Pressing plate controlling system and method of pocket-hole sewing machine

A technology of a control system and a control method, which is applied in the field of sewing machines, and can solve problems such as the work of the middle pressure plate mechanism and work-related accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Specific embodiments of the present invention will be described in further detail below based on the accompanying drawings. It should be understood that the specific embodiments described here are only examples, and are not intended to limit the protection scope of the present invention.

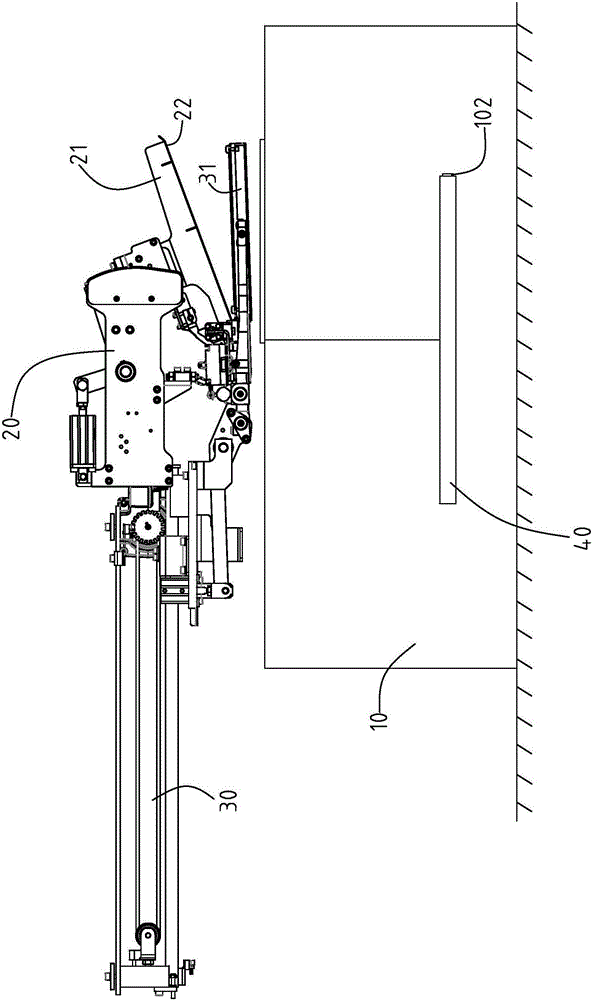

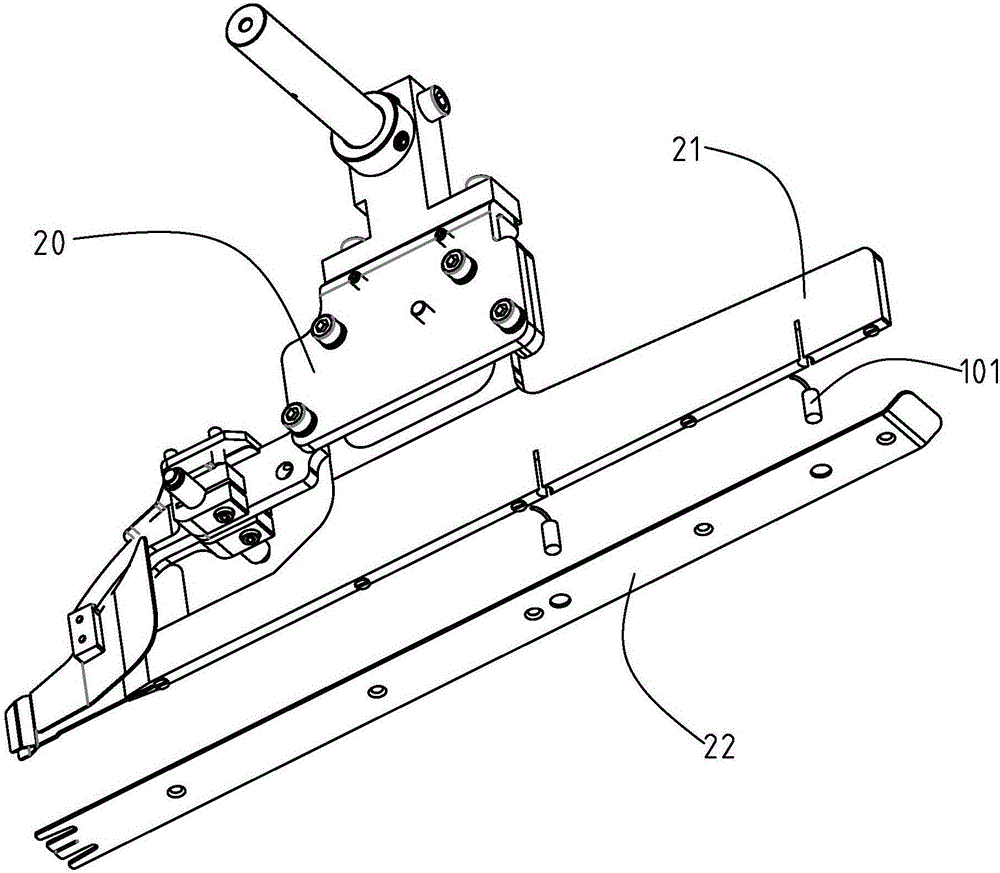

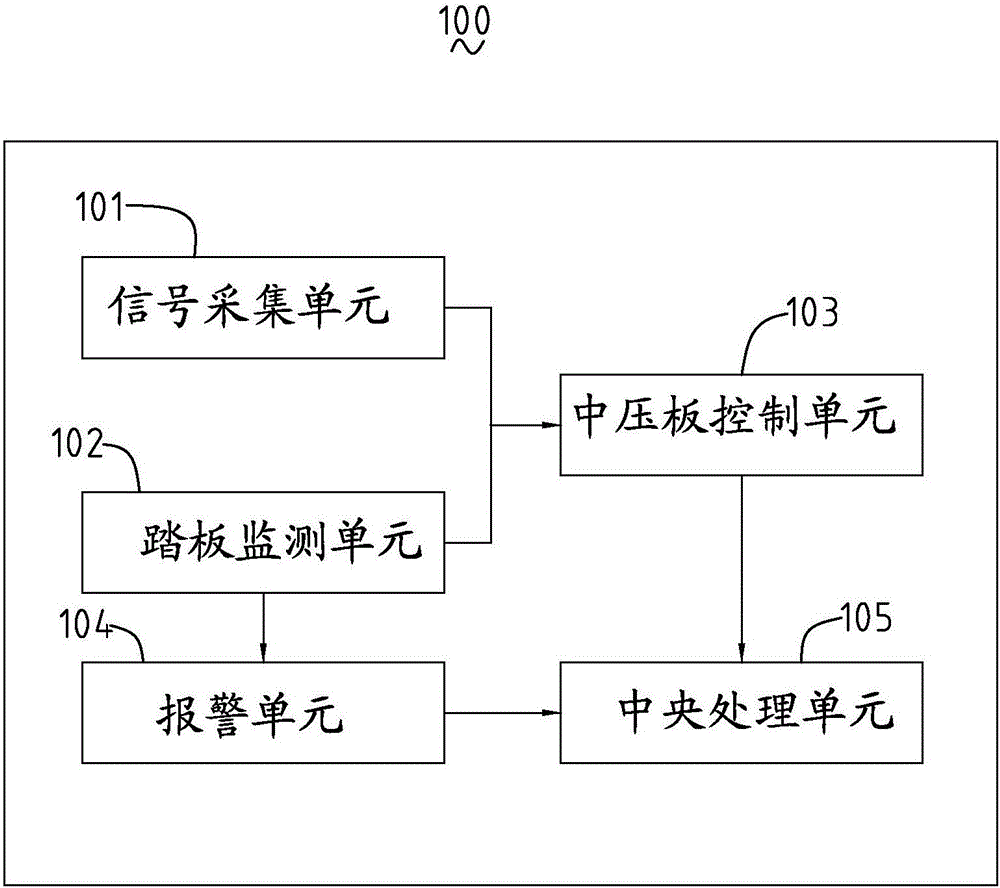

[0031] see figure 1 with figure 2 , which is a structural schematic diagram of a bag opening machine applied to the platen control system 100 of a bag opening machine provided by the present invention. The bag opening machine includes a machine platform 10, a middle plate mechanism 20 arranged on the machine platform 10, a presser foot mechanism 30 arranged on the machine platform 10, and a control mechanism 20 and The pedal mechanism 40 for the mechanical movement of the presser foot mechanism 30 . Of course, it is conceivable that the bag opening machine also includes other equipment, such as sewing mechanism, electric control mechanism, signal control device, etc., as well as t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com