Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about "Safety devices for paper-making machines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

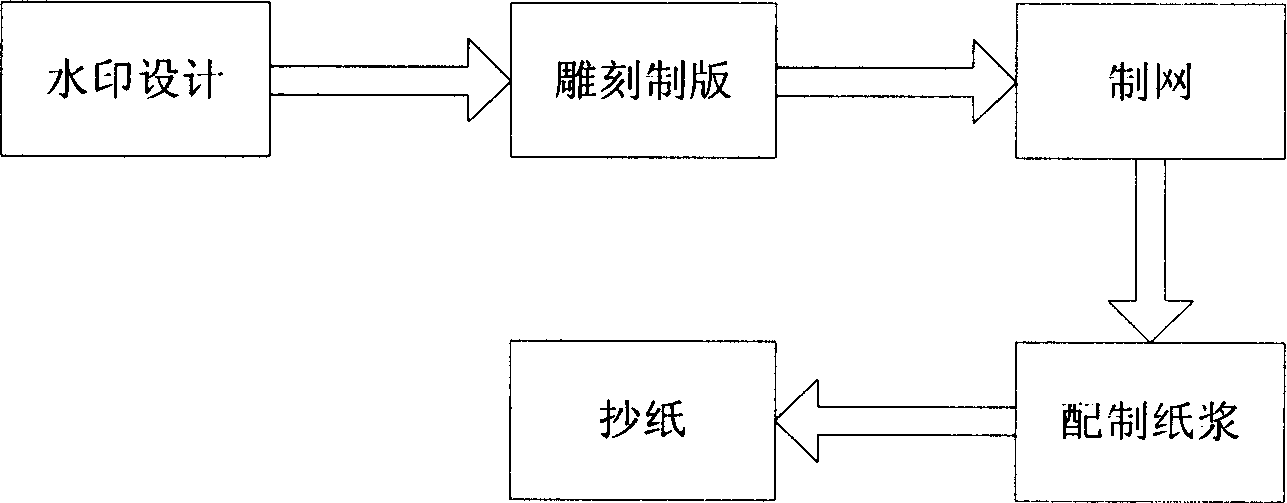

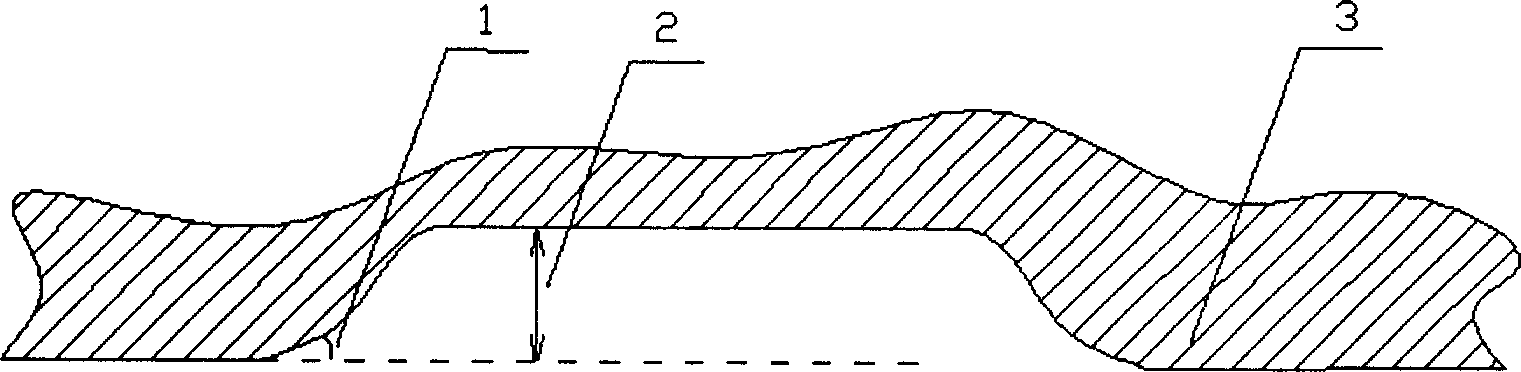

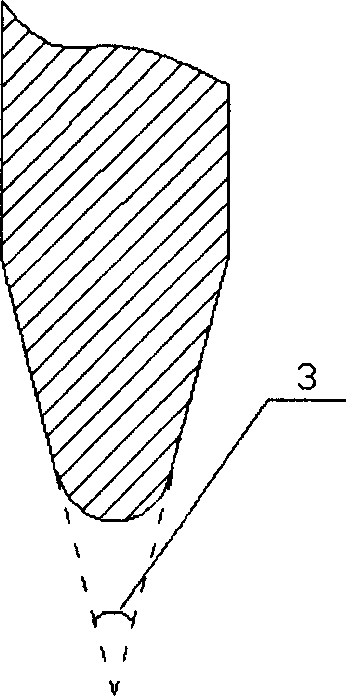

Process for making high quantitative watermark anti-forge paper

ActiveCN1793496AGuaranteed light transmissionGuaranteed anti-counterfeiting performanceMachine wet endSafety devices for paper-making machinesState of artSpelunking

The invention discloses a watermark forge-preventing paper manufacturing method, especially for high weight watermark forge-preventing paper. It is aimed at the current technique to produce watermark paper with high weight and good light permeability and forge-preventing. The method includes the following steps: watermark designing; carving watermark stencil plate; making web; preparing paper pulp; manufacturing paper. The height of the watermark plate is between 1.0mm to -2.5mm. And its grade is between 5 to 20 degrees. The caving is the same. This method can make out non composite high weight watermark forge-preventing paper with good light permeability and forge-preventing and 120-220g / m2 weight.

Owner:CHINA BANKNOTE PRINTING & MINTING

Calender

Owner:VOITH PATENT GMBH

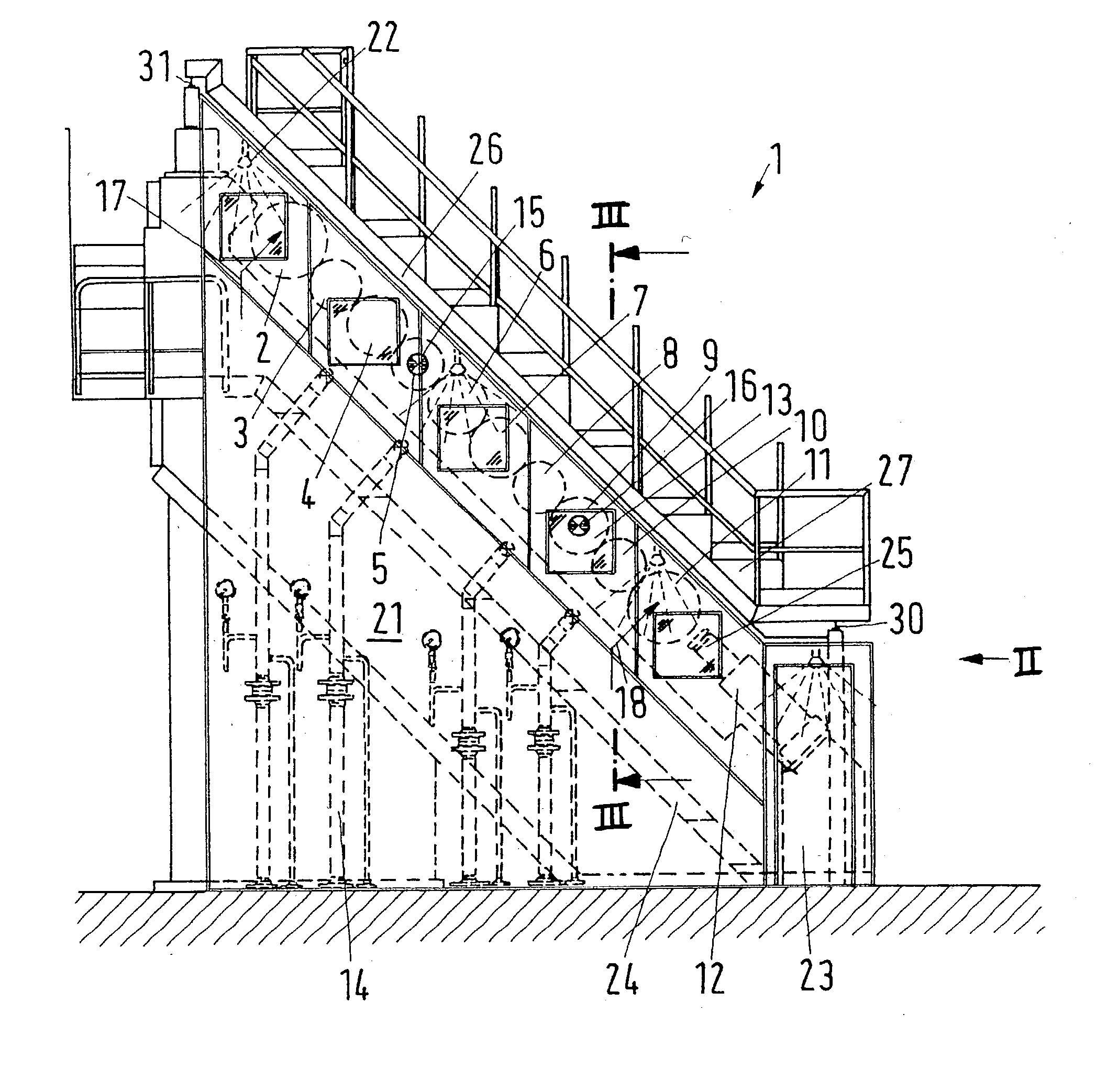

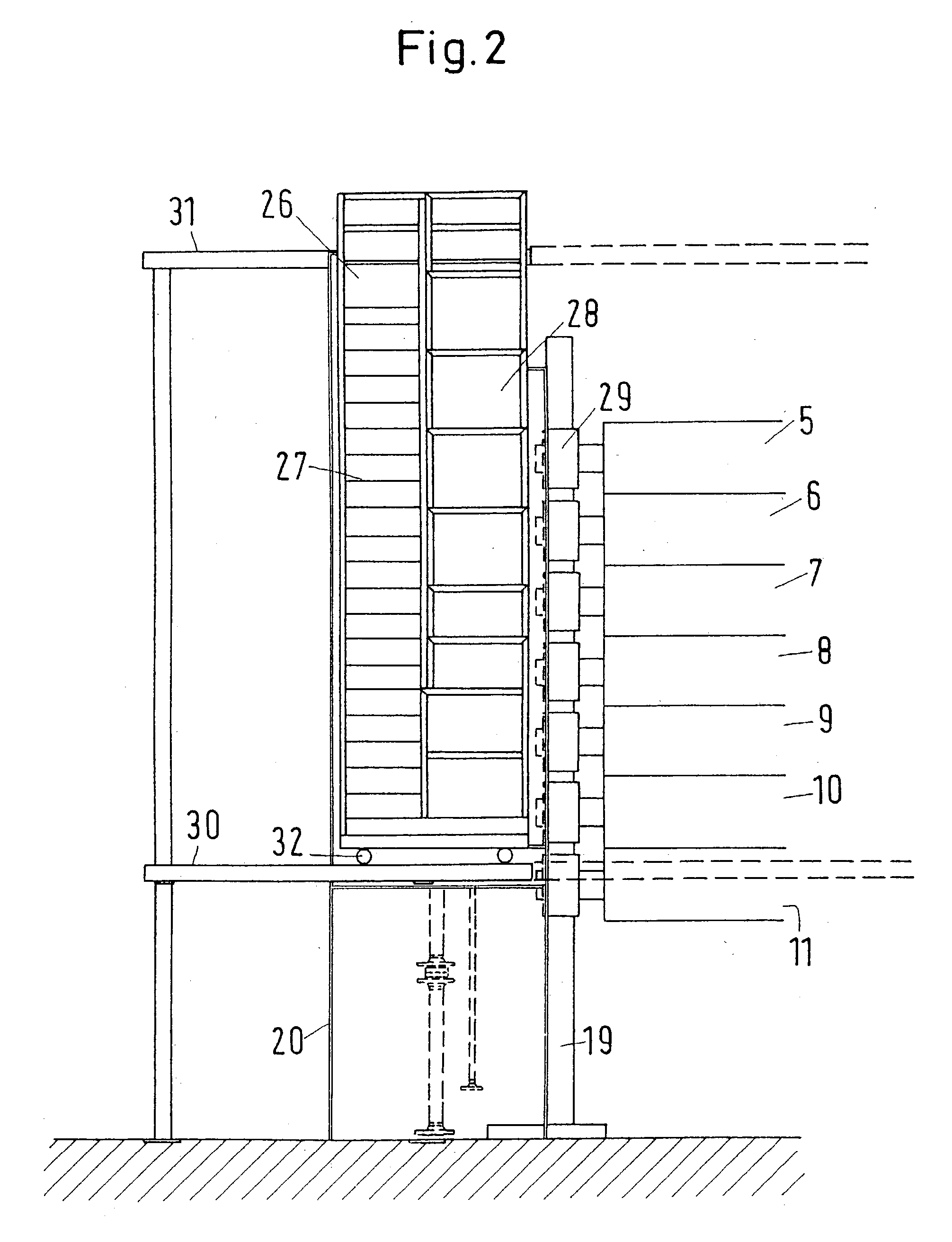

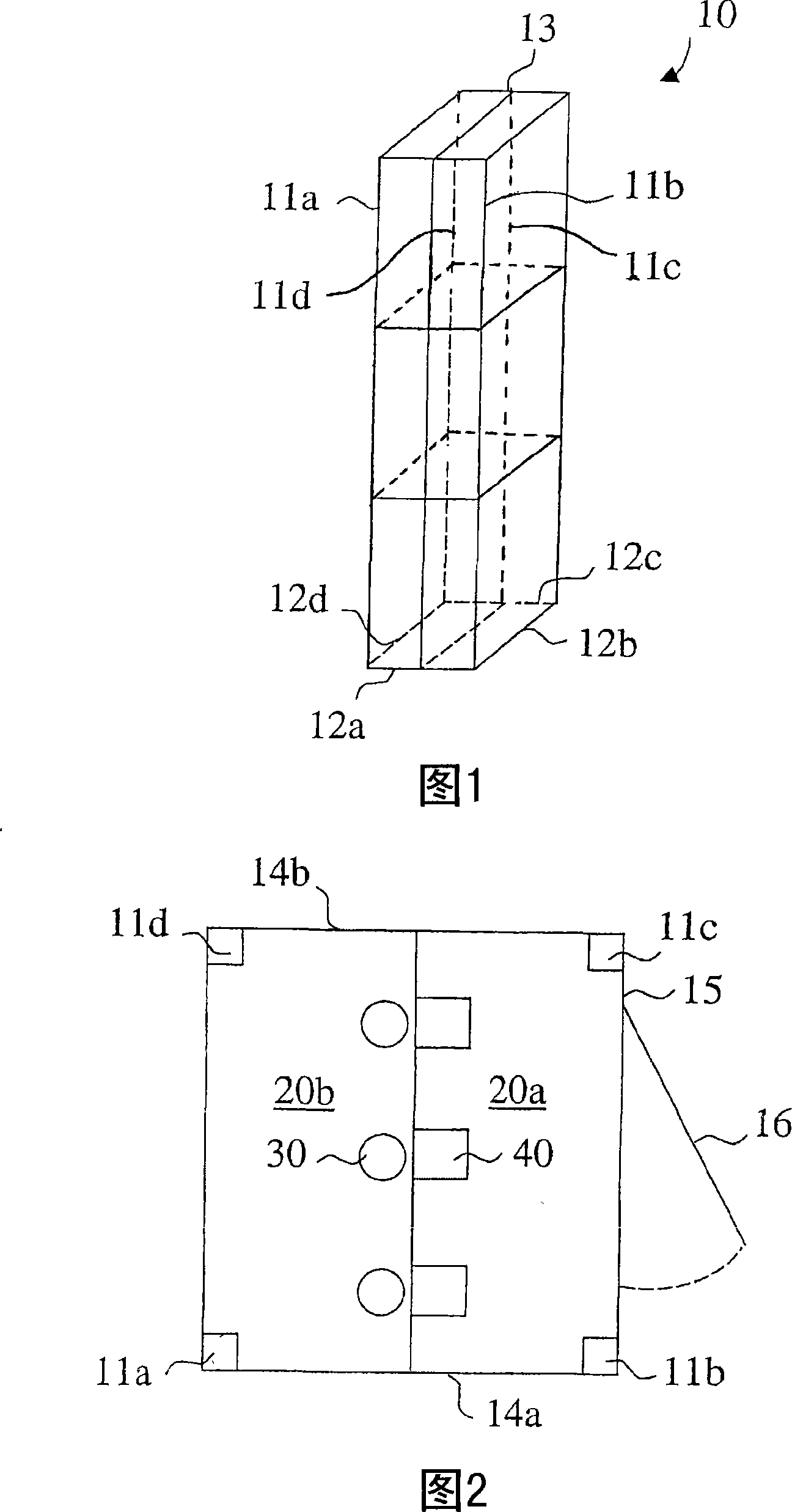

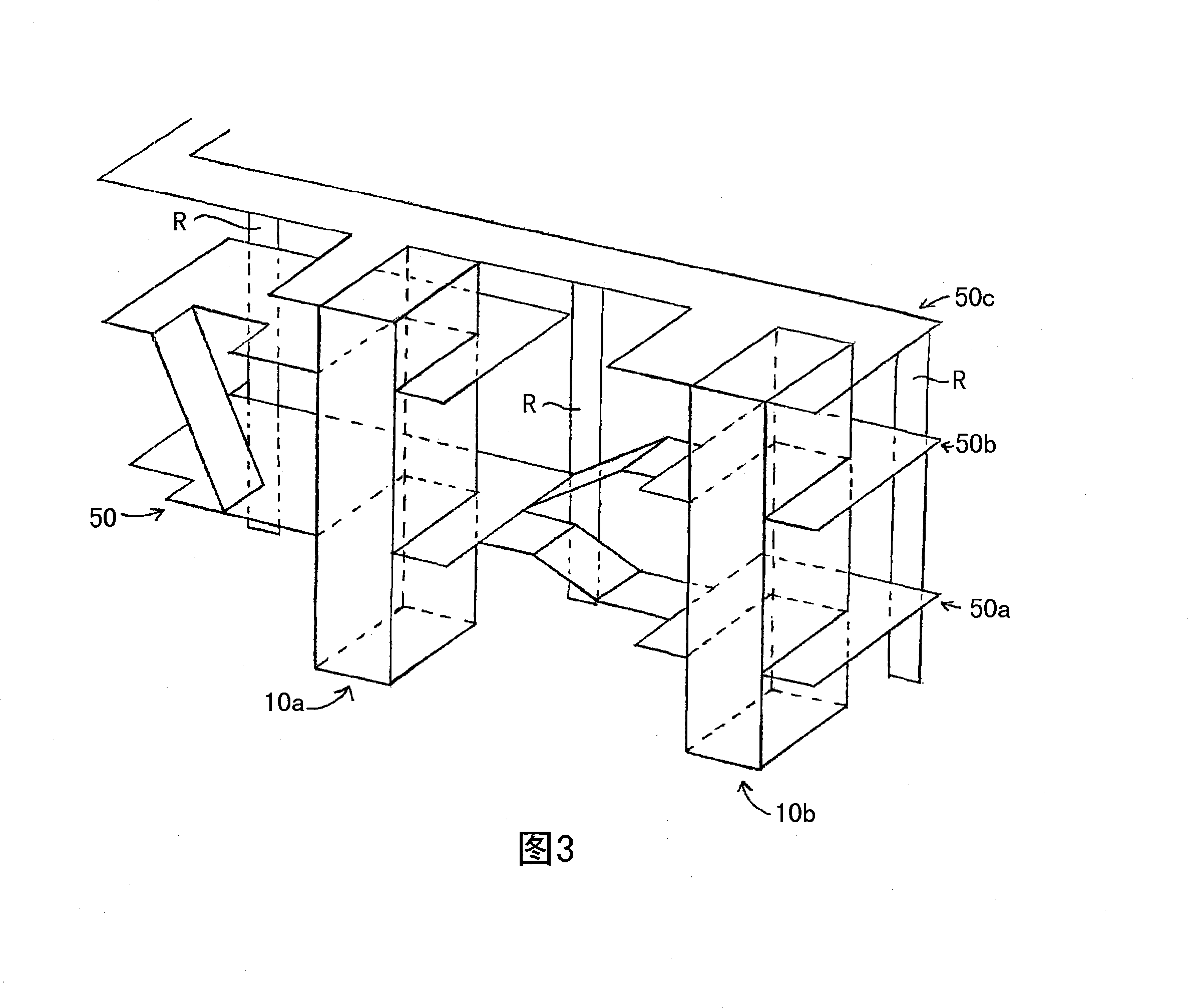

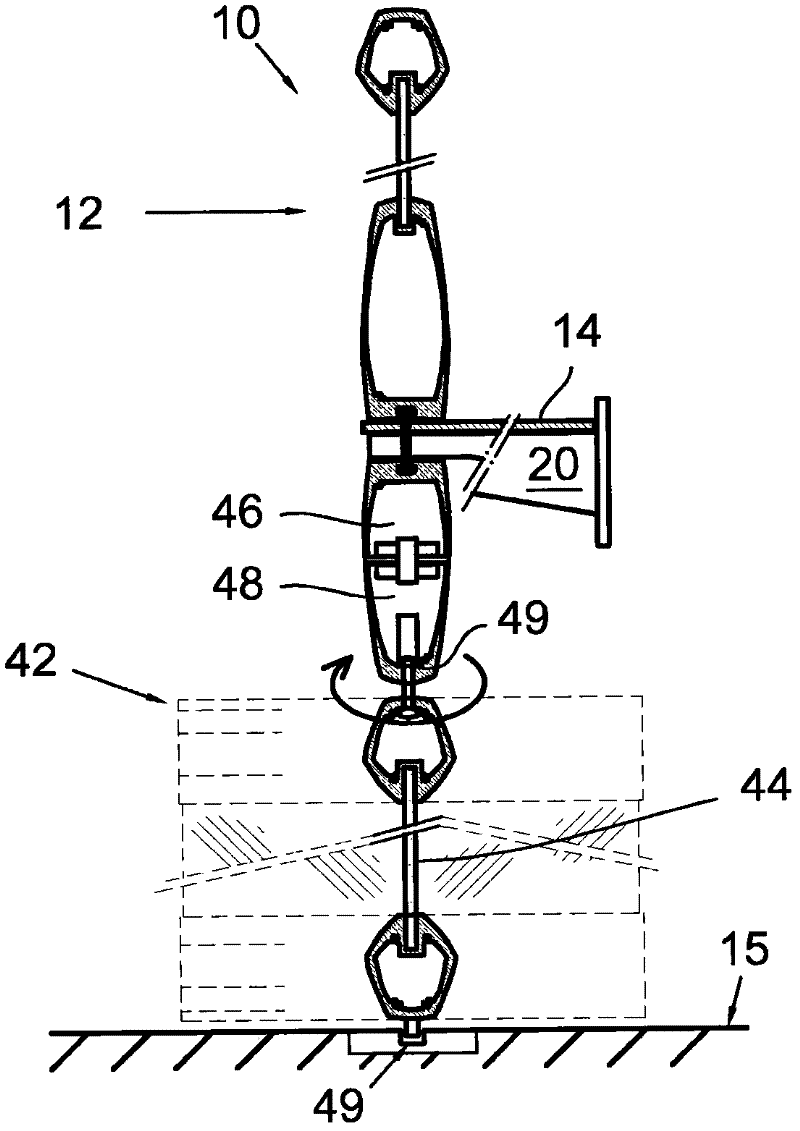

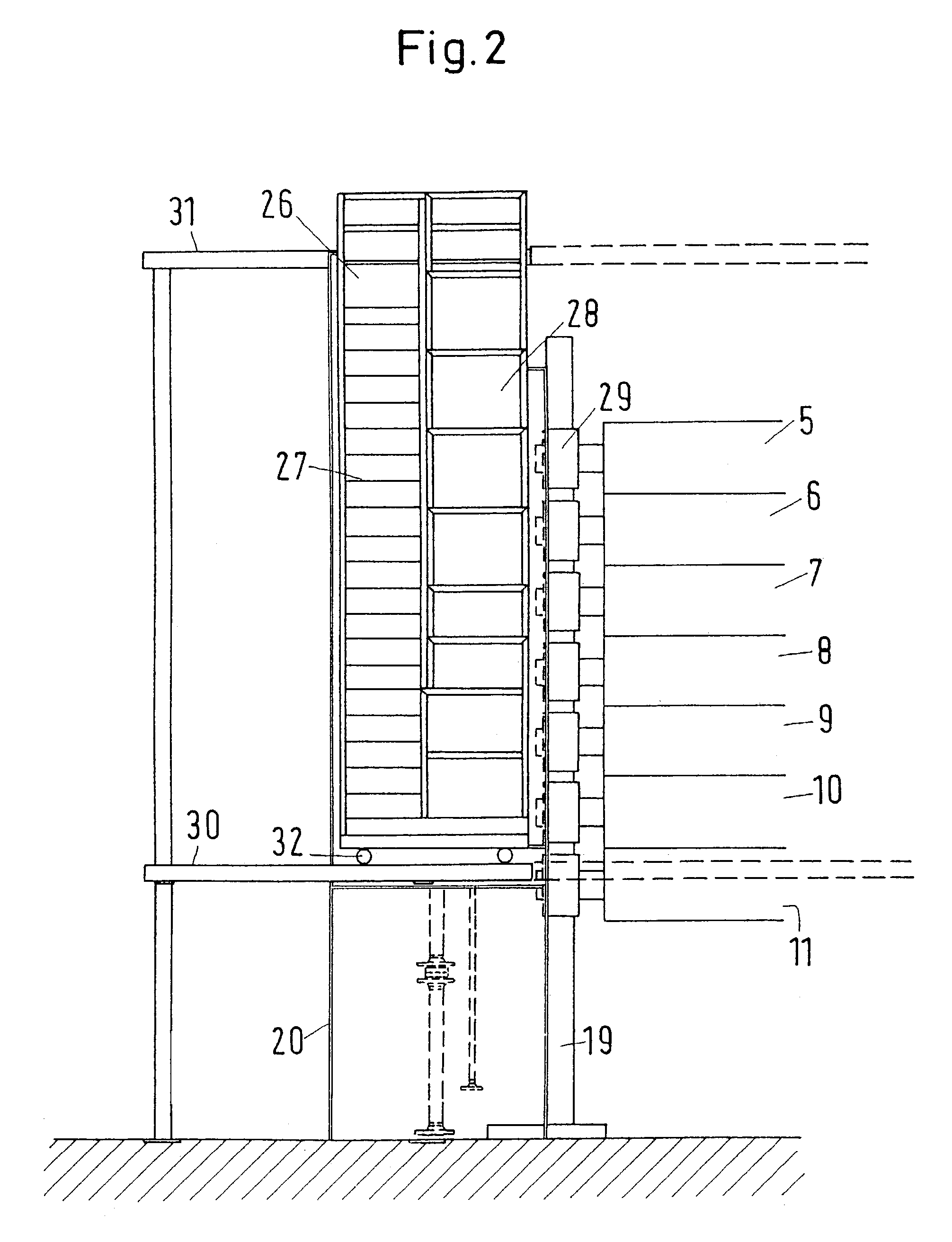

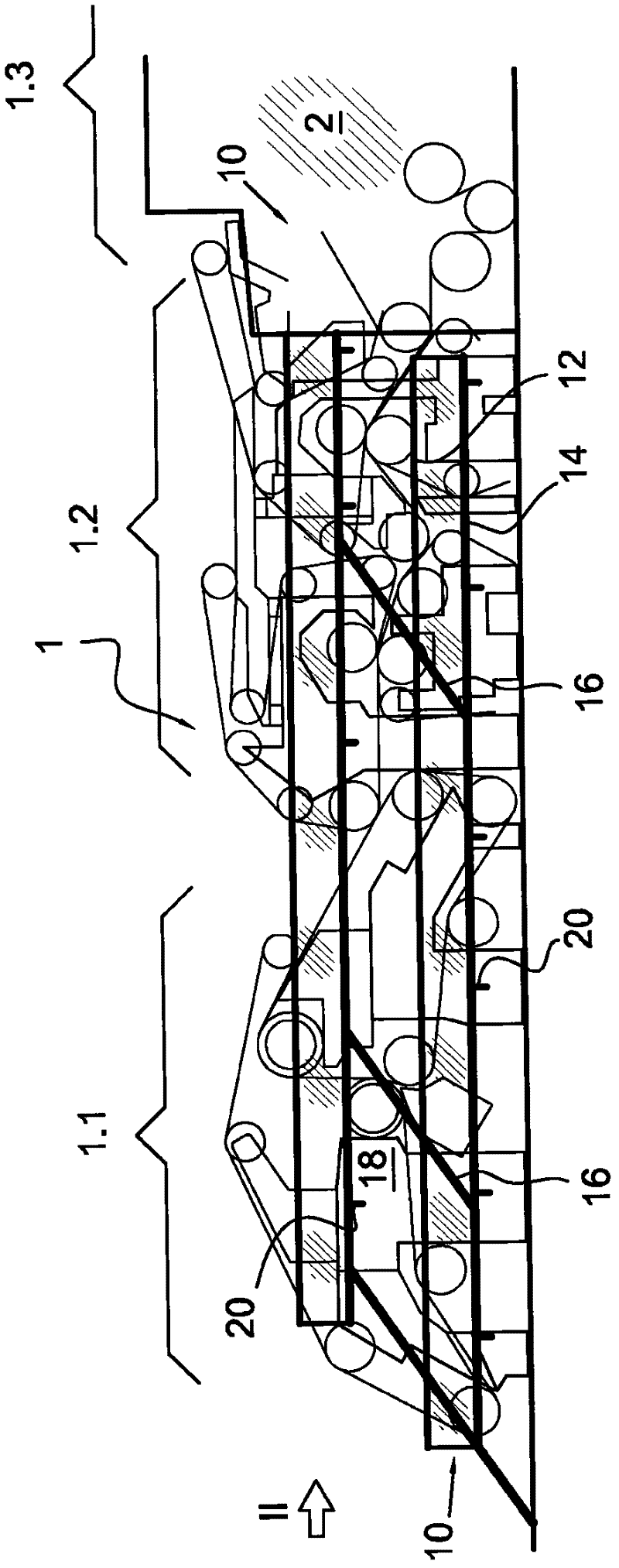

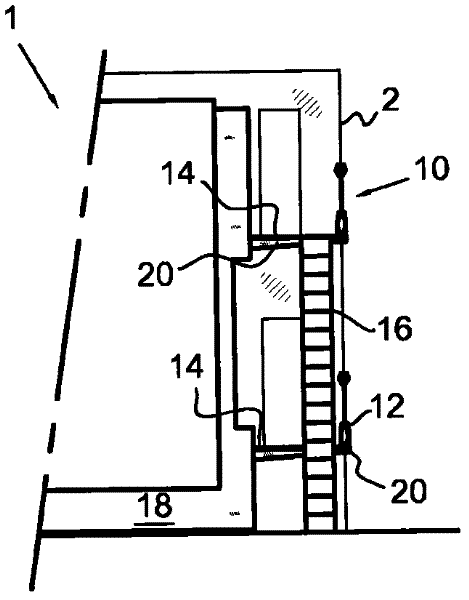

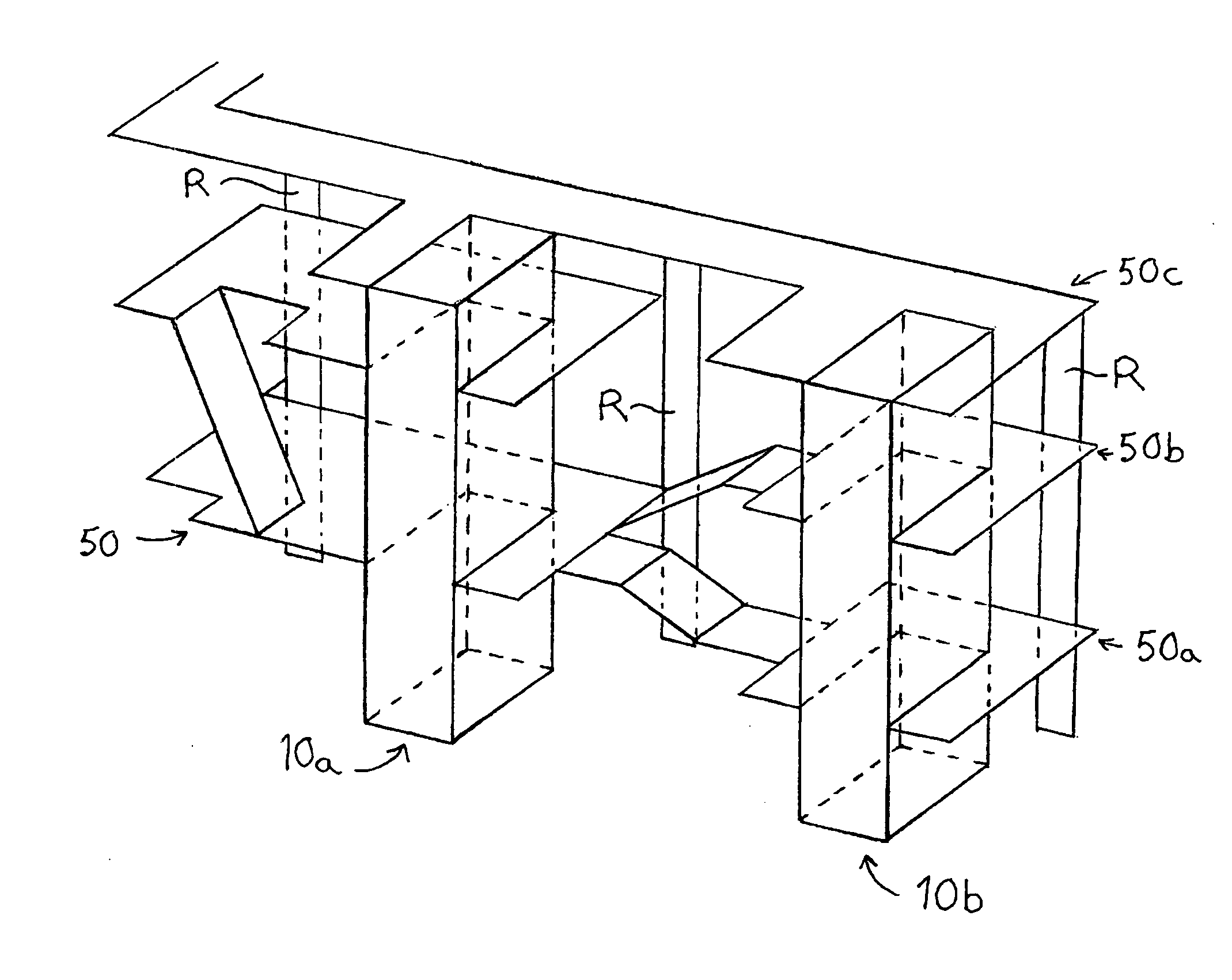

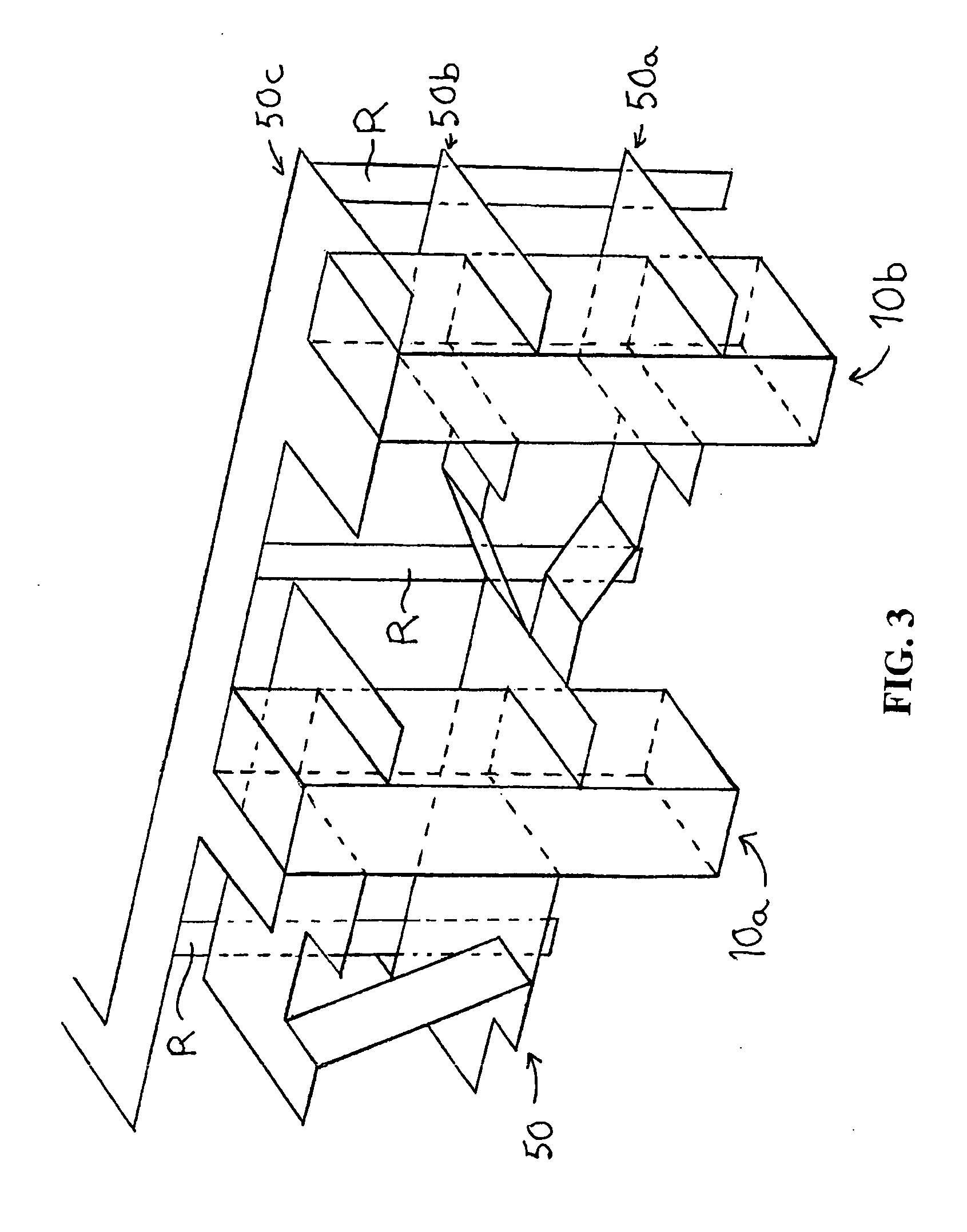

Installation module for paper making machine or paperboard making machine

ActiveCN101194066AReduce demandReduce assemblyMachine wet endSafety devices for paper-making machinesComputer modulePaperboard

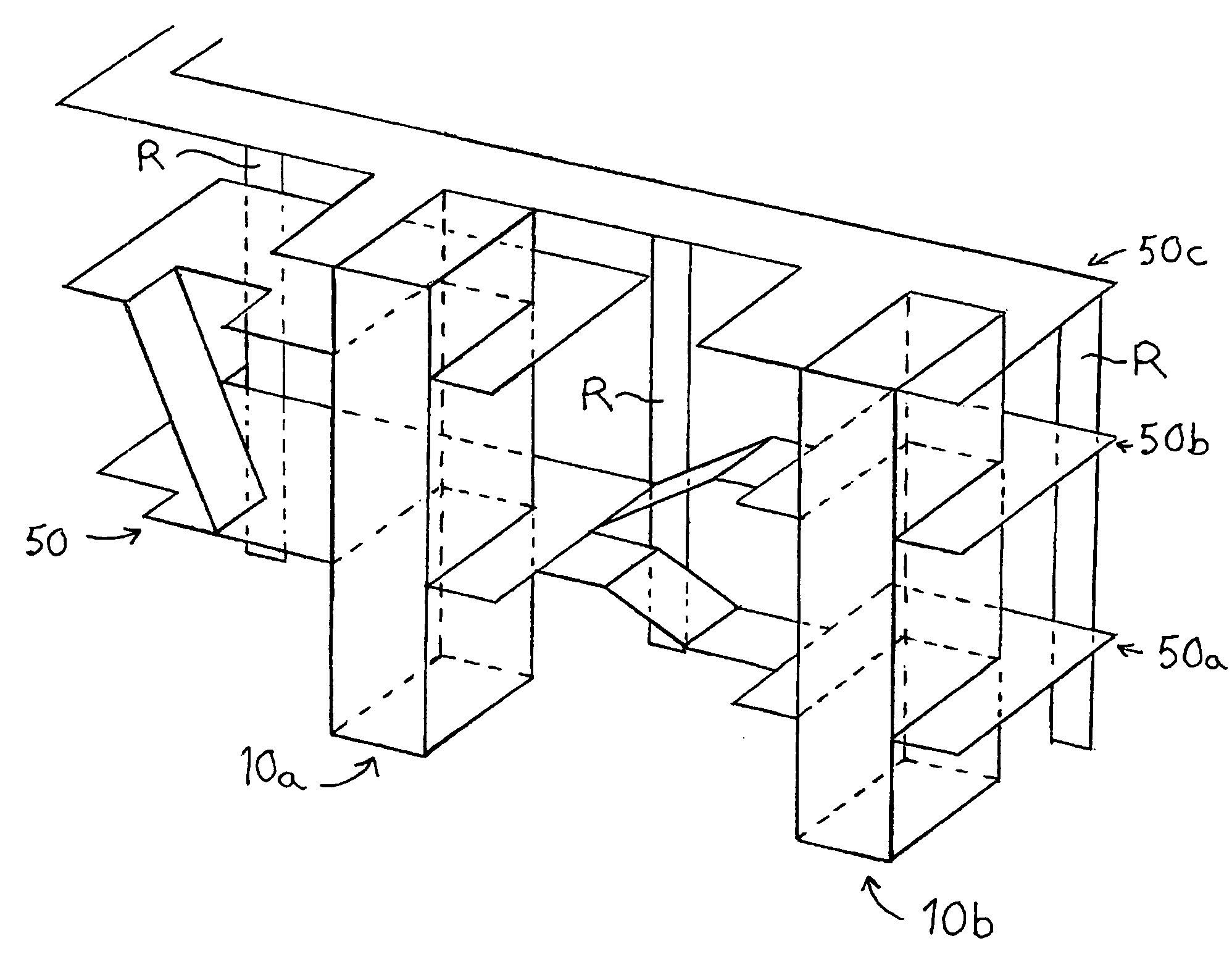

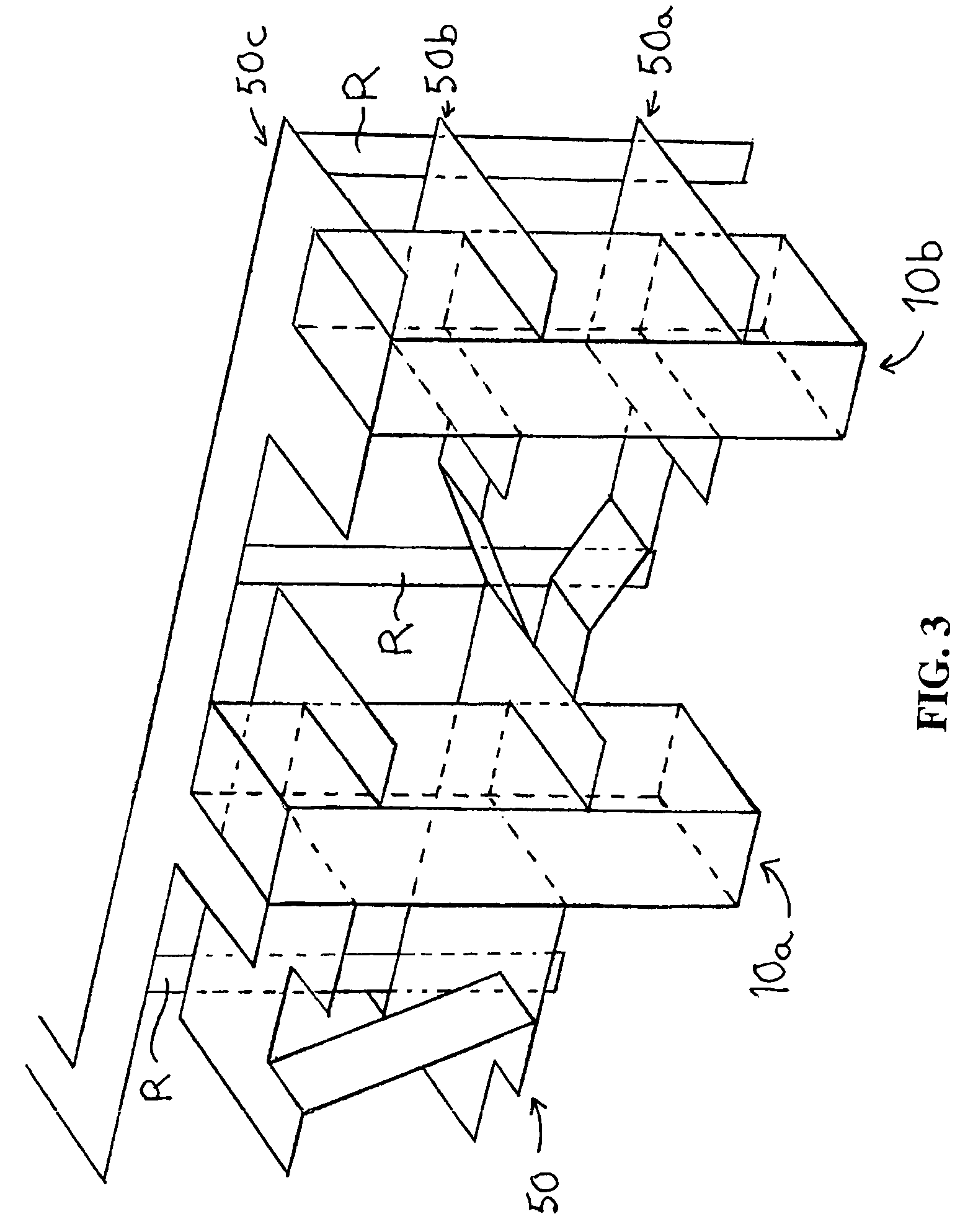

A wet end of the machine comprises at least one vertical, self-supporting installation module (10a, 10b) to be positioned into connection with the machine which module is supported from its lower end by foundation structures of the machine construction and which extends at least to the height of a second maintenance platform (50b) of the machine, which installation module (10) includes at least valves (40) and pipes (30) related to the hydraulic and / or pneumatic actuators of the machine.

Owner:METSO PAPER INC

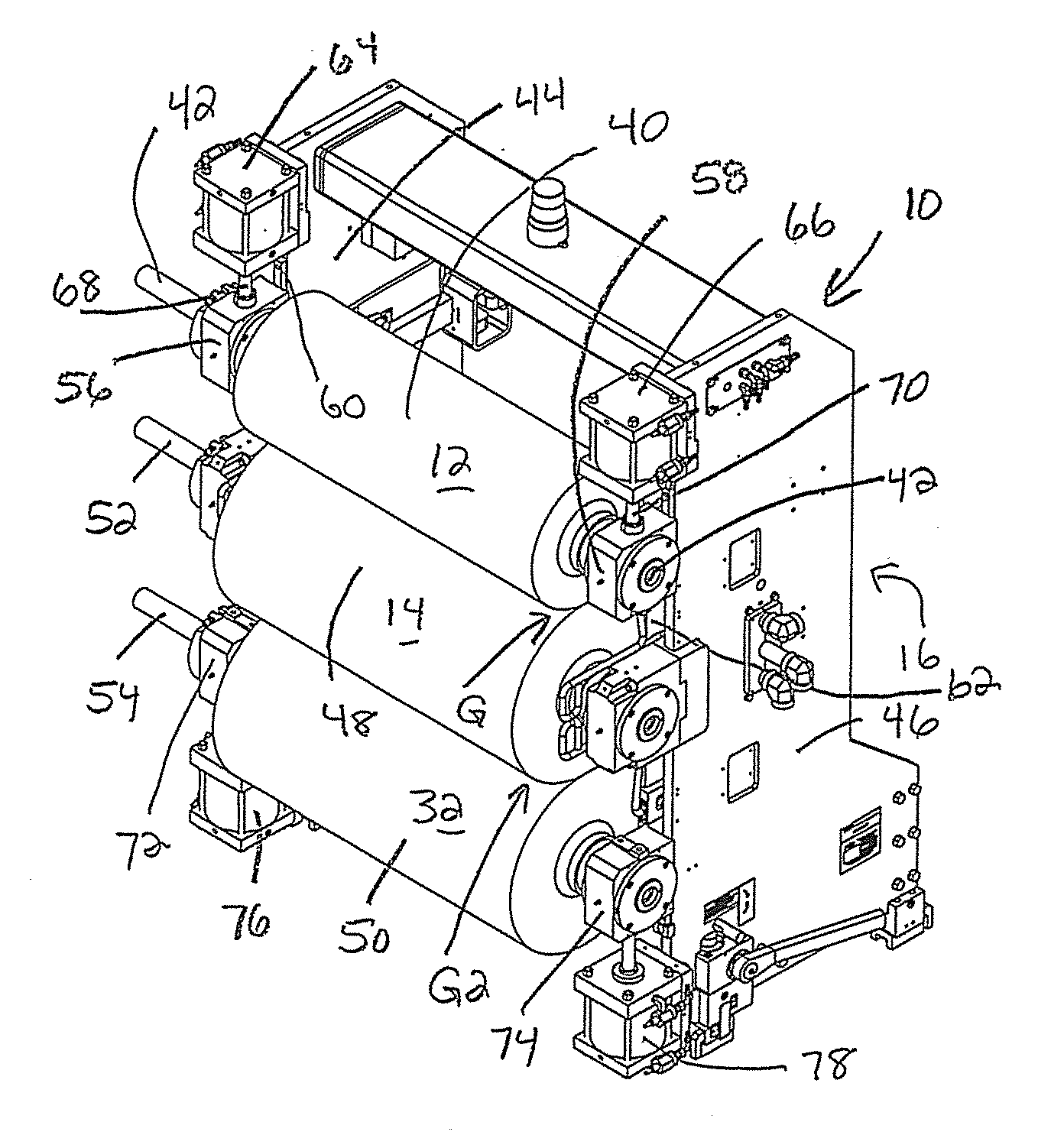

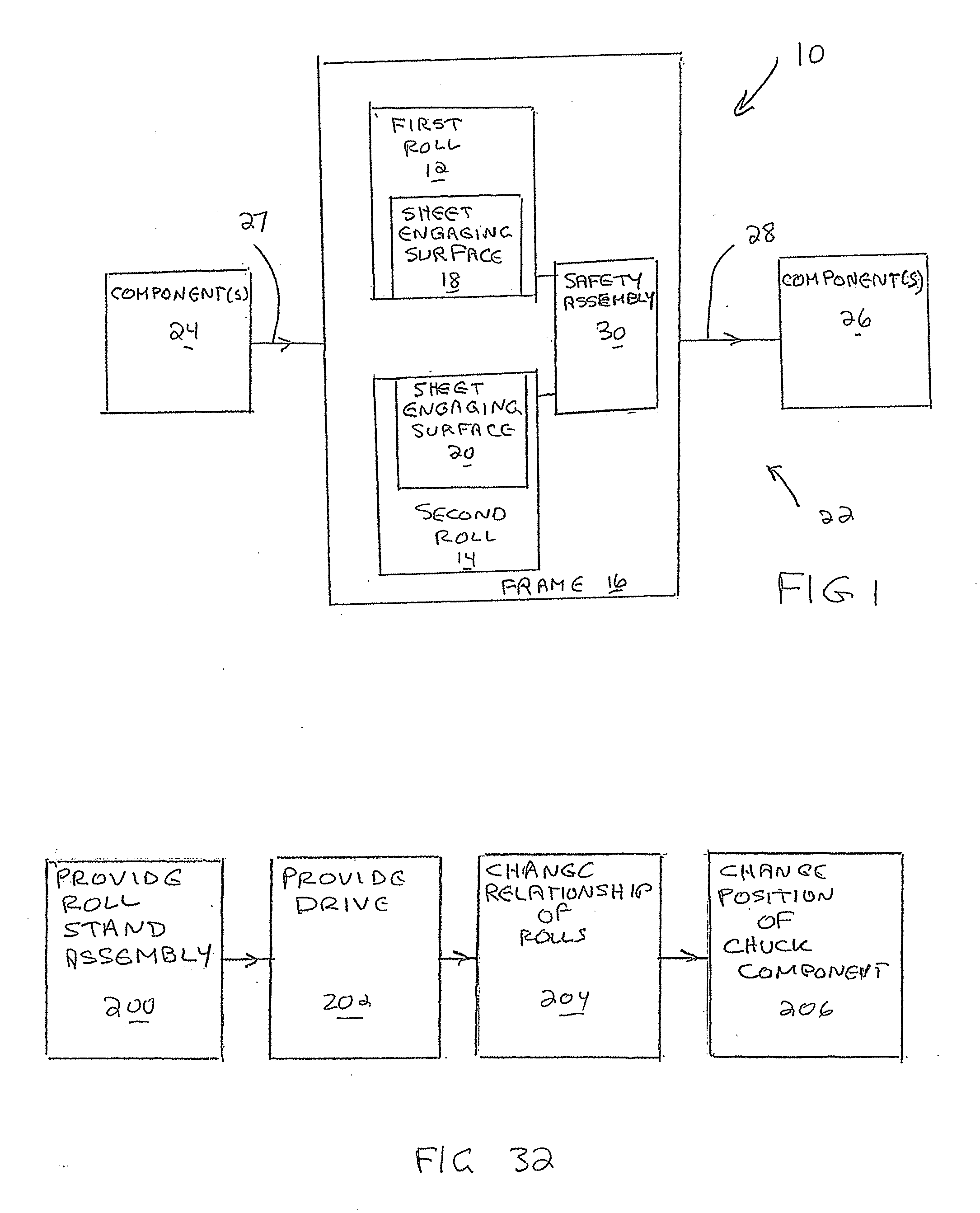

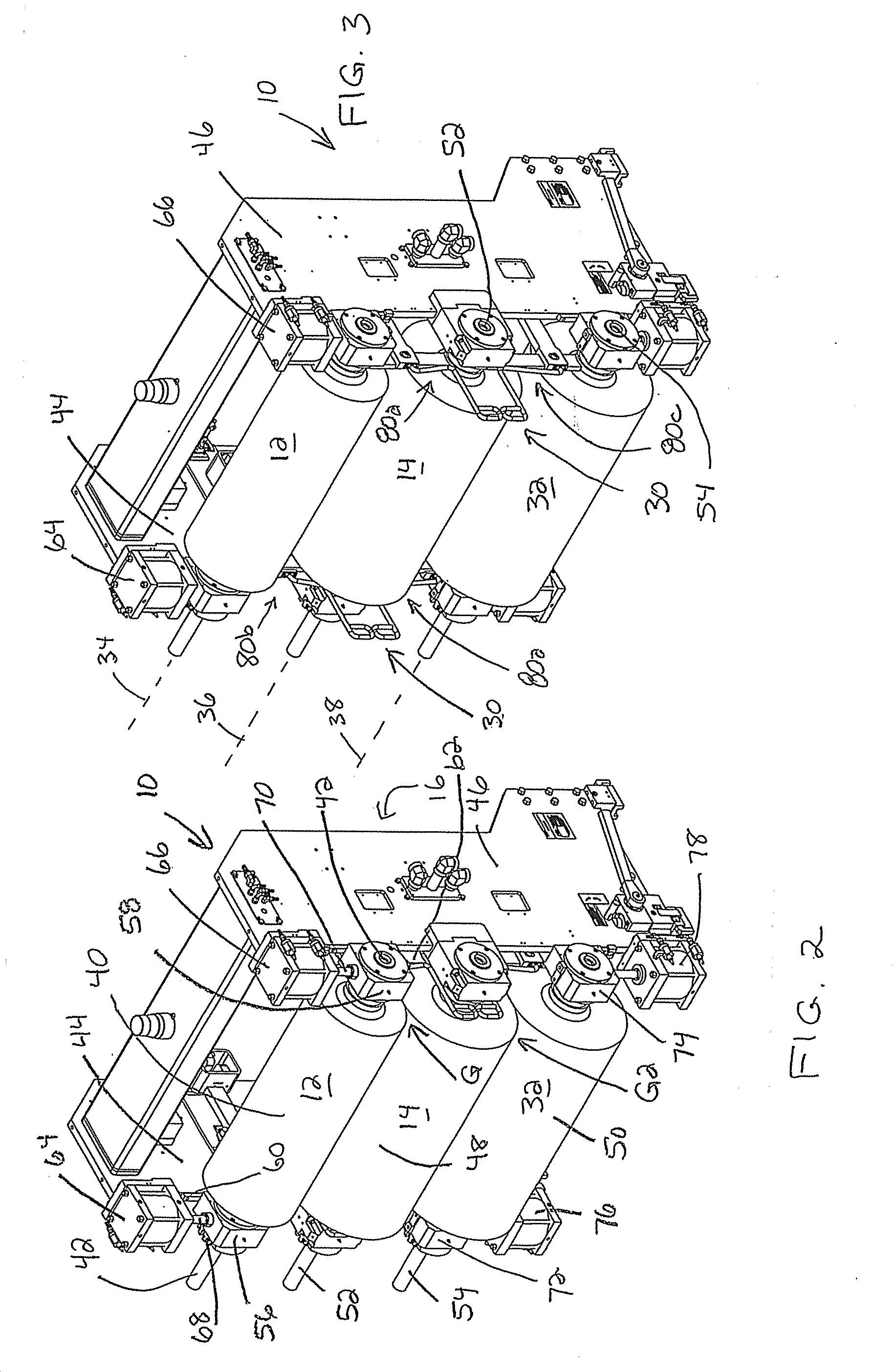

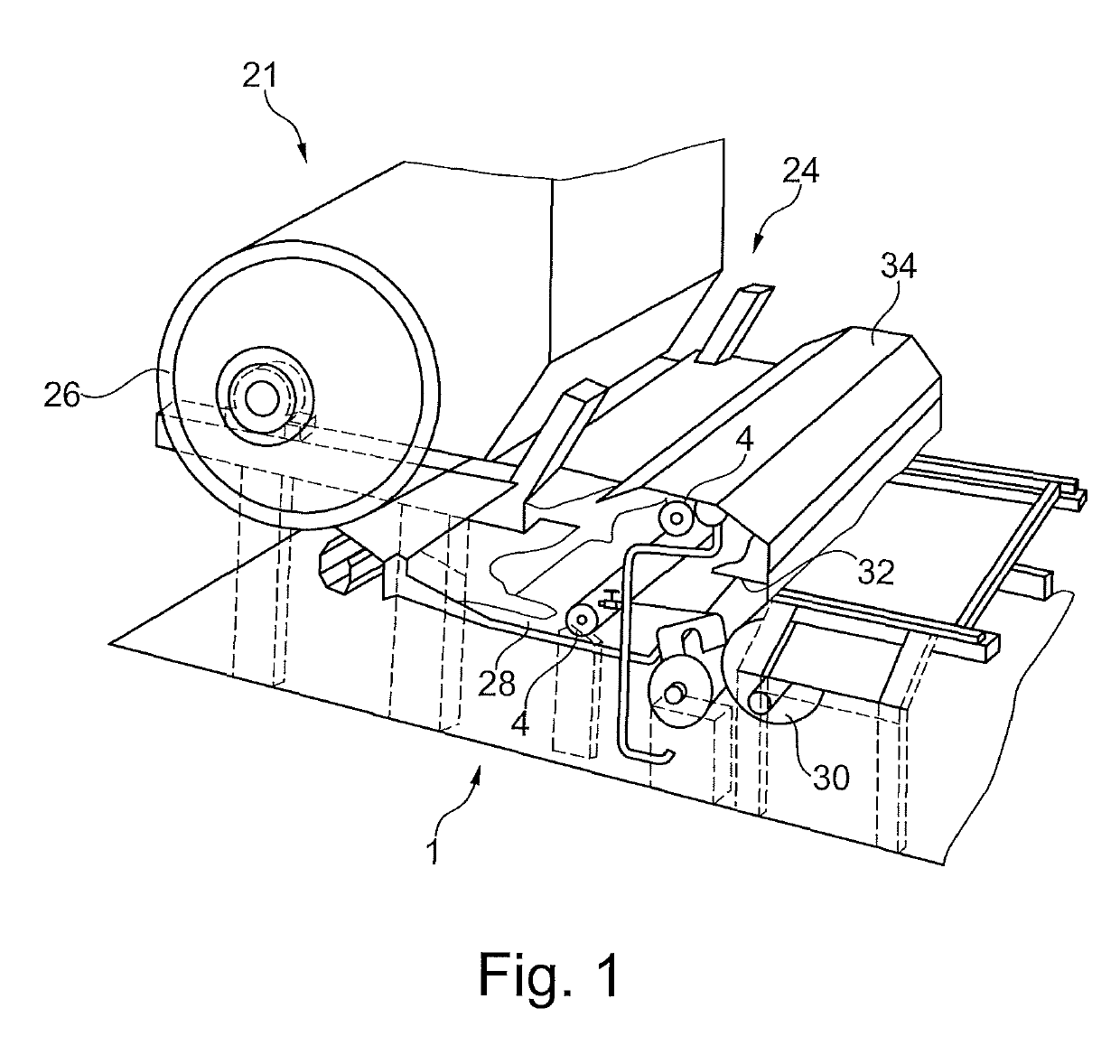

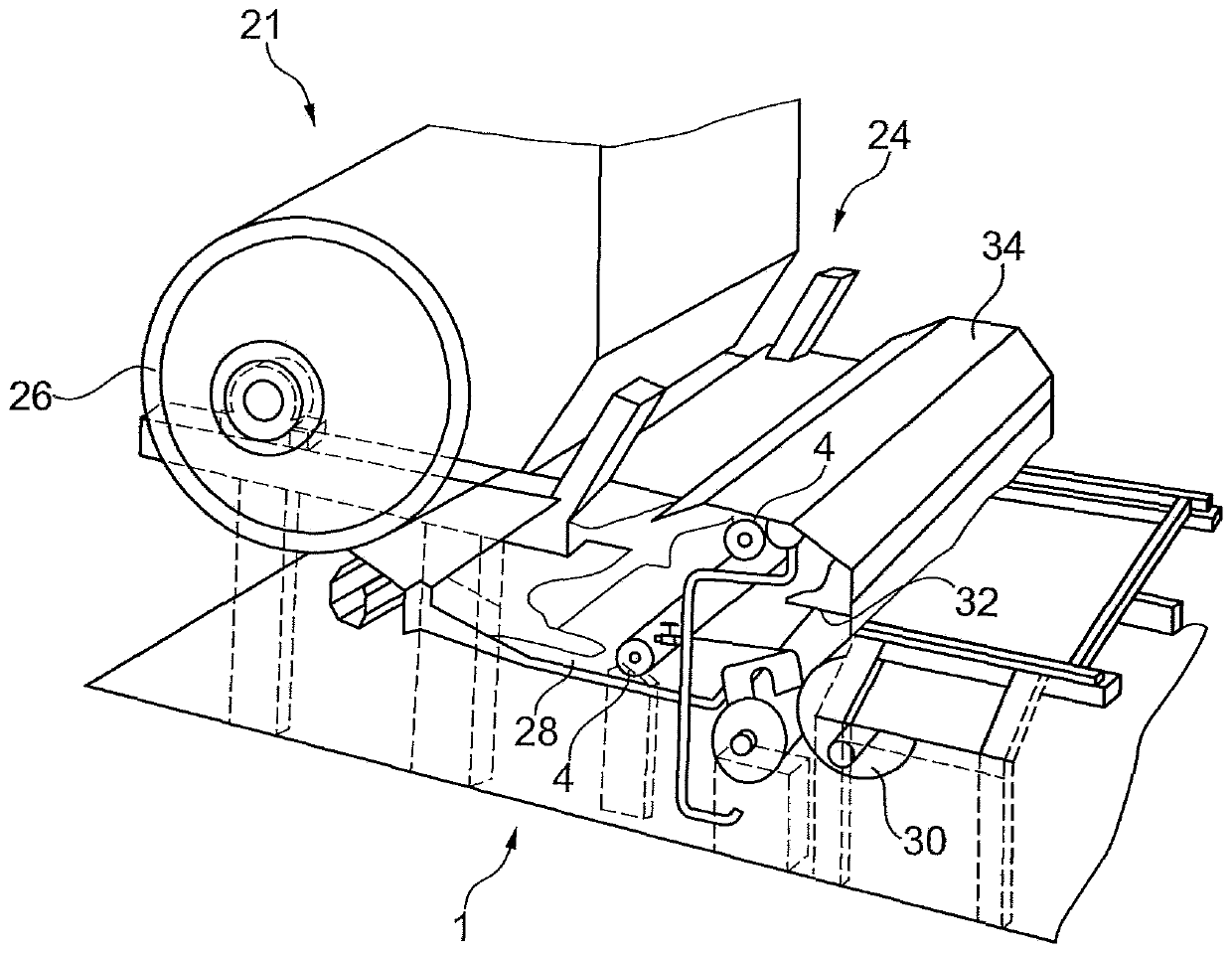

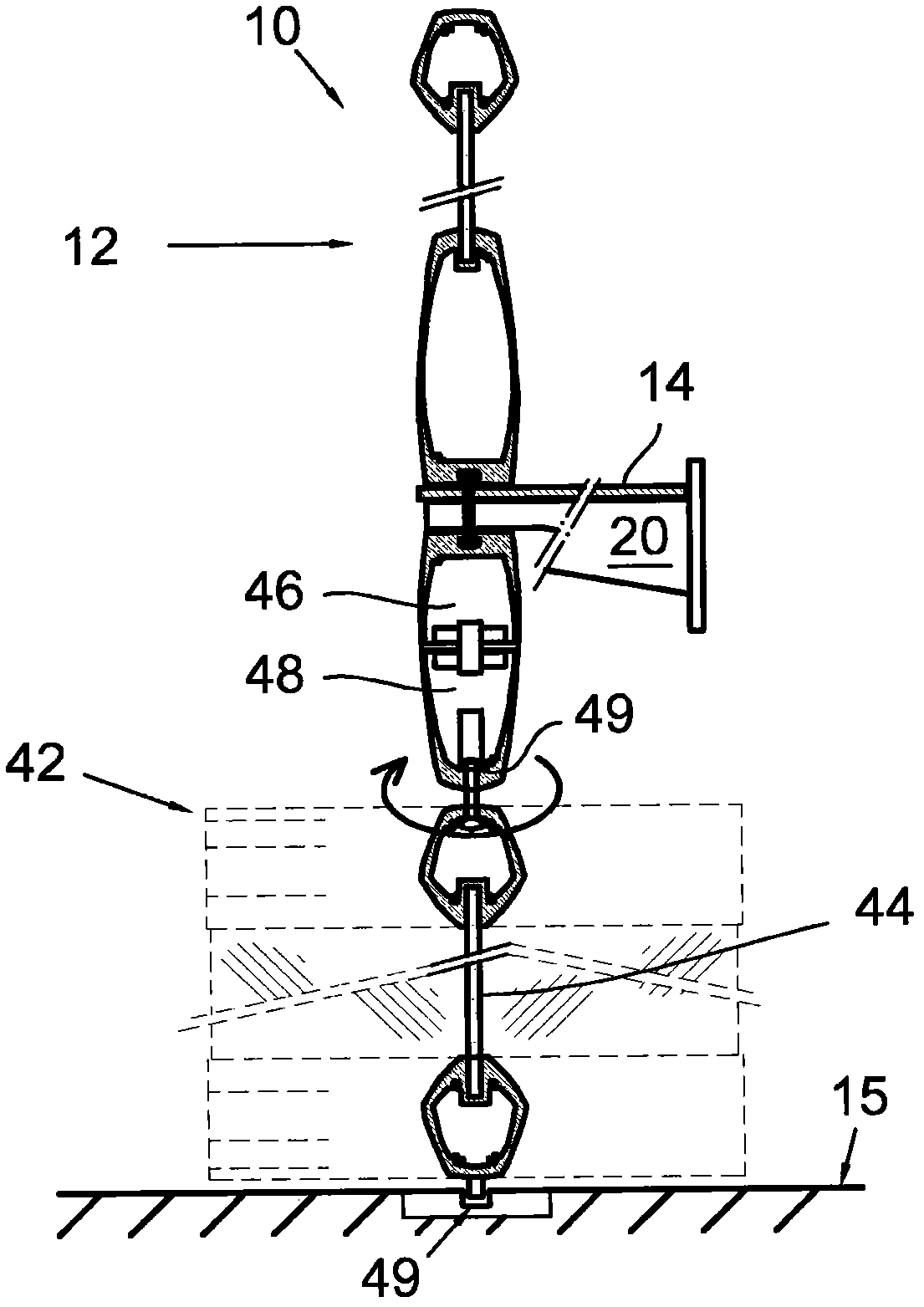

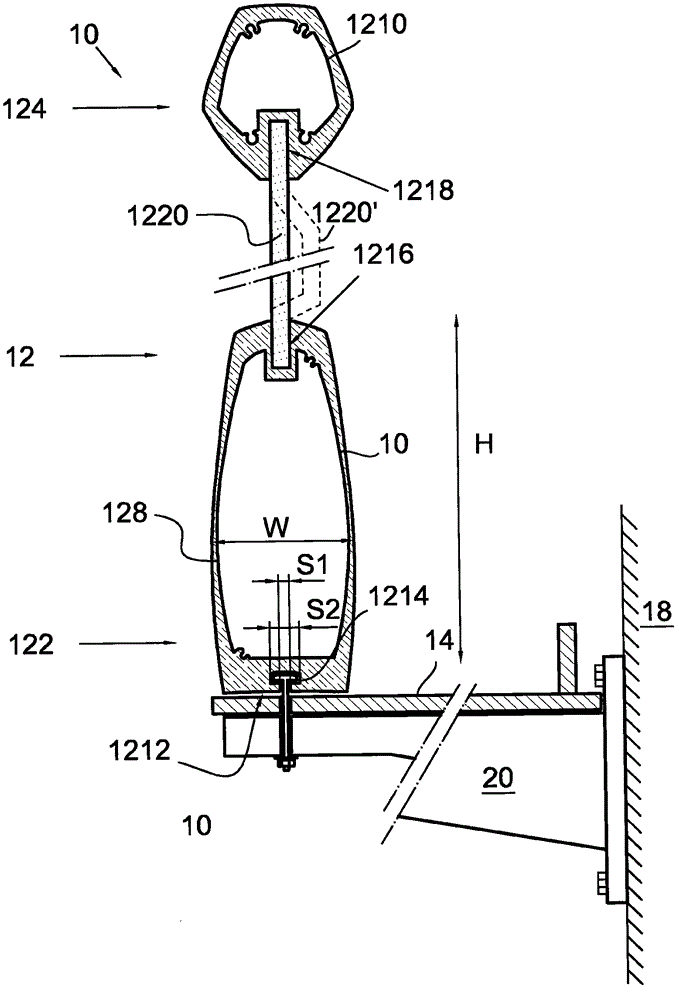

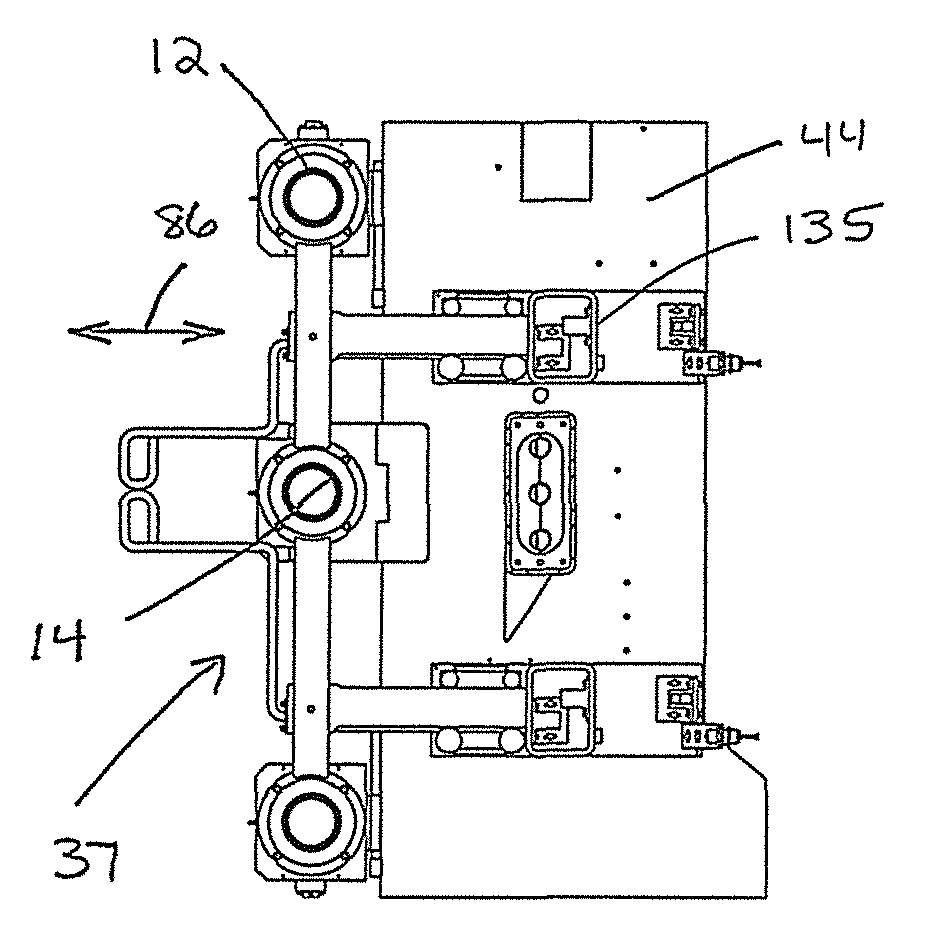

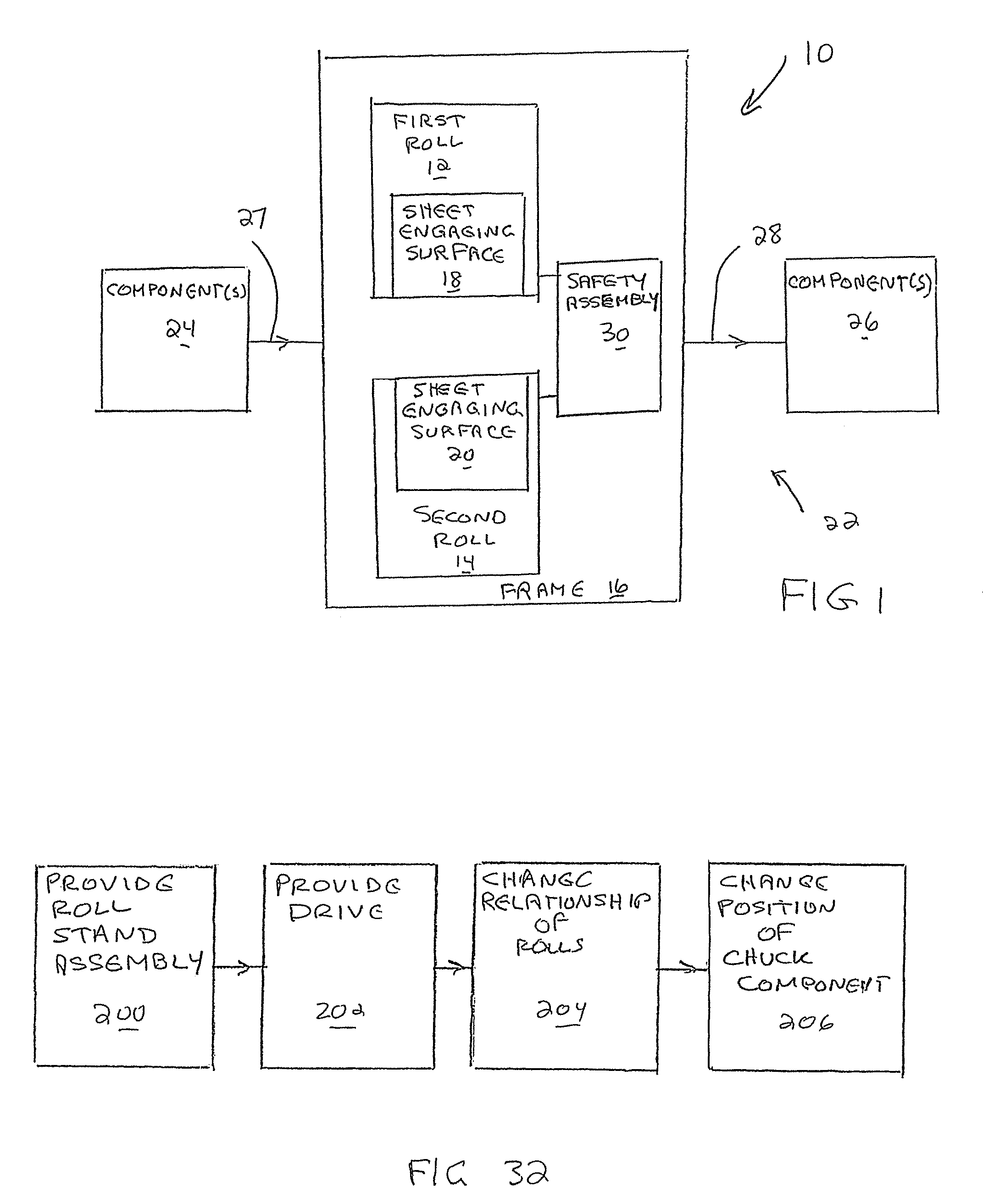

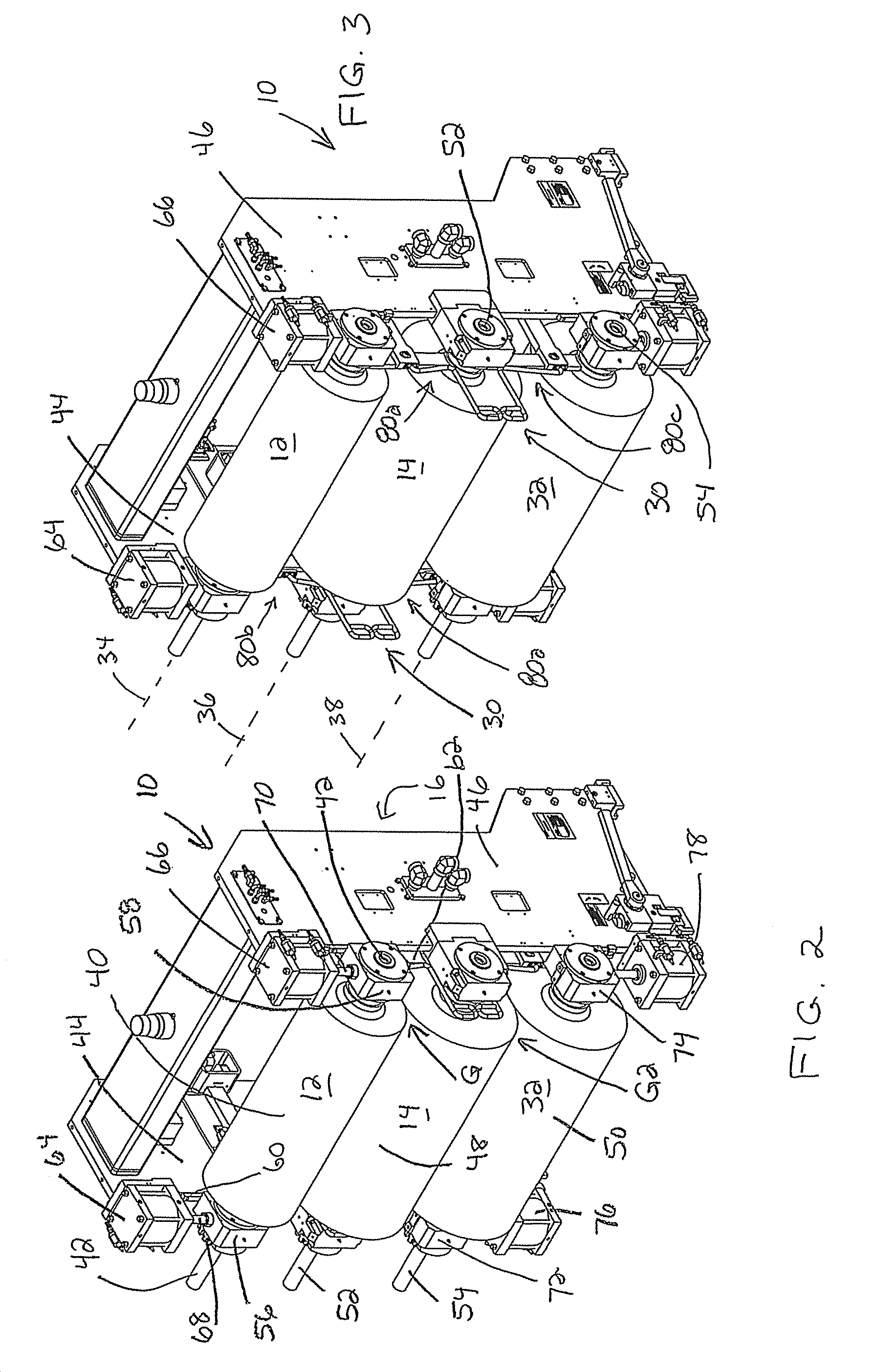

Roll stand assembly

ActiveUS20140138472A1Avoid changePrevent movementFilament handlingEngineering safety devicesSheet materialMechanical engineering

A roll stand assembly for processing a sheet product with a plurality of rolls on a frame. A first roll has a first sheet engaging surface and a first shaft assembly. A second roll has a second sheet engaging surface and a second shaft assembly. The first and second rolls are relatively movable between: a) an operating relationship; and b) an open relationship. A safety assembly prevents inadvertent changing of the first and second rolls from the open relationship into the operating relationship. The safety assembly includes a first chuck component mounted for movement relative to the frame between: a) a running position wherein the safety assembly is in a disengaged state; and b) a lockout position.

Owner:PROCESSING TECH INT

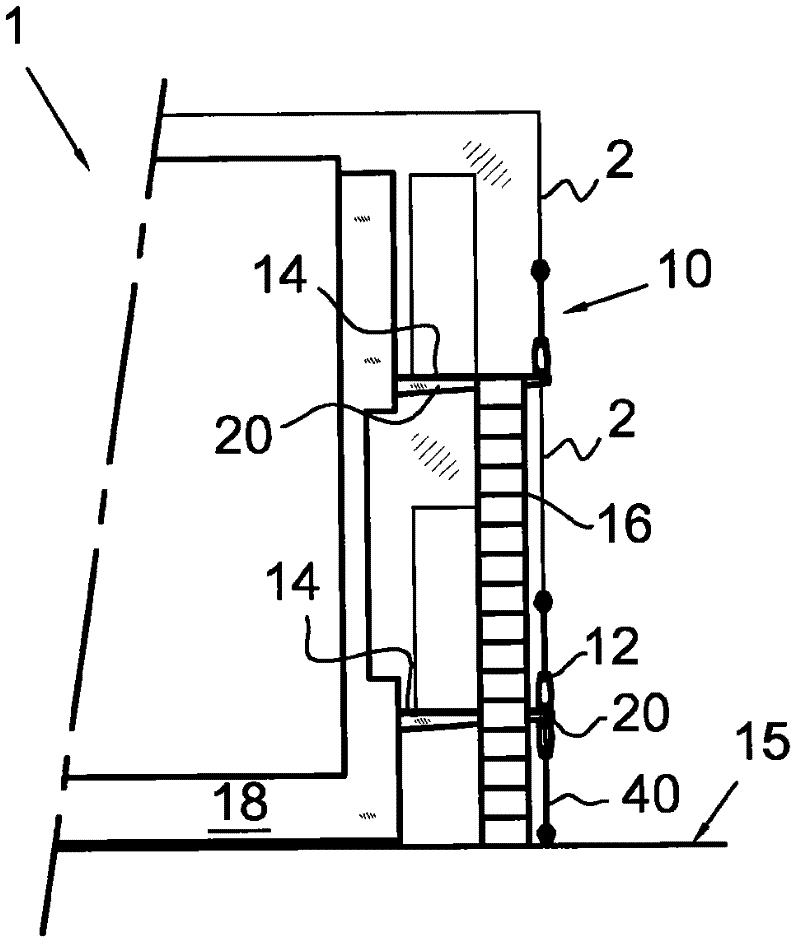

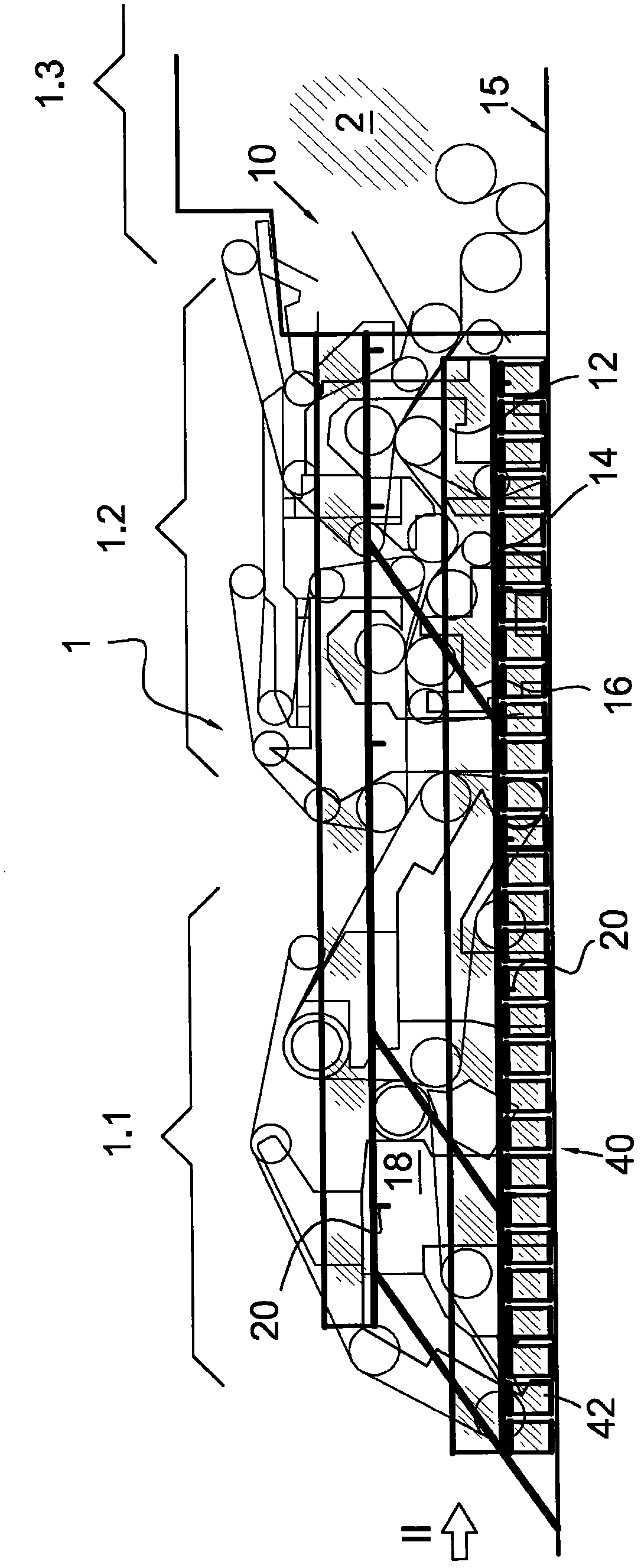

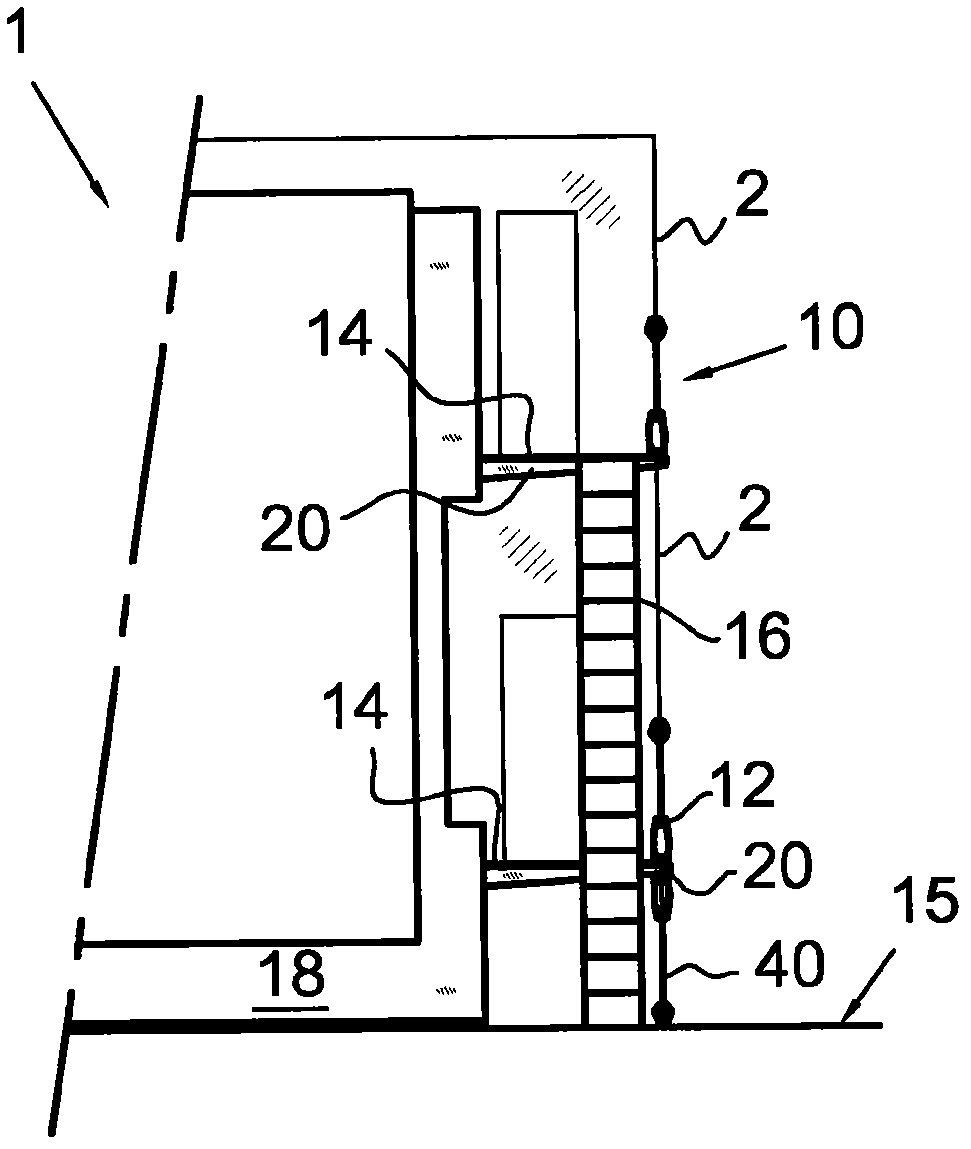

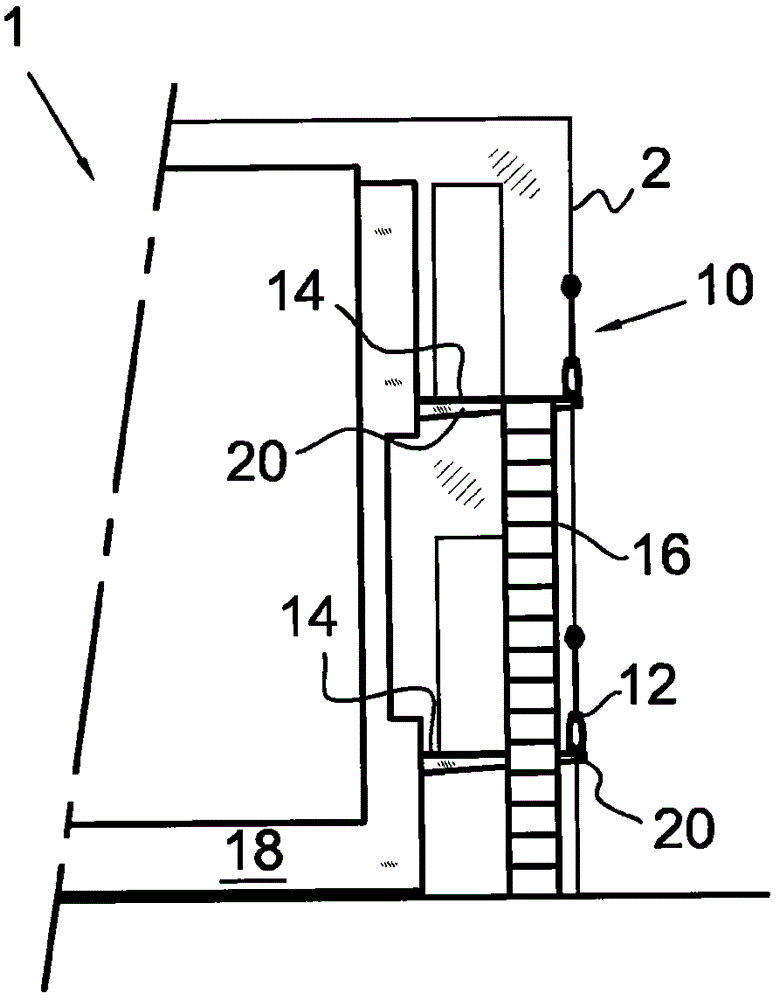

Service platform arrangement for a fiber web machine

InactiveCN102414366AConvenient for daily workEffective movementDryer sectionEngineering safety devicesEngineeringMechanical engineering

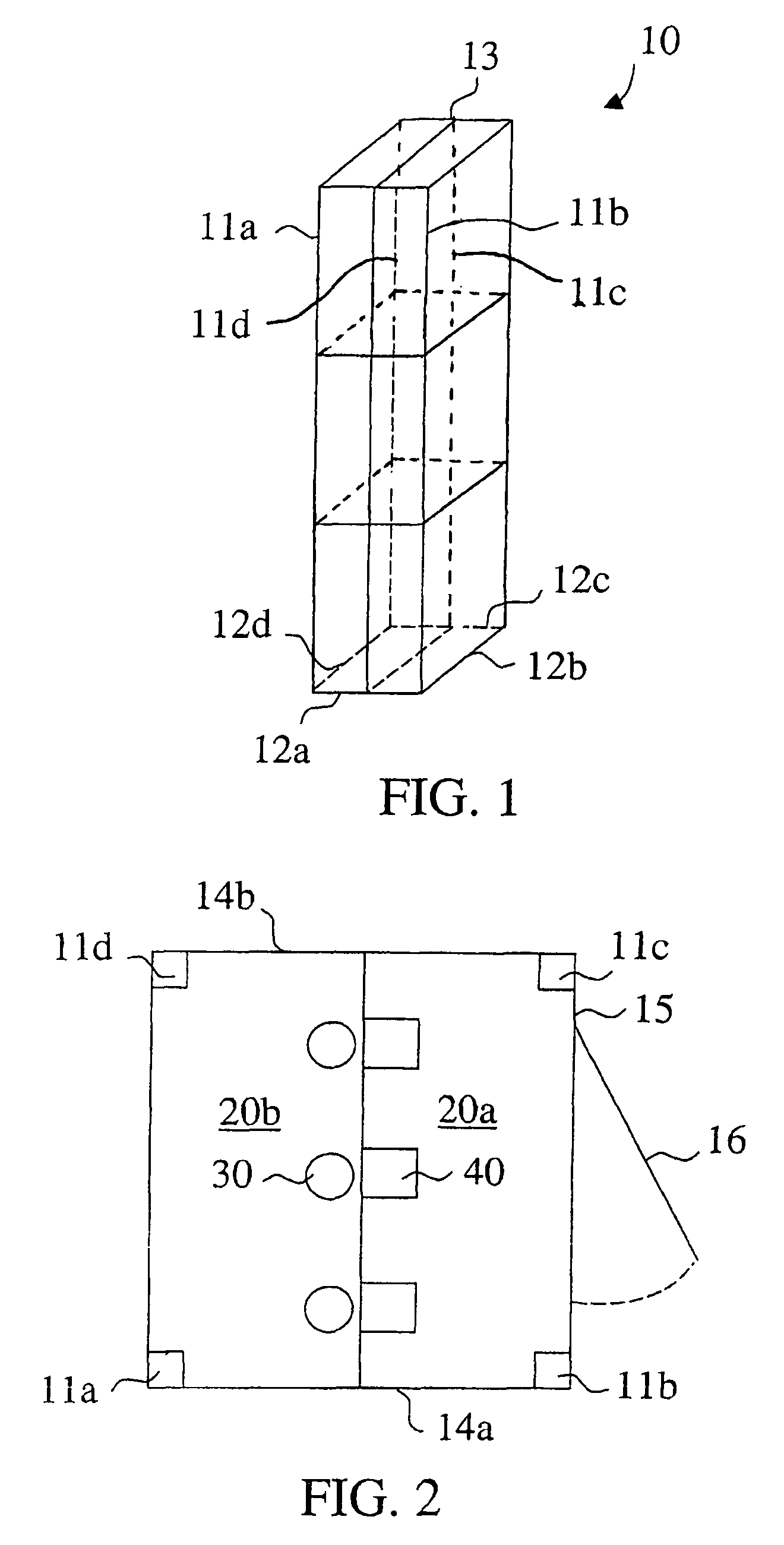

The present invention relates to a service platform arrangement (10) of a fiber web machine, including at least a walkway (14) and a railing (12) disposed in connection with each other so that the railing extends from the walkway to a first direction. The service platform arrangement comprises an essentially closed protecting structure (40) provided in connection with the walkway in a horizontal level essentially at the railing so that it extends from the walkway to another direction, which is essentially the opposite direction in relation to the first direction.

Owner:VALMET CHINA CO LTD

System and a method for collecting and handling dust in a paper-making environment

Owner:VALMET S P A IT

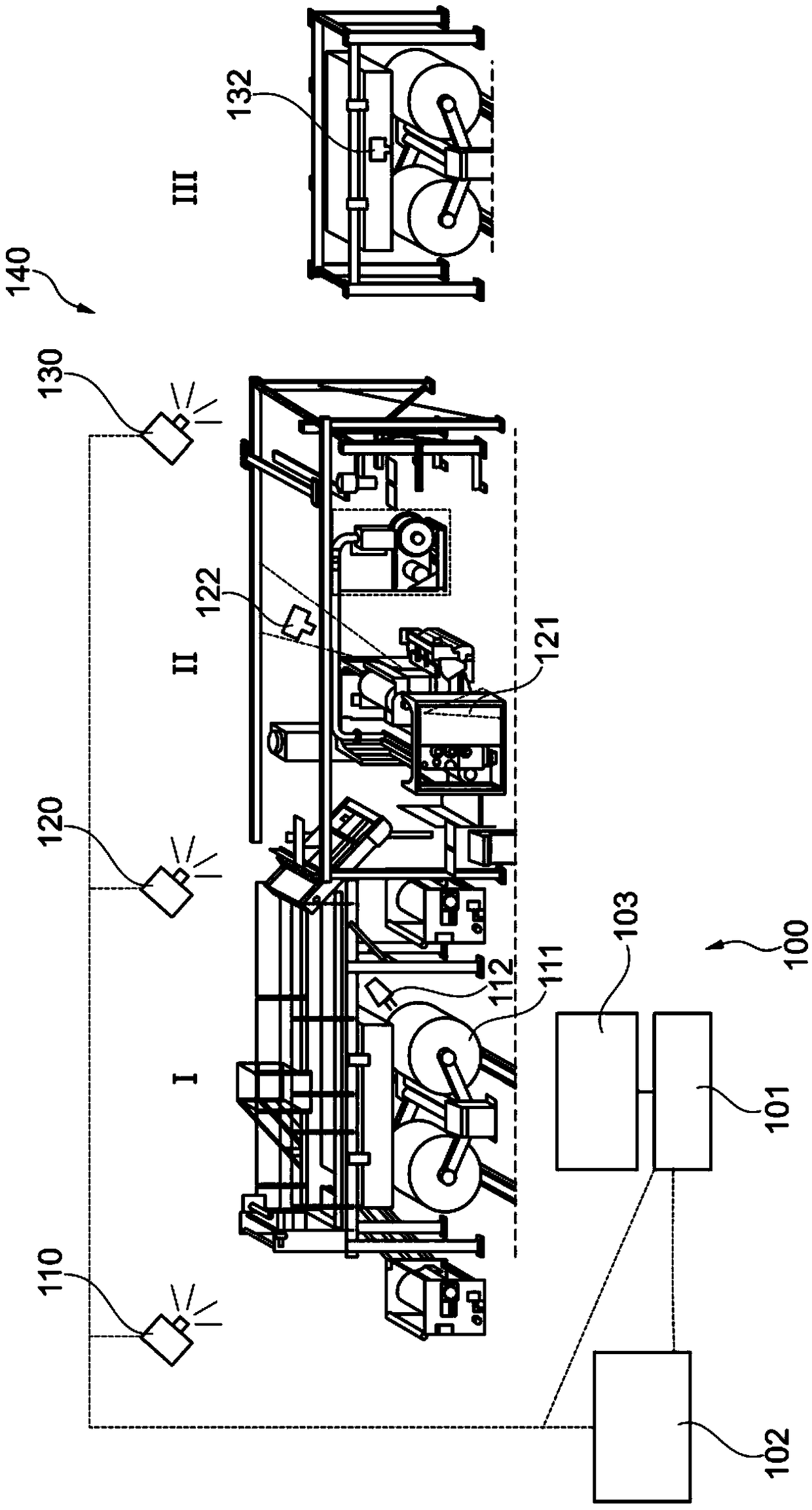

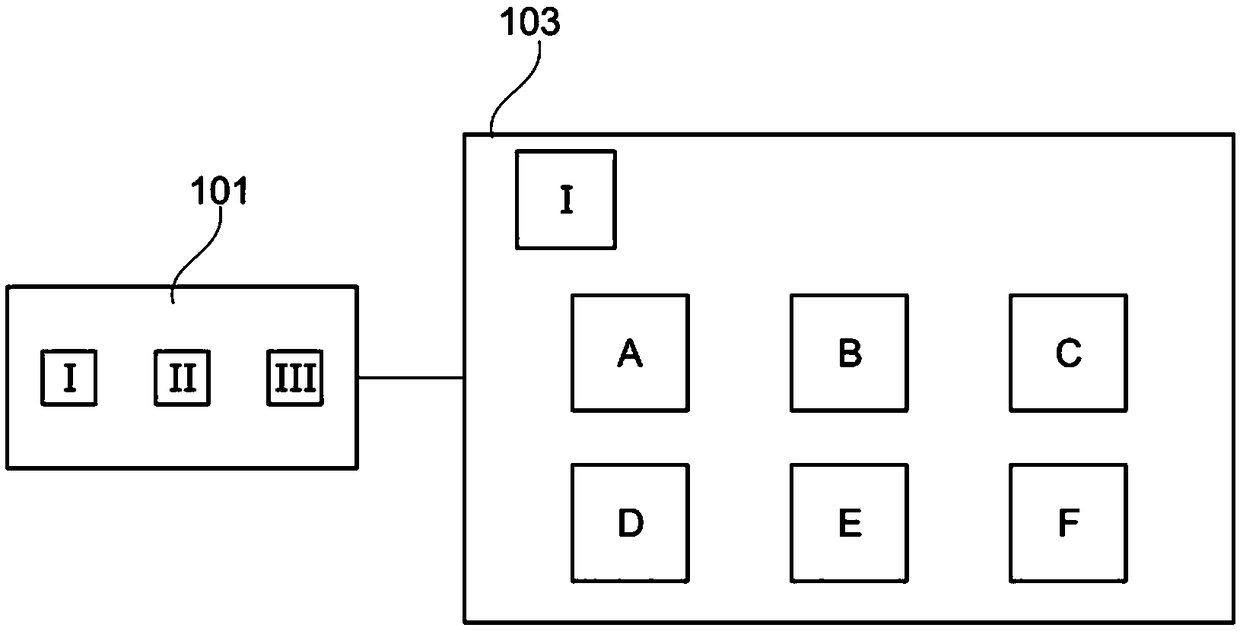

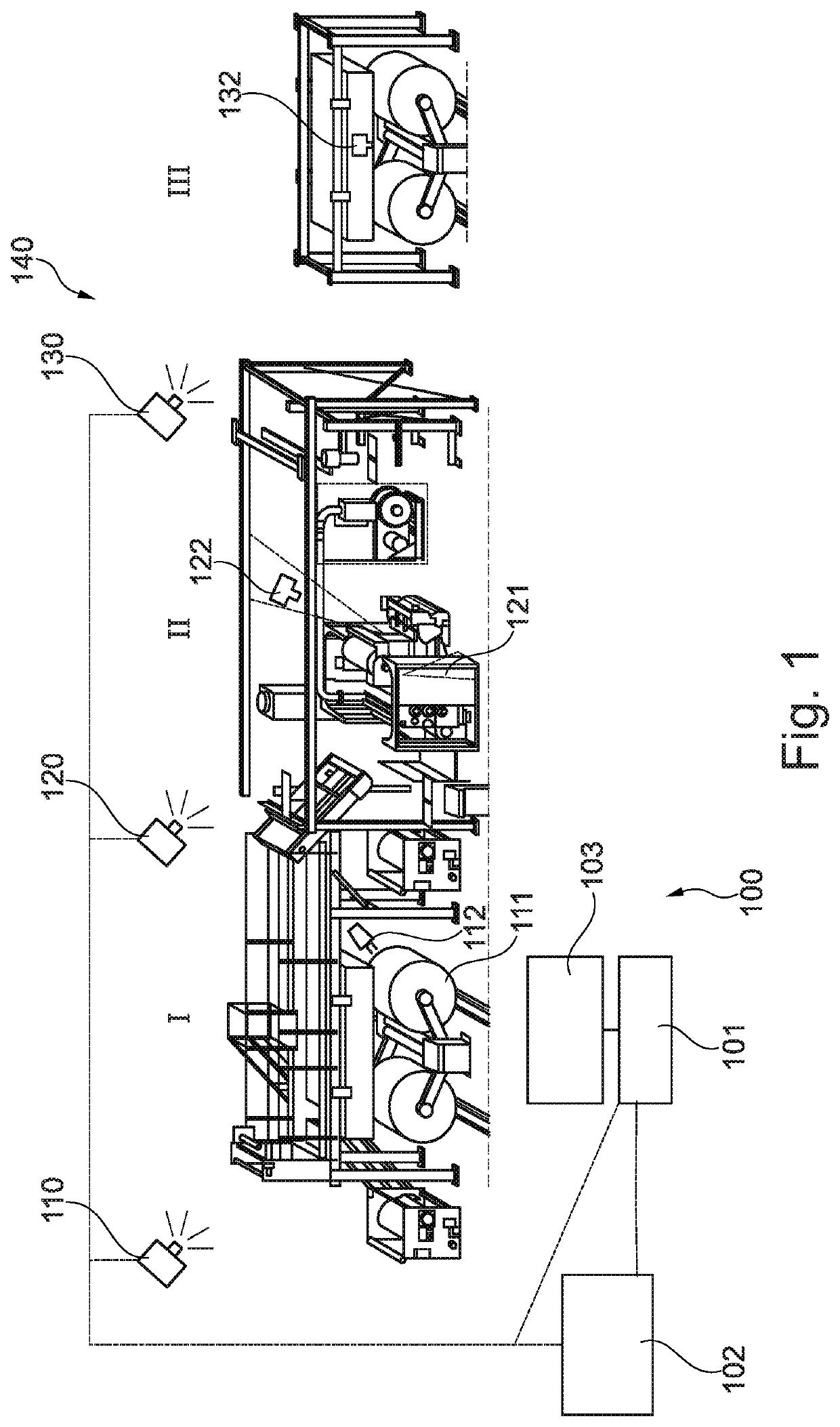

Control system for a functional section of a paper processing device

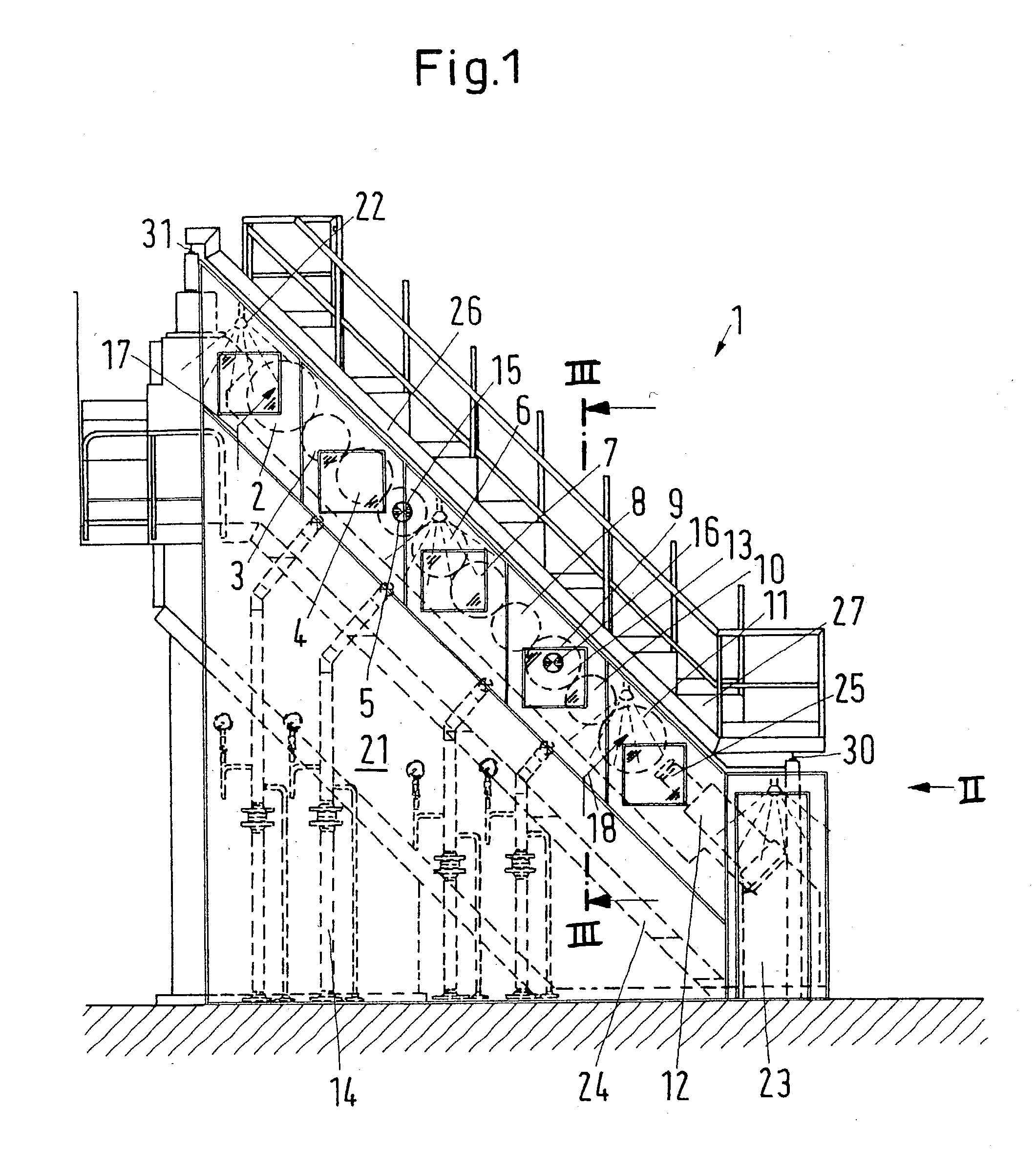

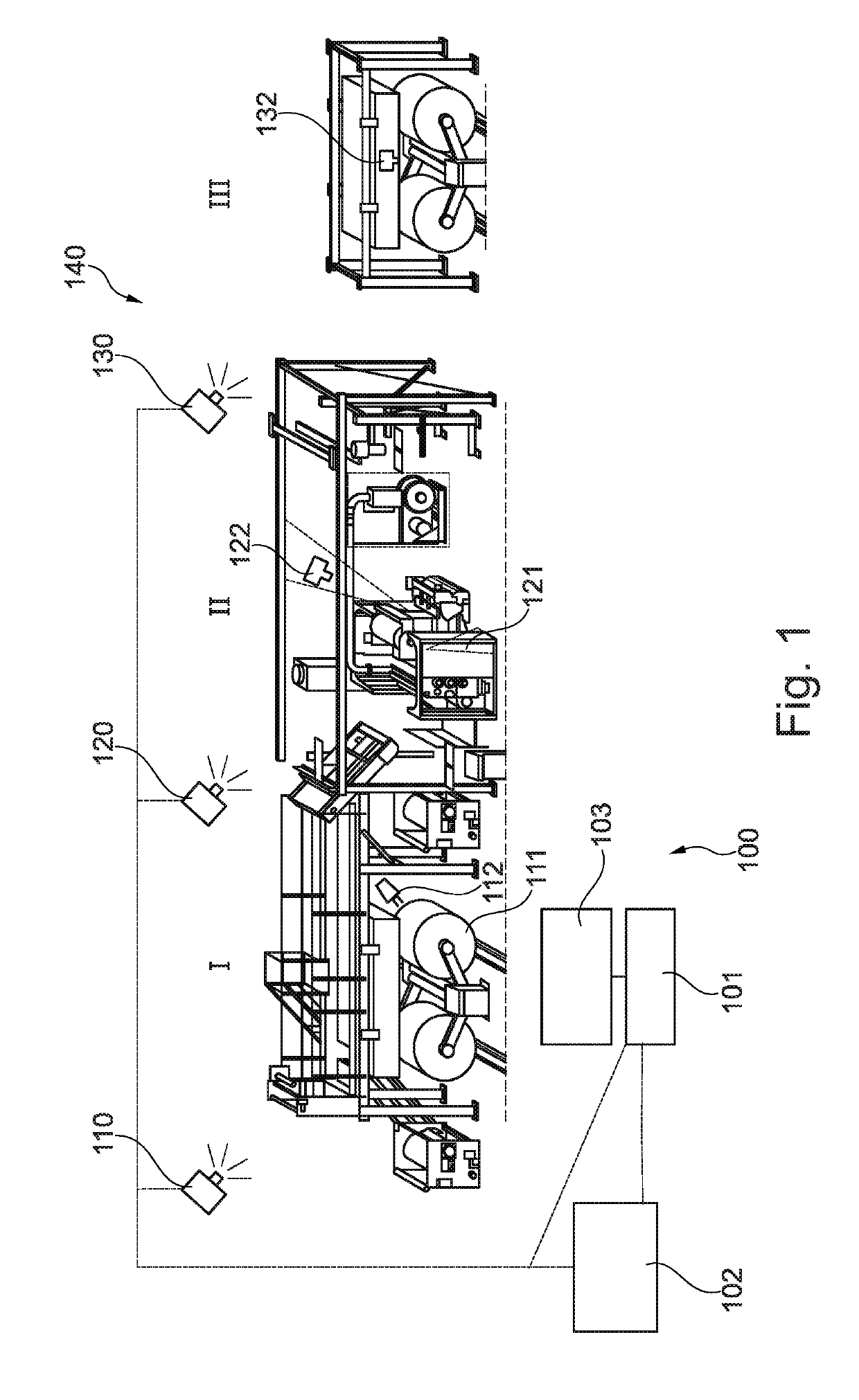

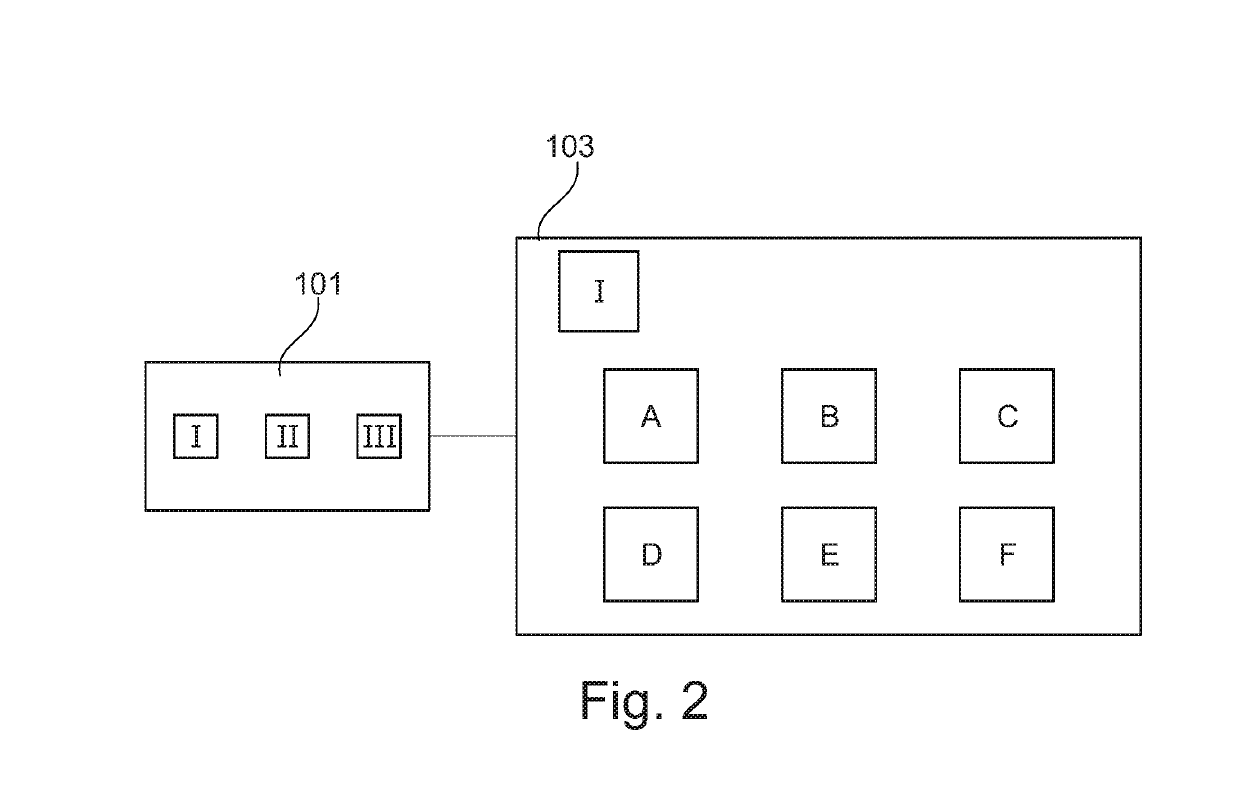

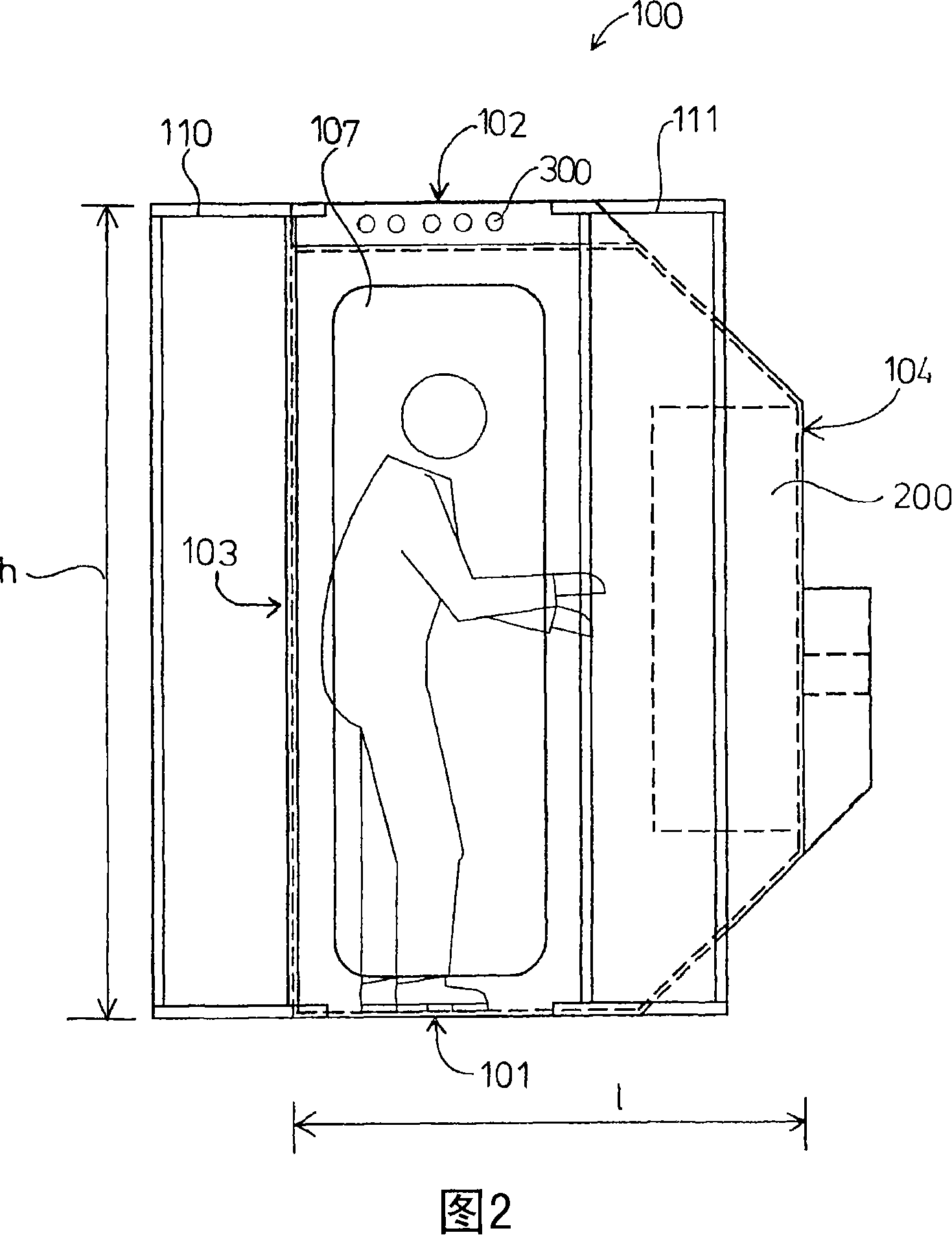

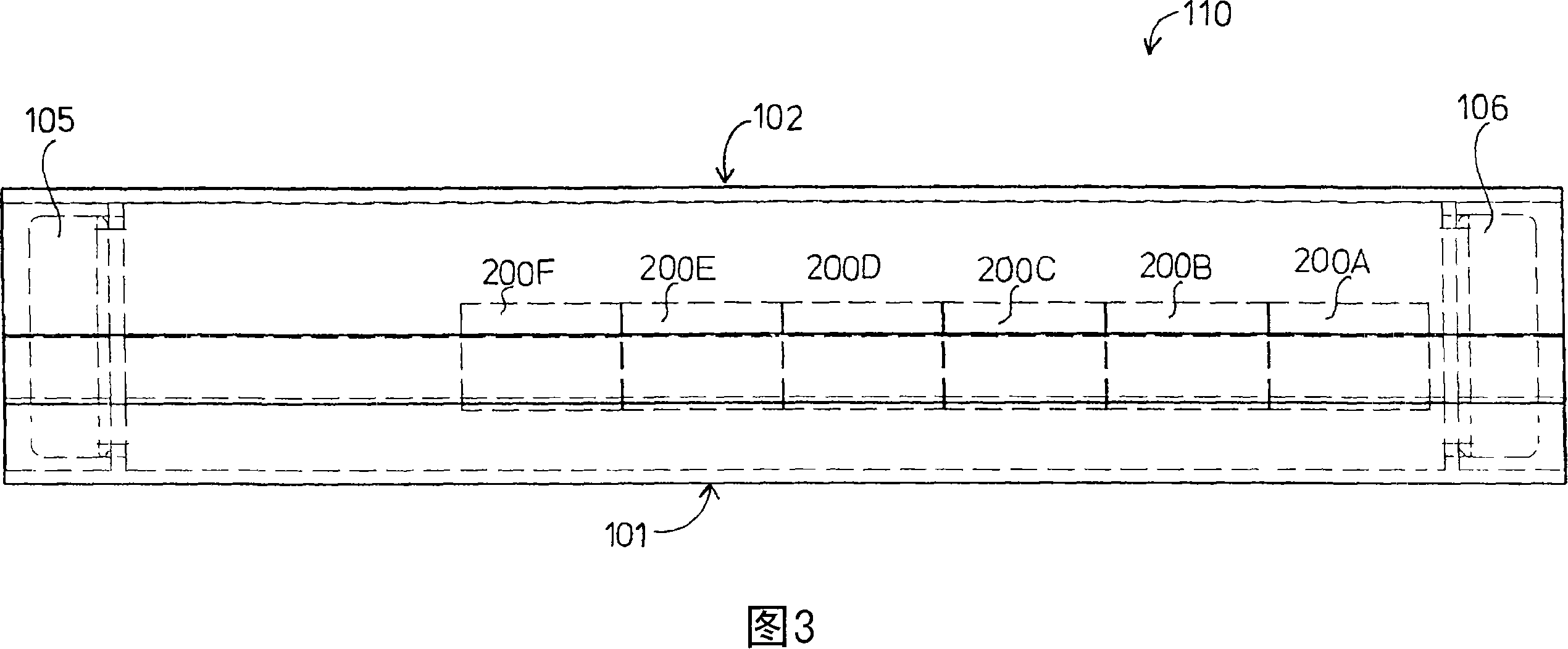

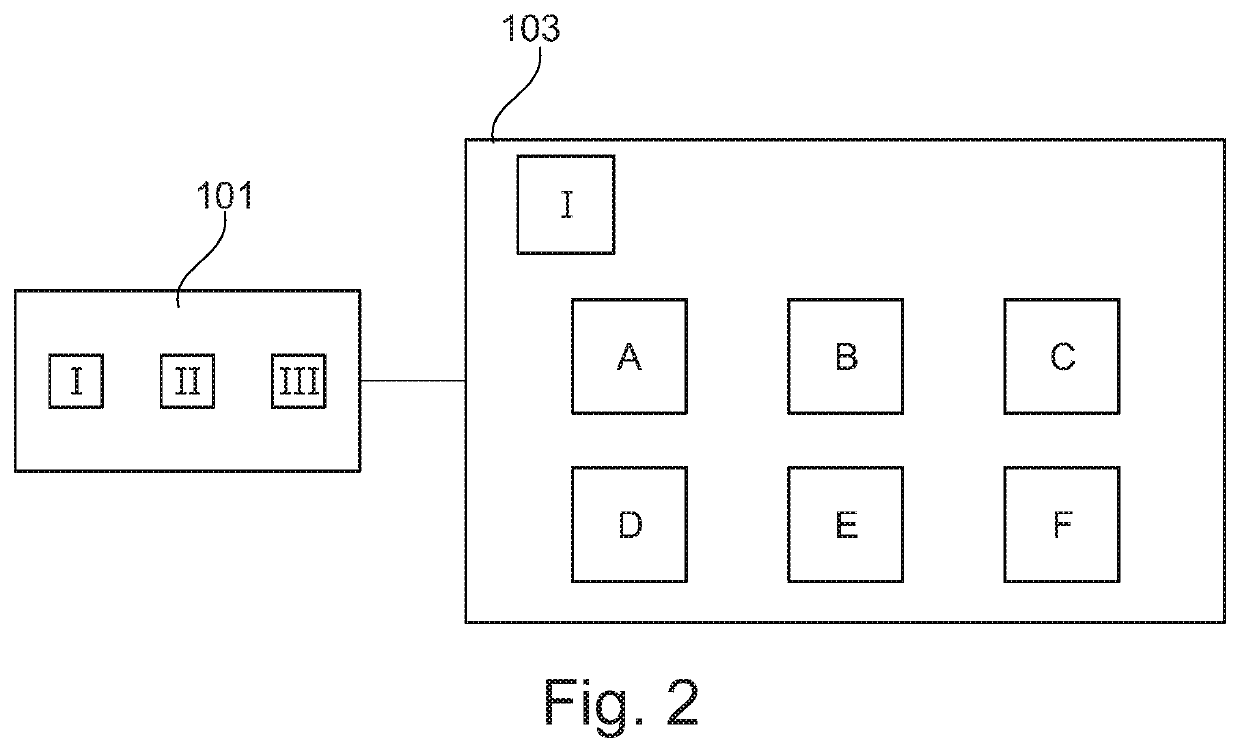

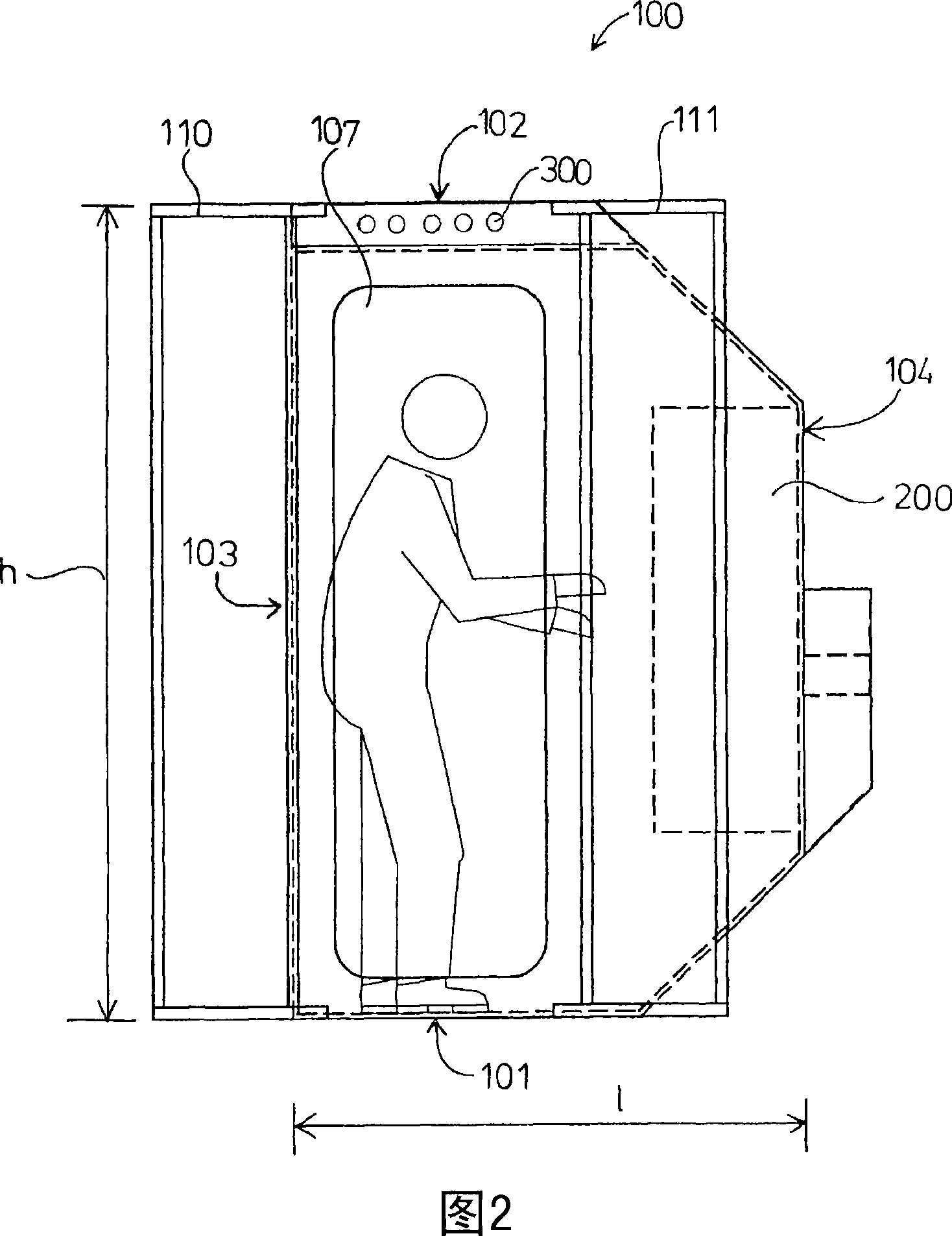

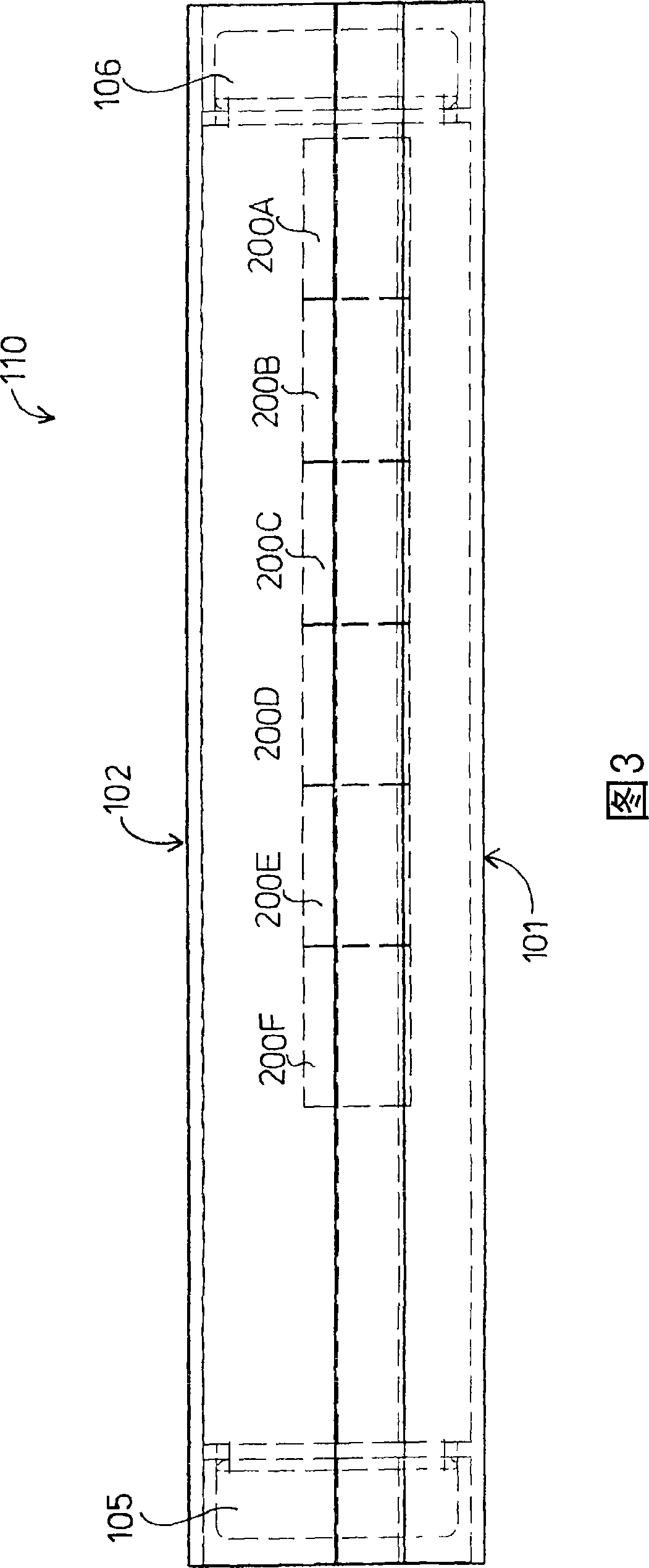

The invention relates to a control system (100) for a functional section (I, II, III) of a paper processing device (140). The control system (100) has at least one safety-monitoring camera (110, 120,130) which is arranged in the functional section (I, II, III) such that a functional region of the functional section (I, II, III) can be captured by the safety-monitoring camera (110, 120, 130). An operating unit (101) of the system (100) is designed to operate the functional section (I, II, III), and image data of the at least one safety-monitoring camera (110, 120, 130) can be selected by the operating unit (101). A display unit (103) is configured to display the selected image data such that a user allows or blocks the operation of the functional section (I, II, III) based on the displayedimage data. A safety device (102) is coupled to the safety-monitoring camera (110, 120, 130) and the operating unit (101), and the safety device (102) receives image data of the safety-monitoring camera (110, 120, 130). The safety device (102) is configured such that the safety device (102) allows or blocks the operation of the functional section (I, II, III) by means of the operating unit (101)on the basis of the received image data of the safety-monitoring camera (110, 120, 130).

Owner:BOBST MEX SA

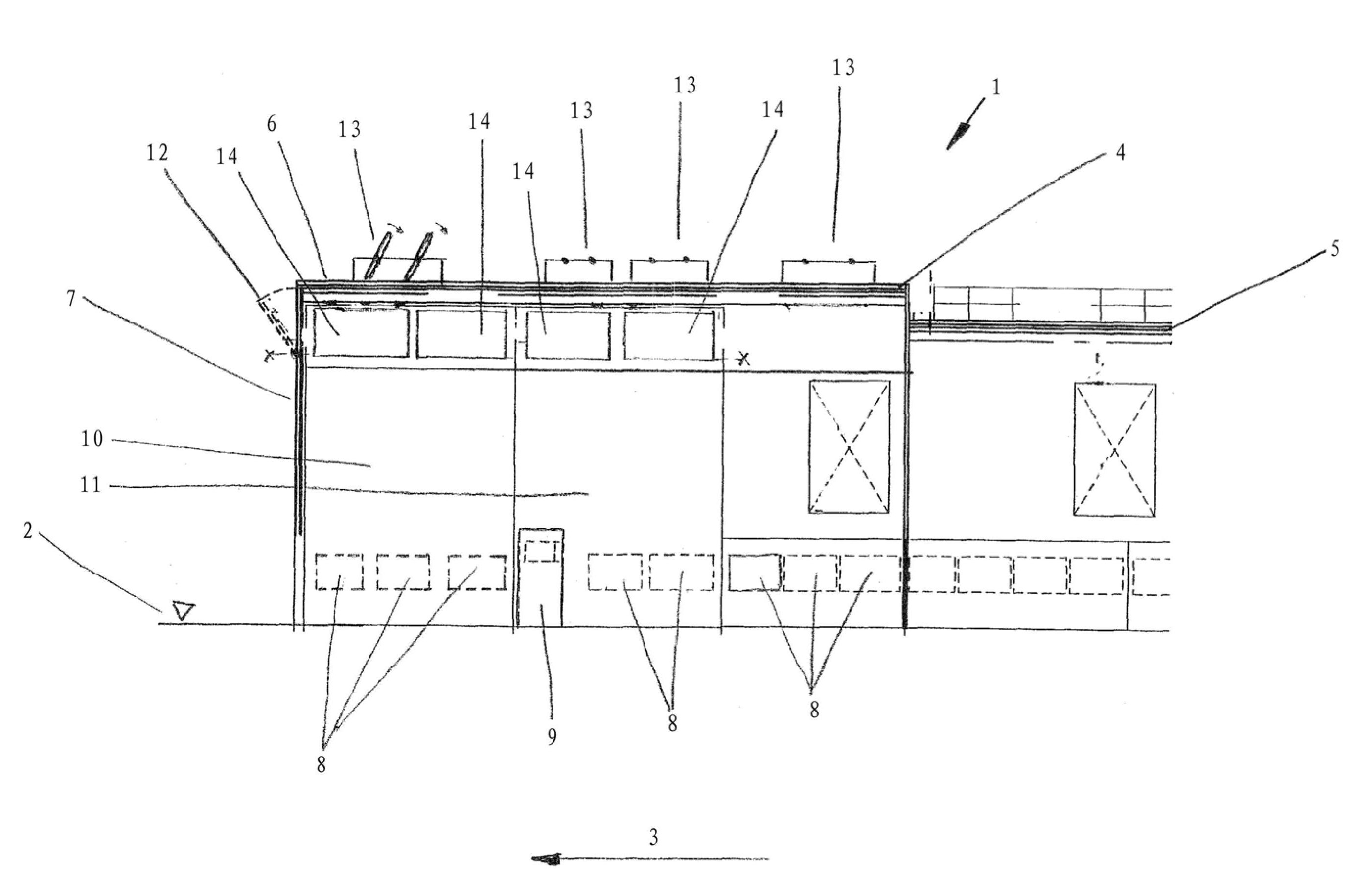

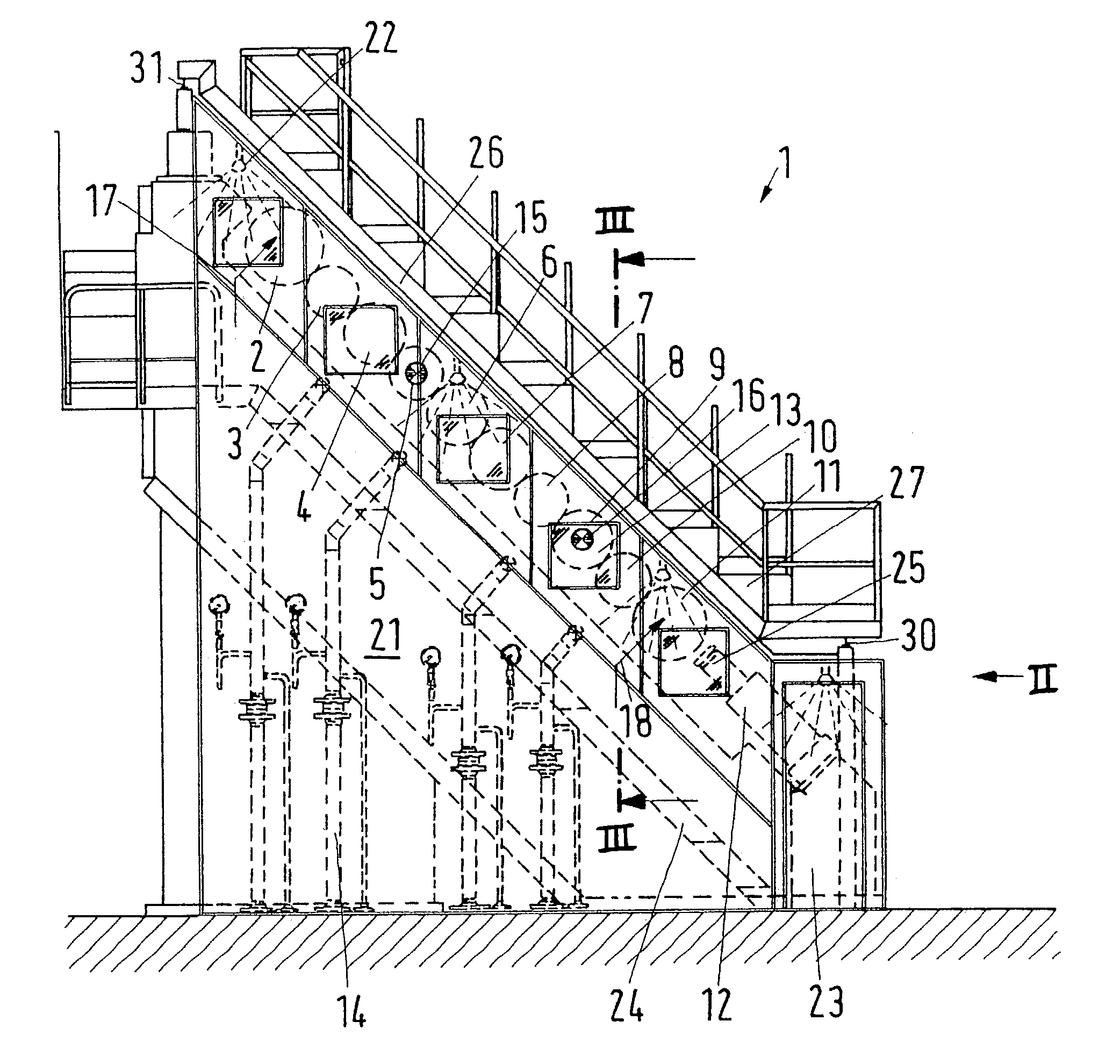

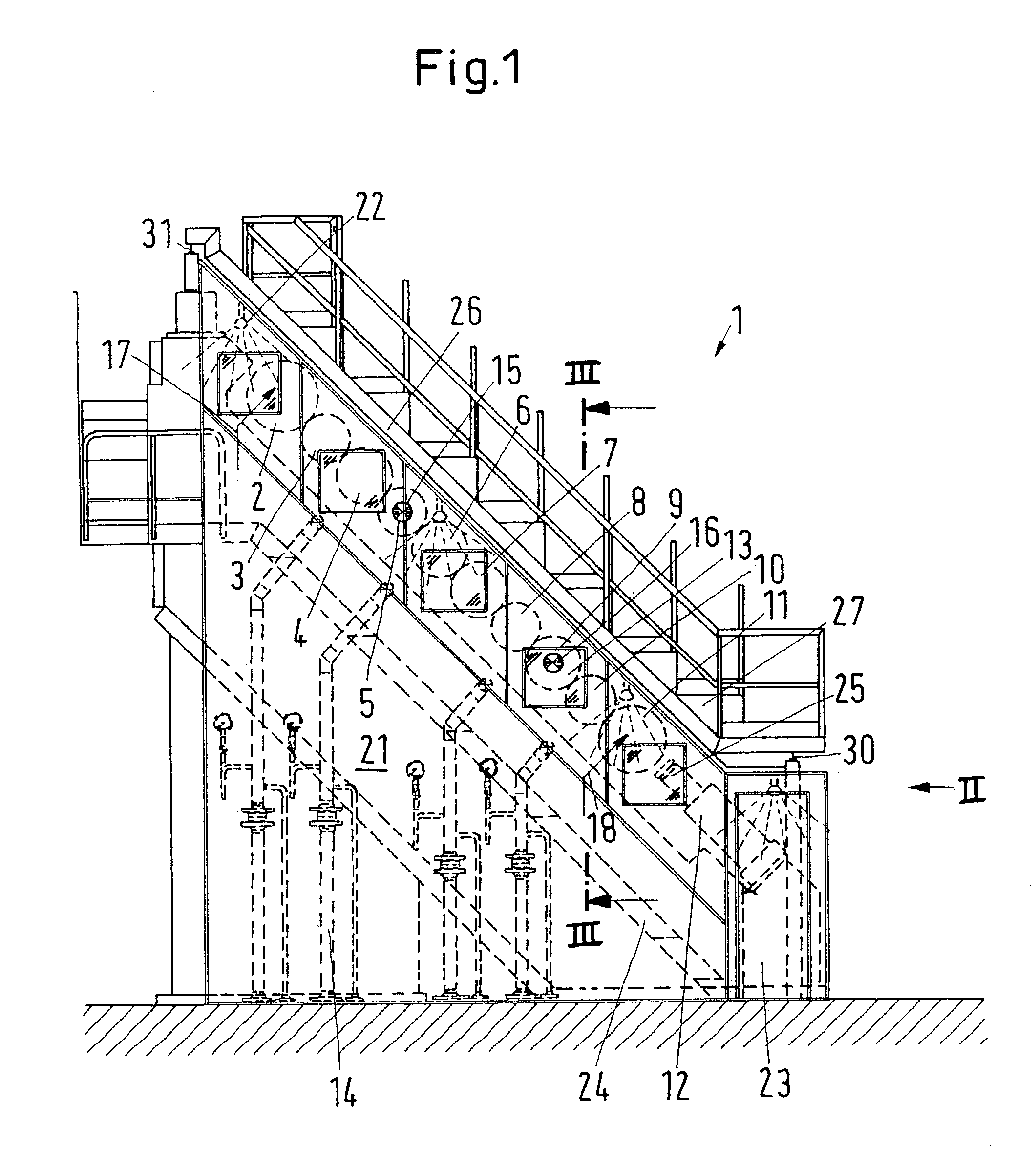

Device for producing a material web

InactiveCN102666979AQuick leakRapid coolingDryer sectionSafety devices for paper-making machinesCardboardPulp and paper industry

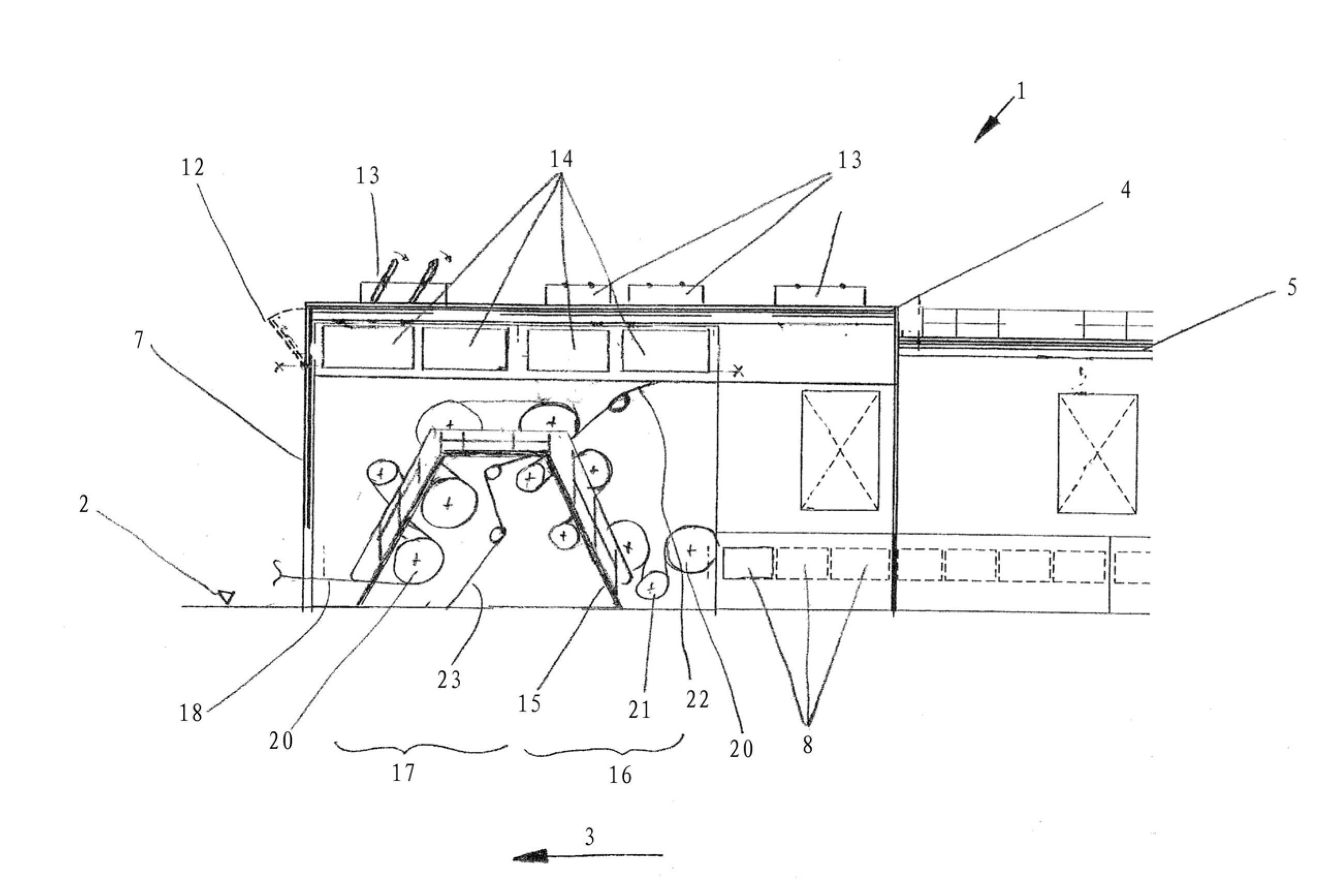

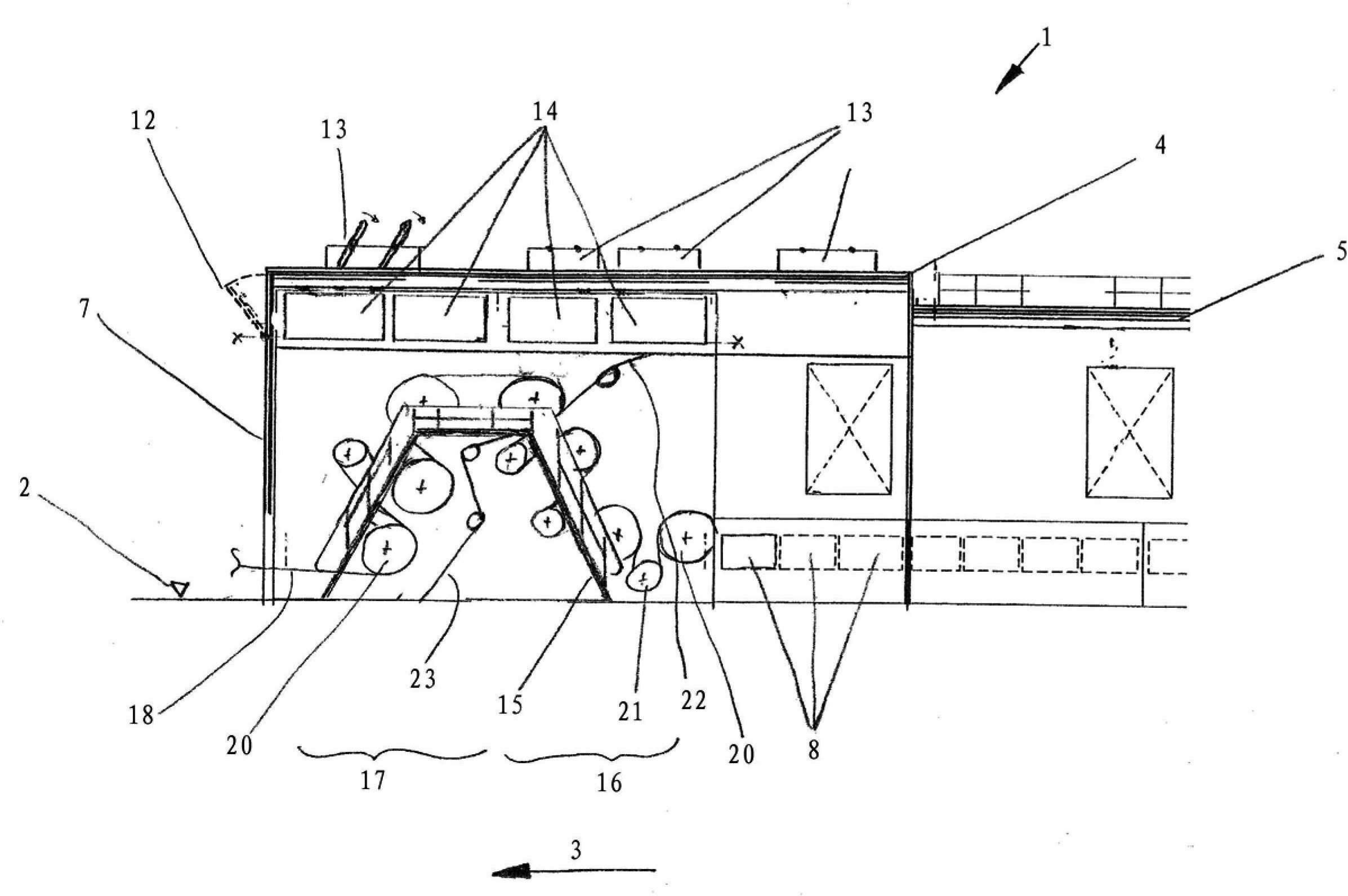

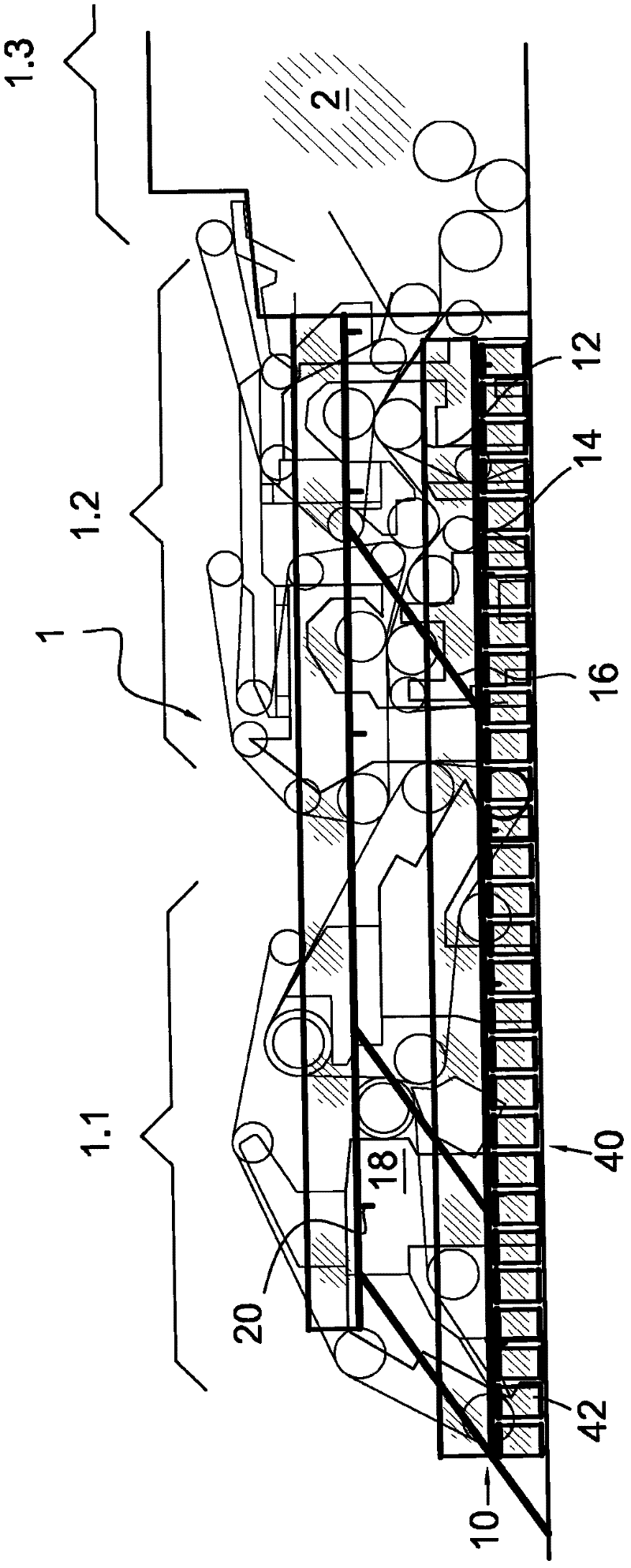

The invention relates to a drying device (1) for a machine for producing a material web (18), in particular a paper, cardboard or tissue web. The drying device (1) comprises at least one first and at least one further subsequent drying group (17, 16) each made up of at least one drying assembly (19), and at least one cover (4) enclosing the drying group (17, 16). At least one drying assembly (19) of the further drying group is disposed higher than the drying assembly (19) of the first drying group (16). The cover (4) comprises a guide side wall, a drive side wall, and a cover roof. The drying device (1) according to the invention is characterized in that the cover (4) comprises at least one area (10, 11, 13, 14) that can be opened rapidly at least in the area of the further drying group (17), in the cover roof (6) and / or in the guide side wall and / or in the drive side wall. Said area than can be opened rapidly allows a rapid escape of hot air from the interior of the cover in case of an interruption in production.

Owner:VOITH PATENT GMBH

Control system for a functional section of a paper processing device

ActiveUS20190211505A1Simple processImprove securityProgramme controlSafety arrangmentsControl systemSafety monitoring

A control system (100) for a functional section (I, II, III) of a paper processing device (140). The control system (100) has at least one safety-monitoring camera (110, 120, 130) which is arranged in the functional section (I, II, III) such that a functional region of the functional section (I, II, III) can be captured by the safety-monitoring camera (110, 120, 130). An operating unit (101) of the system (100) is designed to operate the functional section (I, II, III), and image data of the at least one safety-monitoring camera (110, 120, 130) can be selected by the operating unit (101). A display unit (103) is configured to display the selected image data such that a user allows or blocks the operation of the functional section (I, II, III) based on the displayed image data. A safety device (102) is coupled to the safety-monitoring camera (110, 120, 130) and the operating unit (101), and the safety device (102) receives image data of the safety-monitoring camera (110,120, 130). The safety device (102) is configured such that the safety device (102) allows or blocks the operation of the functional section (I, II, III) by means of the operating unit (101) on the basis of the received image data of the safety-monitoring camera (110, 120, 130).

Owner:BOBST GRENCHEN

Paper or board machine

InactiveCN101155959AReduce workloadShorten the timeMachine wet endSafety devices for paper-making machinesPaper machineCardboard

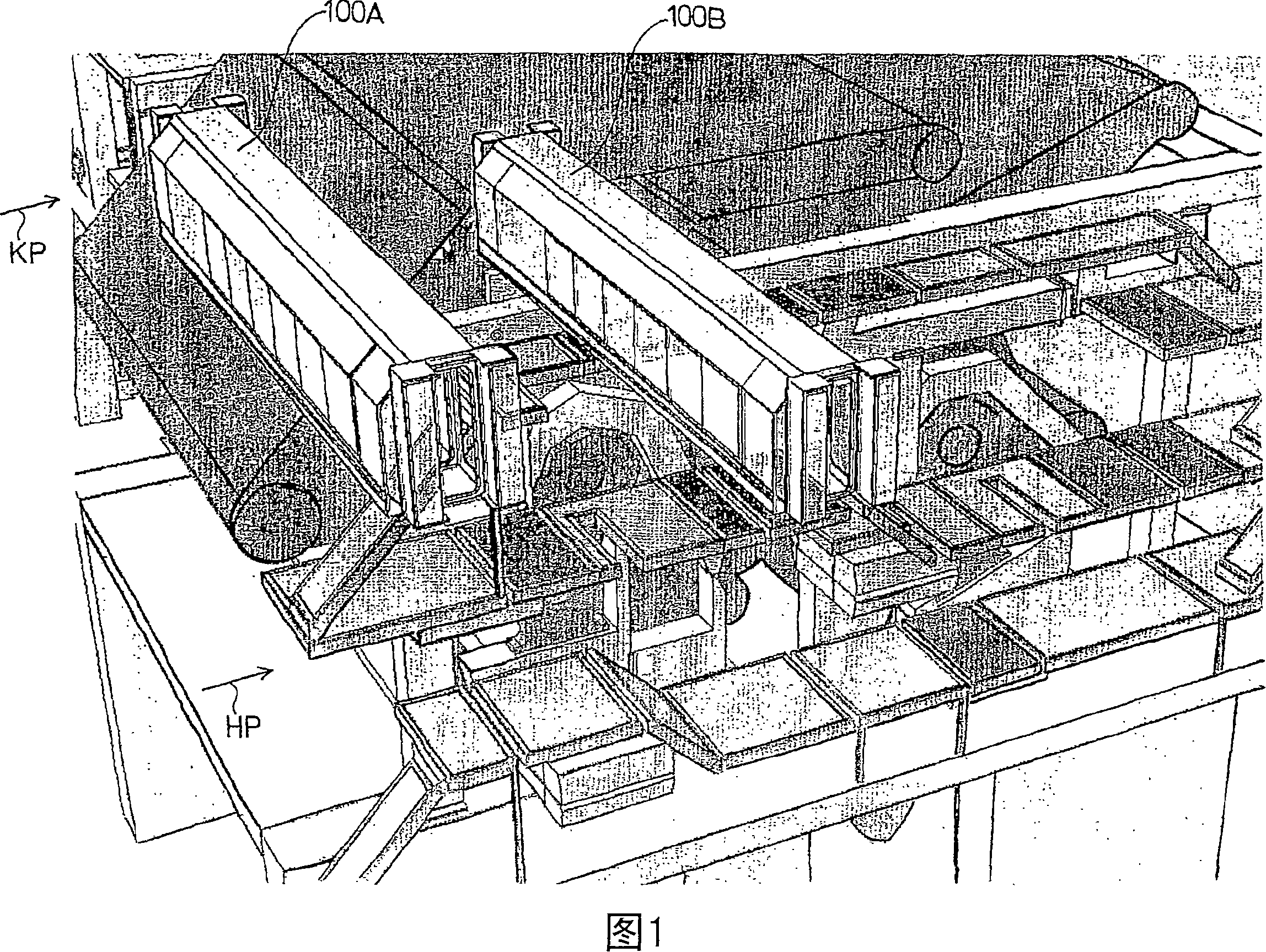

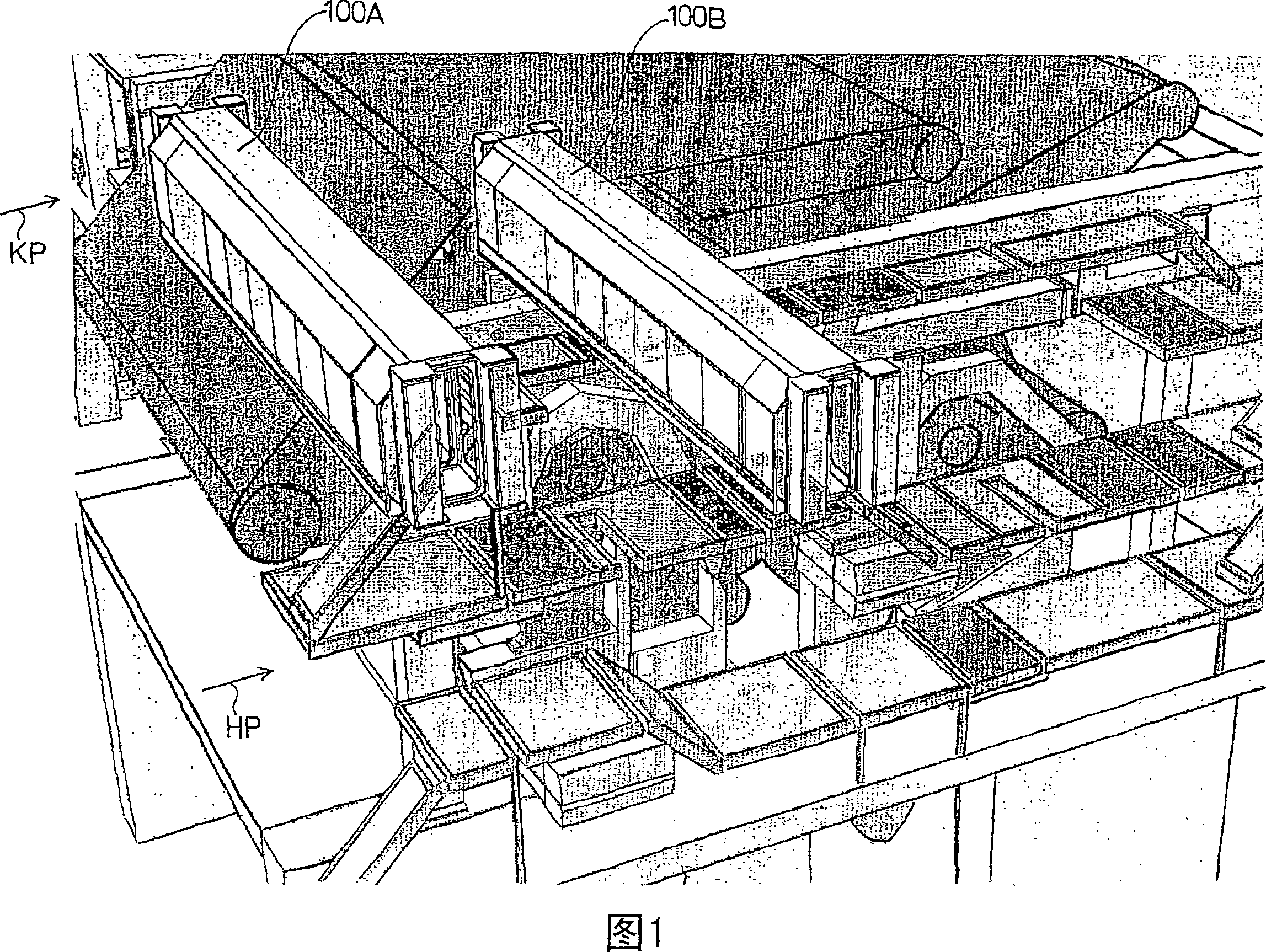

The wet end of the paper machine comprises at least one passage space (100) which extends from a tending side (HP) of the machine to a drive side (KP) of the machine and is closed in a machine direction, and inside which operating staff can walk in an operating situation safely and protected from ambient conditions between the tending side (HP) of the machine and the drive side (KP) of the machine.

Owner:METSO PAPER INC

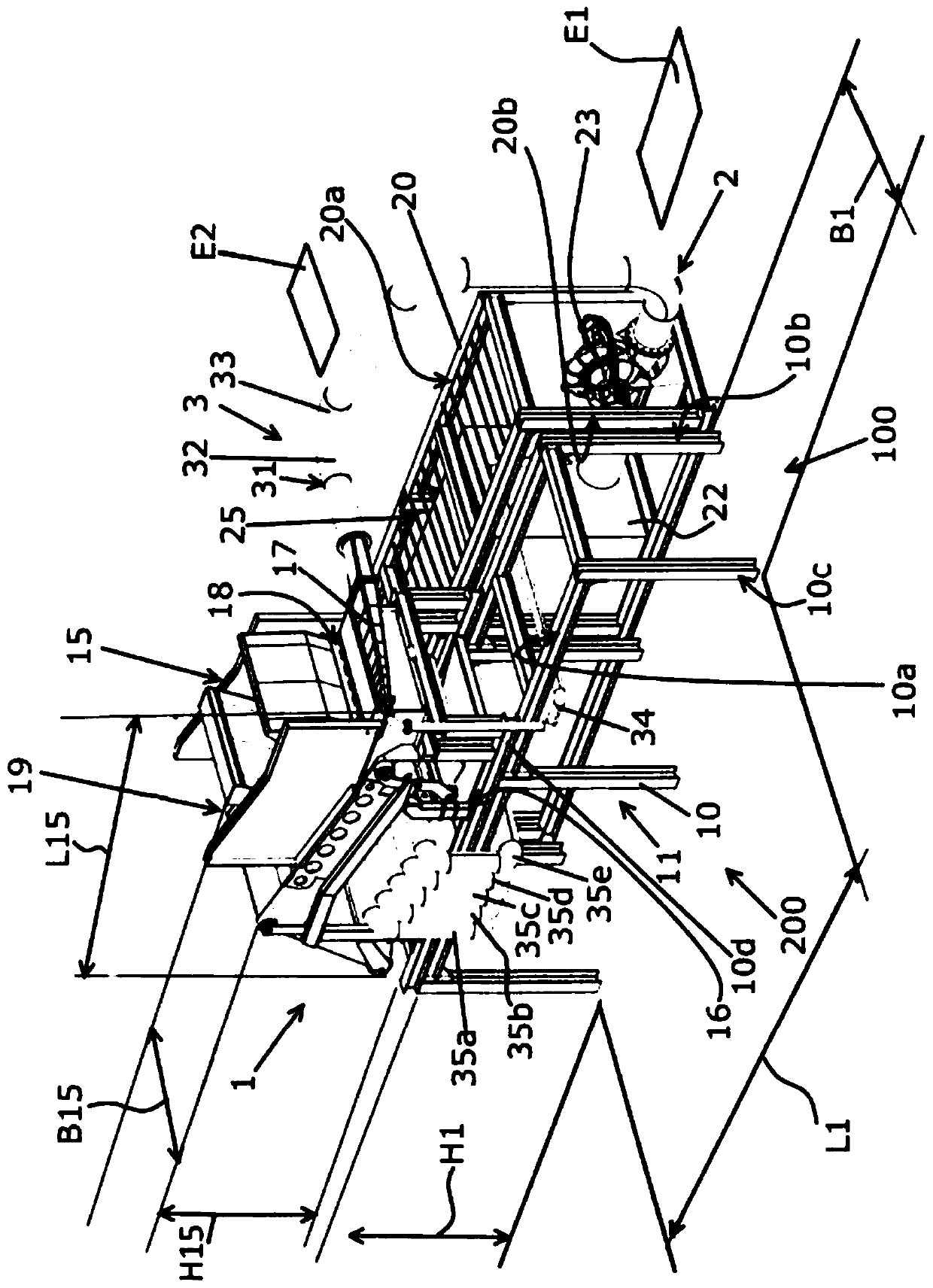

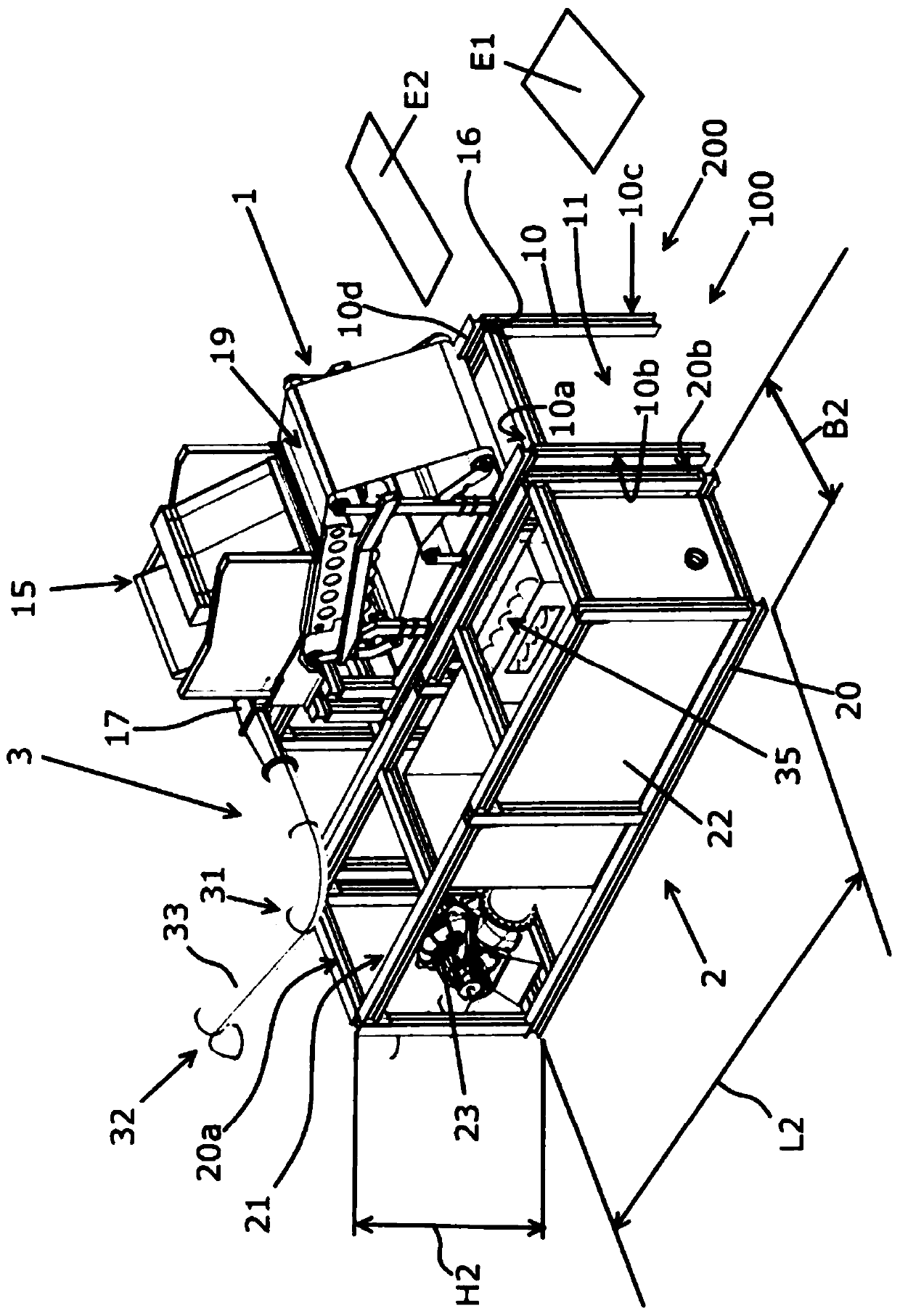

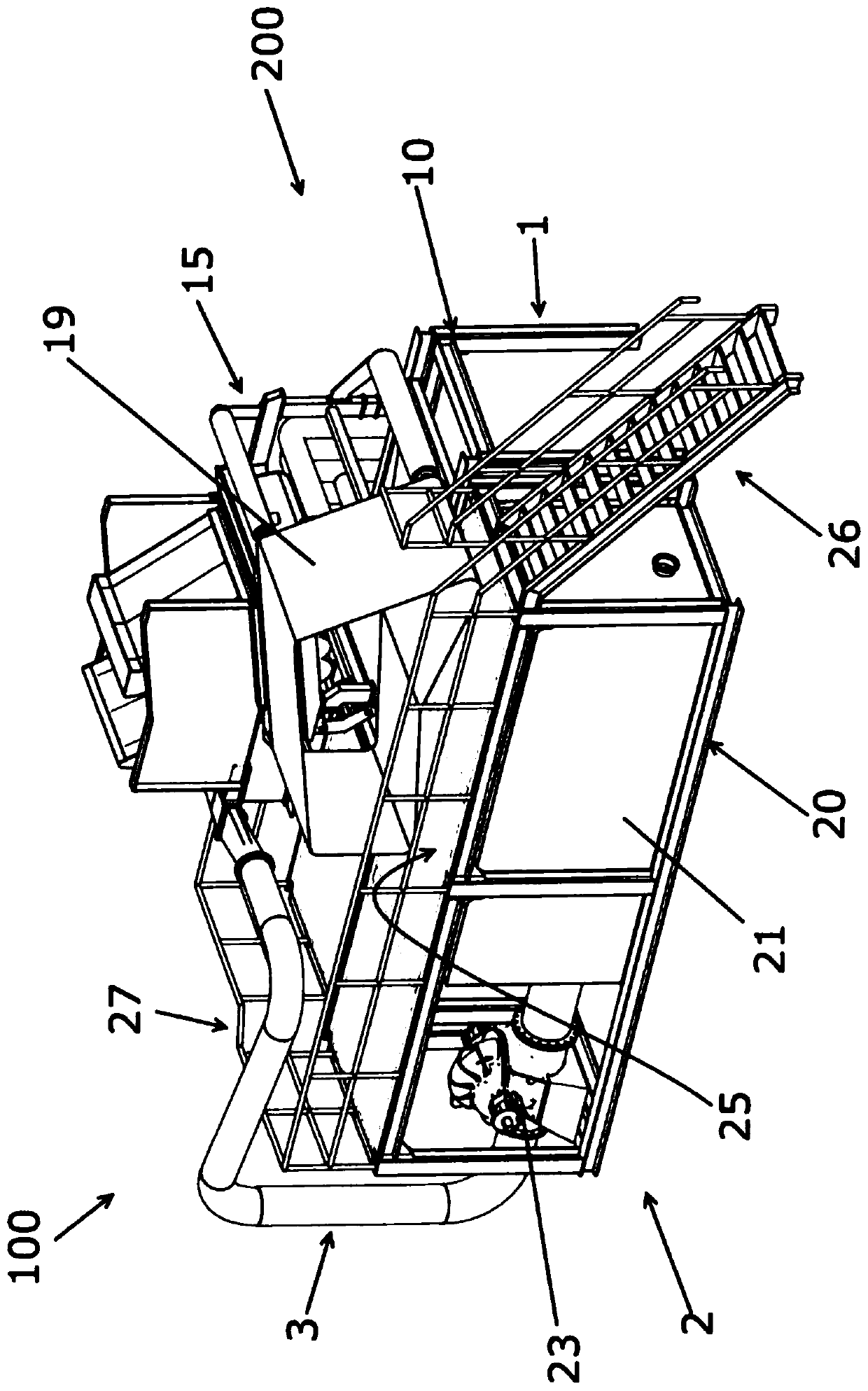

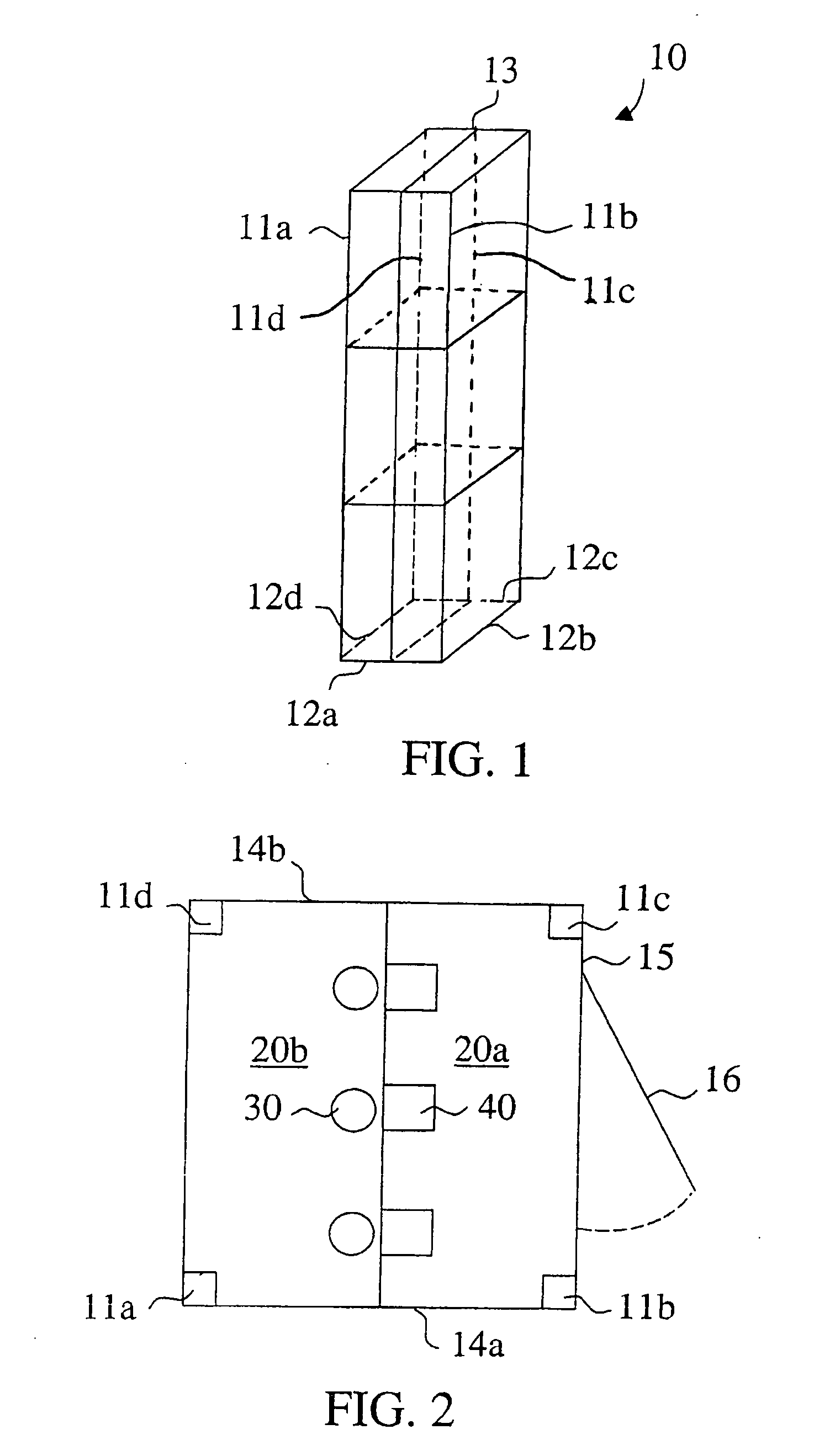

Device for producing nonwoven webs and method for assembling such device

ActiveCN110777557AIncrease heightEasy to transportNon-woven fabricsSafety devices for paper-making machinesEngineeringLiquid tank

The invention relates to a device (100) for the production of nonwoven fabric webs. The device includes a nonwoven production device (15) arranged on a supporting structure (10) in an assembled state, and an auxiliary unit (2) comprising at least one liquid tank (122) and a platform (25) arranged on a top side (20a) of the auxiliary unit (2). The nonwoven production device (15) and the auxiliaryunit (2) are arranged in relation to each other so that, for at least one of assembling, operating, and / or repairing the nonwoven production device (15), access to the nonwoven production device (15)is provided from the platform (25). The invention also relates to a method for assembling the device (100).

Owner:ANDRITZ KUESTERS GMBH & CO KG

Calender

Owner:VOITH PATENT GMBH

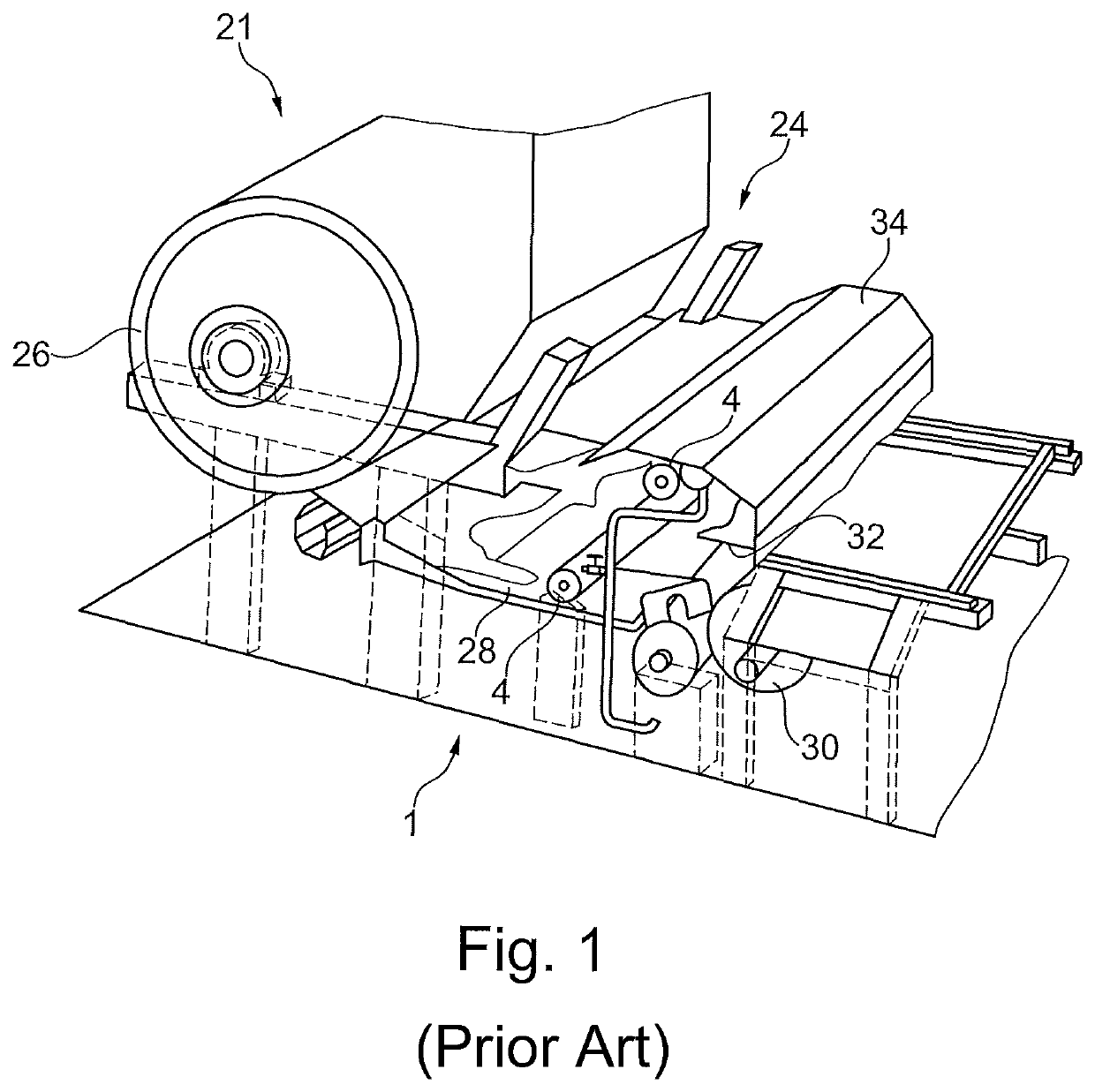

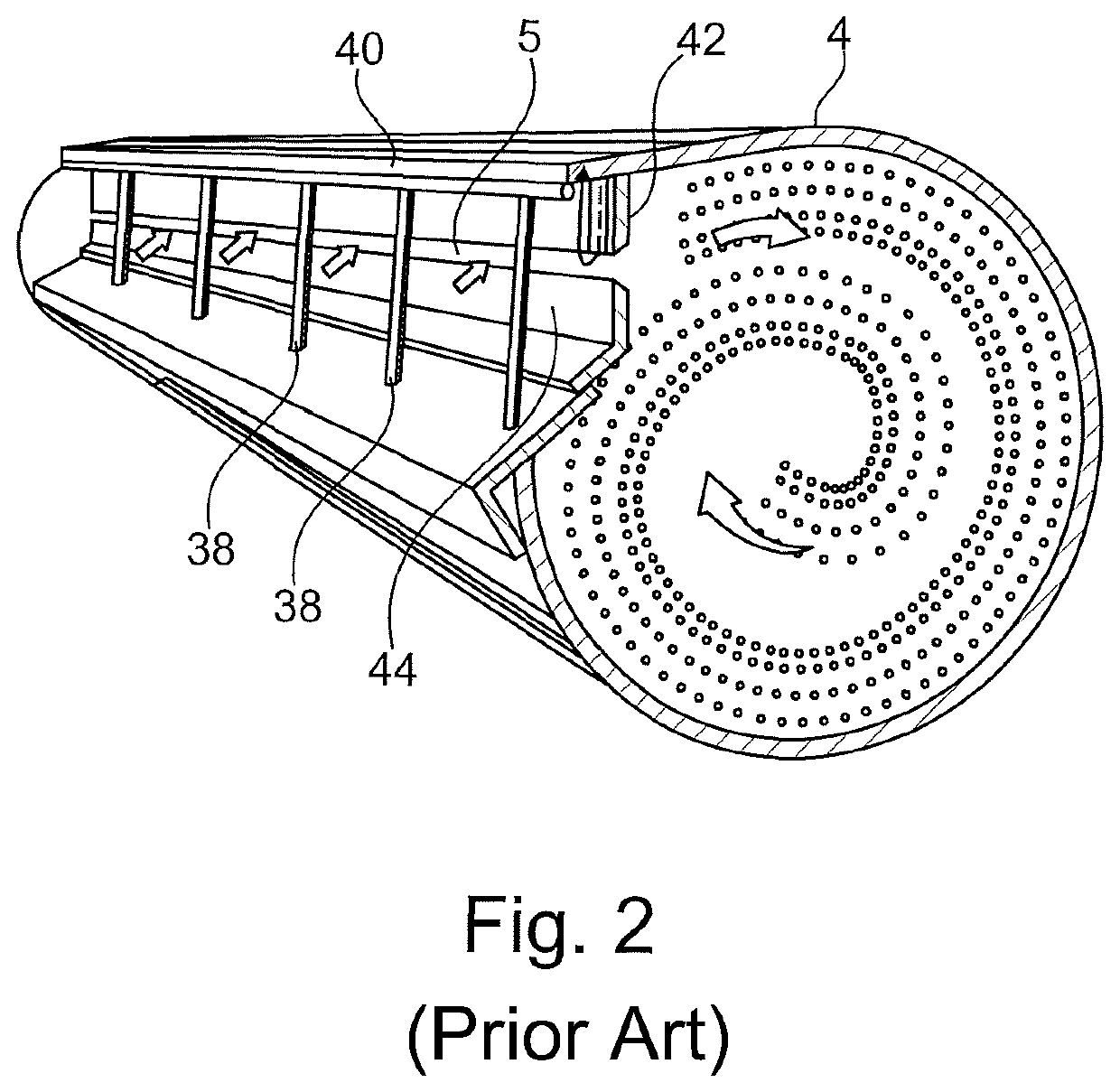

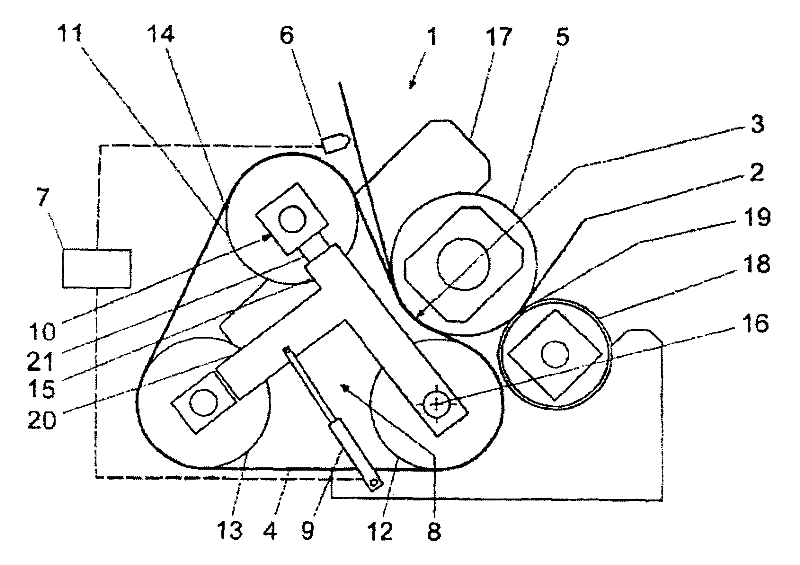

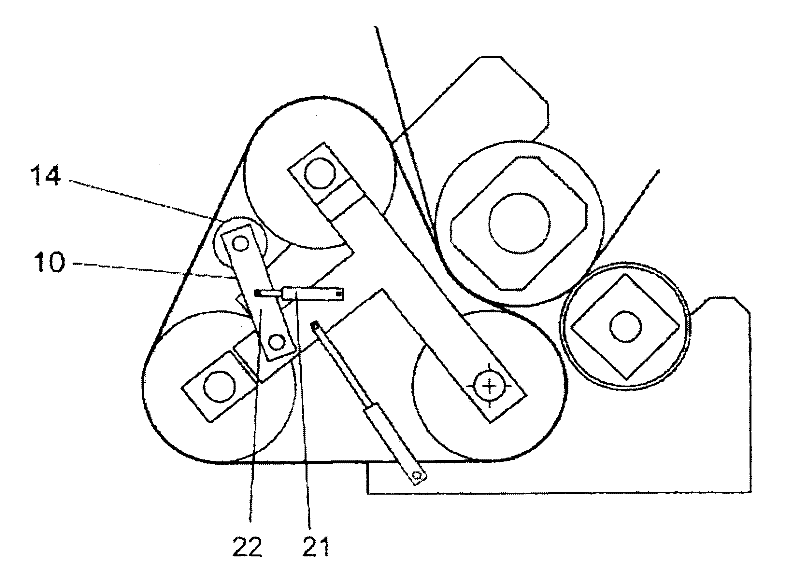

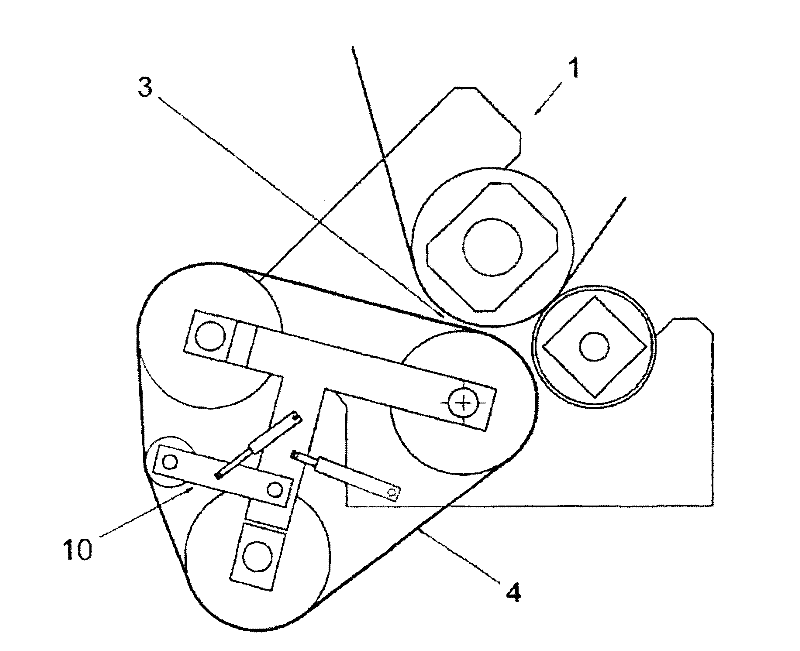

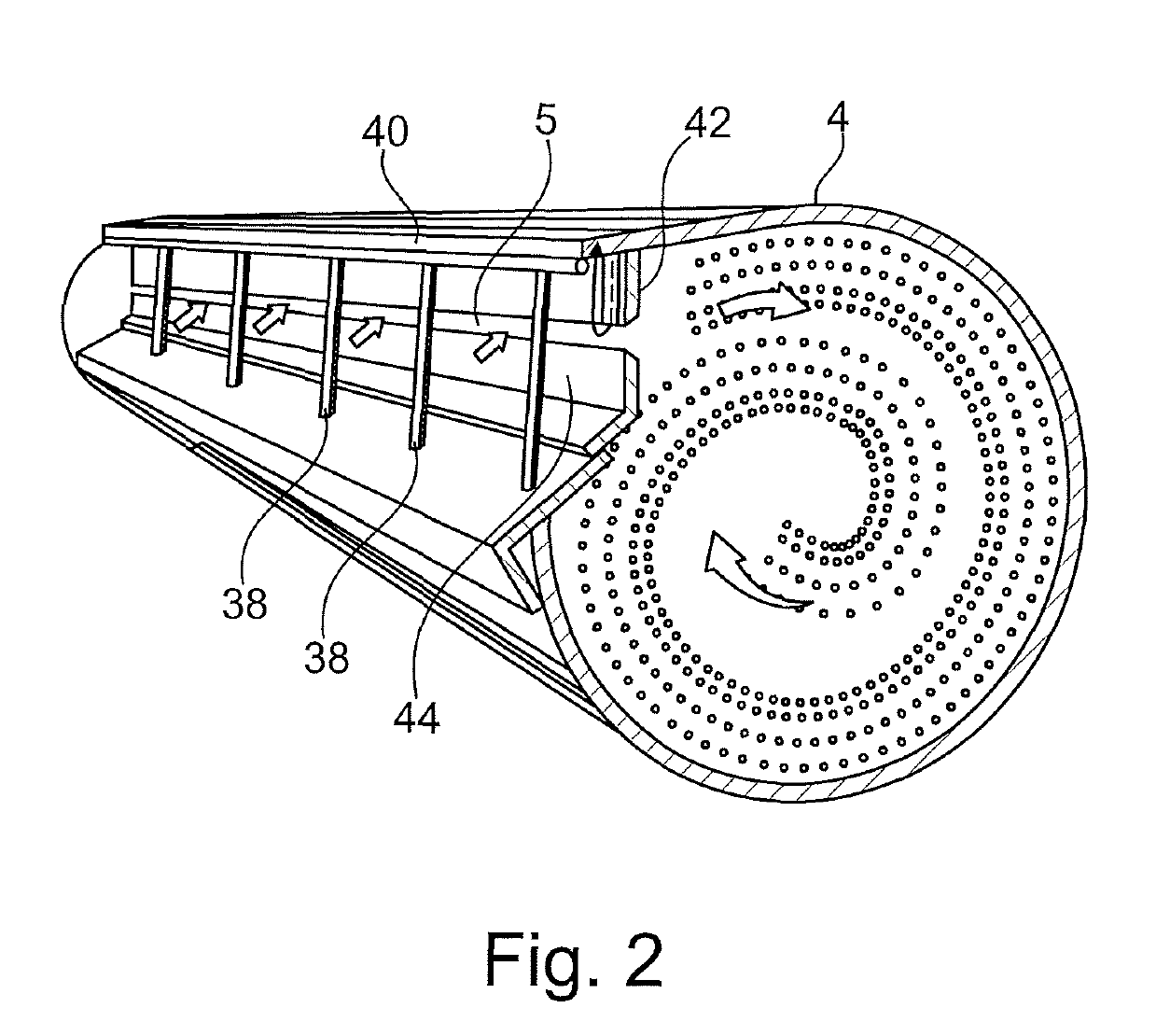

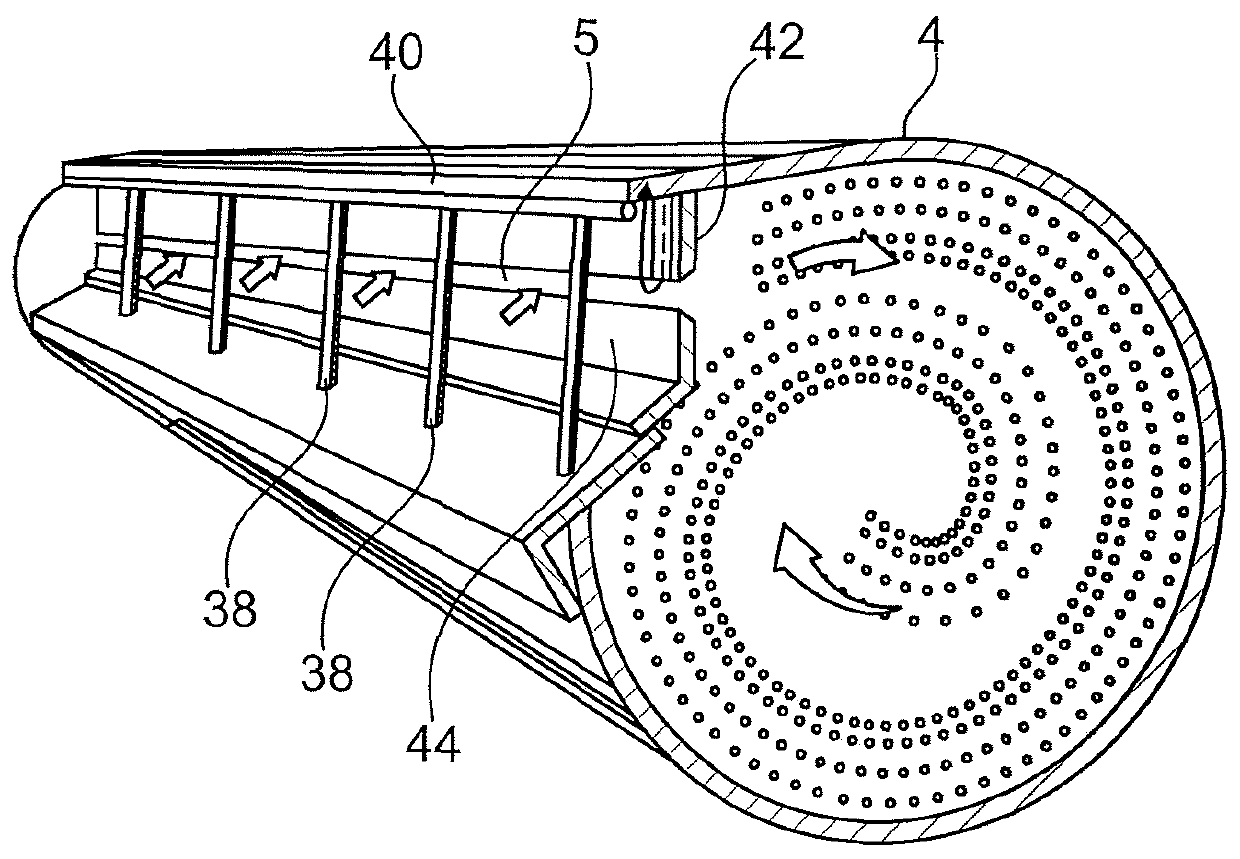

Method and apparatus for opening roller gap

InactiveCN102051838AHigh web qualitySave construction spaceCalendersPress sectionWrinkle skinEngineering

The invention relates to a method and apparatus for opening a roller gap (3) of a belt type calender. The roller gap (3) is formed by a belt (4) circularly enclosing at least two guide rollers (11, 12, 13) and an auxiliary roller (5). The belt (4) clings to the periphery of the auxiliary roller (5) along a winding angle over 5 DEG. A fiber web (2) is used for monitoring crack or wrinkle by means of a sensor (6) in front of the roller gap. When a crack or wrinkle occurs, the sensor (6) sends a signal to a separating device (8) through a controller (7). To create the possibility of the roller gap protecting the belt while being fast separated, the separating device can conduct maneuvering movement on at least one roller gap within 0.9 second during separation process under the maintenance of the belt tension, and the belt (4) can be at a certain distance from the auxiliary roller (5) after the separation process.

Owner:VOITH PATENT GMBH

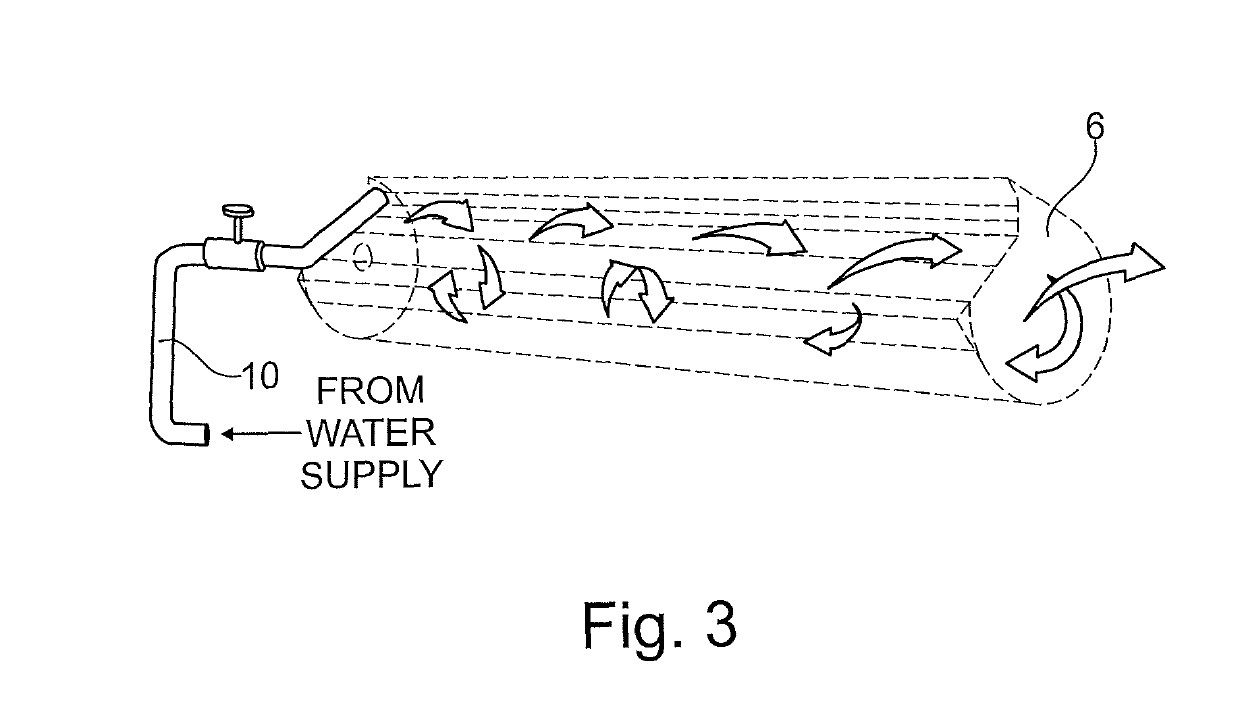

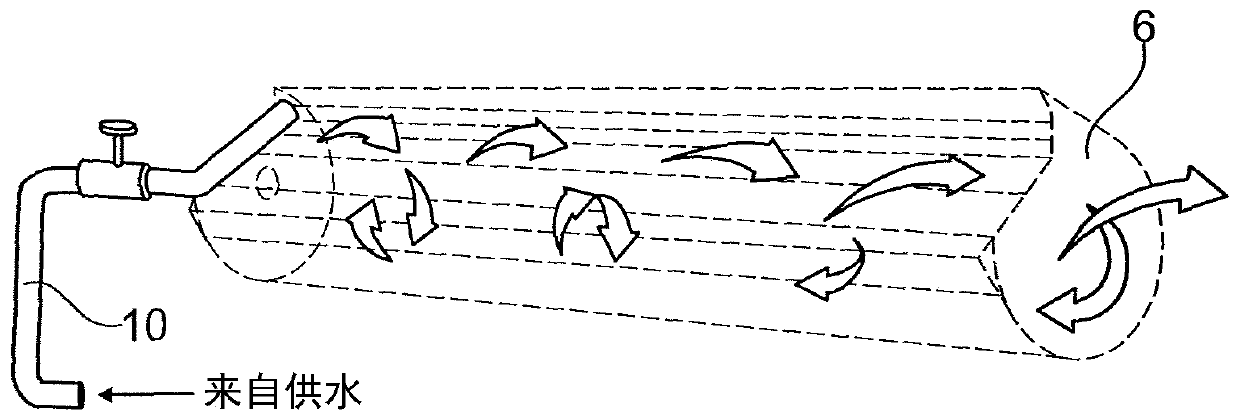

System and a method for collecting and handling dust in a paper-making environment

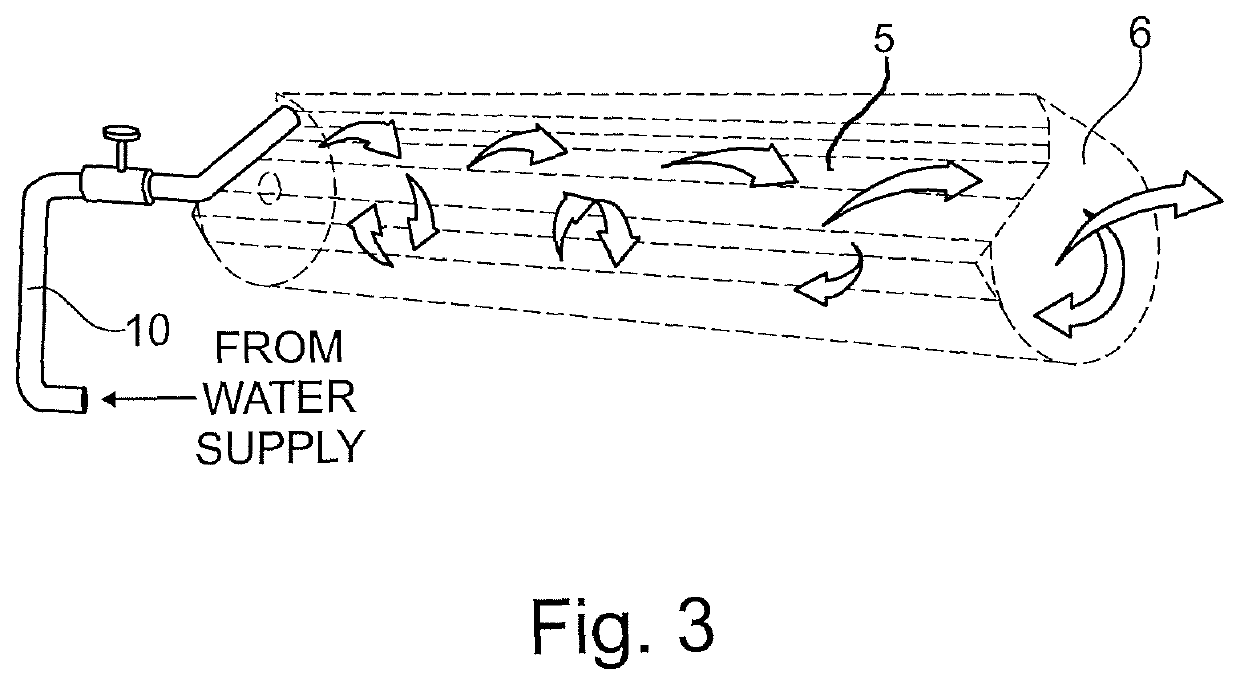

The invention relates to a system (1) and a method for collecting and handling dust in a paper-making environment. The system (1) comprises a source of underpressure (2) and an elongated collector (4) that extends along a longitudinal axis and which elongated collector (4) is connected to the source of underpressure (2) through at least one suction duct (7) such that underpressure can be generated inside the elongated collector (4). The elongated collector (4) has an inlet (5) through which dust-laden air can enter the elongated collector (4) and an exit opening (6) leading to the suction duct (7) through which exit opening (6) dust-laden air can be evacuated from the elongated collector (4). A source of water (8) is connected by at least one water supply duct (10) to the elongated collector (4) such that water from the source of water (8) can be introduced into the elongated collector so that dust in the dust-laden air can be exposed to and mix with the water introduced into the elongated collector (4). A flow meter (12) is functionally connected to the system (1) to measure at least one of a flow of water from the source of water (8) to the elongated collector (4) or a flow of water exiting from the elongated collector (4) through the exit opening (6) of the elongated collector (4) and arranged to send a signal indicating a numerical value for a flow of water that reaches or leaves the elongated collector (4) such that this value can be compared to a predetermined minimum value. The system is used to carry out the inventive method.

Owner:VALMET S P A IT

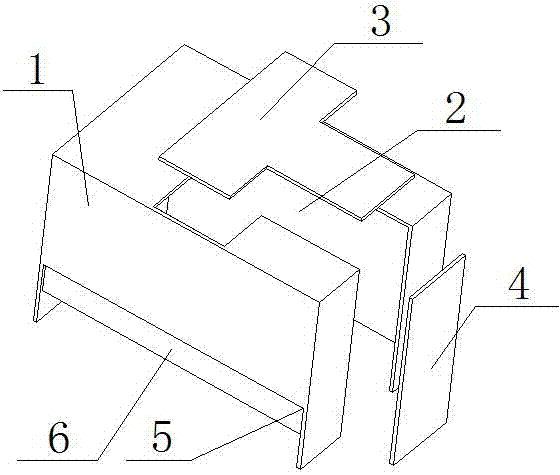

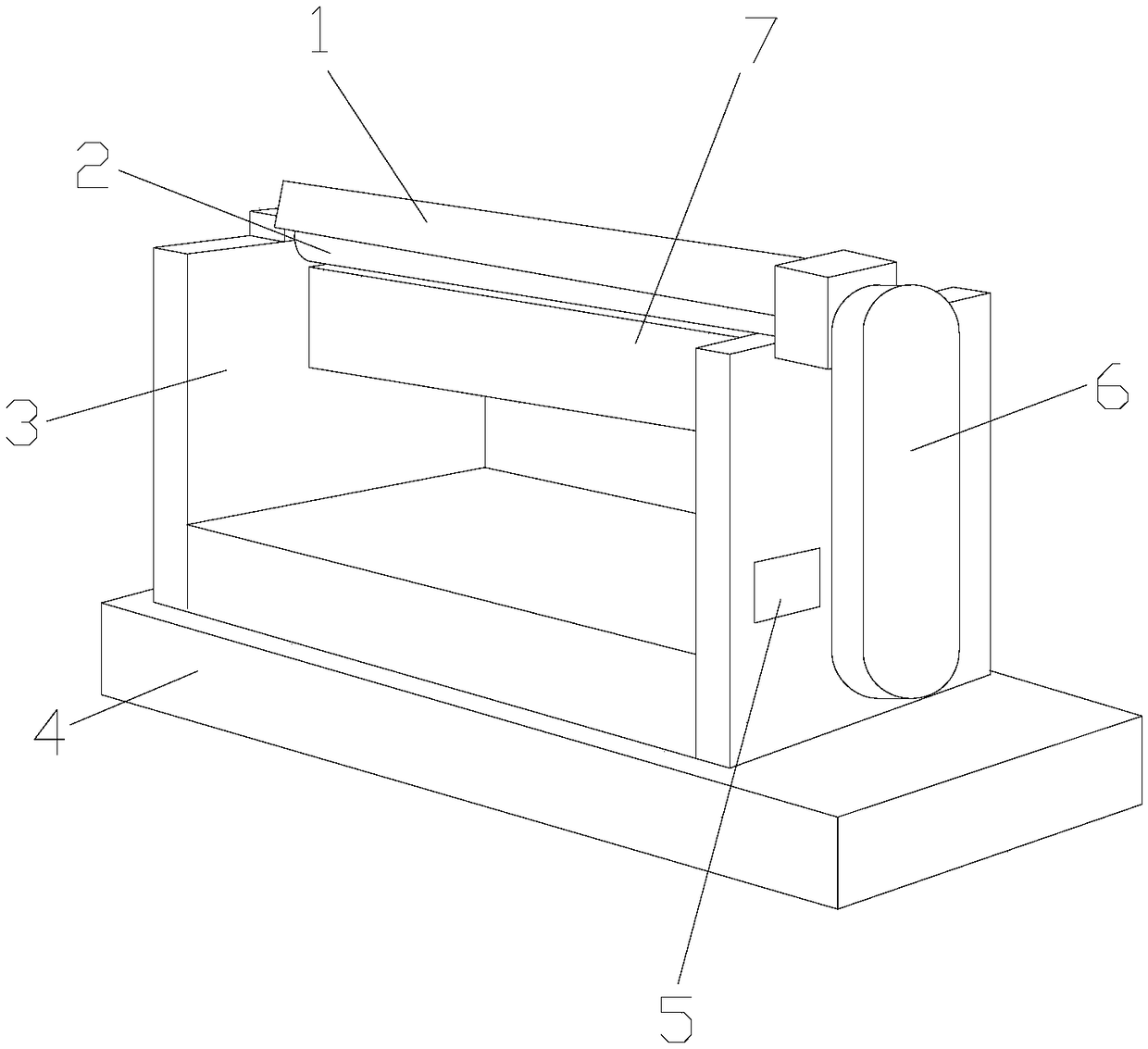

Outer protective cover of drying cylinder glue applicator

PendingCN107460762AEasy to liftEasy to moveSafety devices for paper-making machinesStructural engineeringHeavy equipment

The invention discloses an outer protective cover of a drying cylinder glue applicator, and belongs to the technical field of papermaking machinery. By the aid of the outer protective cover, the technical problems of incapability of quickly shifting existing glue applicators in or out of protective covers, tedious glue applicator breakdown maintenance working procedures, heavy equipment and influence on maintenance progress in the prior art can be solved. The technical scheme includes that a T-shaped open groove I is formed in the top of an outer protective cover body, and a T-shaped seal plate is movably arranged in the T-shaped open groove I; an opening door is arranged in the center of a side surface of the outer protective cover body, and the top of the opening door is correspondingly connected with the T-shaped open groove I; an open groove II is formed in the bottom of a side surface of the outer protective cover body, and a lifting cover wall which is matched with the open groove II is arranged at the open groove II. The outer protective cover has the advantages that the glue applicator can be quickly shifted in or out of the outer protective cover, accordingly, maintenance can be facilitated, and leakage can be prevented.

Owner:山东天和纸业有限公司

A system and a method for collecting and handling dust in a paper-making environment

The invention relates to a system (1) and a method for collecting and handling dust in a paper-making environment. The system (1) comprises a source of underpressure (2) and an elongated collector (4)that extends along a longitudinal axis and which elongated collector (4) is connected to the source of underpressure (2) through at least one suction duct (7) such that underpressure can be generatedinside the elongated collector (4). The elongated collector (4) has an inlet (5) through which dust-laden air can enter the elongated collector (4) and an exit opening (6) leading to the suction duct(7) through which exit opening (6) dust-laden air can be evacuated from the elongated collector (4). A source of water (8) is connected by at least one water supply duct (10) to the elongated collector (4) such that water from the source of water (8) can be introduced into the elongated collector so that dust in the dust-laden air can be exposed to and mix with the water introduced into the elongated collector (4). A flow meter (12) is functionally connected to the system (1) to measure at least one of a flow of water from the source of water (8) to the elongated collector (4) or a flow of water exiting from the elongated collector (4) through the exit opening (6) of the elongated collector (4) and arranged to send a signal indicating a numerical value for a flow of water that reaches orleaves the elongated collector (4) such that this value can be compared to a predetermined minimum value. The system is used to carry out the inventive method.

Owner:VALMET AB

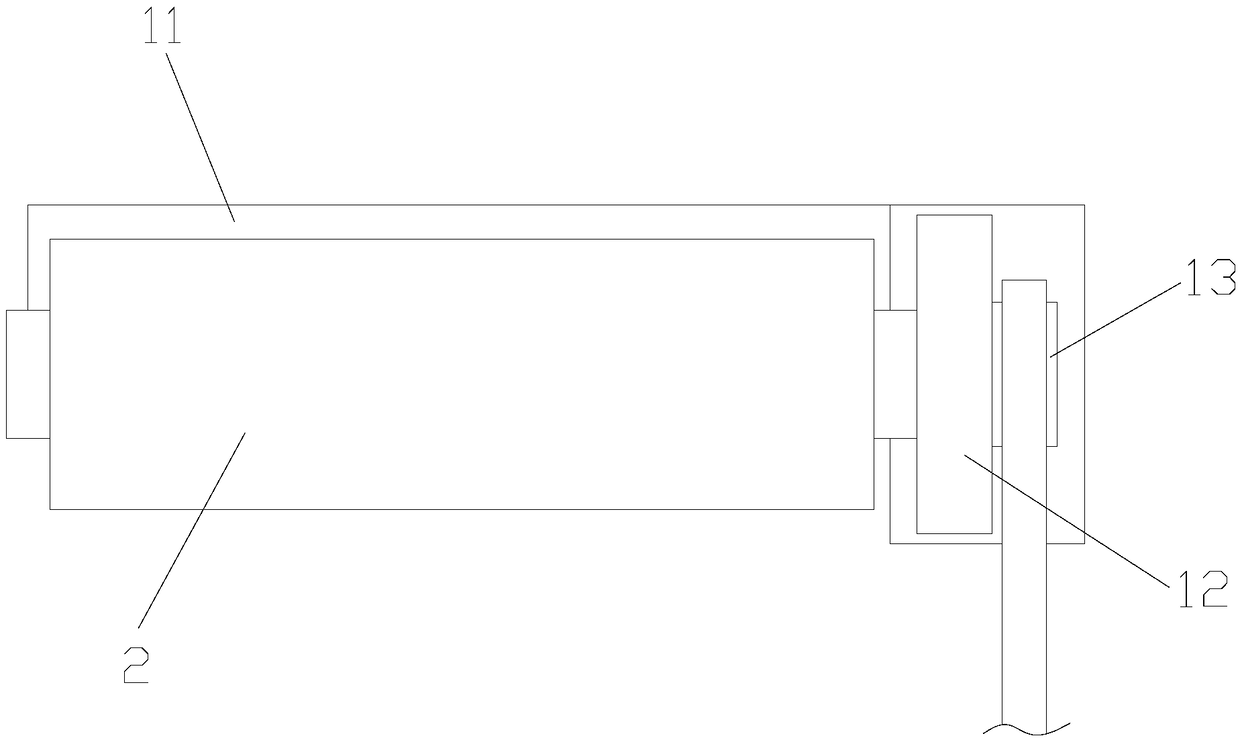

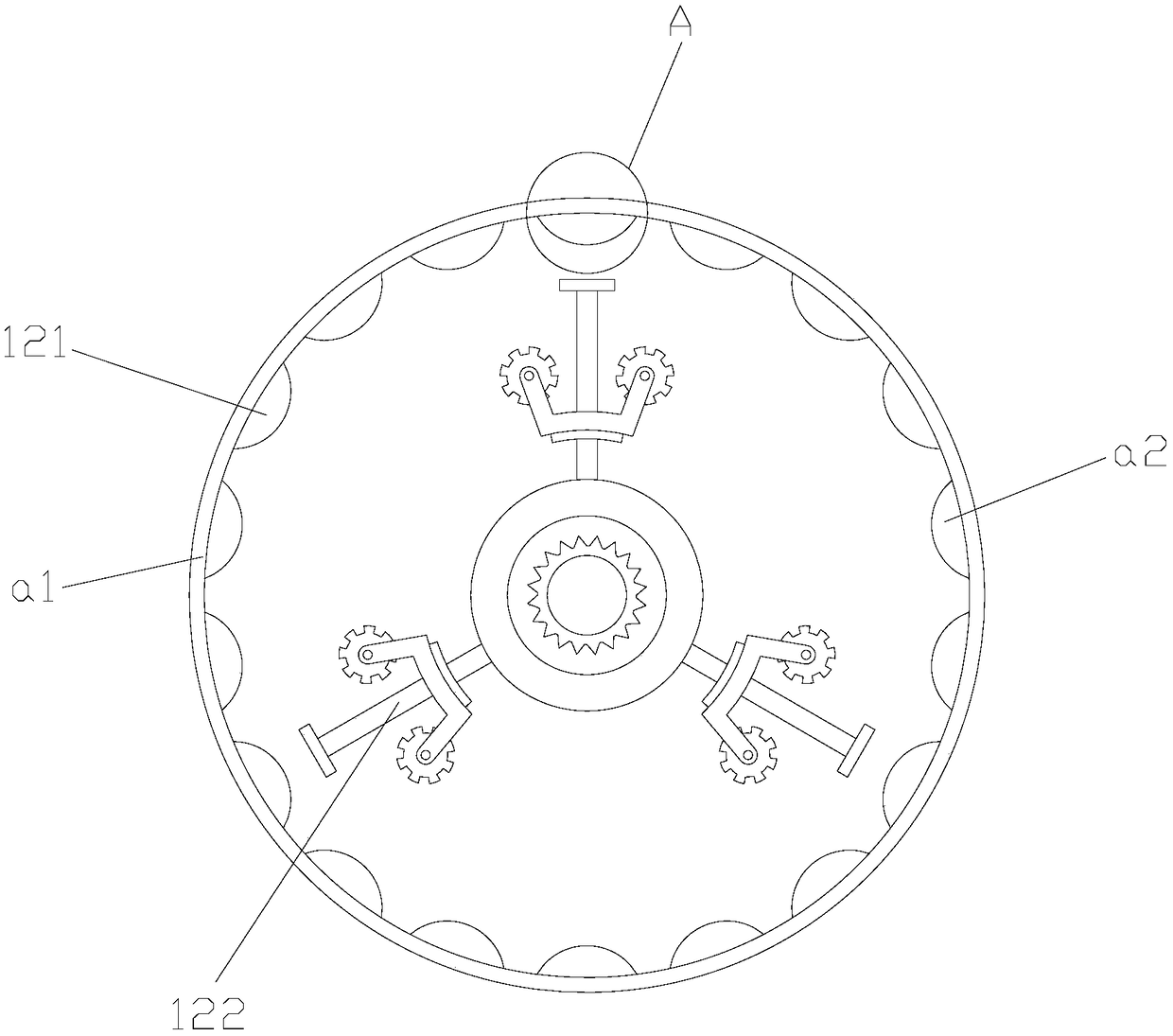

Roller protection device based on centrifugal deceleration for paper machines

InactiveCN109183492AQuality assuranceExtended service lifePress sectionSafety devices for paper-making machinesConveyor beltResistance force

The invention discloses a roller protection device based on centrifugal deceleration for paper machines. The roller protection device includes a protection structure, a paper machine pressure roller,a pressure roller support frame, a fixed base, a pulse controller, a conveyor belt protection cover and a compression block. The roller protection device is equipped with an over-speed protector. Through a deceleration mechanism and a centrifugal drive structure, when the drive speed of the motor is too high, the over-speed protector can produce resistance to reduce the speed and ensure that the paper machine pressure roller works at a safe speed. Thus, the surface of the paper machine pressure roller after high-speed rotation is prevented from deforming by heat, the paper machine pressure roller is prevented from falling off due to shaking during rotation, the quality of paper dehydrated by the pressure roller is ensured, and the service life of the paper machine is prolonged.

Owner:吴斌

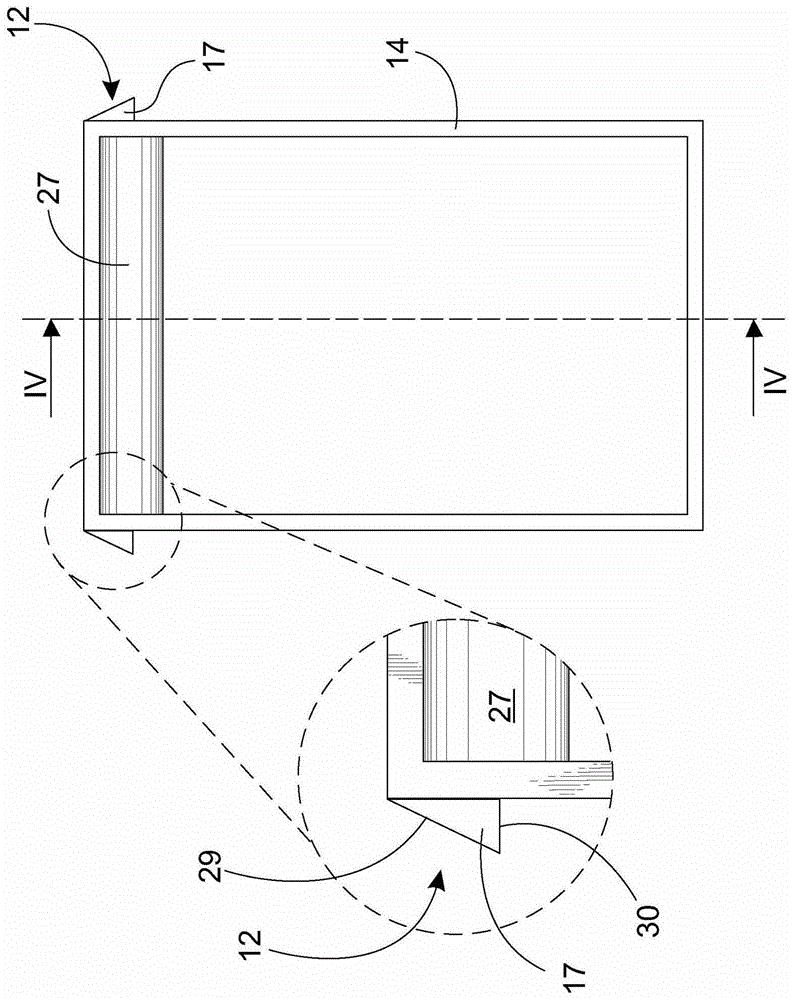

Service platform arrangement for a fiber web machine

InactiveCN102414368AEffective operabilityEffective maintenanceDryer sectionEngineering safety devicesEngineeringMechanical engineering

The present invention relates to a fiber web machine comprising a service platform arrangement (10) including at least a railing (12) and a walkway (14) disposed in connection with each other. The service platform arrangement has been provided to extend to at least two machine sections essentially at the same horizontal level.

Owner:VALMET TECH OY

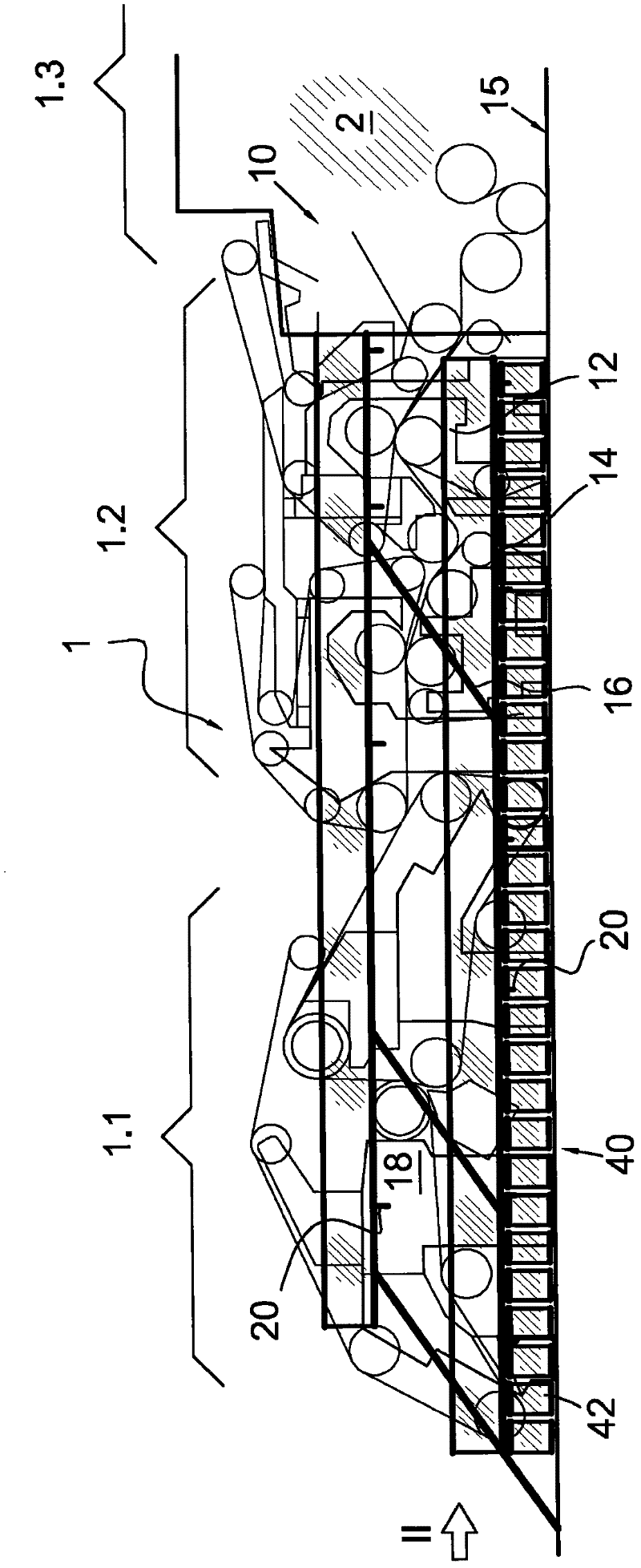

Installation module for a paper or board machine

ActiveUS7749358B2Work lessReduce needPublic buildingsMachine wet endComputer modulePulp and paper industry

A wet end of a paper or board machine has at least one vertical, self-supporting installation module (10a, 10b) to be positioned into connection with the machine which module is supported from its lower end by foundation structures of the machine construction and which extends at least to the height of a second maintenance platform (50b) of the machine, which installation module (10) includes at least valves (40) and pipes (30) related to the hydraulic and / or pneumatic actuators of the machine.

Owner:VALMET TECH INC

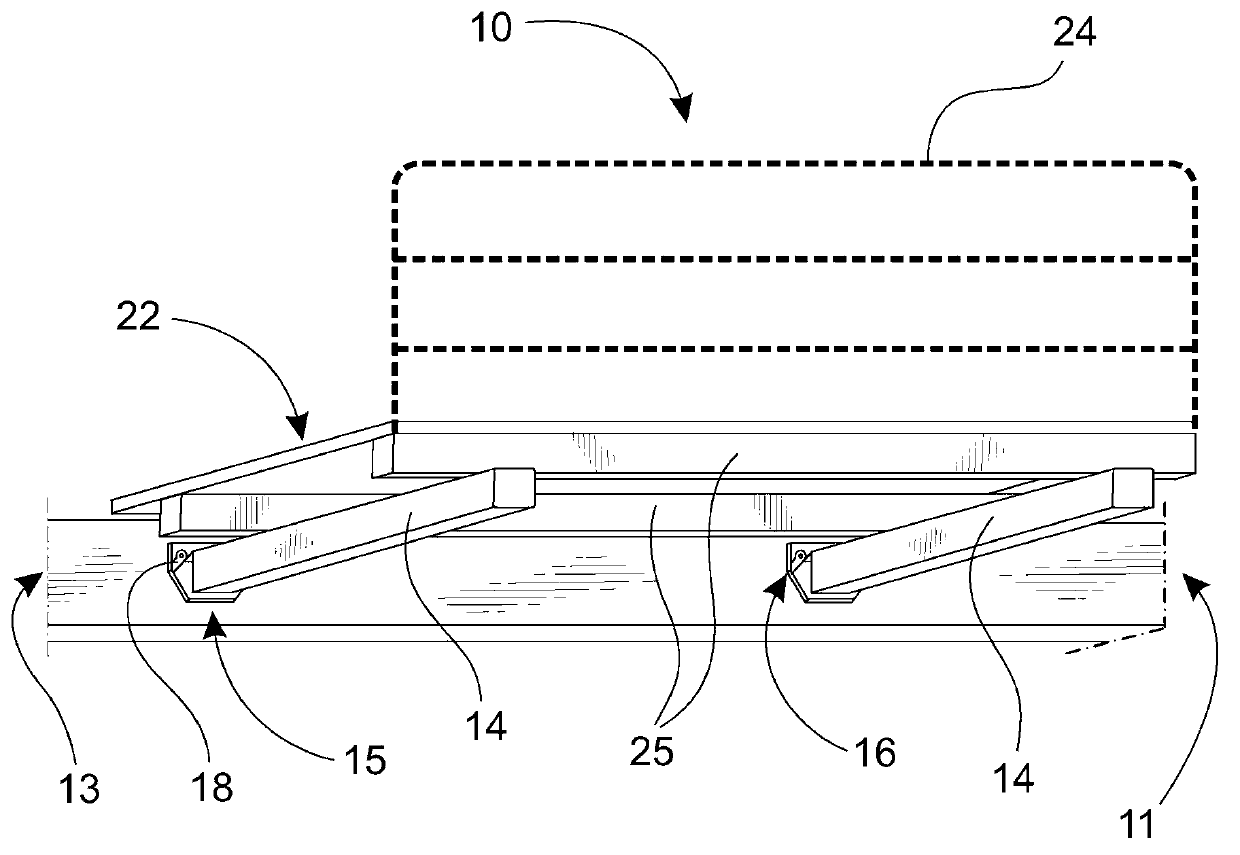

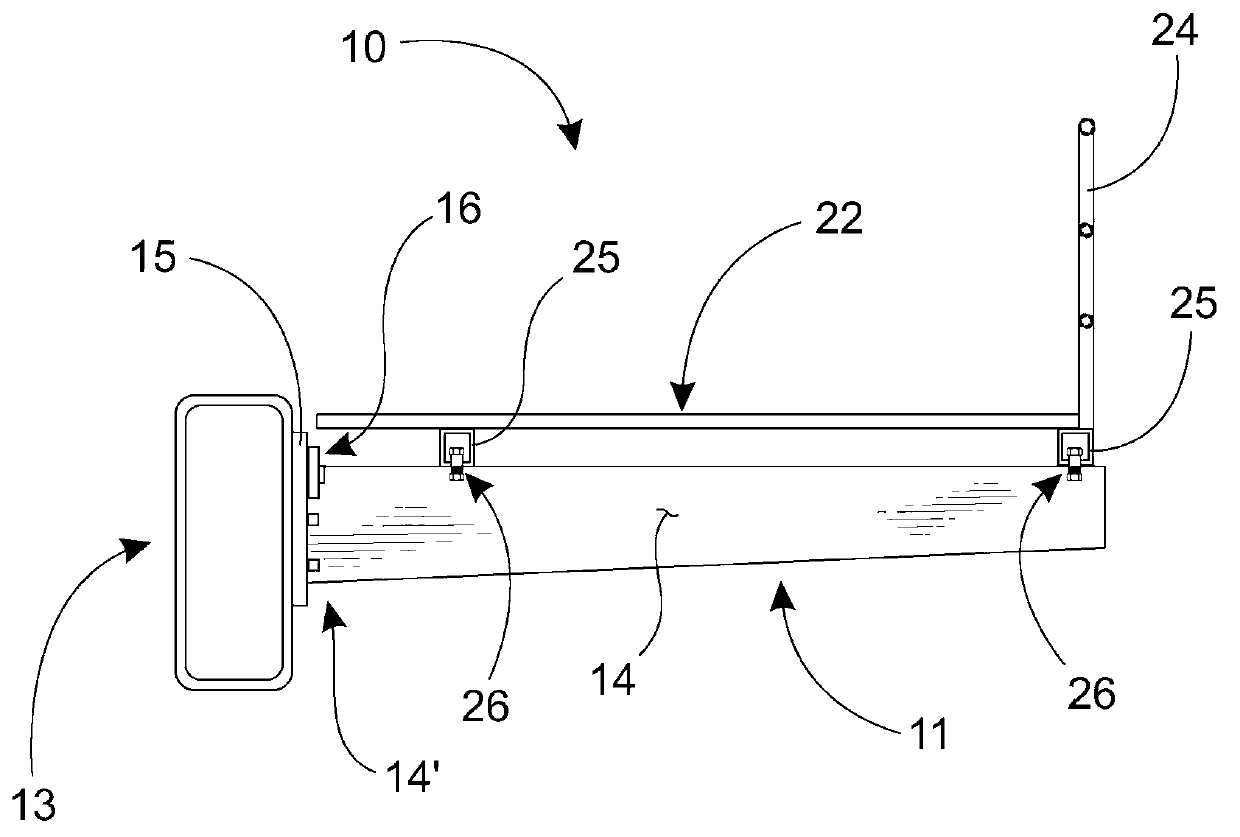

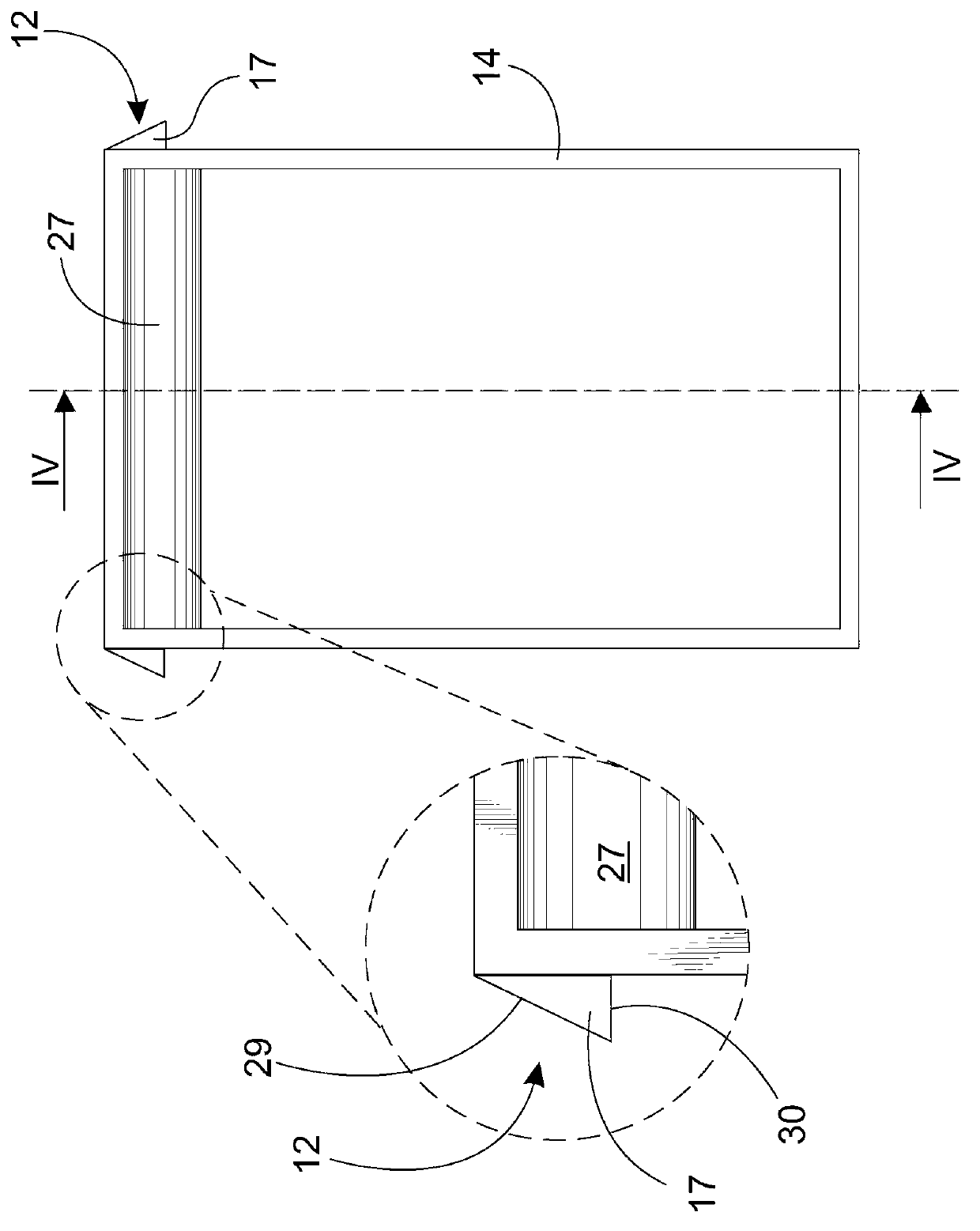

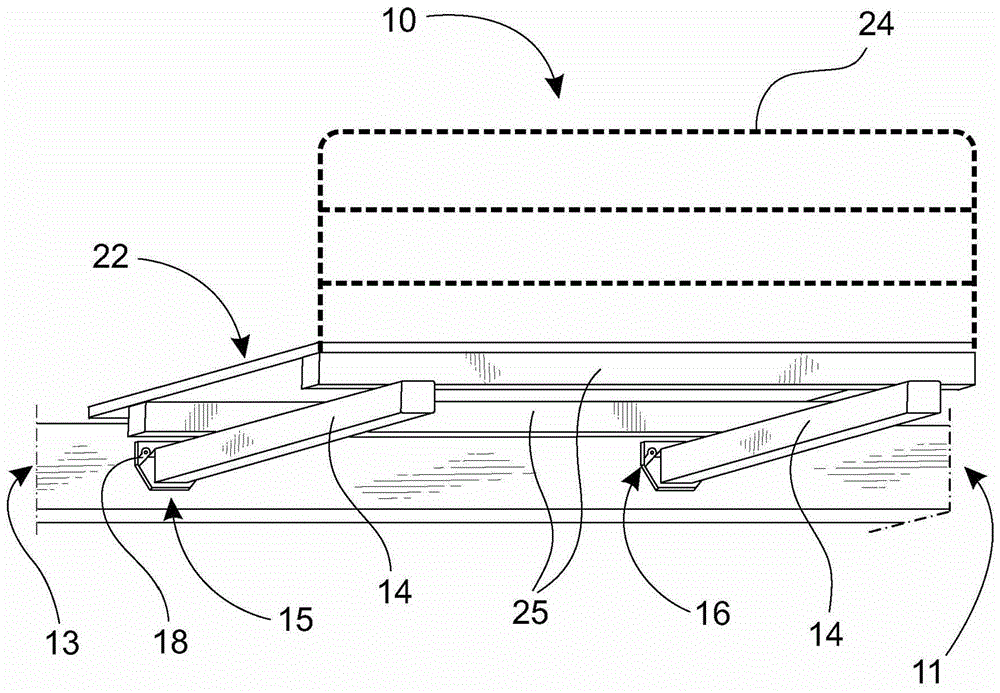

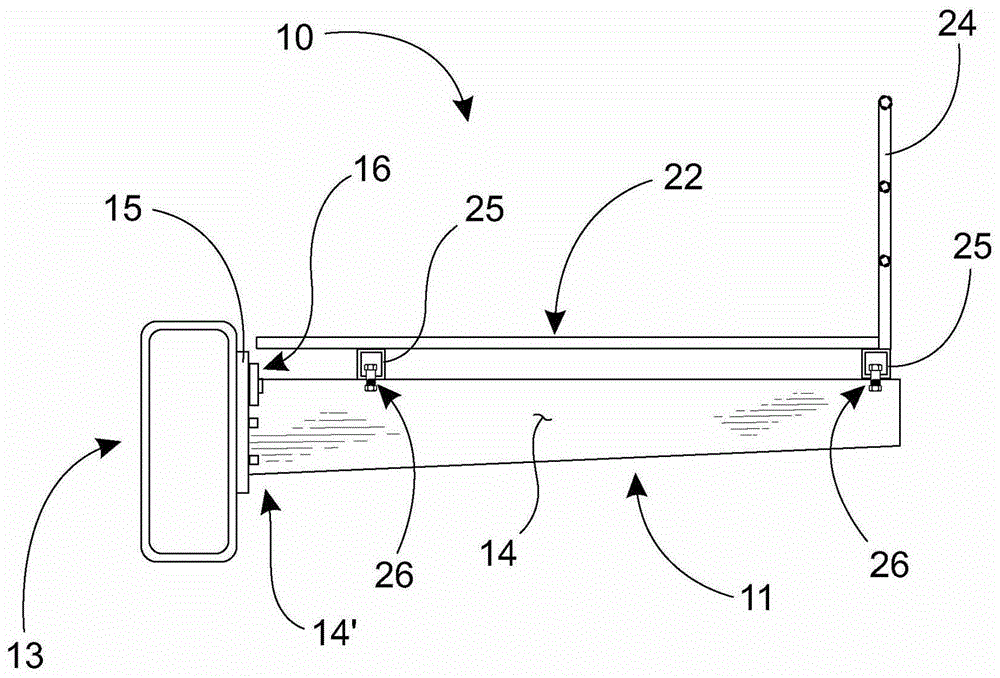

Walking platform, walking platform fixing device and operation method

ActiveCN103132362ADoes not hinder maintenance workEasy to openSafety devices for paper-making machinesFiberEngineering

The invention relates to a walking platform, a walking platform fixing device and an operation method. The device used for fixing the walking platform onto a fiber web material machine comprises a work platform (22) and a support structure (11), wherein the work platform (22) is arranged on the walking platform (10), the support structure (11) is arranged below the work platform (22) and is fixed onto the fiber web material machine (13), the support structure comprises at least a support member (14) which extends in the transverse direction of the fiber web material machine (13), and the support member is used as a part of the walking platform (10). The walking platform (10) and the support member (14) can be detachably fixed onto the fiber web material machine (13). The invention also relates to a walking platform of the fiber web material machine and an operation method applied to connecting the walking platform and the fiber web material machine.

Owner:VALMET TECH OY

Control system for a functional section of a paper processing device

A control system (100) for a functional section (I, II, III) of a paper processing device (140). The control system (100) has at least one safety-monitoring camera (110, 120, 130) which is arranged in the functional section (I, II, III) such that a functional region of the functional section (I, II, III) can be captured by the safety-monitoring camera (110, 120, 130). An operating unit (101) of the system (100) is designed to operate the functional section (I, II, III), and image data of the at least one safety-monitoring camera (110, 120, 130) can be selected by the operating unit (101). A display unit (103) is configured to display the selected image data such that a user allows or blocks the operation of the functional section (I, II, III) based on the displayed image data. A safety device (102) is coupled to the safety-monitoring camera (110, 120, 130) and the operating unit (101), and the safety device (102) receives image data of the safety-monitoring camera (110, 120, 130). The safety device (102) is configured such that the safety device (102) allows or blocks the operation of the functional section (I, II, III) by means of the operating unit (101) on the basis of the received image data of the safety-monitoring camera (110, 120, 130).

Owner:BOBST GRENCHEN

Service platform arrangement for a fiber web machine

InactiveCN102414366BConvenient for daily workEffective movementDryer sectionEngineering safety devicesEngineeringMechanical engineering

Owner:VALMET CHINA CO LTD

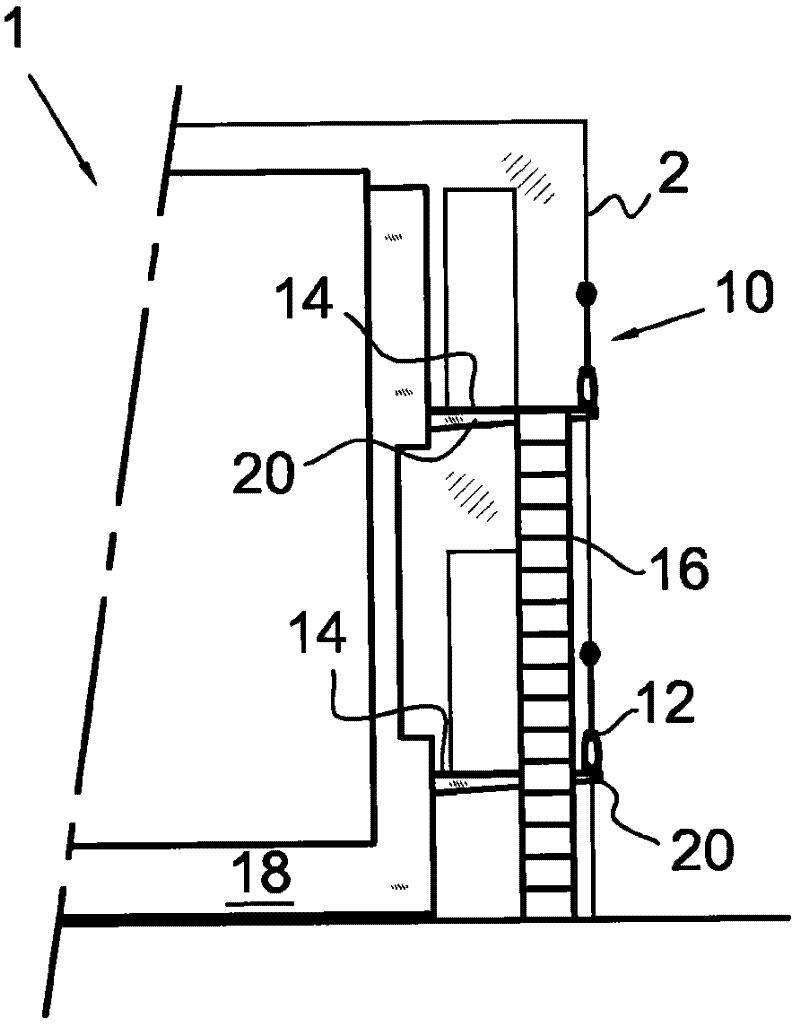

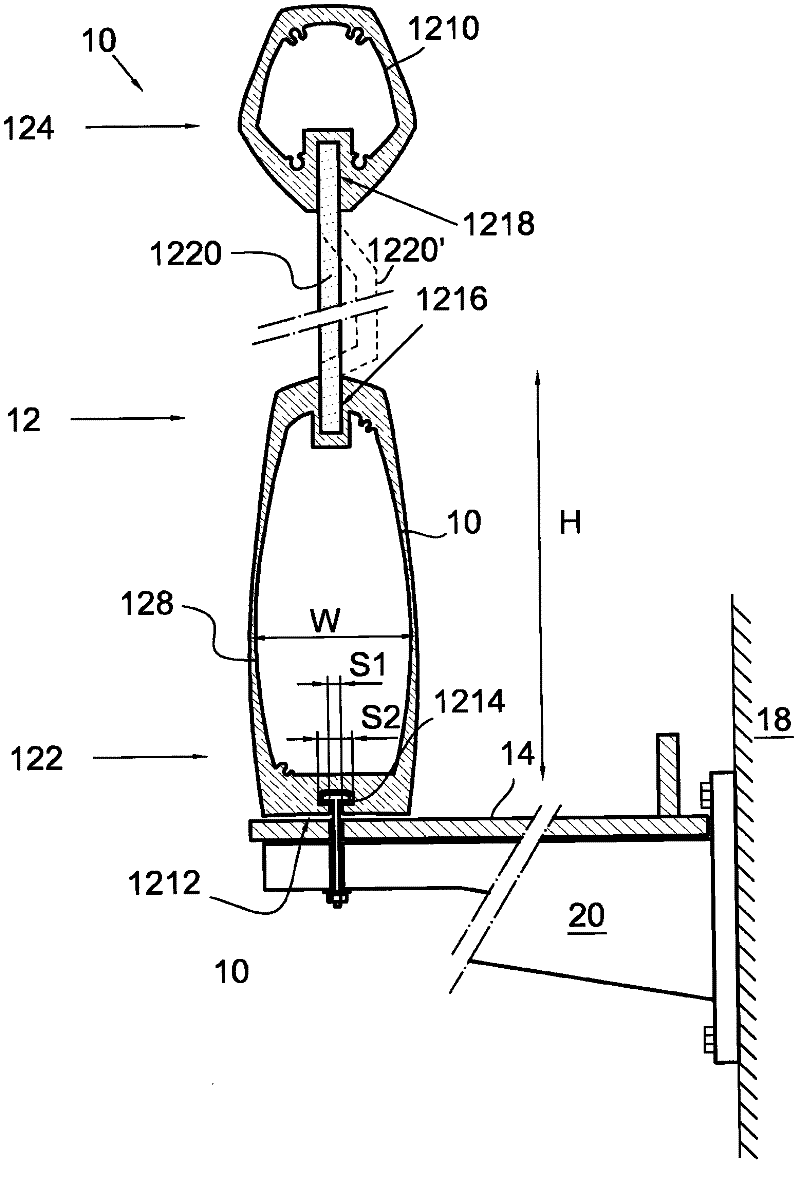

Service platform arrangement for a fiber web machine

InactiveCN102414367AConvenient for daily workEffective movementEngineering safety devicesMachine wet endMechanical engineering

The present invention relates to a service platform arrangement (10) of a fiber web machine, including at least a railing (12) and a walkway (14) disposed in connection with each other. In the service platform arrangement the railing (12) is a so-called supporting structure and the walkway (14) has been supported to the railing.

Owner:VALMET TECH OY

Maintenance platform arrangement for a fiber web machine

InactiveCN102414367BConvenient for daily workEffective movementEngineering safety devicesMachine wet endFiberEngineering

The present invention relates to a service platform arrangement (10) of a fiber web machine, including at least a railing (12) and a walkway (14) disposed in connection with each other. In the service platform arrangement the railing (12) is a so-called supporting structure and the walkway (14) has been supported to the railing.

Owner:VALMET TECH OY

Installation Module for a Paper or Board Machine

ActiveUS20100139882A1Easy to changeShorten the lengthPublic buildingsMachine wet endPulp and paper industryPneumatic actuator

A wet end of the machine comprises at least one vertical, self-supporting installation module (10a, 10b) to be positioned into connection with the machine which module is supported from its lower end by foundation structures of the machine construction and which extends at least to the height of a second maintenance platform (50b) of the machine, which installation module (10) includes at least valves (40) and pipes (30) related to the hydraulic and / or pneumatic actuators of the machine.

Owner:VALMET TECH INC

Roll stand assembly

ActiveUS9139393B2Avoid changePrevent movementEngineering safety devicesSafety devices for paper-making machinesEngineeringMechanical engineering

Owner:PROCESSING TECH INT

Gangway

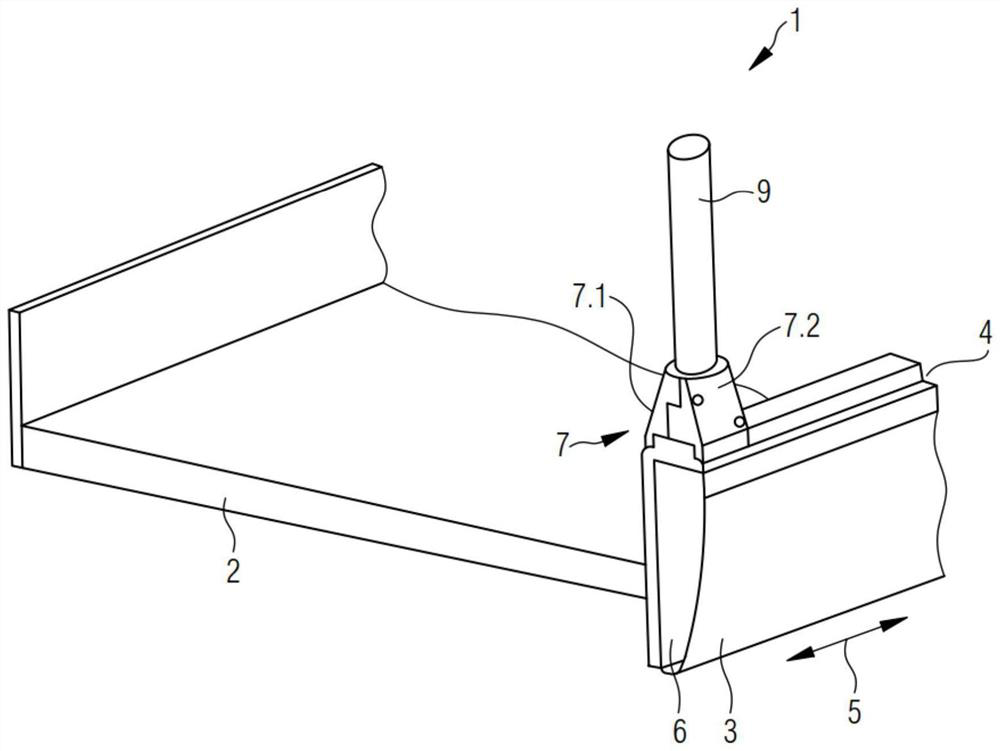

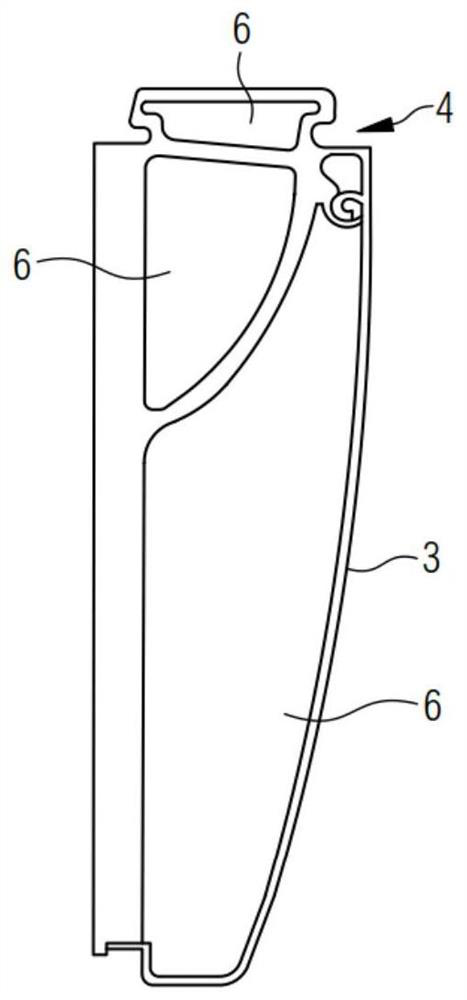

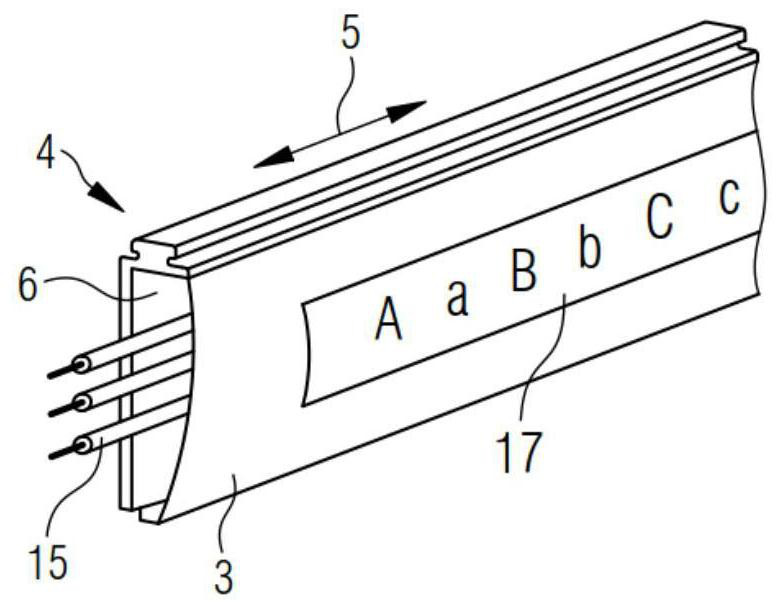

ActiveCN111851116AImprove securityImprove tidinessBalustradesSafety devices for paper-making machinesMachineGangway

The invention relates to a walkway (1) for mounting on a machine, comprising a walkway floor (2), which is connected to a walkway cheek (3), which is preferably designed as a hollow profile, at leaston the boundary side, and which comprises at least one handrail column (9), which is fixed to the handrail. According to the invention, the walkway cheek (3) has a cross-sectional profile (4) on its upward facing side, preferably extending over the entire length in the longitudinal direction (5) of the walkway cheek (3), for slidable, form-fitting connection to at least one clamping element (7) having a complementary profile (8).

Owner:VOITH PATENT GMBH

Walking platform, fixing device and operation method of walking platform

ActiveCN103132362BDoes not hinder maintenance workEasy to openSafety devices for paper-making machinesFiberEngineering

The device has a work platform (22) arranged at a gangway (10). A support block (11) is fixed at a fiber web machine (13) and located under the work platform. The support block comprises carriers (14) that are formed as a part of the gangway. The carriers are extended along transverse direction of the fiber web machine. The gangway and the carriers are releasably fixed at the fiber web machine. A quick lock unit is arranged at the fiber web machine to releasably fasten the gangway at the fiber web machine. The carriers include a fastening set device that is adaptable to a locking unit. An independent claim is also included for a method for handling a gangway connected with a fiber web machine.

Owner:VALMET TECH OY

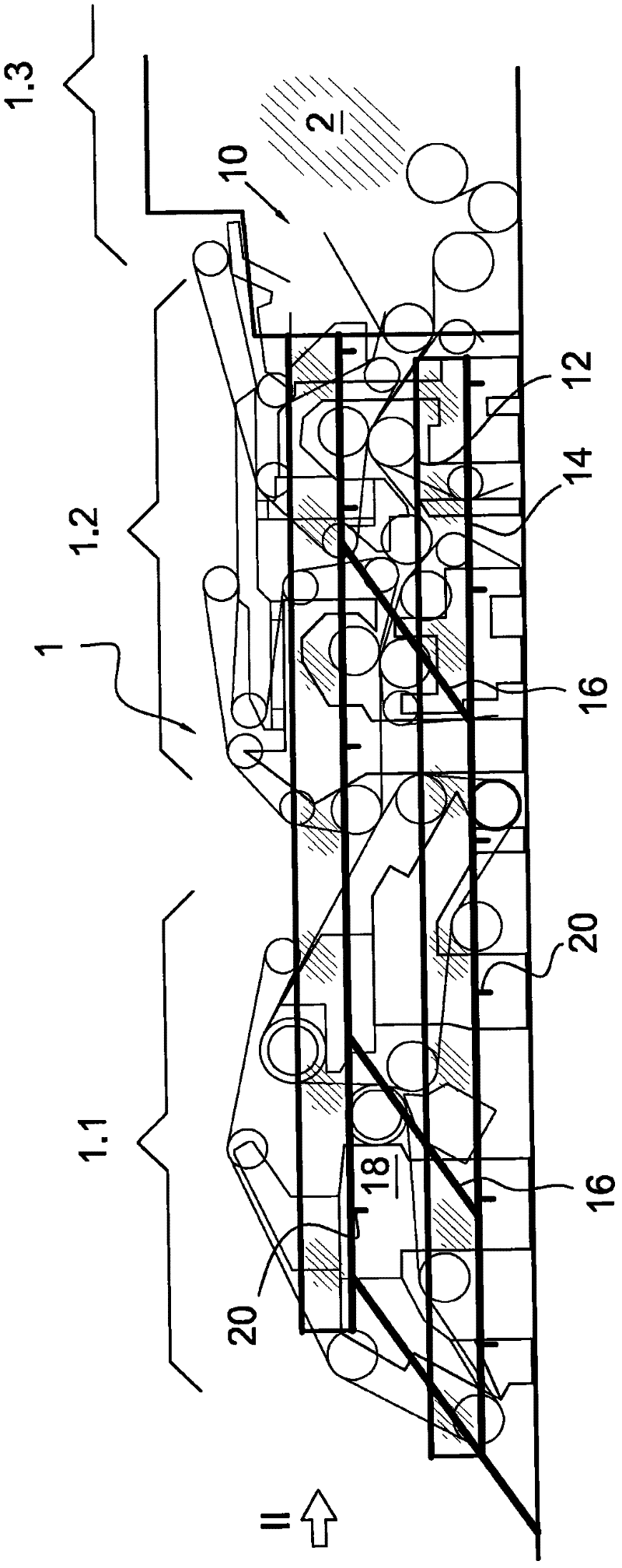

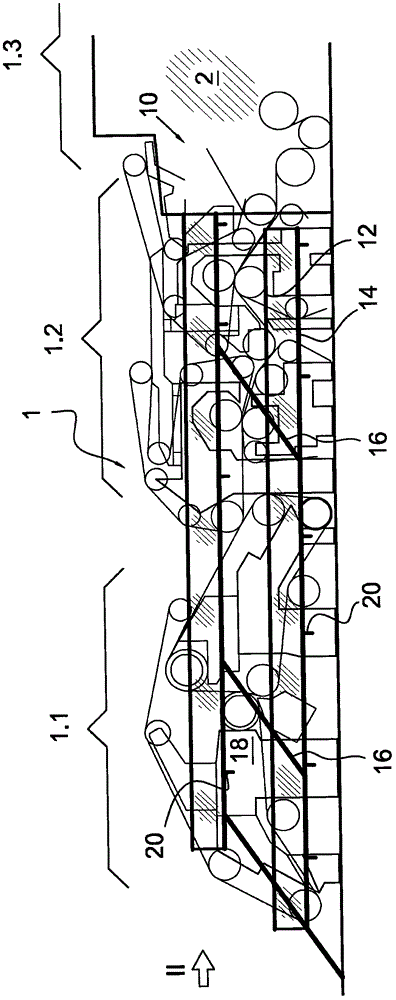

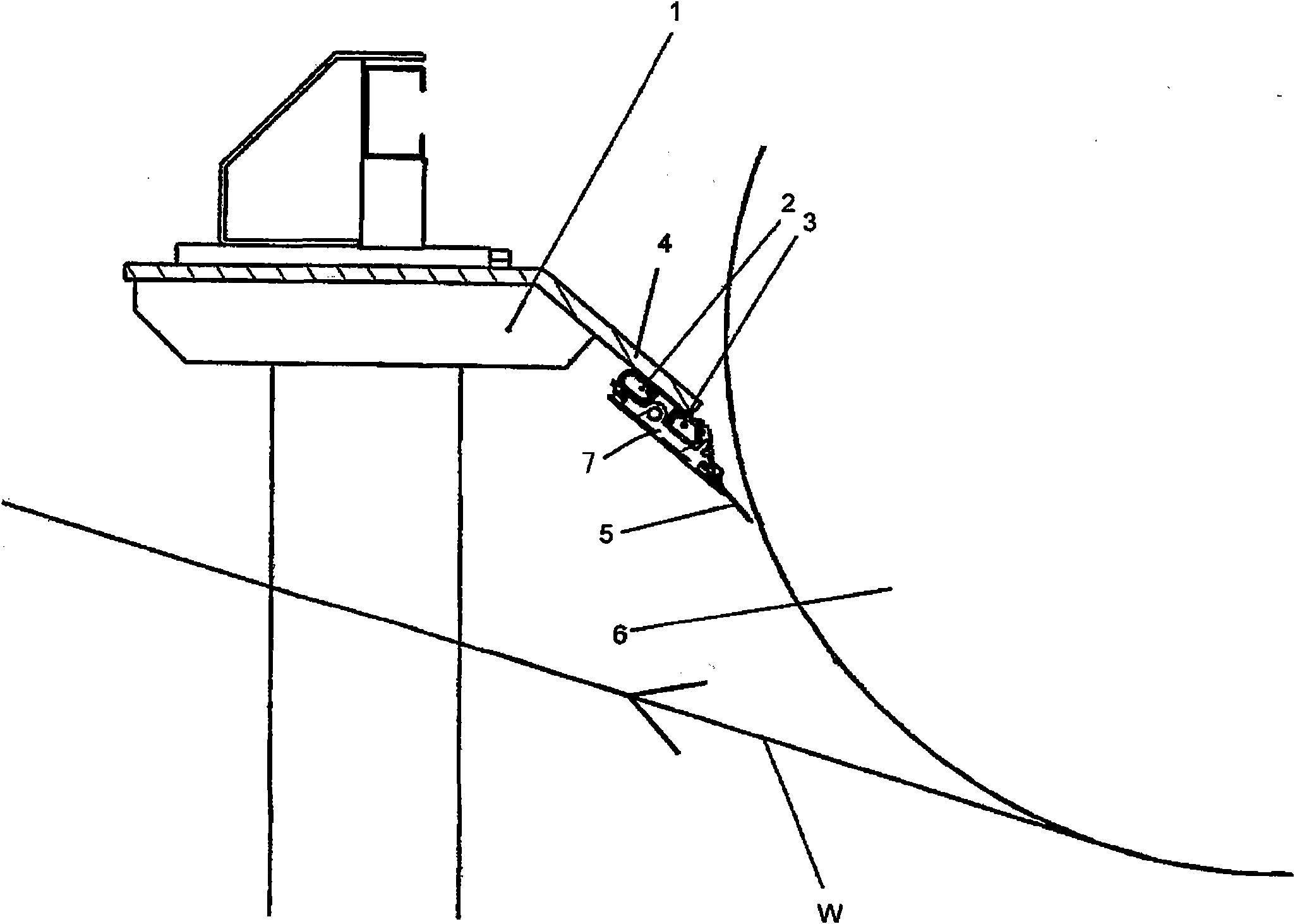

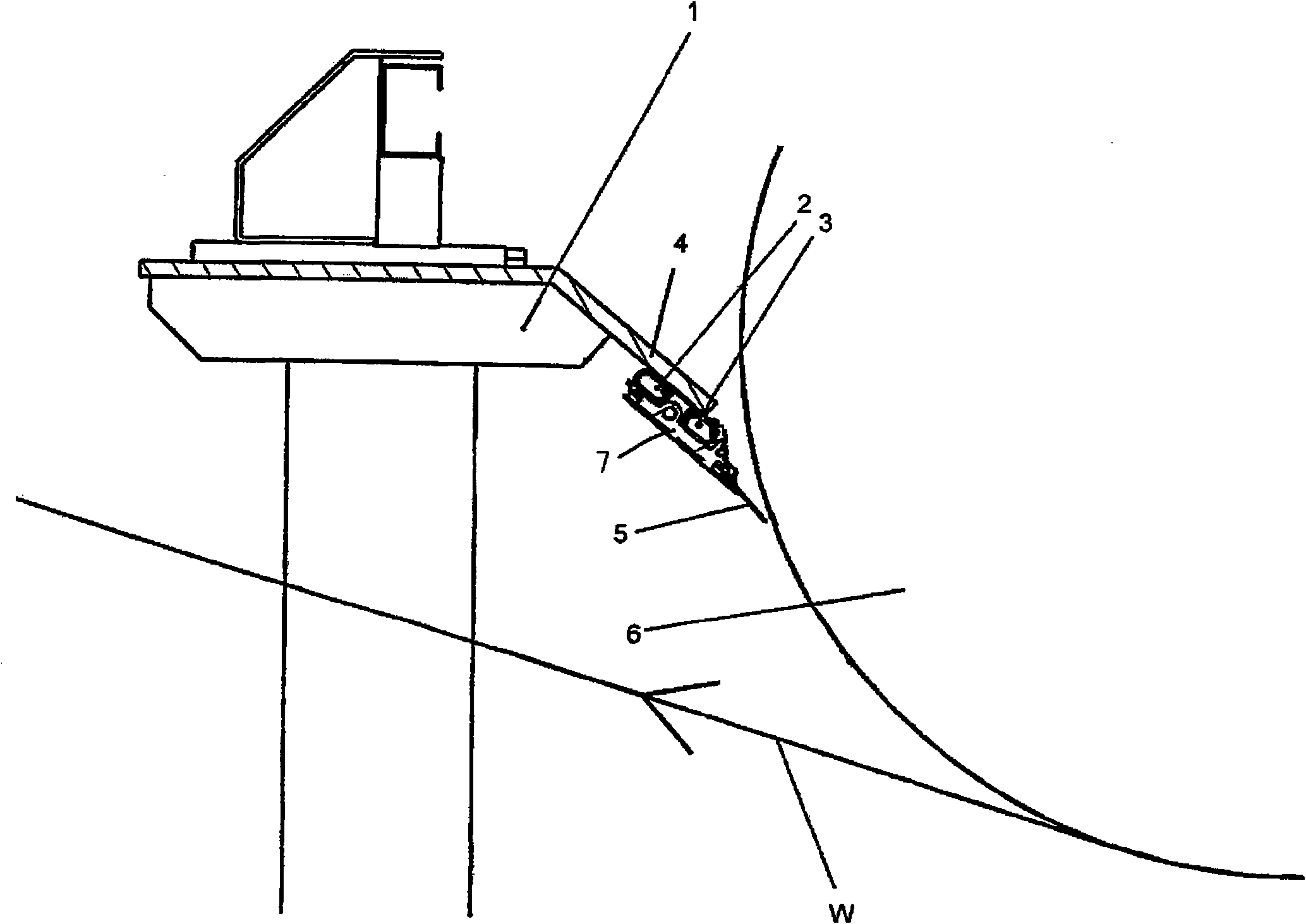

Arrangement of paper-/tissue paper-/cardboard- or after-treatment machine

The present invention relates to an arrangement for guiding a fiber web (W) to be handled from a surface of a roller or belt cycle during normal operation in a paper- / tissue paper- / cardboard- or after-treatment machine so as to prevent the fiber web from winding around the roller or the belt cycle. The arrangement has a scraper-type blade (5) extending in a transverse direction of the roller (6) or metal belt cycle and detachably arranged in a surface of the roller or belt cycle during normal operation of the fiber web (W). The blade has pressure pipes (2, 3) for guiding the fiber web (W) using rapid-motion against the surface of the roller (6) or belt cycle.

Owner:METSO PAPER INC

Paper or board machine

InactiveCN101155959BReduce workloadShorten the timeMachine wet endSafety devices for paper-making machinesPaper machine

The wet end of the paper machine comprises at least one passage space (100) which extends from a tending side (HP) of the machine to a drive side (KP) of the machine and is closed in a machine direction, and inside which operating staff can walk in an operating situation safely and protected from ambient conditions between the tending side (HP) of the machine and the drive side (KP) of the machine.

Owner:METSO PAPER INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com