Method and apparatus for opening roller gap

A technology of roll gap and equipment, applied in the field of opening roll gap and equipment, can solve problems such as increasing the risk of belt damage, and achieve the effect of high web quality, structural space saving, space and material saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

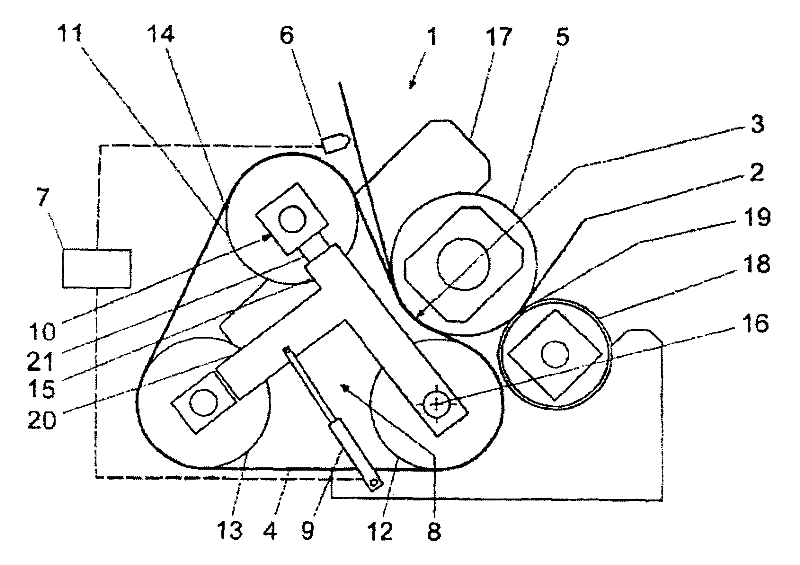

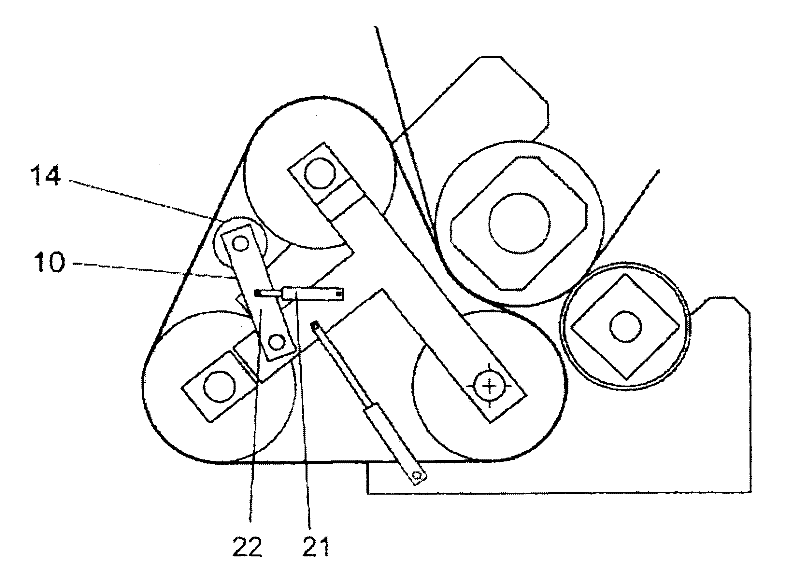

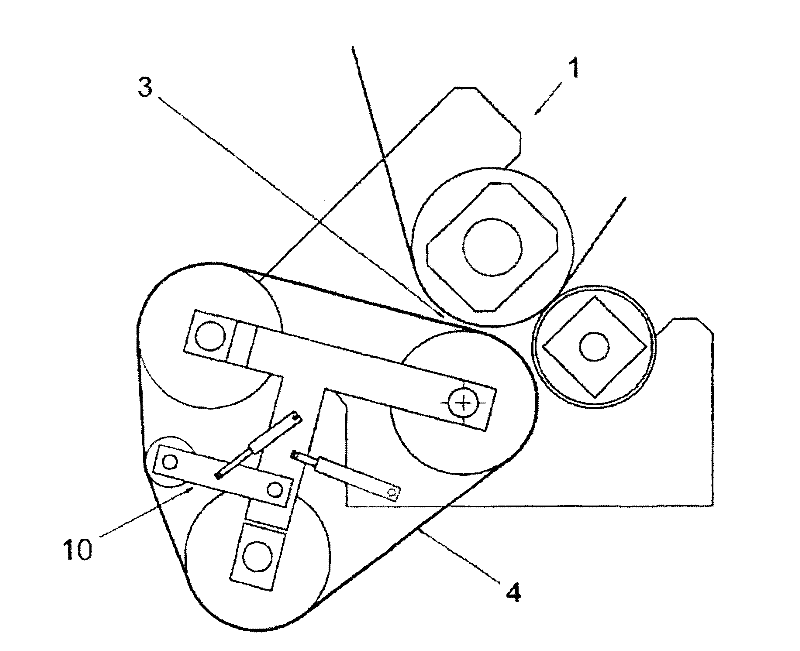

[0029] figure 1 The belt calender 1 in is essentially composed of a belt 4 looped around three guide rolls 11, 12, 13, which contacts the counter roll 5 along a wrap angle > 5°. The belt 4 is driven, for example in a manner not shown, by means of one of the three guide rollers 11 , 12 , 13 until it reaches the peripheral speed of the auxiliary roller 5 or of the fibrous web 2 . In practice such strips may be up to 10 m wide. The fibrous web 2 runs through a nip 3 between a belt 4 and a secondary roll 5 . That is to say, the nip 3 is a contact area between the belt 4 and the counter roll 5, said contact area may have a dimension in the direction of web travel of between 100 and 1000 mm, depending on the type of fibrous web.

[0030] The secondary roll 5 is heated in a manner not shown to a surface temperature of over 130° C. and is mounted in a stationary manner. Suitable for heating are heat transfer fluids, which are guided through the interior of the rollers, but also ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com