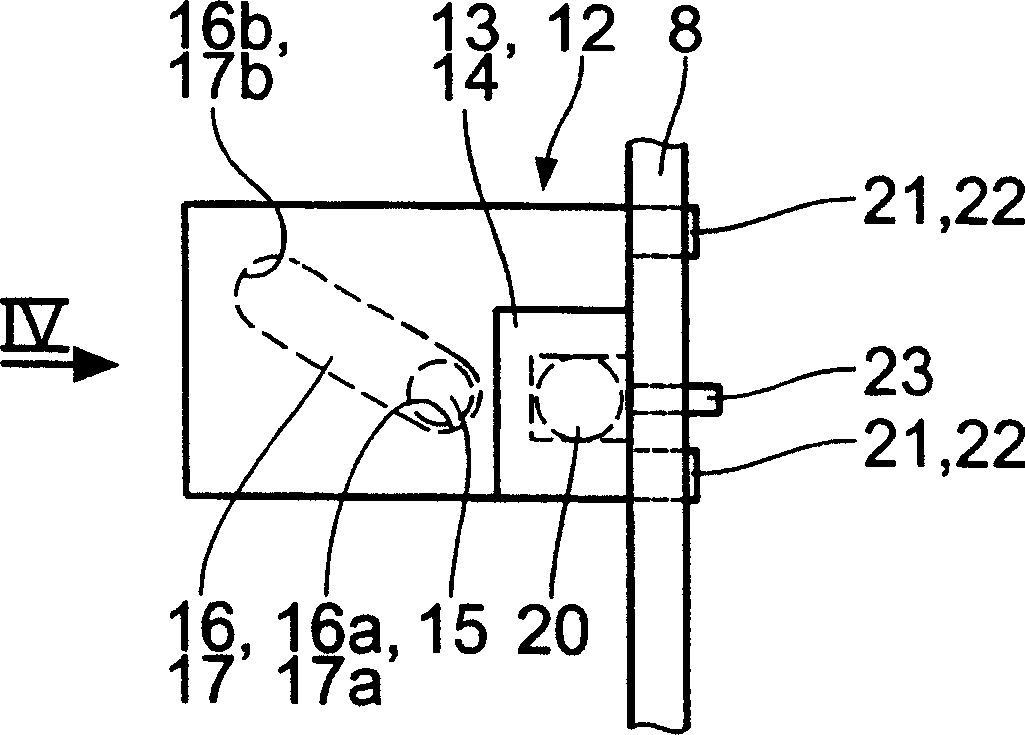

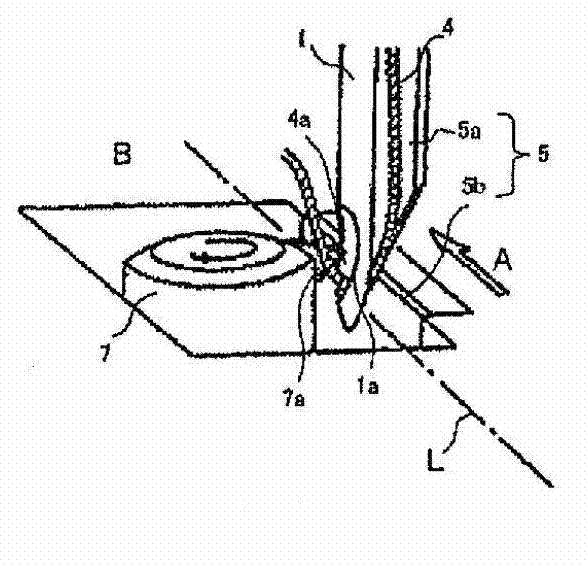

Sewing machine

InactiveCN1673434AIncreased functional reliabilityReduce assemblySewing-machine control devicesSafety devices for sewing-machinesControl systemDrive motor

The sewing machine is provided with sewing machine cases (1, 2) arranged on an upper table surface (7) so that it can be driven from an operative position (A) to a maintenance position (B). The sewing machine is provided with a driving motor (3) which connects with a main shaft (4) of the sewing machine and makes rotary action. A safety device (12) is provided and the safety device (12) has a switch which blocks power supply to the driving motor (3) when the sewing machine cases (1, 2) are driven to the maintenance position (B). The switch (20) is a lead switch (20) which is designed to operate with gravity and arranged on a printed circuit board (8) connecting to a control system of the driving motor (3). The lead switch (20) operates inductively with a permanent magnet which is guided / arranged within the casing arranged on the printed circuit board (8) so that it can be displaced.

Owner:DURKOPP ADLER AG

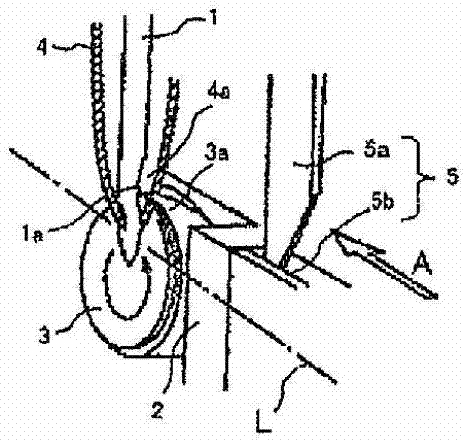

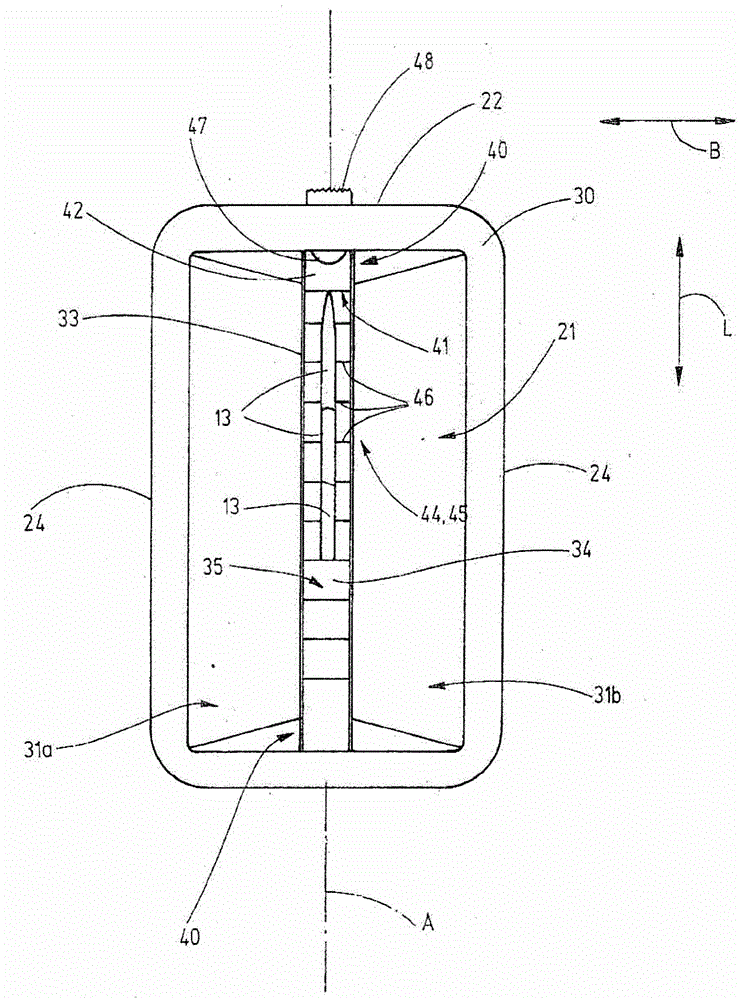

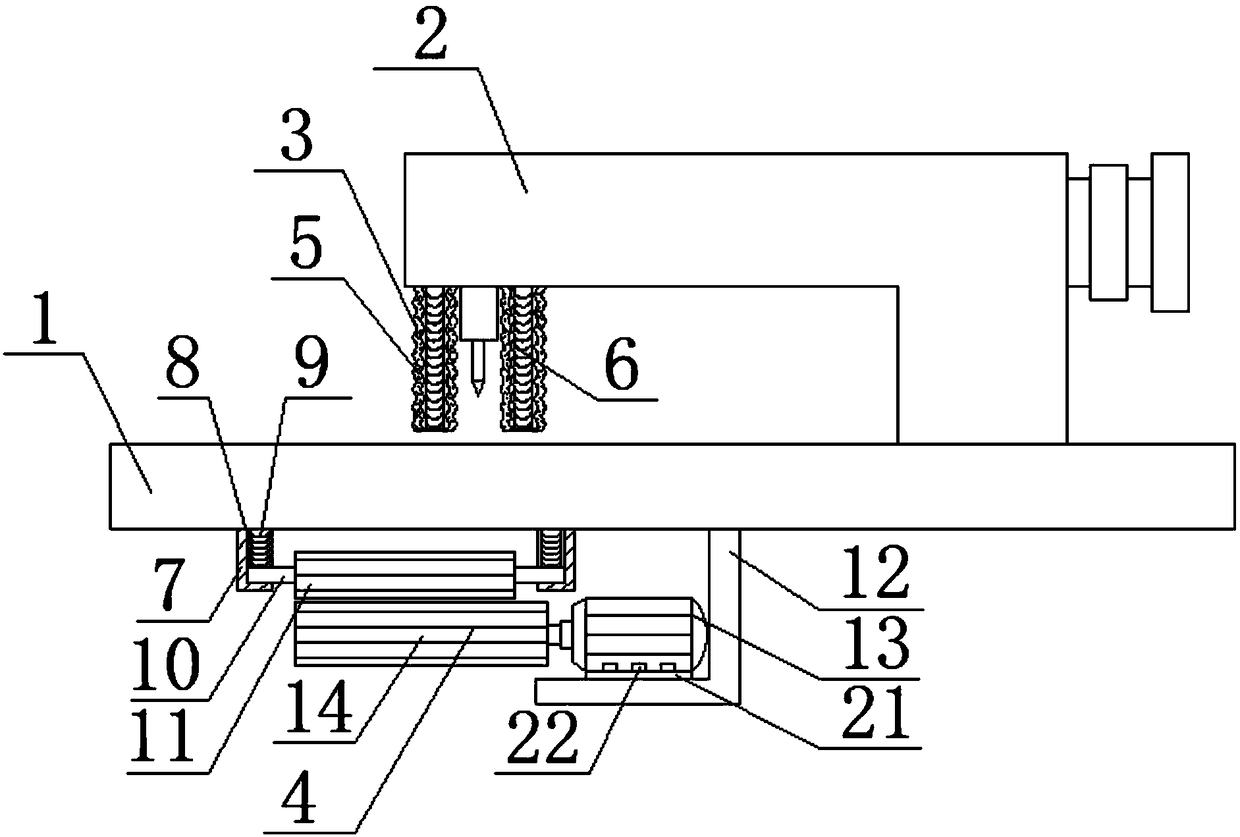

Device for cutting an article being stitched by a sewing machine

InactiveCN103119210AEffectively cut offCut off stable and effectiveWorkpiece carriersSafety devices for sewing-machinesFixed frameEngineering

To provide a device for cutting an article being stitched by a sewing machine, which can cut from any position on the article being stitched regardless of whether or not stitching is present. A device (20) for cutting an article being stitched by a sewing machine comprises a fixed frame (41) attached to a sewing machine main body (21b), and a mobile frame (42) which is movably attached to the fixed frame (41). A rotary blade (34) is rotatably provided on the mobile frame (42). The fixed frame (41) is provided with a drive means (37) for driving the rotary blade (34) by way of a power transmission part (36), and an operation means (43) for operating the mobile frame (42) in such a way that the rotary blade (34) is moved from a position (P1) of not cutting the article being stitched to a position (P2) of cutting the article being stitched. A throat plate (32) provided on a bed part (22) side where the sewing machine main body (21b) is fixed is provided with a fixed blade (38) which cooperates with the rotary blade (34) in order to cut the article being stitched.

Owner:MIDORI ANZEN +1

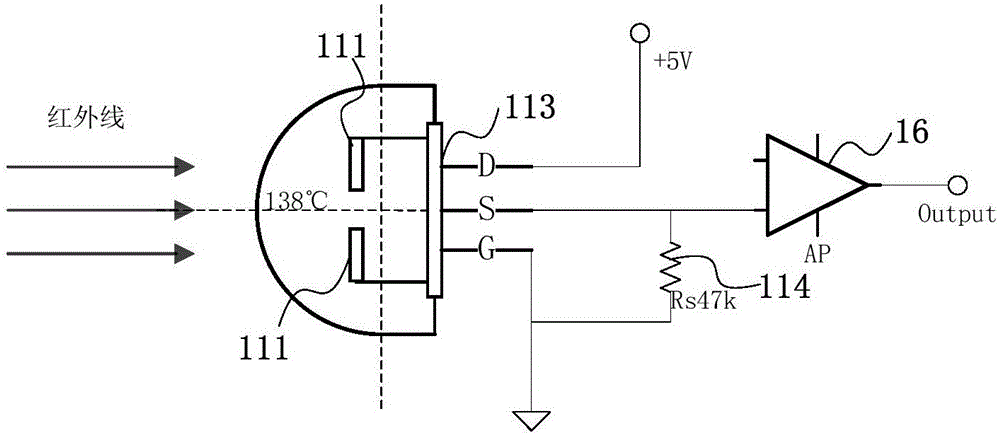

Presser foot position detection system of sewing equipment

InactiveCN106120173AAvoid dangerous situationsPressersSafety devices for sewing-machinesEngineeringPosition sensor

The invention discloses a presser foot position detection system of sewing equipment. The presser foot position detection system comprises a presser foot position sensor and a controller. The presser foot position sensor is a magnetic sensor, and is arranged on a presser foot arm and used for collecting position signals of a presser foot and sending the collected presser foot position information to the controller, and the controller is used for judging whether the presser foot position is correct or not after receiving the signals and controlling the equipment to start normally if presser foot position is correct. According to the presser foot position detection system of the sewing equipment, the presser foot position sensor is arranged and used for collecting the presser foot position signals, the controller is used for judging whether the presser foot position is correct or not according to the signals and controlling the operation of the equipment according to a judging result, dangerous situations caused when the equipment operates under the abnormal state are avoided, and the presser foot position detection system can be conveniently applied and popularized industrially, and has important production practice and practical significance.

Owner:天津市中马骏腾精密机械制造有限公司

Safety sewing machine

InactiveCN103789942ASimple structureReasonable designSafety devices for sewing-machinesForeign matterElectric machinery

The invention discloses a safety sewing machine. By arranging a protection strip and a photoelectric sensing device, hands of a person are effectively prevented from being close to a needle head, unwanted damage is avoided, and breaking of the needle head due to the fact that a foreign matter collides with the needle head moving at high speed. The safety sewing machine comprises a base, a machine body and a machine head, the machine body is arranged on the base, the machine head is mounted at the tail end of the machine body, a motor is arranged in the machine body, a sewing needle is mounted below the machine head, a press pin is further arranged below the machine head, and the protection strip is arranged at the edge of the press pin. The protection strip can prevent the hands of the person to be close to the needle head, and the photoelectric sensing device can further guarantee the hands of the person or other objects not to collide with the needle head, so that safety in the process of sewing is guaranteed.

Owner:WUJIANG JIAYUN TEXTILE FINISHING

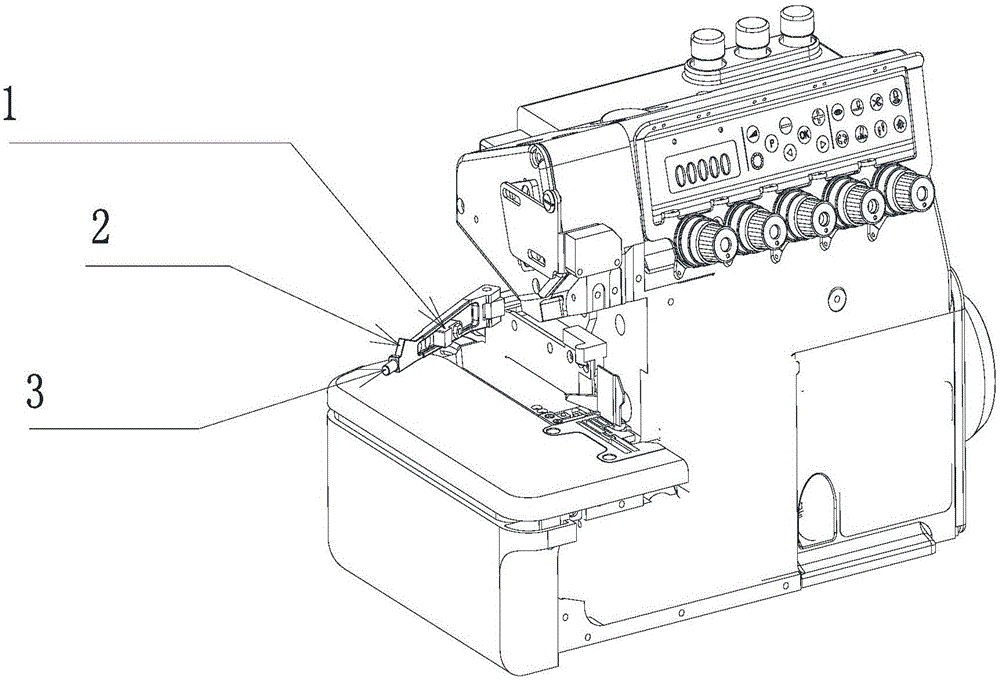

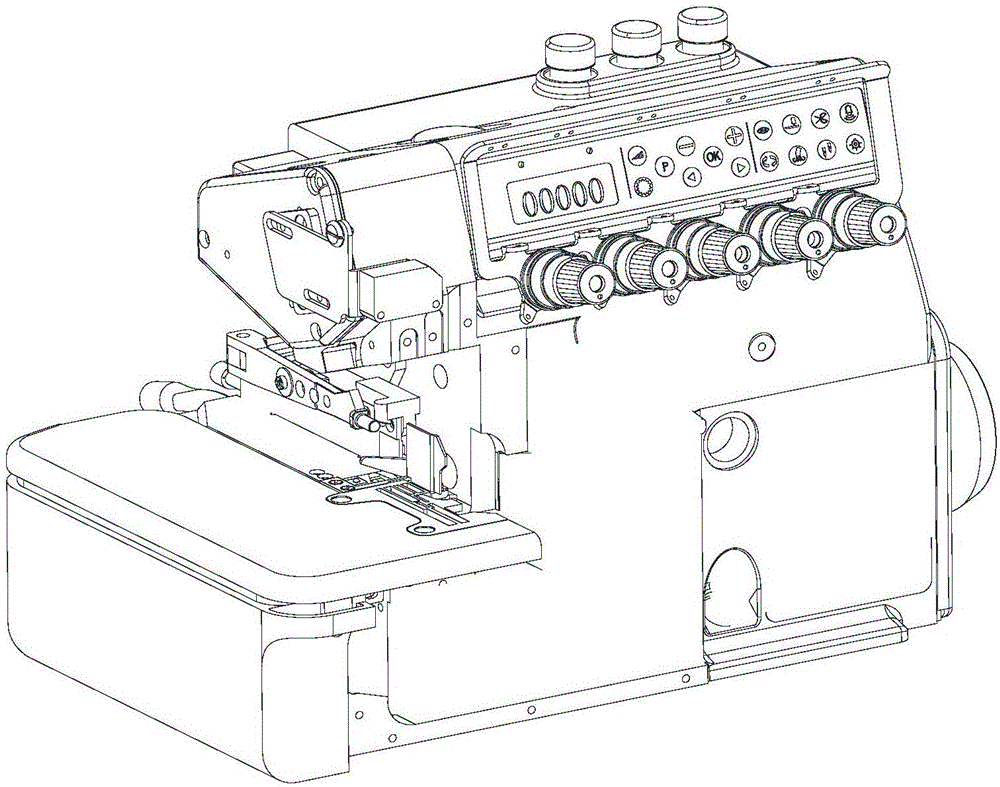

Overedger shield safety switch structure and overedger shield safety protecting method

ActiveCN103205866AAvoid personal injuryAvoid damageSafety devices for sewing-machinesControl systemEngineering

The invention provides an overedger shield safety switch structure. The overedger shield safety switch structure comprises a shell and a protecting cover used for protecting a line crossing rod and a needle rod. The protecting cover is pivoted on the shell, and a safety switch enabling an overedger to stop when the protecting cover is opened is arranged between the protecting cover and the shell. The invention further provides an overedger shield safety protecting method. The openable protecting cover used for protecting the line crossing rod and the needle rod is arranged on the shell of the overedger. The overedger shield safety protecting method includes that when the protecting cover is opened, the safety switch on the protecting cover transmits a signal to a control system which forbids the overedger to start; when the protecting cover is closed, the safety switch transmits a signal to the control system which allows the overedger to be started. By arranging the safety switch between the protecting cover and a frame, the overedger shield safety switch structure and the overedger shield safety protecting method have the advantages that the overedger cannot be started even by misoperation of a maintainer who is threading a line and changing a needle, so that the maintainer is prevented from being injured, and damage to a machine is avoided.

Owner:JACK SEWING MASCH CO LTD

Manual rotary devices of sewing machines

InactiveCN1439761AImprove cooling effectEasy to operate manuallySewing-machine control devicesSafety devices for sewing-machinesCouplingOperability

To provide a manual rotation device, capable of reducing the occurrence of an injury near a manually operating pulley during the drive of a sewing machine and improving the operability of the manually operated pulley. This manual rotation device of a sewing machine is provided with an upper shaft cased in a sewing machine, a sewing machine motor having an output shaft of a clutch plate and connected to the upper shaft through a coupling, and a manually operating pulley shaft having an engagement plate engaged with the clutch plate of sewing machine motor and adapted to manually rotate the upper shaft. An output shaft of the sewing machine motor is made intersect perpendicularly to the manual operated pulley shaft.

Owner:PEGASUS SEWING MACHINE MFG

Needle guard mechanism for sewing machines

A needle guard mechanism for sewing machines aims at stabilizing needles during lowering for stitching operation to prevent needle wobbling caused by high speed motion thereby to avoid the needles from breaking or skipping. The needle guard mechanism adopts an independent design to adjust needle lowering and lifting time separately. The mechanism includes a needle guard and a transmission mechanism. The needle guard consists of a movable member, a front needle guard straddled on the movable member and a rear needle guard fastened to the movable member. The transmission mechanism provides a force to drive the movable member to move reciprocally so that the front needle guard swings in the opposite direction against the reciprocal motion thereby it moves close to the rear needle guard to hold the lowering needles steadily to prevent needle wobbling.

Owner:SHING RAY SEWING MACHINE

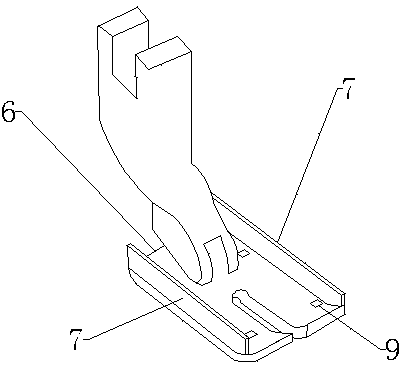

Novel machine needle protective cover special for sewing machine

InactiveCN102433697ABlock flying outAvoid harmSafety devices for sewing-machinesNeedle penetrationEngineering

The invention relates to a novel machine needle protective cover special for a sewing machine. A vertical machine needle assembly and a press foot assembly are connected with a machine head of the sewing machine, the protective cover mainly comprises a main protective cover body, wherein the main protective cover body is arranged on a lateral face, which faces an operator, of the machine head, and can rotate relative to the machine head, the protective cover is characterized in that the main protective cover body is a vertical plate, and an auxiliary protective cover is a vertical thin plate connected on a press foot near a machine needle. The auxiliary protective cover can be used for preventing a finger of the operator from being injured by needling, so that the operator can be protected more comprehensively except the shielding of a main protective cover, and the safety is increased; the main protective cover body can be integrated with a connecting plate thereof, the rotation maneuverability of the main protective cover body is ensured, and parts are saved; moreover, the main protective cover and the auxiliary protective cover can be made of transparent materials, so that the operator is convenient to cleanly observe the operating conditions of the machine needle and the press foot which are in back of the protective cover.

Owner:吴江丰榖布艺整理厂

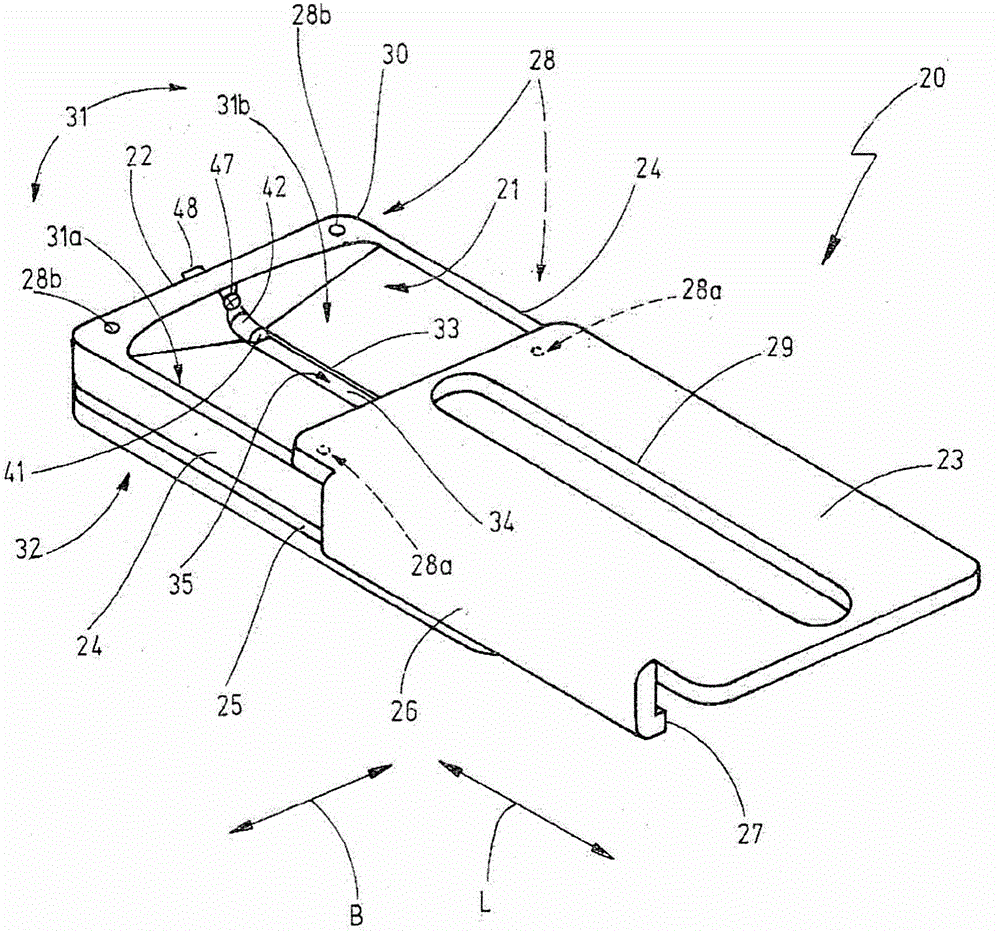

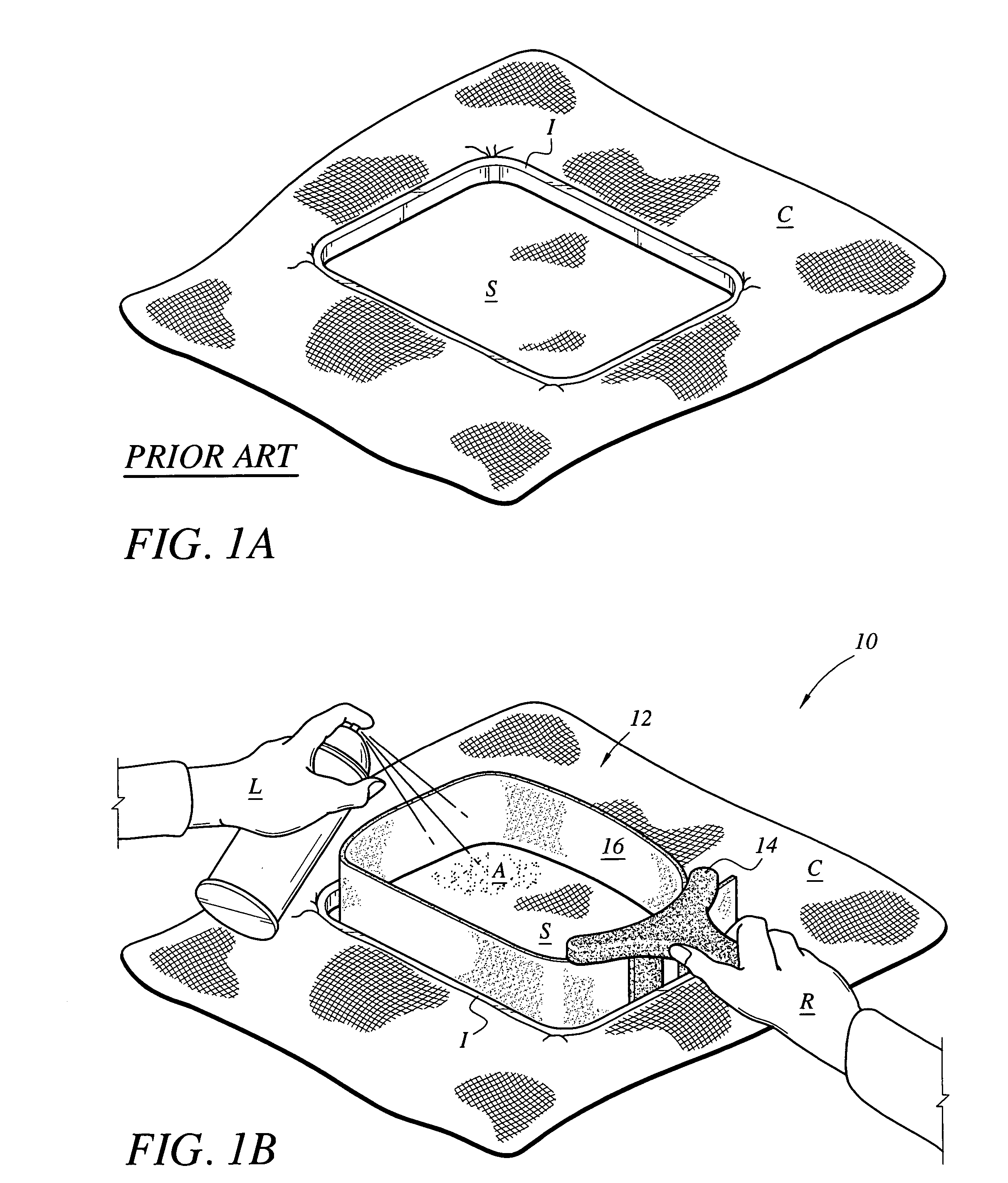

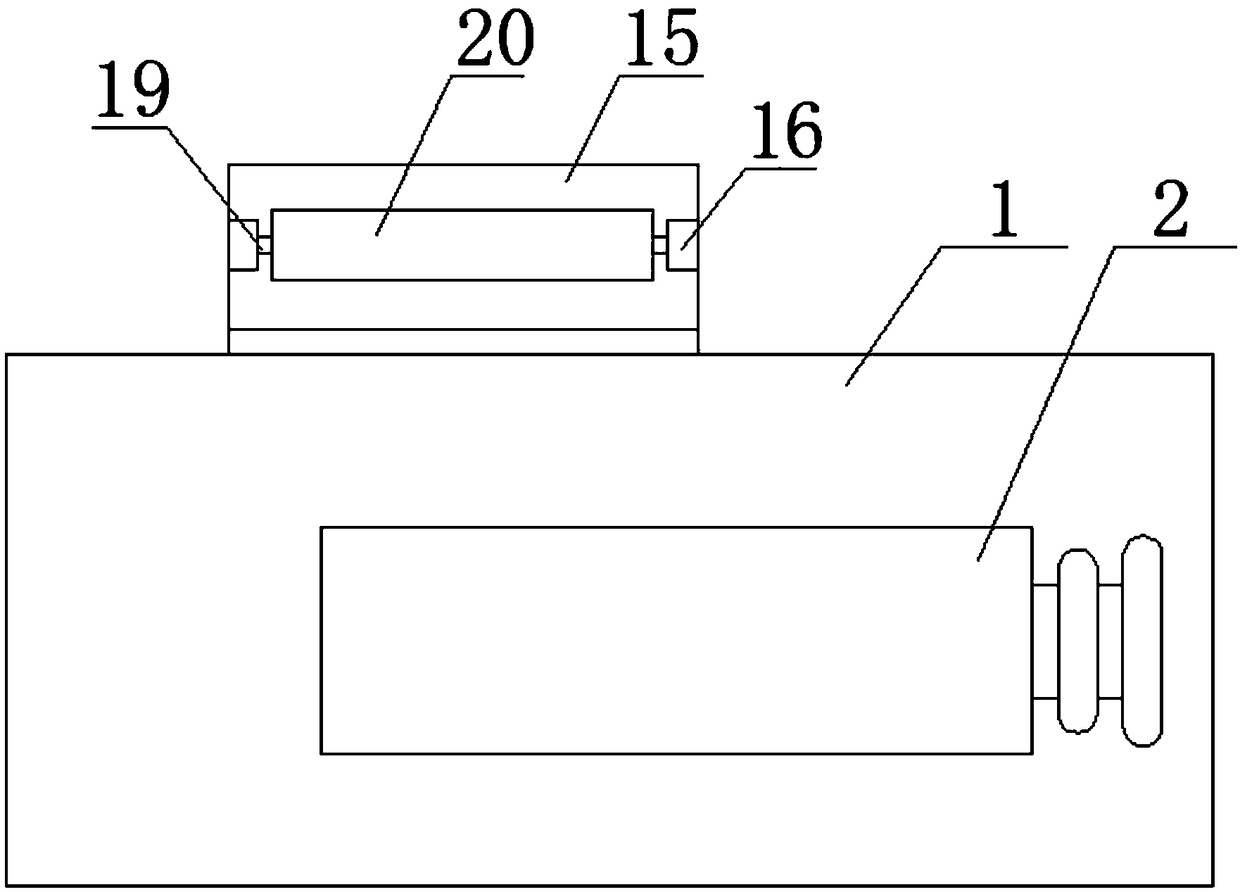

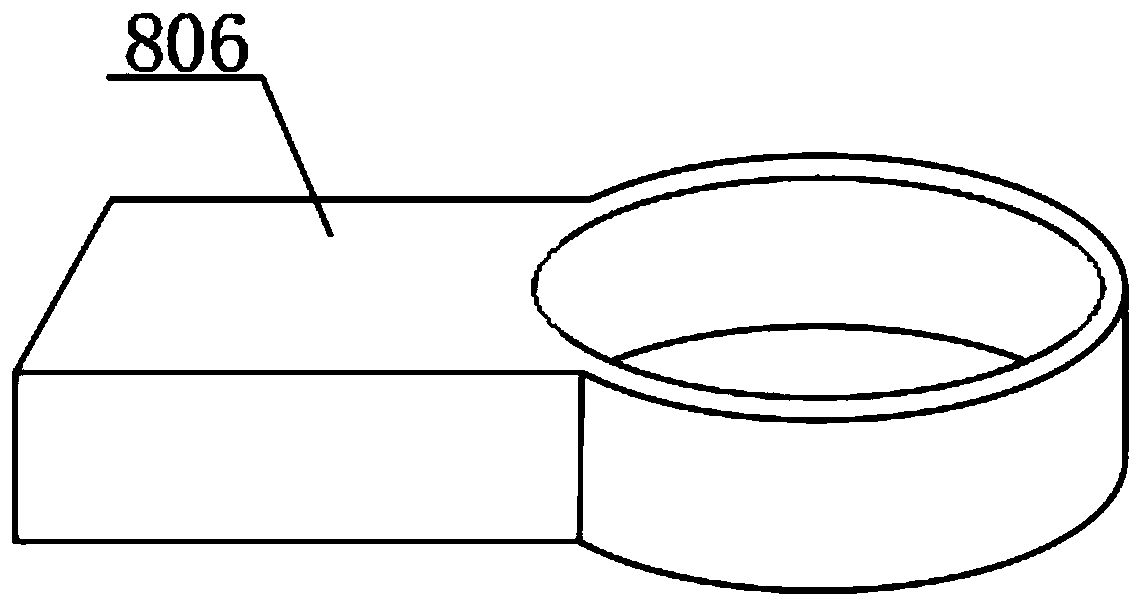

Method and container for verifying whether all fragments of a broken needle are present

ActiveCN104919103AOptimize layoutReduce missingSafety devices for sewing-machinesEngineering safety devicesWorkstationBiomedical engineering

The method involves orientedly accommodating fragments of a broken needle in an accommodation space (21) of a container (20) by retaining magnets (34). The accommodation space is defined by a base body (22) and a lid (23). Test is made whether the fragments of the broken needle are provided in the container. A replacement needle is provided for a workstation once established that the fragments are removed from the workstation. The retaining magnets are arranged in a region of a base (32) of the base body extending along an axis.

Owner:GROZ BECKERT KG

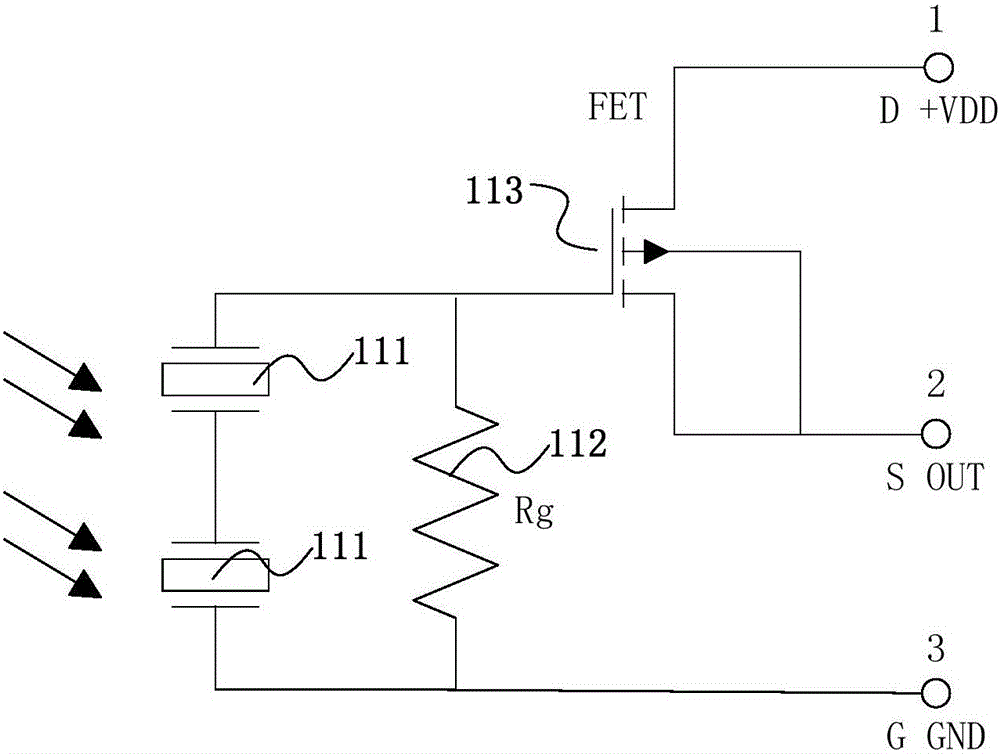

Detector for sewing machine

InactiveCN102851883AAvoid harmSimple structureSewing-machine control devicesSafety devices for sewing-machinesEngineeringPhotoelectric sensor

The invention relates to a detector for a sewing machine. The detector for the sewing machine comprises a bend plate, a nose disposed on the bed plate, a needle bar connected to the nose, and a needle shaft driving the needle bar to move. The needle shaft is connected with a piston rod of a cylinder. A controller, a photoelectric sensor and an alarm are disposed on the nose. The controller is connected with the cylinder, the photoelectric sensor and the alarm. The detector for the sewing machine is simple in structure and convenient to use. The length of a needle on the needle bar is detected by the photoelectric sensor so as to determine presence of a broken needle in a garment being sewn. The acoustic-optic alarm is capable of reminding people of taking corresponding measures to avoid injury of human bodies.

Owner:WUJIANG XIAOYU JET WEAVING

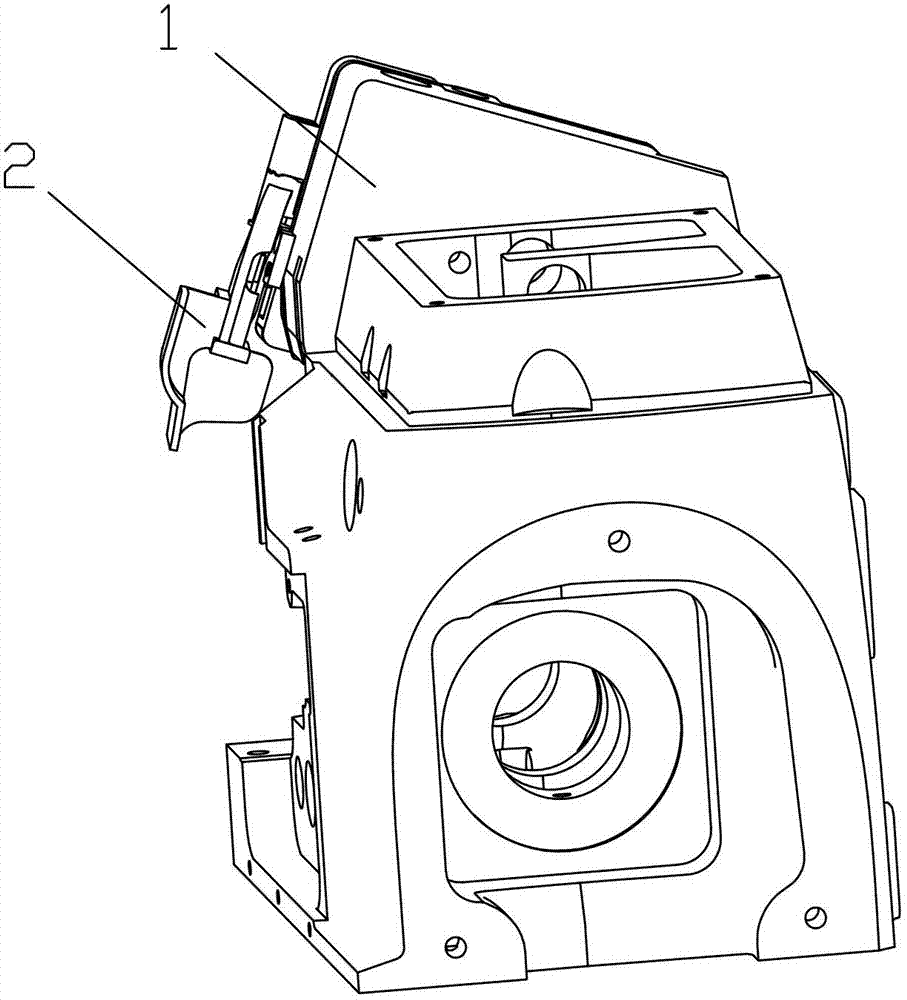

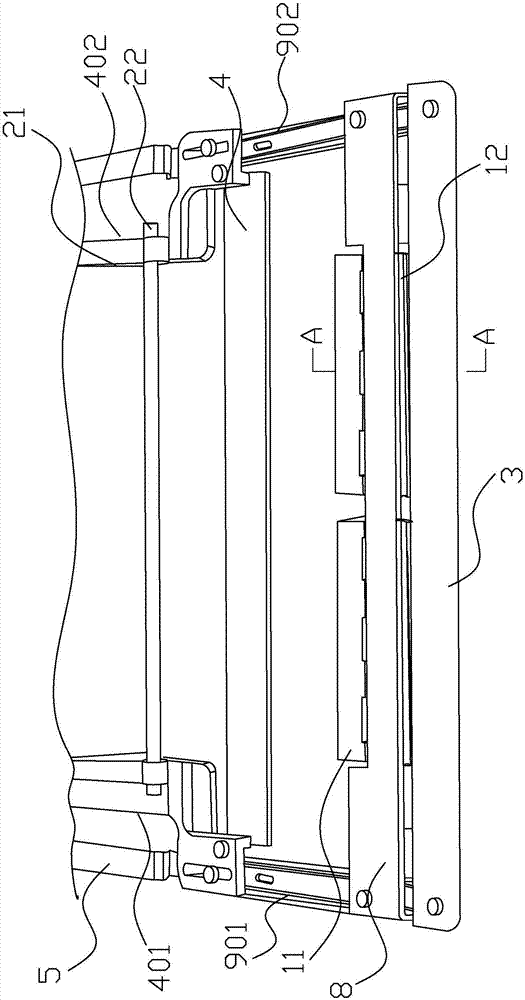

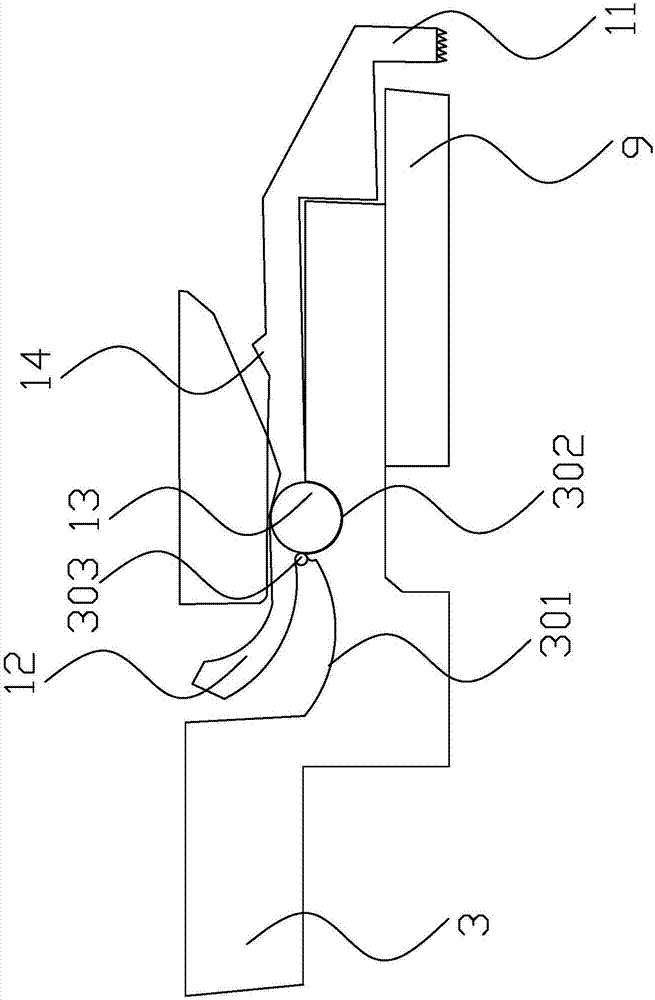

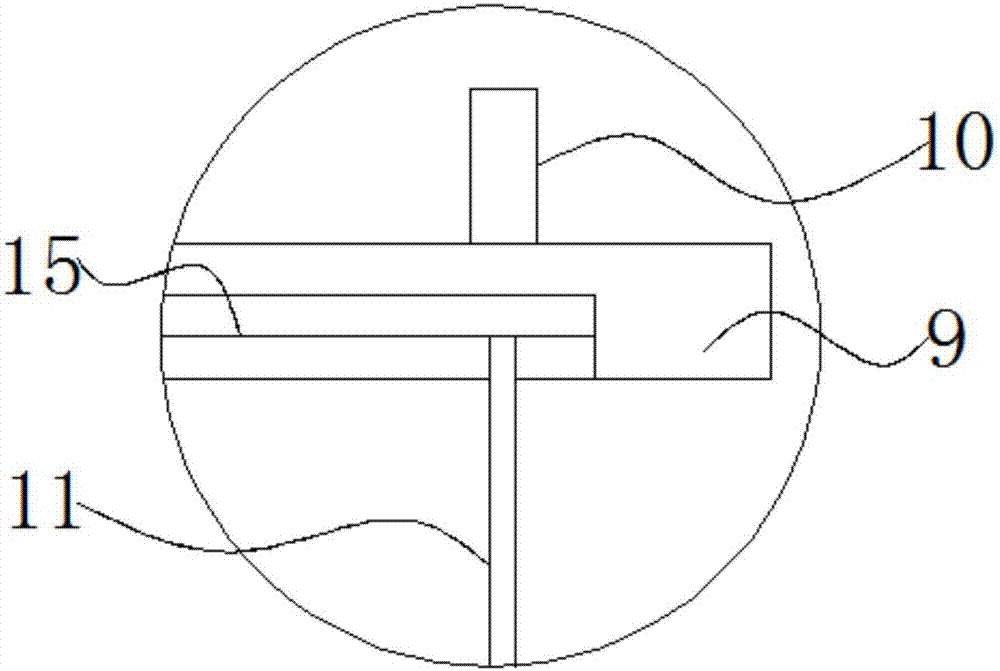

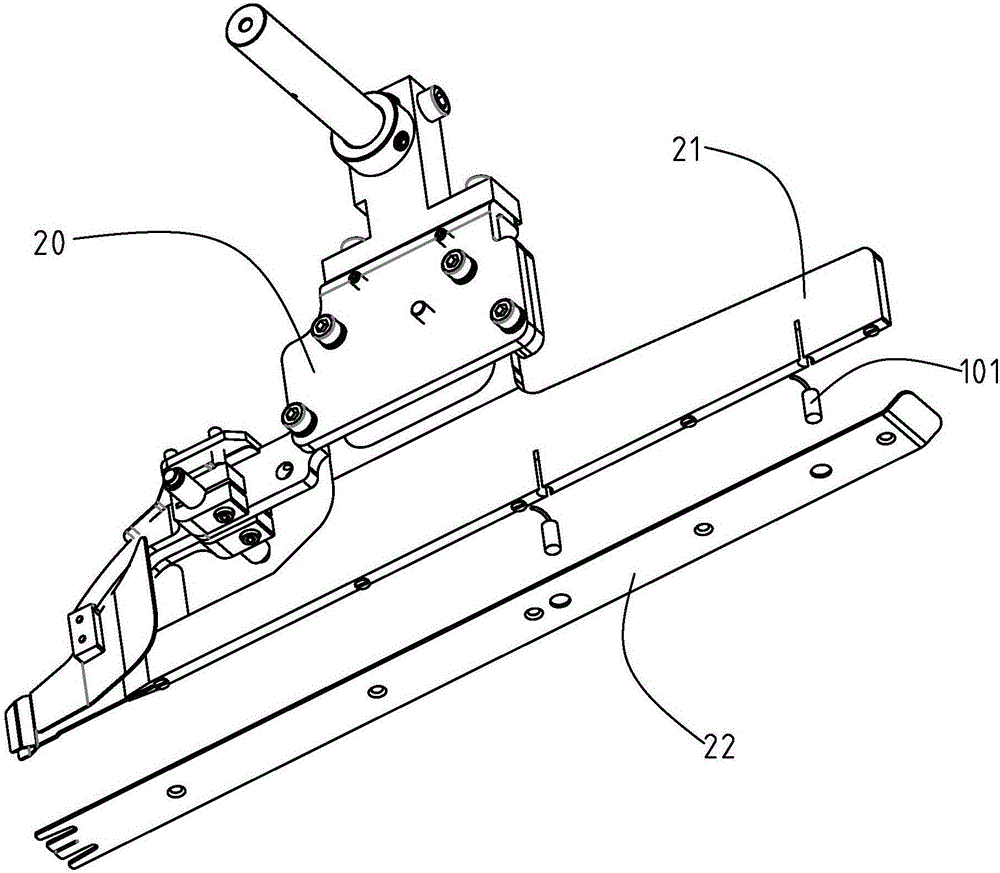

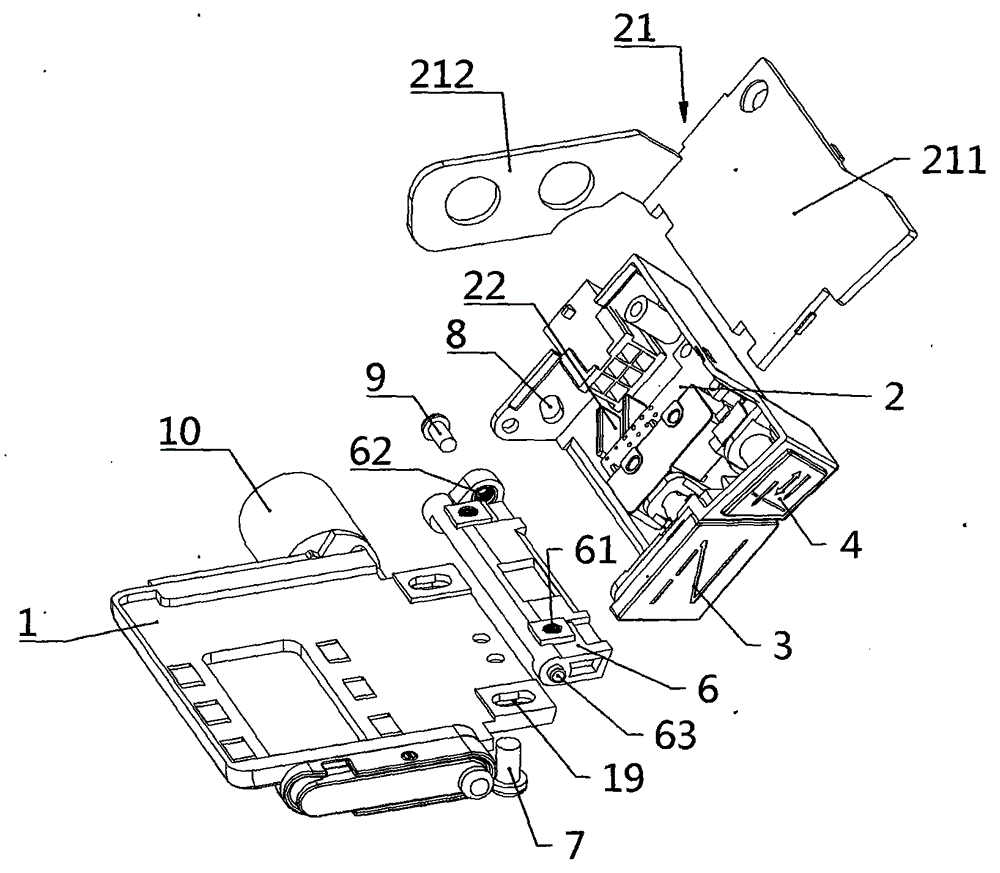

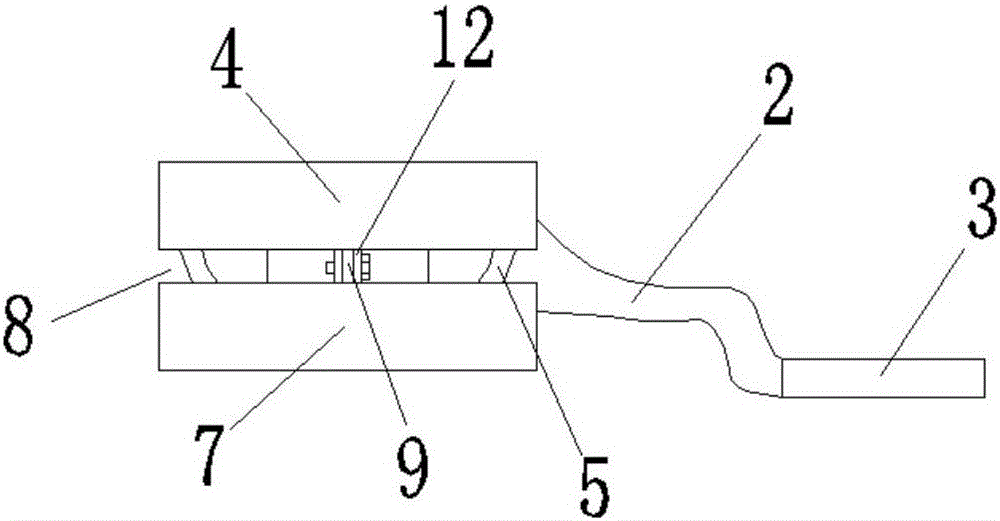

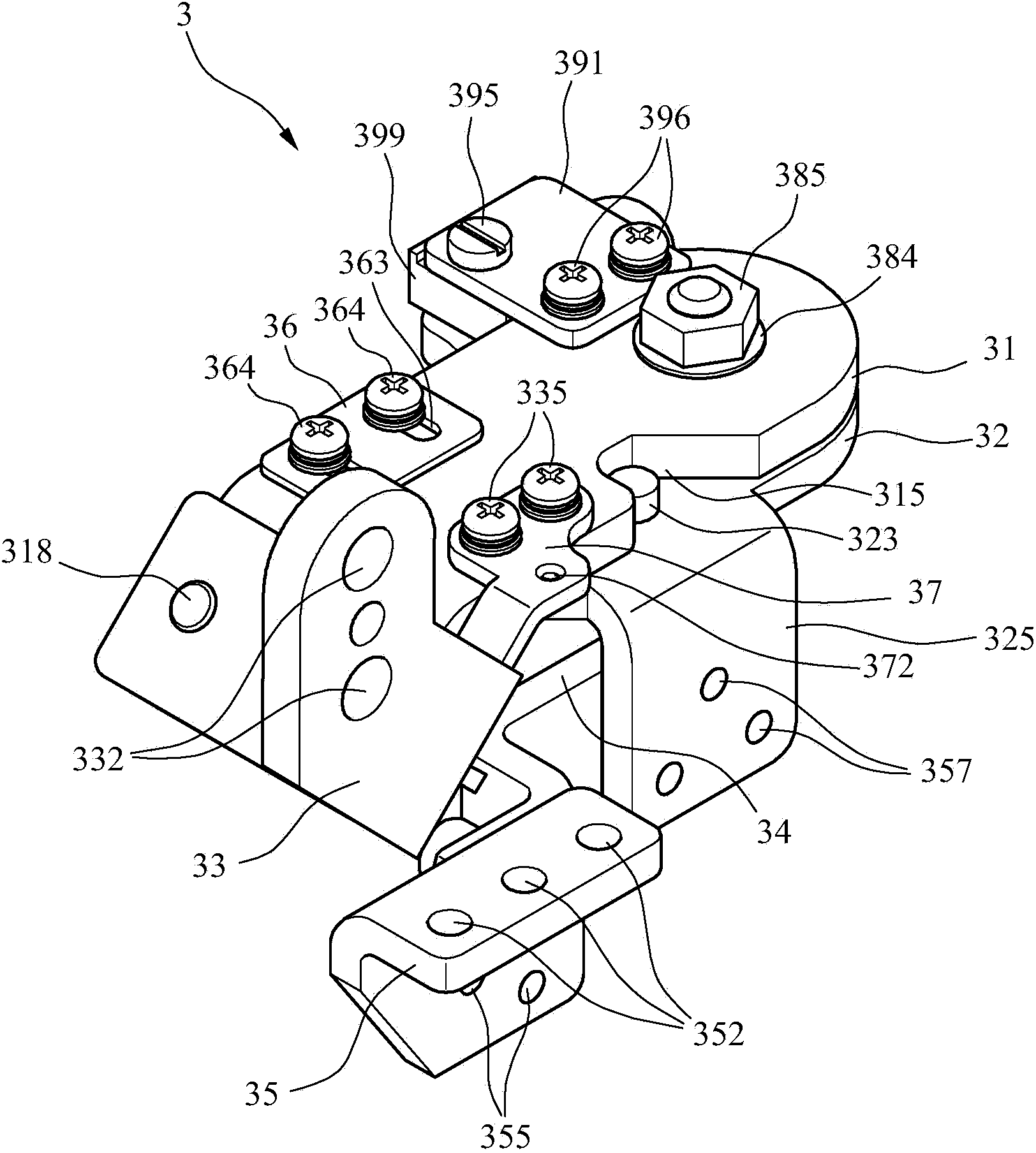

Clamping device for bag opening machine

ActiveCN106868725AReduce labor intensityAvoid damageWork-feeding meansPressersEngineeringSewing machine

The invention relates to the technical field of sewing machines, and provides a clamping device for a bag opening machine. The clamping device includes a controller, a fixing support, a first driving mechanism, a second driving mechanism, a first pressing pawl mechanism, a second pressing pawl mechanism, a moving base, a fixing base, a first connection rod, a second connection rod, a third connection rod, and a pressing plate; the first pressing pawl mechanism can lift / press the pressing pawl so as to arrange the pressing pawl on an upper surface of the moving base by matching an arc portion and an arc groove and matching a semi-circular shaft and a semi-circular groove; the second driving mechanism can lift / press the pressing pawl of the pressing pawl plate through the third connection rod and is fixed on an upper surface of the fixing base; and the first driving mechanism and the second driving mechanism are connected to and are controlled by a controller. The problem that the clamping devices of the conventional bag opening machines are large in labor intensity, and are low in production efficiency can be solved.

Owner:石狮市众利缝制科技有限公司

Intelligent sewing machine protection device

InactiveCN106930017ASolve the phenomenon that there will inevitably be broken needlesSolve the phenomenon of broken needleSafety devices for sewing-machinesEngineeringMagnet

The invention discloses an intelligent sewing machine protection device, which comprises a support plate, a sewing machine body is fixedly connected to the top of the support plate, two support blocks are arranged on the left side of the front surface of the sewing machine body, and a A transparent plate is provided, a connection block is fixedly connected to the inner side of the support block, a slider is fixedly connected to the back of the connection block, and slide rails are symmetrically fixedly connected to the front surface of the transparent plate. The present invention is provided with support plate, sewing machine body, support block, transparent plate, connecting block, slider, slide rail, first magnet, fixed block, positioning block, guide rod, hollow column, spring, buffer pad and second magnet, It solves the problem that the existing sewing machine will inevitably break the needle during operation and easily injures the user, increases the safety of the user when using the sewing machine, ensures the work efficiency of the user, and is convenient for the user to use .

Owner:浙江高派机器人科技有限公司

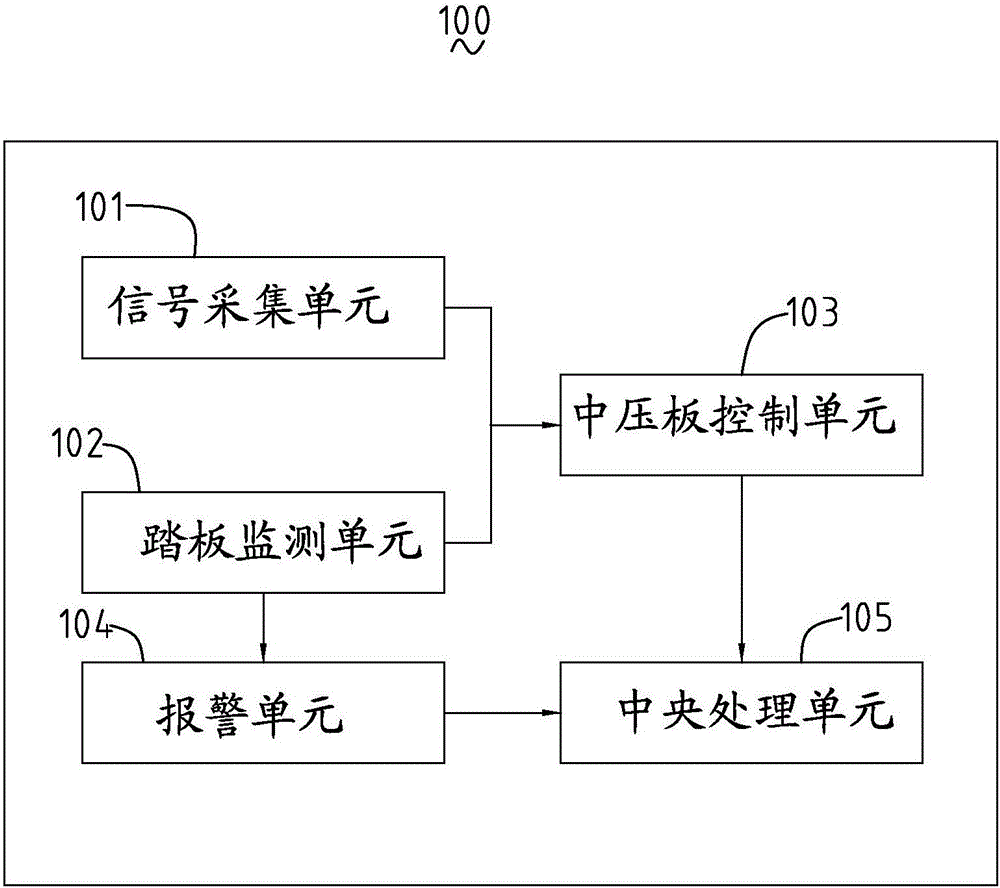

Pressing plate controlling system and method of pocket-hole sewing machine

ActiveCN106835528AWill not cause industrial accidentsSewing-machine control devicesSafety devices for sewing-machinesStopped workIndustrial Accident

The invention provides a pressing plate controlling system and method of a pocket-hole sewing machine. The pressing plate controlling system of the pocket-hole sewing machine comprises a signal collection unit, a pedal monitoring unit and a middle pressing plate controlling unit. When the signal collection unit collects a signal that hands of people enter between a middle pressing plate mechanism and a presser foot mechanism, the middle pressing plate controlling unit outputs a signal for stopping work of the middle pressing plate mechanism. When the signal collection unit collects a signal that no hands of the people enter between the middle pressing plate mechanism and the presser foot mechanism and the pedal monitoring unit monitors that a pedal mechanism is pedaled, the middle pressing plate controlling unit outputs a signal for starting the work of the middle pressing plate mechanism. Due to the existence of the signal collection unit and the pedal monitoring unit, when inserting the position between the middle pressing plate mechanism and the presser foot mechanism, the hands of the people is sensed by the signal collection unit so that no industrial accident can be caused even if the pedal mechanism is pedaled mistakenly. The invention further relates to the controlling method.

Owner:BULLMER ELECTROMECHANICAL TECH

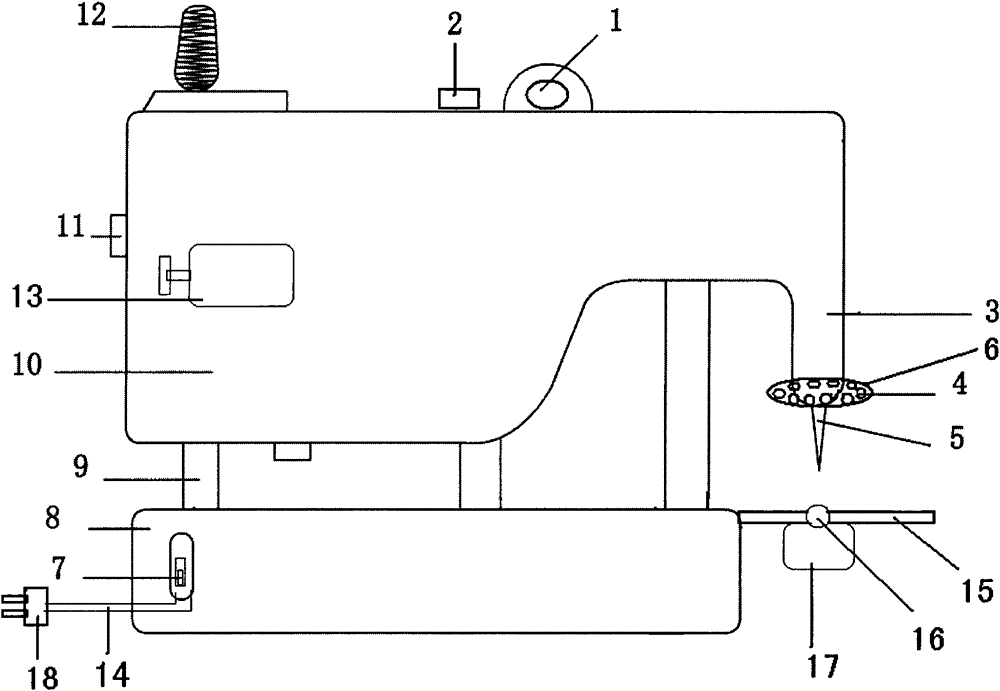

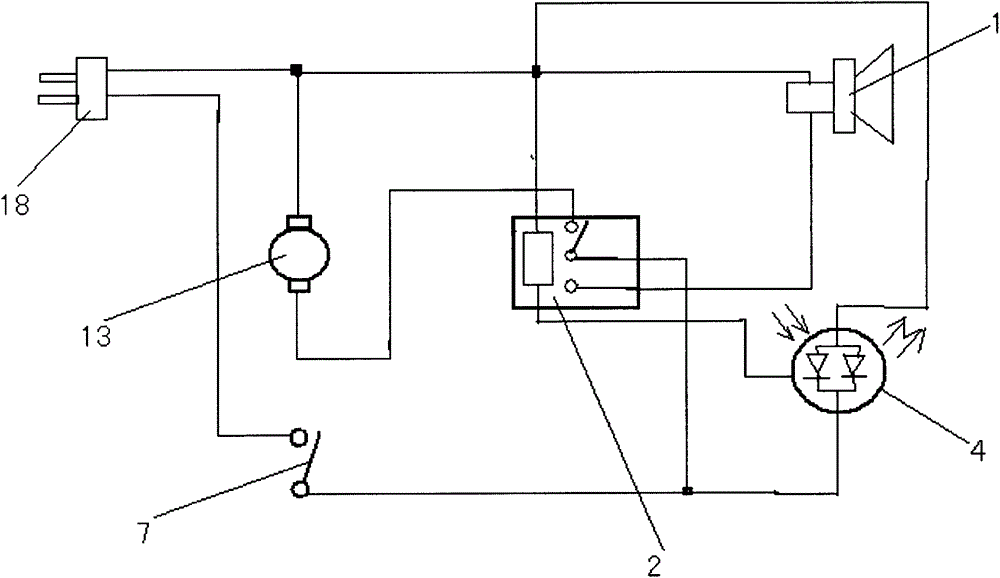

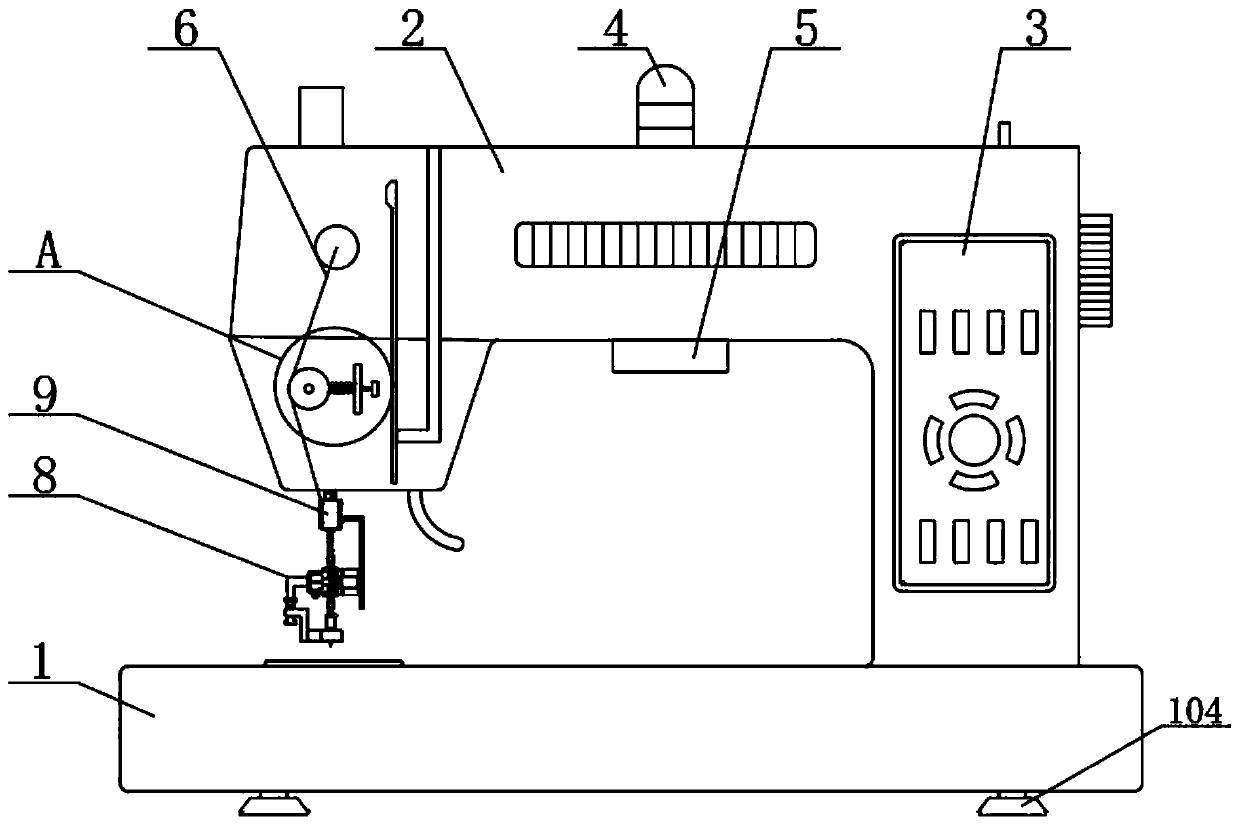

Electric sewing machine capable of not pricking hands

InactiveCN104420086ASewing-machine control devicesSafety devices for sewing-machinesInfraredStopped work

The invention provides an electric sewing machine capable of not pricking hands. The electric sewing machine comprises a base, a bracket, a machine body, a wire ring, a wire, a machine head, a needle, a sewing machine plate, a sewing needle hole and a bottom wire box, which are connected in sequence, wherein a power supply switch is mounted at the left side of the base and is connected with a power supply plug through a power line; the motor is mounted at the left part of the machine body; an alarm and a control relay are mounted at the top of the machine body; a fixed ring is mounted at the bottom of the machine head and is provided with infrared ray approach switch probes. According to the electric sewing machine, the fixed ring is mounted at the bottom of the machine head in order to enable the electric sewing machine to be safer; the plurality of infrared ray approach switch probes are mounted at the periphery of the fixed ring and are mounted above the needle; the alarm and the control relay are mounted at the top of the machine body; if fingers go across the infrared ray approach switch probes in a sewing process, the alarm makes the sound and a power supply of the motor is automatically switched off, so that the sewing machine automatically stops working and the electric sewing machine is very safe.

Owner:KUNSHAN CITY YUSHAN TOWN SHILONG DESIGN STUDIO

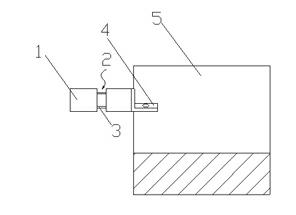

Novel thread cutting device for sewing machine

InactiveCN102359000AAccurate entryReducing Hazardous TouchesNeedle severing devicesSafety devices for sewing-machinesEngineeringKnife blades

The invention relates to a novel thread cutting device for a sewing machine. A vertical presser foot rod is arranged on a machine head of the sewing machine, a presser foot is connected to the lower end of the presser foot rod, and the thread cutting device comprises a blade connected to the rear end of the presser foot. The novel thread cutting device is characterized in that the blade is arranged between two cylindrical barrels which are arranged transversely. The cylindrical barrels play a role of stopping fingers of an operator from touching the built-in blade, meanwhile, no edge angles are arranged on the circular-arc outer surface of the cylindrical barrels per se, so that touching dangers are reduced when the blade is used for cutting a thread, and the use safety is increased. The width of the blade can be set to be 1-2mm so as to ensure that a sewing thread can get in accurately and a finger cannot touch the blade, thus, the thread cutting efficiency is increased on the basis of safety. The cylindrical barrels are arranged on the presser foot in a spiral connection manner, are convenient to detach and replace and have prolonged service lives. The novel thread cutting device disclosed by the invention has the advantages of simple structure, small size and low cost and is very suitable for the household sewing machine.

Owner:吴江丰榖布艺整理厂

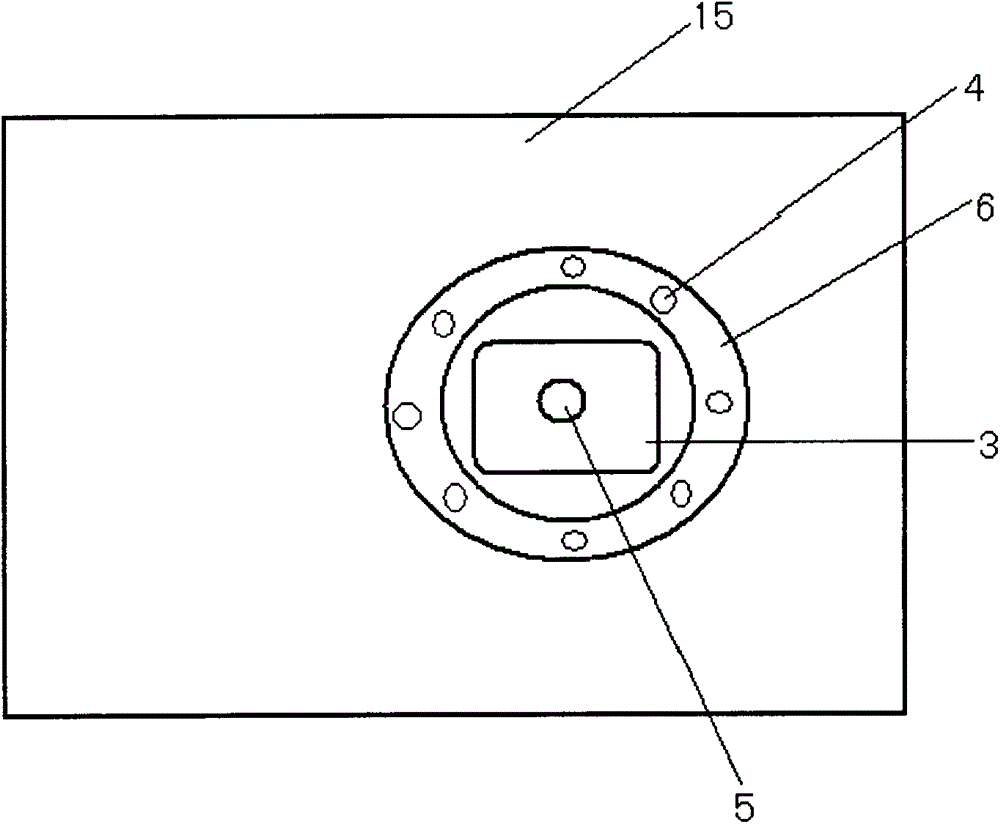

Embroidery sewing machine hoop guard

InactiveUS20050120931A1Accurate areaPrecision SprayingSafety devices for sewing-machinesCarpetsAdhesiveEngineering

An embroidery sewing machine hoop guard includes a strap held by a handle portion having a grip, a strap attachment wall for attachment of one end of the strap, and a buckle for receiving the other end, allowing the strap to be held on edge in a generally circular position. The strap adjusts to fit within a hoop while allowing adhesive spraying of a flat area of clothing material to be embroidered, protecting from overspray of adhesive, thus avoiding periodic cleaning of the hoop. The hoop guard may be held on any surface within which a spray material or coating is applied to the surface, by gripping with one hand while a spray device is operated by the other hand to spray an area of the surface within the boundary formed by the strap and handle portion. This prevents overspray beyond that area, protecting other elements or surfaces.

Owner:MANSON ADRIANNE L

Finger protecting ring of sewing machine

InactiveCN102465399AAvoid stab woundsEasy to observeSafety devices for sewing-machinesMetallurgyProduct processing

A finger protecting ring of a sewing machine is characterized in that a first-section steel wire, a second-section steel wire, a third-section steel wire, a fourth-section steel wire, a fifth-section steel wire, a six-section steel wire, a seventh-section steel wire and an eight-section steel wire are formed by bending backward from one end of a steel wire in sequence, after bending, from the first-section steel wire to the eight-section steel wire, an inverted door-shaped steel wire piece, an U-shaped steel wire piece and a framed steel wire connecting piece with a square opening are formed; the U-shaped steel wire piece and the framed steel wire connecting piece with the square opening are arranged on the same plane surface, and the steel wire at the rear part of the second-section steel wire is vertically connected with the steel wire of the U-shaped steel wire piece after 90 degrees of bending; a metal flat plate is mounted on the square steel wire frame to form the finger protecting ring of a sewing machine, and the finger protecting ring of the sewing machine is fixedly mounted on the presser foot of the sewing machine. During product processing, personal injury to operation crews and economic losses are avoided.

Owner:JIHUA 3542 TEXTILE CO LTD

Double-thread sewing machine capable of preventing hand pinching

InactiveCN109082787AEasy to sewImprove work efficiencyWork-feeding meansSafety devices for sewing-machinesCouplingFixed frame

The invention discloses a double-thread sewing machine capable of preventing hand pinching. The double-thread sewing machine comprises a supporting plate and a double-thread sewing machine body, the double-thread sewing machine body is arranged on the top surface of the supporting plate, the two sides of the output end of the double-thread sewing machine body are provided with rubber sleeves, first springs are arranged in the rubber sleeves, and two first fixing frames are fixed at the bottom of the supporting plate; second springs are fixed to the top surfaces of the interiors of first grooves, and a motor is installed on the top surface of a first mounting plate; the end of an output shaft of the motor is rotationally connected with a second roller through a coupler, and a second mounting plate is fixed to the outer wall of the supporting plate; a second fixing frame is fixed to the top surface of the second mounting plate, and the bottom of a third spring is located in a second groove and is rotationally connected with a third roller through a second connecting pin. The double-thread sewing machine can well prevent hands from being pinched during work, meanwhile, long cloth canbe conveniently sewn, and the working efficiency is improved.

Owner:开平雄信制衣有限公司

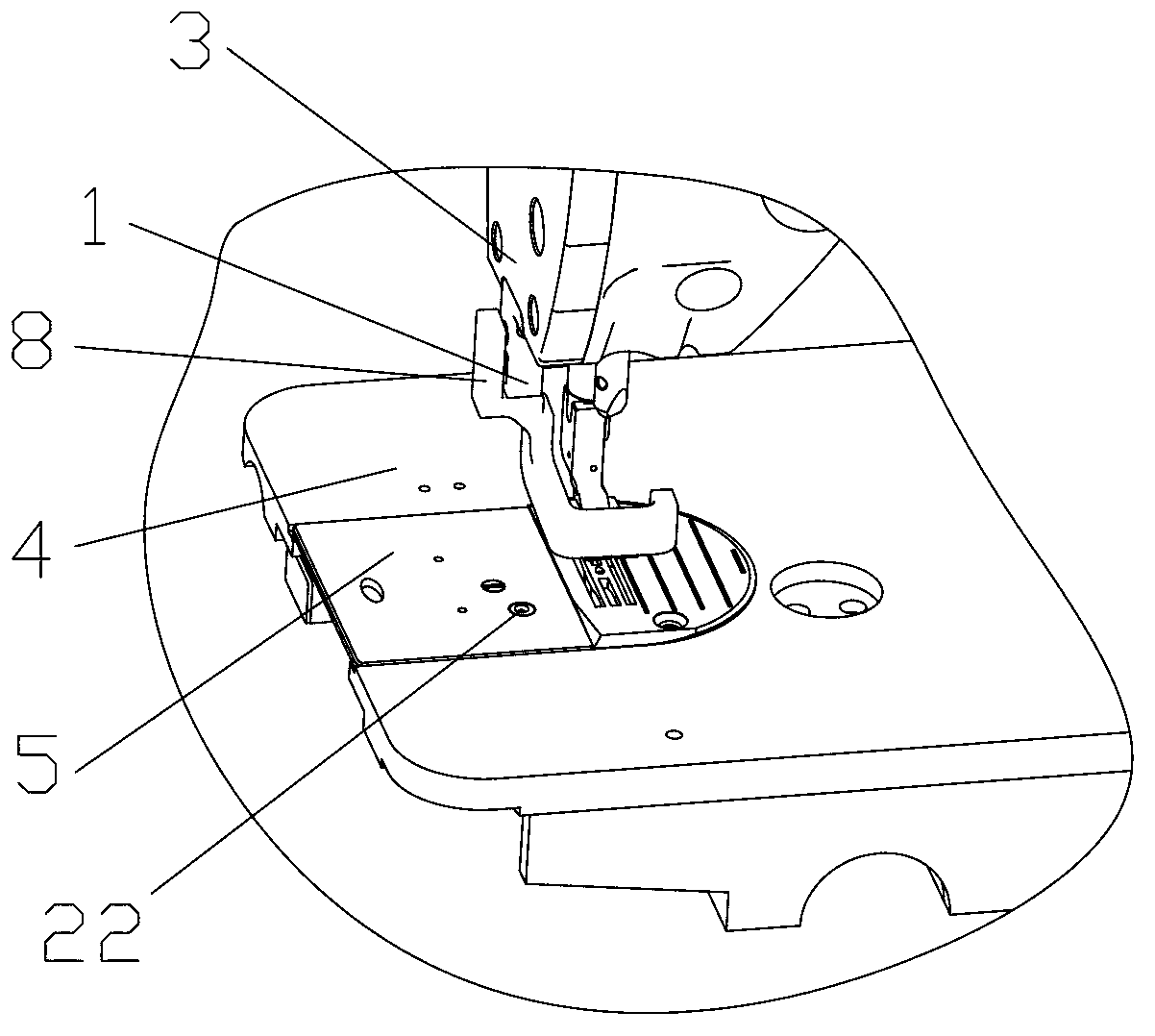

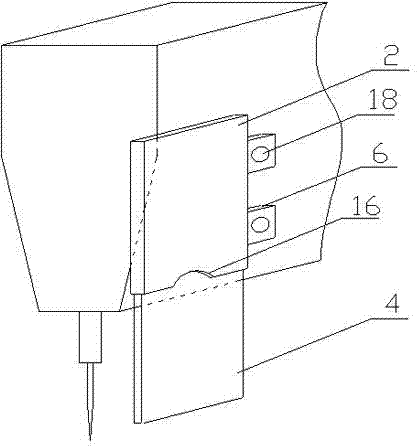

Integrated switch component mounted at sewing machine head

InactiveCN104480648AImprove quality and efficiencyImprove work efficiencySewing-machine control devicesSafety devices for sewing-machinesEngineeringLED lamp

The invention relates to the field of industrial sewing machines, in particular to an integrated switch component mounted at a sewing machine head. The integrated switch component comprises a mounting plate, the mounting plate is horizontally arranged at the lower end of the sewing machine head, a sliding seat is arranged on the mounting plate and can be bilaterally adjusted relative to the mounting plate, a rotating shaft is arranged on the sliding seat and parallel to the front and back direction of the mounting plate, a mounting frame is connected on the rotating shaft, can vertically rotate and can be adjusted around the rotating shaft in a certain angle, a sewing machine thread end control device and an LED (light-emitting diode) lamp are arranged on the mounting plate, the LED lamp is arranged on the bottom surface of the mounting plate, a reverse stitching key, a needle supplement key and an LED lamp key controlling on and off of the LED lamp are arranged on the mounting frame, a fixing frame is arranged on the mounting frame, and the integrated switch component is fixedly connected with the machine head through the fixing frame. The switch component integrates functions such as needle supplement, reverse stitching, lighting and sewing machine thread end control, is convenient to popularize, and production efficiency and quality are improved.

Owner:乐清市佳星缝纫机配件厂

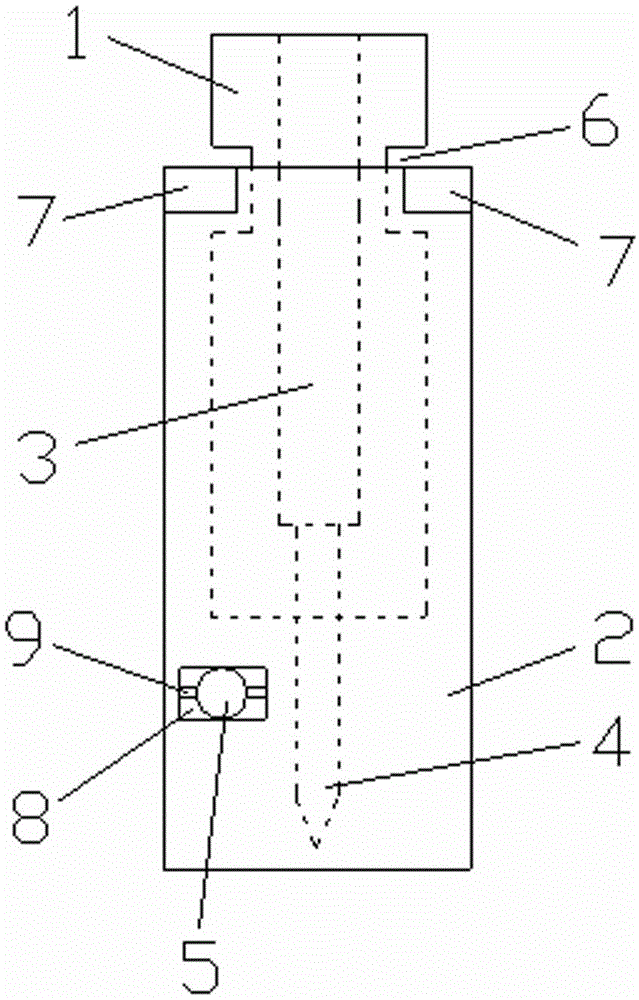

Sewing needle protection device

InactiveCN103556405AAvoid stabbingGuaranteed smoothSafety devices for sewing-machinesSewing needlesVertical barEngineering

The invention relates to a sewing needle protection device, which comprises a vertical bar and a protection sleeve which is sheathed on the vertical bar. The vertical bar is hollow and cylindrical. A convex lens is arranged at the lower end of the protection sleeve. The sewing needle protection device has the advantages that the structure is simple, the device is convenient to use, a needle bar with a sewing needle can penetrate through the vertical bar and is arranged in the protection sleeve, the external impact force is avoided, an operator is prevented from being stabbed, the arranged convex lens can be used for observing the moving situation of fabrics, the flatness of the fabrics is ensured and the sewing quality is enabled to be good.

Owner:WUJIANG XILI MACHINERY FACTORY

Sewing machine needle correcting device with transposition function

InactiveCN111826821AEasy to installGuarantee the safety of useSewing-machine control devicesSafety devices for sewing-machinesEngineeringPhysics

The invention relates to the technical field of sewing machines, and discloses a sewing machine needle correcting device with a transposition function. The sewing machine needle correcting device comprises a needle rod, wherein the inner cavity of the needle rod is rotationally connected with a connecting pipe; an elastic ejector rod is inserted into the right wall of the needle rod in a sliding manner; a detection column is slidably connected to the right wall of the connecting pipe; a first spring is fixedly connected between the detection column and the right wall of the connecting pipe; ametal elastic piece is arranged on the right side of the detection column in the inner cavity of the right wall of the connecting pipe; and an extrusion column is slidably connected to the lower portion of the detection column in the inner cavity of the right wall of the connecting pipe. According to the sewing machine needle correcting device with the transposition function, a rotating ring is arranged and matched with the elastic ejector rod to fix a machine needle, then the detection column is arranged in a matching way to detect the orientation of the mounting surface of the machine needleand control starting and stopping of an electromagnet, and a rack can drive a transmission fluted disc to rotate through a transmission gear, so that the machine needle is more convenient to mount, and the situation of needle breaking and thread jumping in the sewing process is avoided.

Owner:广州麦火文化传媒有限公司

Sewing machine with hand pressing prevention device

InactiveCN111748929AAvoid damageConvenience for subsequent usePressersSafety devices for sewing-machinesHand partsEngineering

The invention relates to the technical field of sewing machines, and discloses a sewing machine with a hand pressing prevention device. The sewing machine is characterized in that a buffer assembly ismounted at one end of a sewing machine body, the upper surface of a presser foot is in threaded connection with a fastening bolt, the rear surface of the presser foot is in sliding connection with anextendable plate, a limiting block fixedly connected to one end of the extendable plate is further slidably connected into the presser foot, and compacting assemblies are mounted on the two sides ofthe upper surface of the extendable plate correspondingly. According to the sewing machine, the periphery of the sewing machine body can be shielded through a shielding frame, the sewing machine bodyis prevented from being damaged by external force, meanwhile, the sewing machine body can be subjected to dustproof treatment through the shielding frame, and follow-up use is easy; and a certain buffering effect can be achieved in the pressing-down process of the presser foot through the buffer assembly, when fingers of a user make contact with the bottom of the presser foot, the hands of the user can be protected through elastic deformation of a second spring, a third spring and an air bag, and the fingers of the user are prevented from being crushed by the presser foot.

Owner:高邮萤火贸易有限公司

Lockstitch sewing machine with automatic induction function

ActiveCN103243499AEnsure safetyEnsure personal safetySafety devices for sewing-machinesControl systemEngineering

The invention provides a lockstitch sewing machine with an automatic induction function. The lockstitch sewing machine is provided with a cloth inductor connected with a control system. The cloth inductor comprises a transmitting sensor and a receiving sensor. The lockstitch sewing machine further comprises a lockstitch sewing machine sewing table and a lockstitch sewing machine head. A detachable pushing plate is arranged on the lockstitch sewing machine sewing table, the receiving sensor is arranged on the pushing plate, and the transmitting sensor is arranged on the lockstitch sewing machine head. A safety switch is arranged between the transmitting sensor and a finger protecting device, and a safety switch is arranged between the receiving sensor and the lockstitch sewing machine sewing table. By arranging the safety switch around the pushing plate and the finger protecting device, when the pushing plate is pulled out and the finger protecting device is opened, the lockstitch sewing machine can not be started, the safety of operation staff in threading, maintaining and the like is guaranteed, and personal safety of the operation staff is guaranteed.

Owner:JACK SEWING MASCH CO LTD

Crimping device for sewing machine with thread trimming function

InactiveCN106245242AEasy to cutEasy to disassembleWork-feeding meansNeedle severing devicesAgricultural engineeringSewing machine

The invention relates to a crimping device for a sewing machine with a thread trimming function comprising a crimping plate, a connecting plate and a mounting plate; the front end of the crimping plate is provided with an arc plate A which overturns downwards; the left side and the right side of the crimping plate turnover inwards and downwards to form crimping grooves; a fixing plate is installed between the crimping grooves at the left side and the right side of the crimping plate; the front end of the fixing plate is provided with an arc plate B which overturns upwards; the arc plate B is positioned under the arc plate A; a gap zone is installed between the arc plate A and the arc plate B; a shear blade is provided between the front end of the crimping plate and the front end of the fixing plate; the left side of the crimping plate is connected with the connecting plate; the connecting plate is connected with the mounting plate; the mounting plate is provided with a mounting groove. The crimping device of the invention has the trimming function to facilitate the shearing of the thread ends after the crimping sewing; the device has simple operation and high safety and is not liable to injure hands.

Owner:ZHEJIANG HUASHENG GARMENTS

Intelligent sewing machine

InactiveCN110670260AAvoid empty seamsPrevent movementSewing-machine control devicesSafety devices for sewing-machinesControl engineeringElectric machinery

The invention discloses an intelligent sewing machine which comprises a shell and a control panel. The lower end face of the shell is fixedly connected with an adjusting mechanism, the adjusting mechanism comprises a base, an electric telescopic rod and a sliding cylinder, the internal center of the base is fixedly connected with a rotating motor, the tail end of a spindle of the rotating motor isfixedly connected with a threaded rod, the outer side of the threaded rod is spirally connected with a threaded cylinder, and the upper end face of the threaded cylinder is fixedly connected with a seal sliding plate. By the aid of a pressure sensor, a limit spring and a tensioning wheel, a sewing thread contacts with the tensioning wheel, so that the tensioning wheel squeezes a sliding rod and further squeezes the pressure sensor, the pressure sensor transmits a signal to a controller, the controller controls the sewing machine to normally run, the sewing thread is broken when the pressure sensor detects no pressure, another signal is transmitted to the controller, the controller controls the sewing machine to stop working, and empty sewing is avoided.

Owner:溆浦县顺成服装有限公司

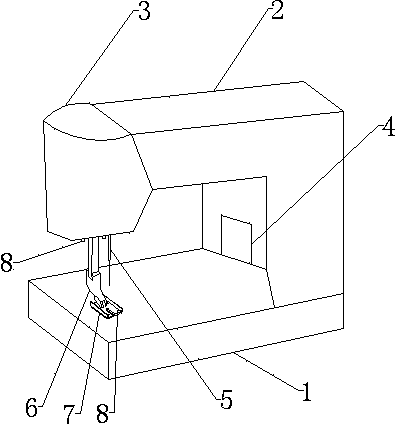

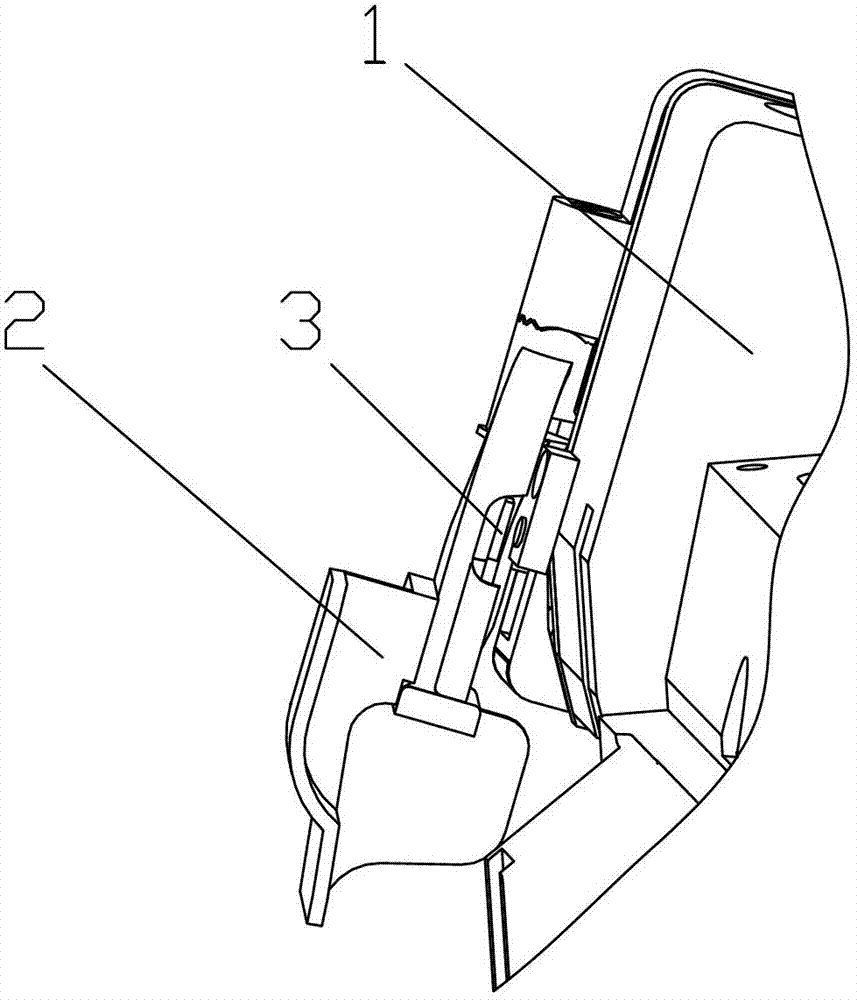

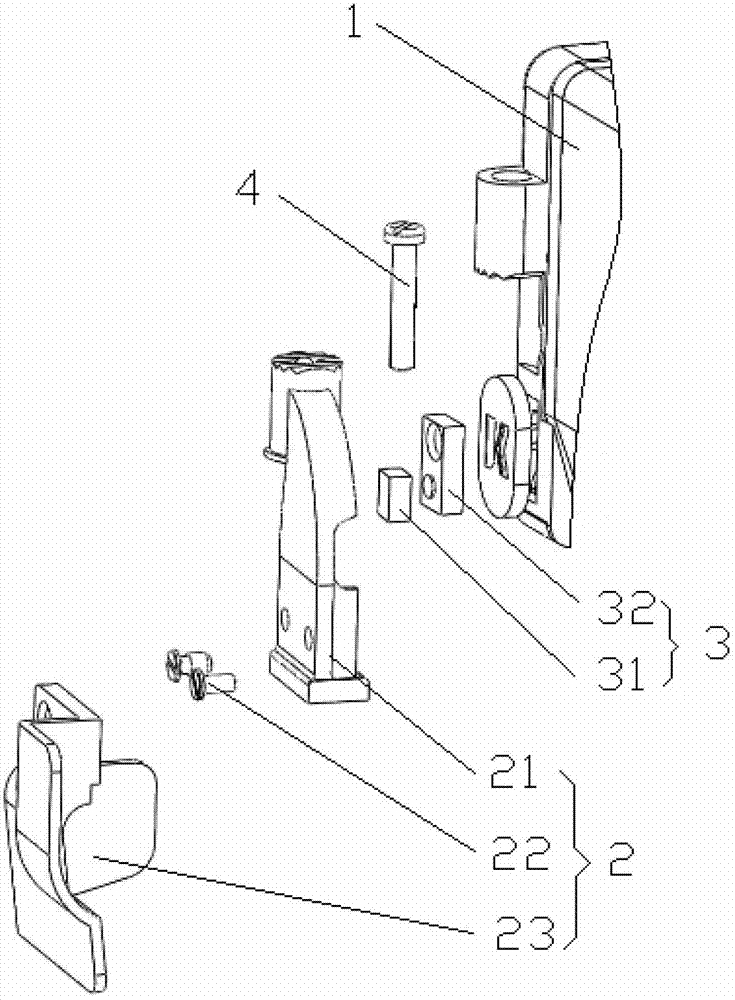

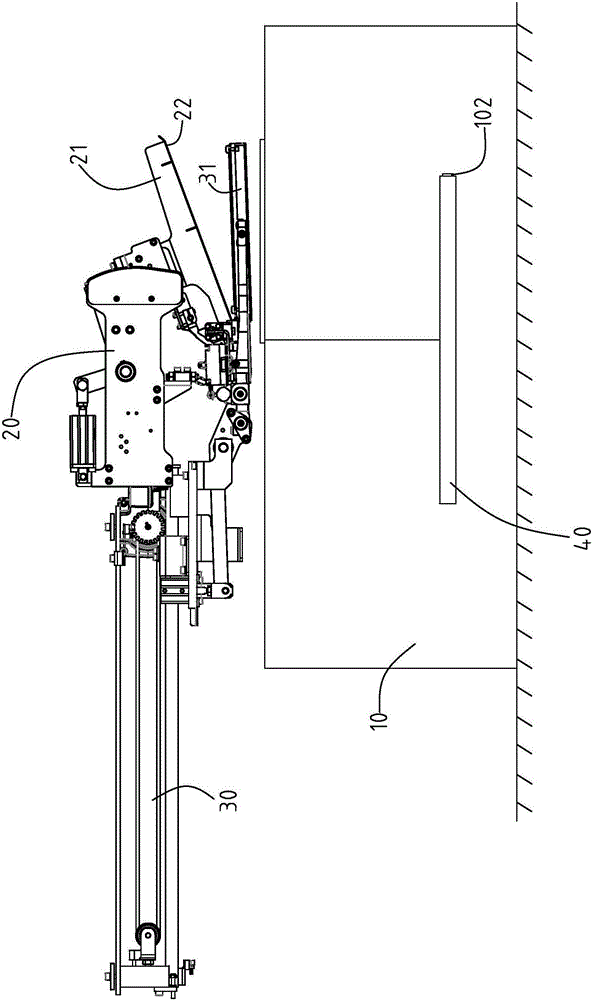

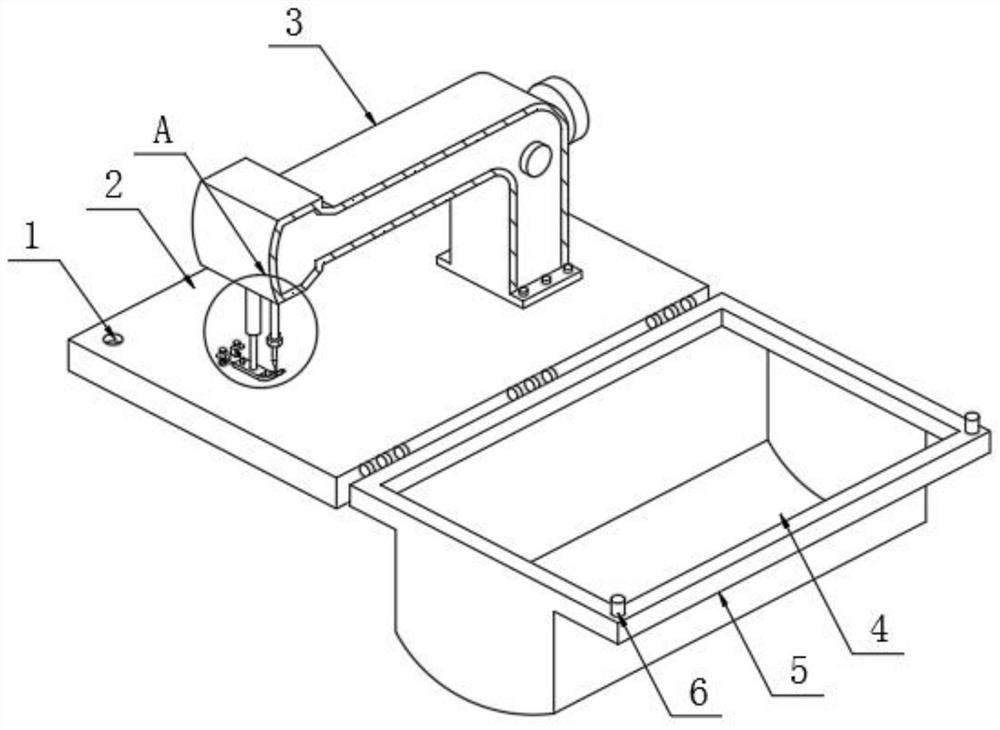

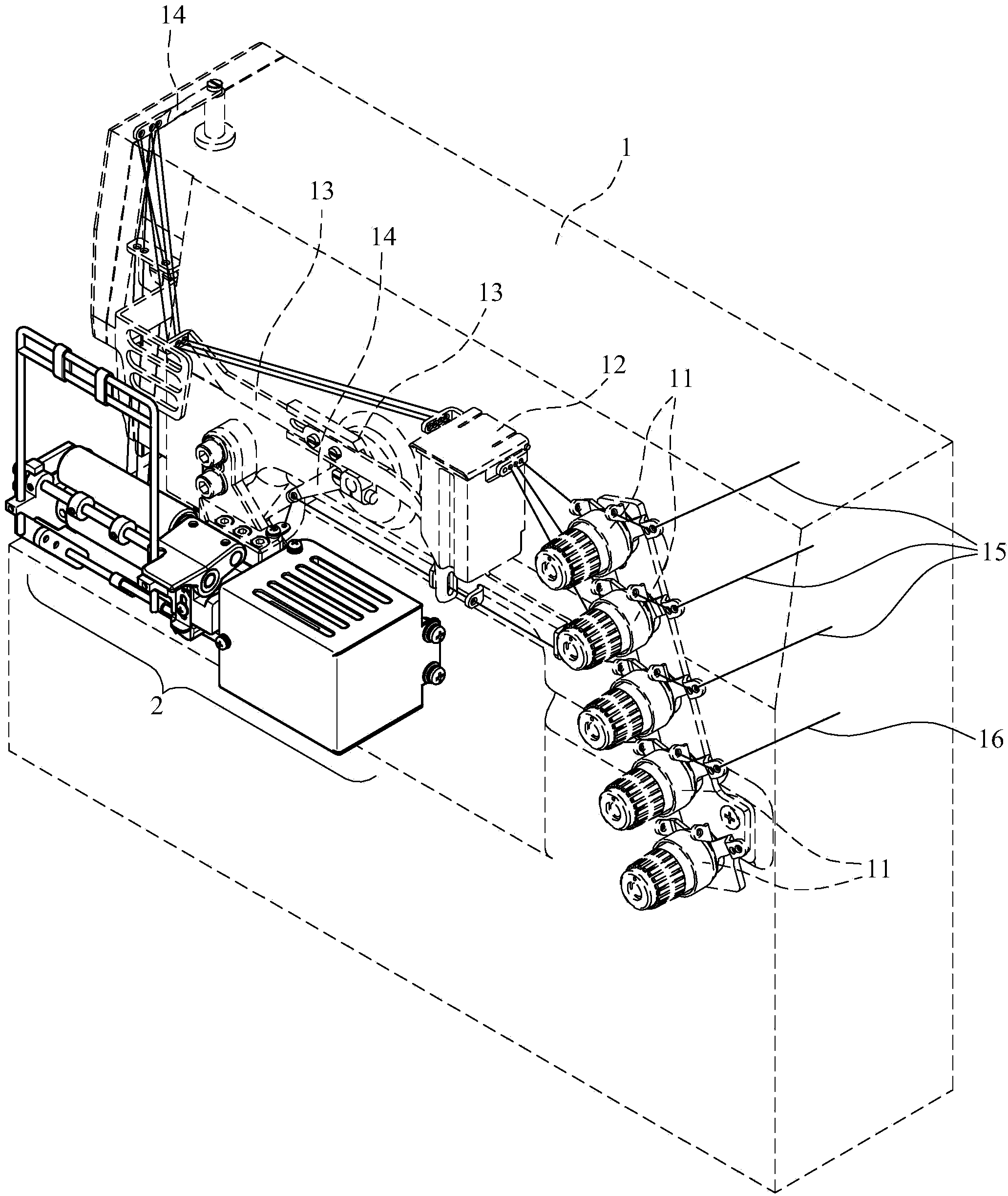

Withdrawing mechanism used during threading of sewing equipment

The invention provides a withdrawing mechanism used during threading of sewing equipment. The withdrawing mechanism comprises a sewing machine, a band-shaped material feeding device and a quick withdrawing mechanism, wherein the quick withdrawing mechanism comprises a base support, a steering support, a supporting fixing piece, a bent connecting piece, a fixing piece and a pivot; the base support is fixedly provided with the support fixing piece so as to be fixed on the sewing machine; the steering support is pivotally arranged below the base support, and the bent connecting piece is fixed by the steering support; the fixing piece is fixedly arranged on the bent connecting piece; and the band-shaped material feeding device is fixed on the fixing piece, so that the band-shaped material feeding device can be withdrawn along with rotation of the steering support. During threading of a stitching thread and a bottom stitching thread, the steering support and the band-shaped material feeding device rotate so as to be withdrawn, open space is formed, and a stitching needle, a bottom stitching thread adjustor close to the stitching needle and a thread guiding rack close to the stitching needle are not stopped. During threading of the stitching thread and the bottom stitching thread, the withdrawing mechanism is simple, convenient, time-saving and easy.

Owner:H S MASCH CO LTD

Machine needle protection plate device for sewing machine

InactiveCN102373589AEasy to stretchFew partsSafety devices for sewing-machinesEngineeringElastic plastic

The invention relates to a machine needle protection plate device for a sewing machine, which is characterized by comprising a flat box-shaped protection plate cover, wherein a long stripped opening is arranged on the wall surface at one side of the protection plate cover, a protection plate is accommodated in an internal space, and the protection plate can extend out of the protection plate cover from the opening. The machine needle protection plate device provided by the invention has the advantages that the protection plate is arranged in the protection plate cover, and safety and dustlessness are realized. When the machine needle protection plate device is used, the protection plate is pulled out to block a machine needle, convenience and practicability are realized, and parts are reduced. Elastic plastic pulleys are arranged at the side edge of the protection plate, so the protection plate extends out of the cover body and can be stopped at any height for adapting to various conditions. The lower end of the protection plate cover is provided with a notch, and the protection plate can be conveniently pinched for extending.

Owner:WUJIANG DEKELI TEXTILE PROD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com