Installation module for paper making machine or paperboard making machine

一种安装模块、纸板机的技术,应用在造纸安全装置、造纸机、造纸等方向,能够解决可维护性复杂等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

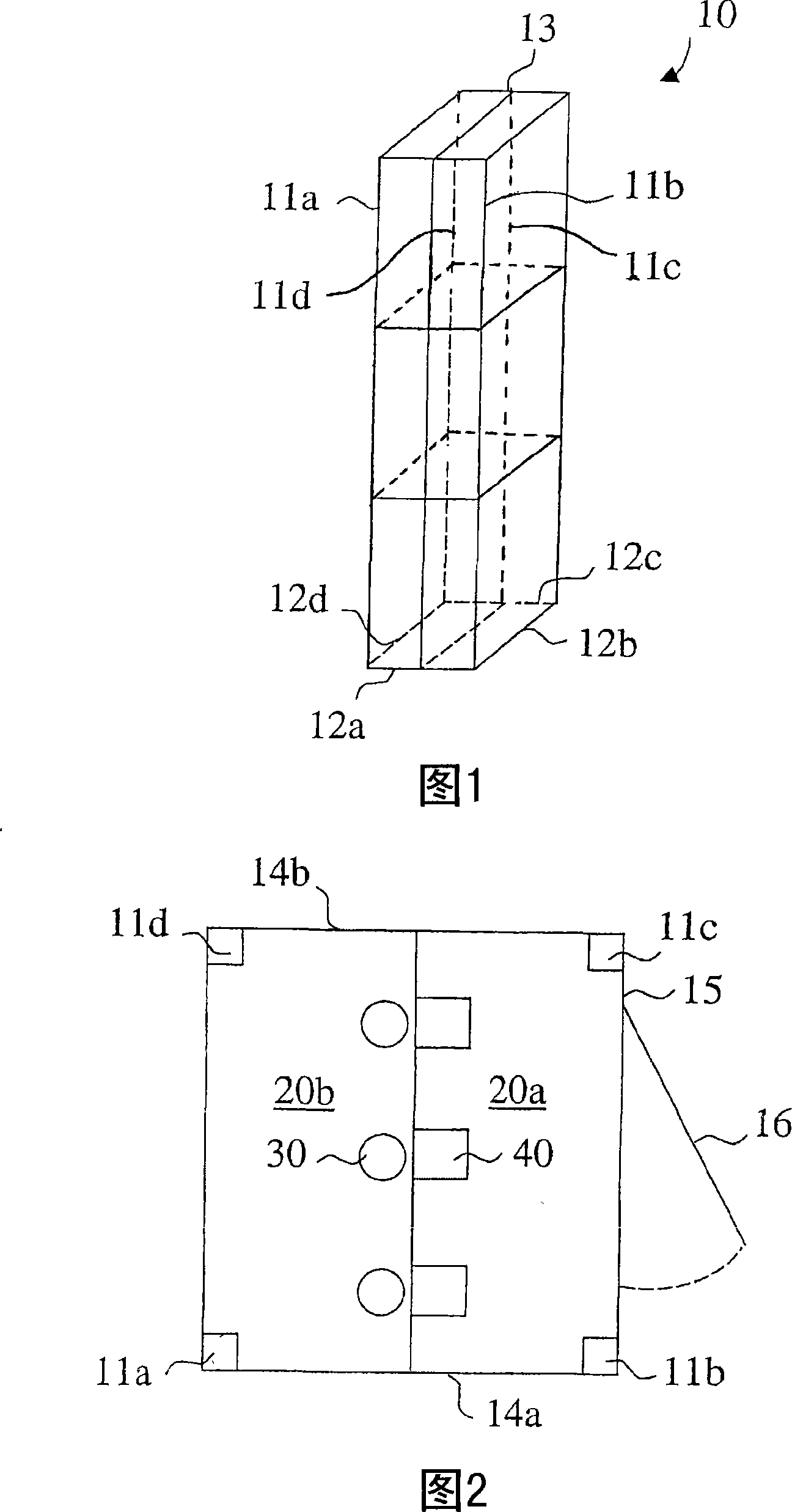

[0016] FIG. 1 shows an isometric view of a mounting module 10 according to the invention, and FIG. 2 shows a horizontal section of said mounting module 10 . At the wet end of the machine, the installation module 10 is installed on the drive side KP of the paper or board machine. The mounting module 10 comprises a frame comprising vertical brackets 11a, 11b, 11c, 11d mounted to the corners of the rectangle and intermediate brackets 12a, 12b, 12c, 12d connecting the vertical brackets. The intermediate brackets are arranged at an appropriate distance along the height direction of the installation module 10, so that the frame obtains sufficient firmness and self-support. The frame is divided into two compartments 20a, 20b by a partition wall 33 fastened to the middle bracket of the frame. Vertical banks of tubes 30 are arranged in one compartment 20b, and valves 40 are arranged in the other compartment. The compartment 20b comprising a bundle of tubes 30 may be open, whereas the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com