Roller protection device based on centrifugal deceleration for paper machines

A protective device and technology for paper machines, applied in the direction of paper-making safety devices, paper machines, paper-making, etc., can solve problems such as damage to paper machines, imperfect technical considerations, entanglement of limbs and clothing, etc., and achieve the effect of extending the quality of paper sheets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

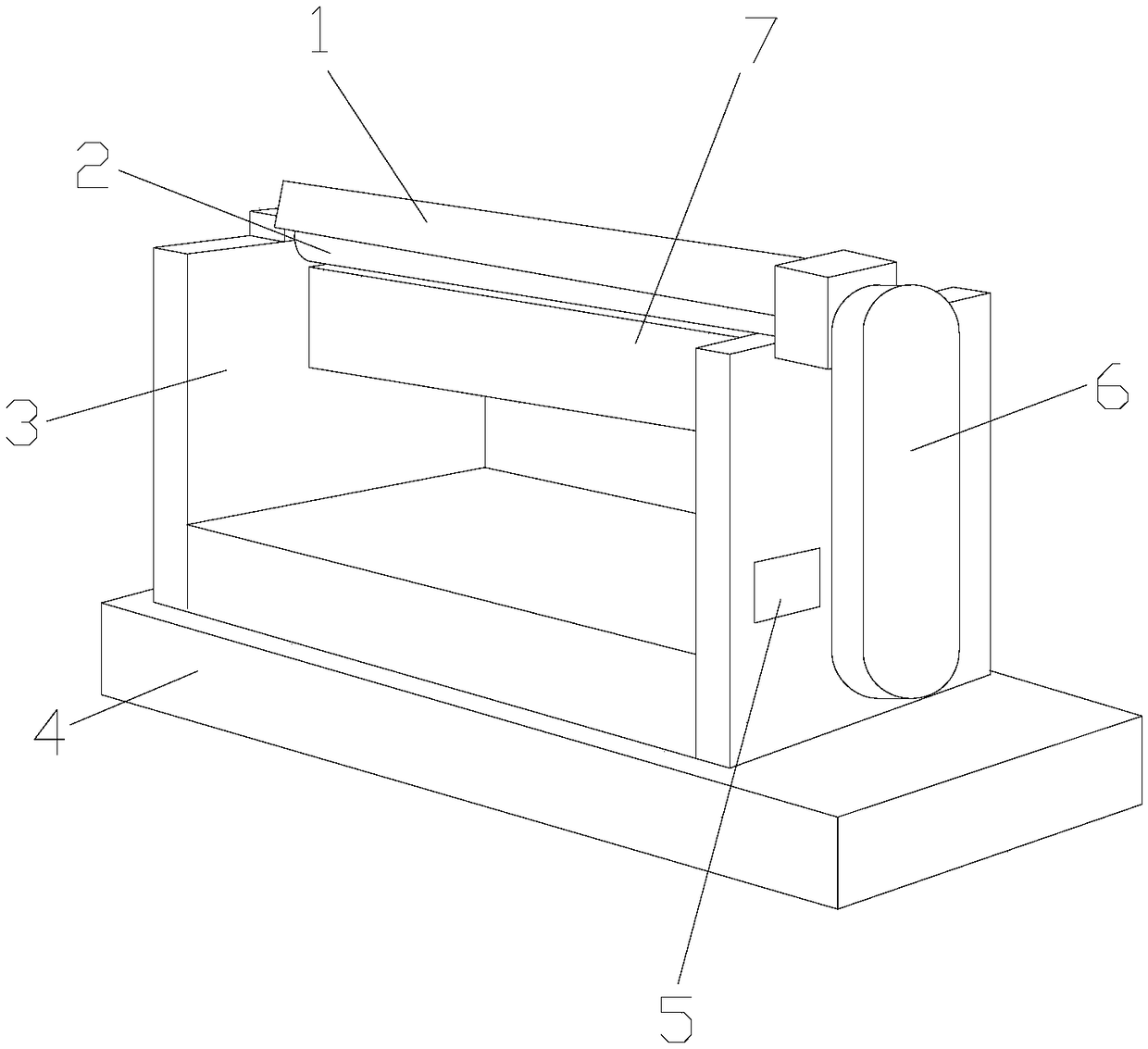

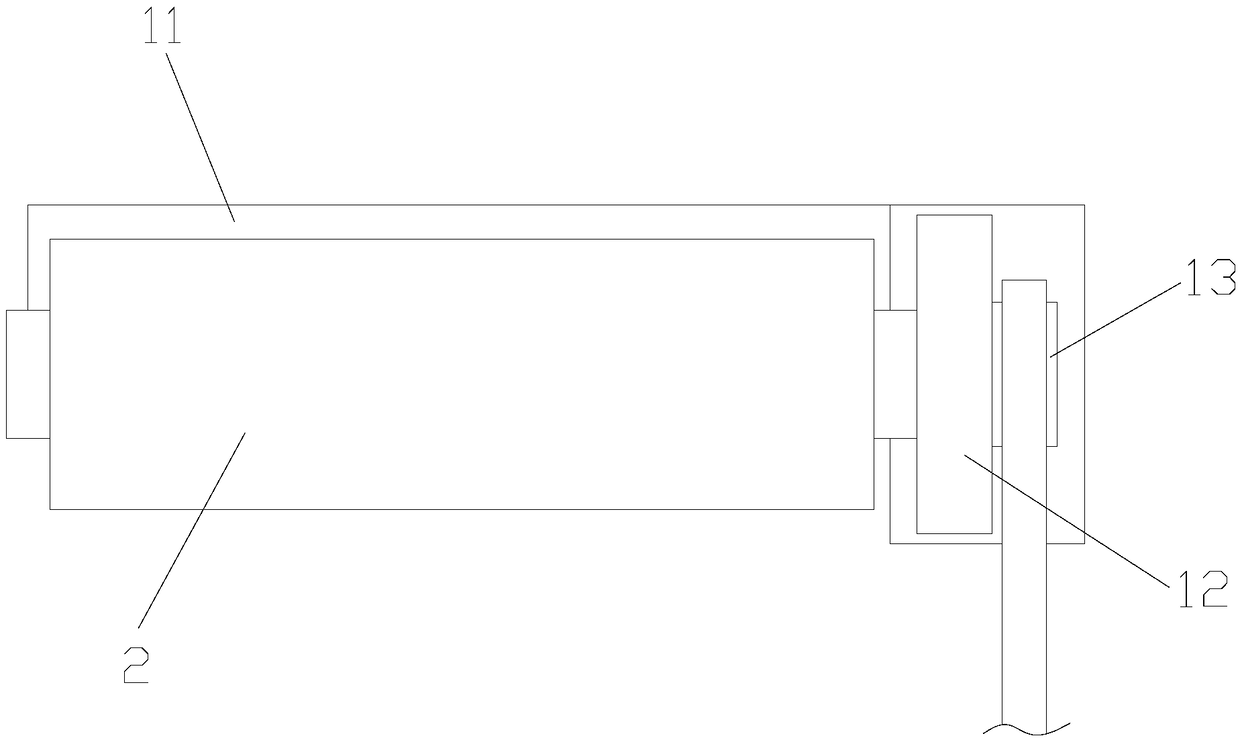

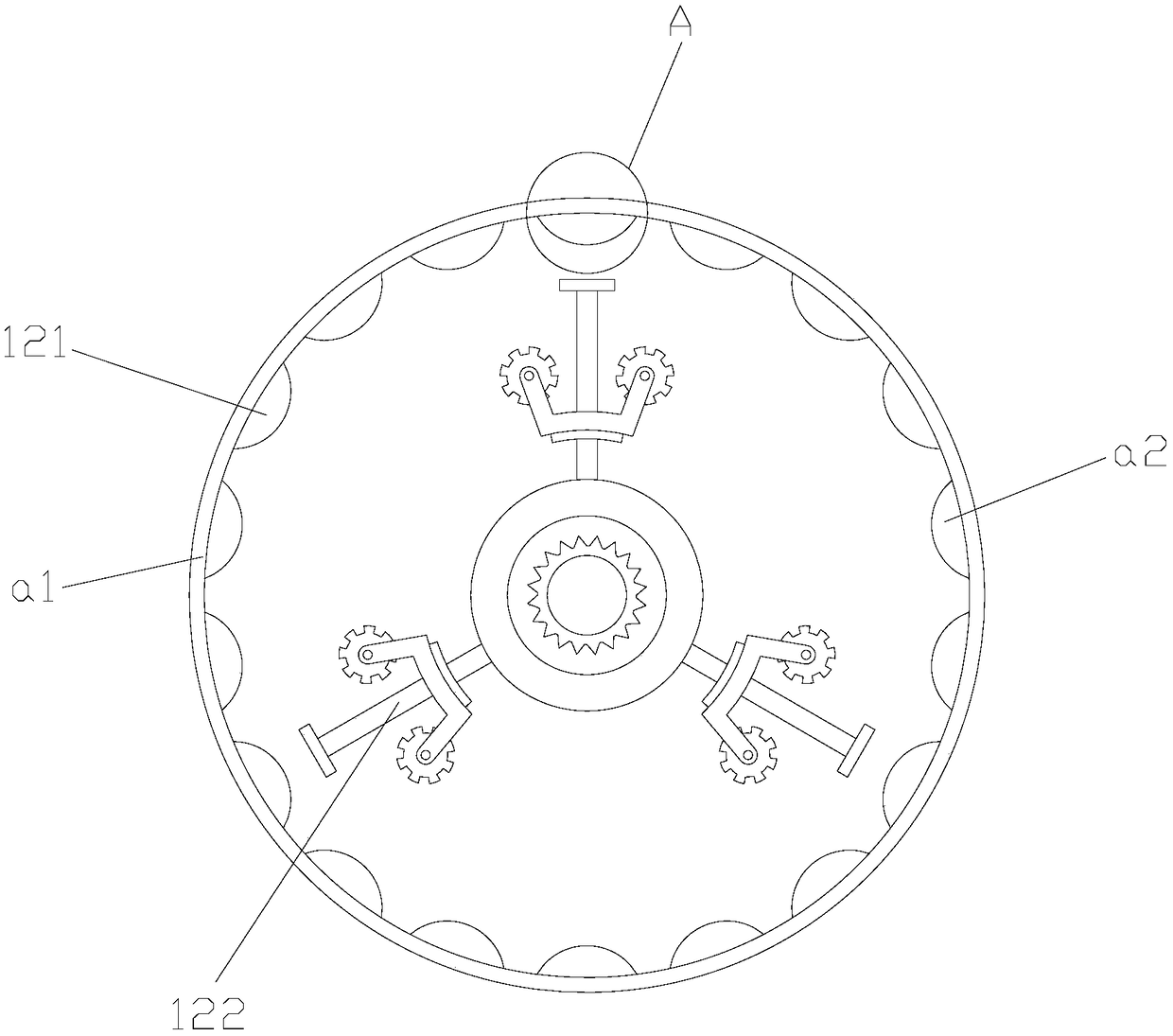

[0024] see Figure 1-Figure 2 , the present invention provides a pressure roller protection device based on centrifugal deceleration for a paper machine, the structure of which includes a protection structure 1, a paper machine pressure roll 2, a pressure roll support frame 3, a fixed base 4, a pulse controller 5, and a conveyor belt protection cover 6. Pressing block 7, the fixed base 4 is a rectangular structure and placed on the ground, the pressure roller support frame 3 is located above the fixed base 4, and the paper machine pressure roller 2 is nested on the top of the pressure roller support frame 3 In the middle, the pressure block 7 is located below the paper machine press roll 2 in the press roll support frame 3, the protective structure 1 is fixed by bolts on the top of the press roll support frame 3 above the paper machine press roll 2, and the pulse controller 5 is nested on the right side of the pressure roller support frame 3, the conveyor belt protective cover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com