Sewing machine with hand pressing prevention device

A sewing machine and anti-pressing hand technology, applied in the field of sewing machines, can solve the problems of lack of buffer mechanism, damage, limited area of presser feet, etc., and achieve the effects of improving sewing quality, increasing pressing range and increasing pressing area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

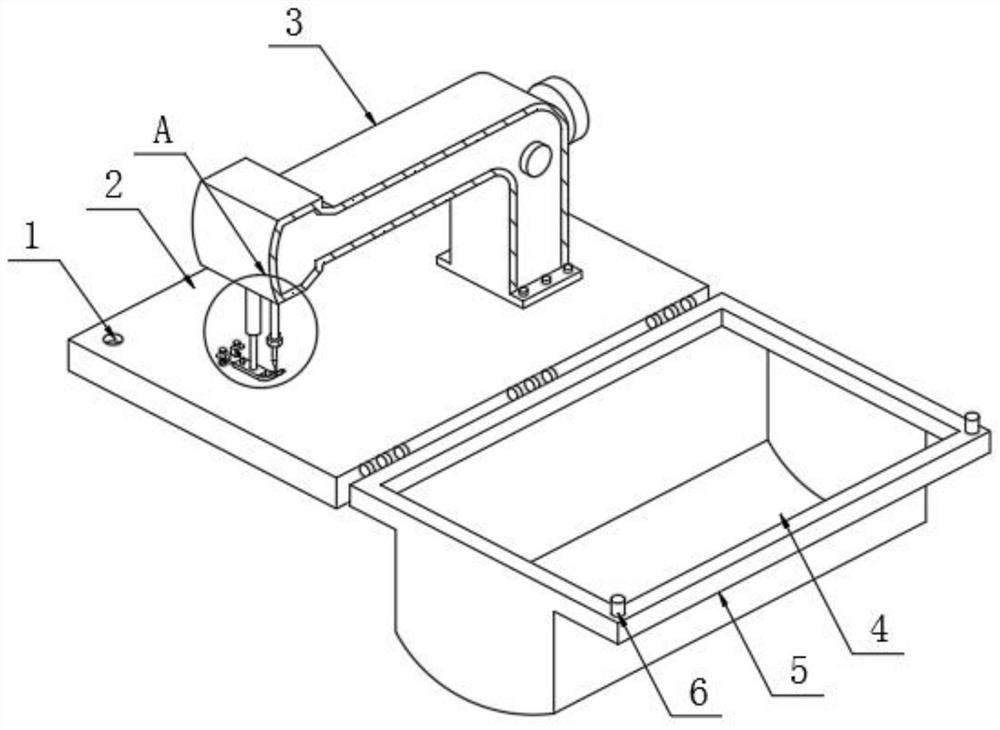

[0026] see Figure 1-7 , in an embodiment of the present invention, a sewing machine with an anti-pressure hand device includes a workbench 2 and a sewing machine body 3 installed on the workbench 2, and two socket holes 1 are opened at the corners of the upper surface of the workbench 2, And the front surface of the workbench 2 is hinged with a shielding frame 5, the upper surface of the shielding frame 5 is provided with a placement groove 4, and the corners of the upper surface of the shielding frame 5 are also fixedly connected with two plug posts 6, the plug posts 6 Adapted to the socket hole 1, the shielding frame 5 and the workbench 2 are engaged and fixed by the socket post 6 and the socket hole 1, the shielding frame 5 is transparent, and the lower surface of the shielding frame 5 is also fixed with a handle. The volume of the placement slot 4 is greater than the volume of the sewing machine body 3, and the periphery of the sewing machine body 3 can be shielded by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com