Device for producing a material web

A material web, web technology, applied in the direction of papermaking, paper machine, textile and papermaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

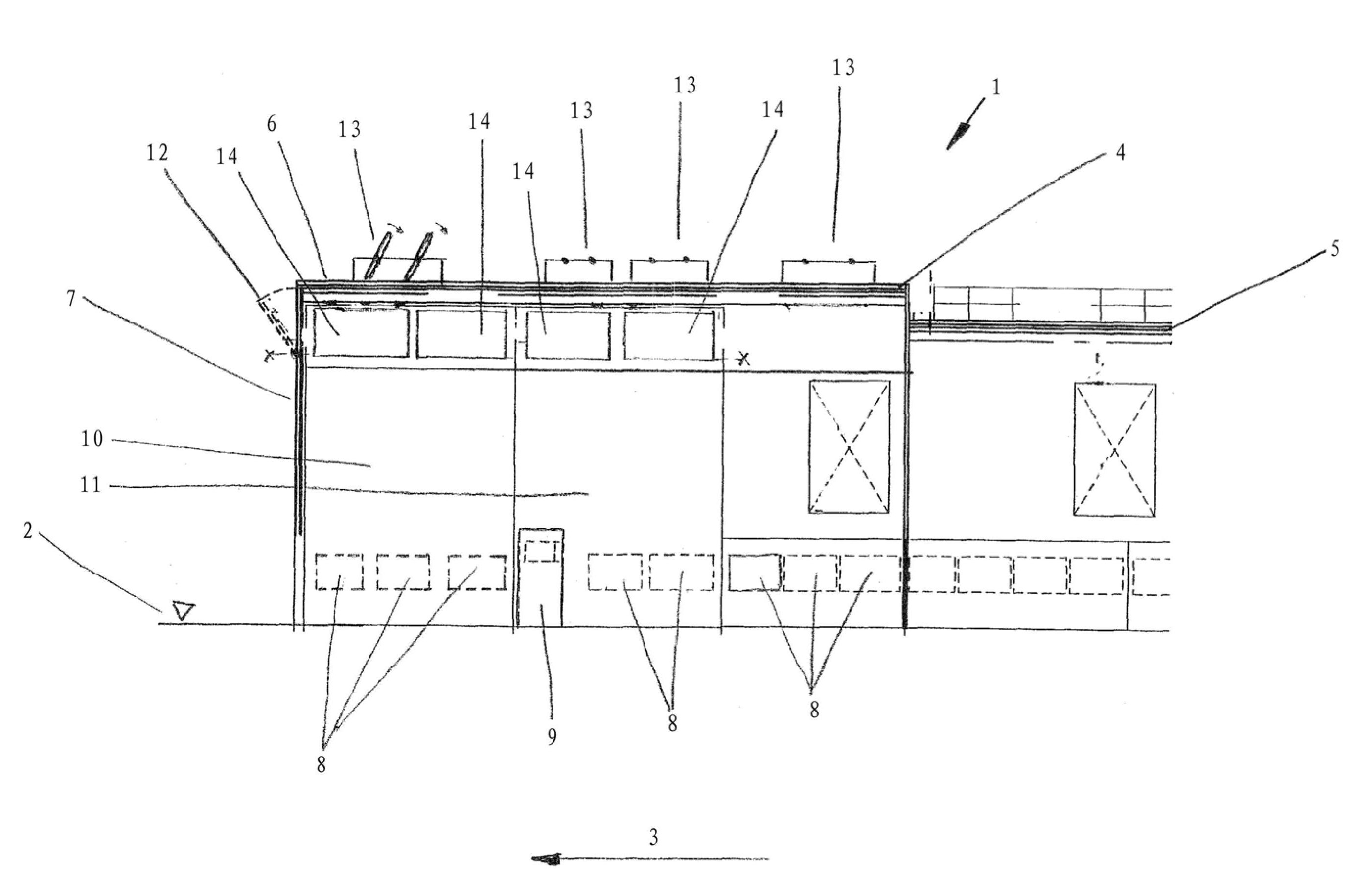

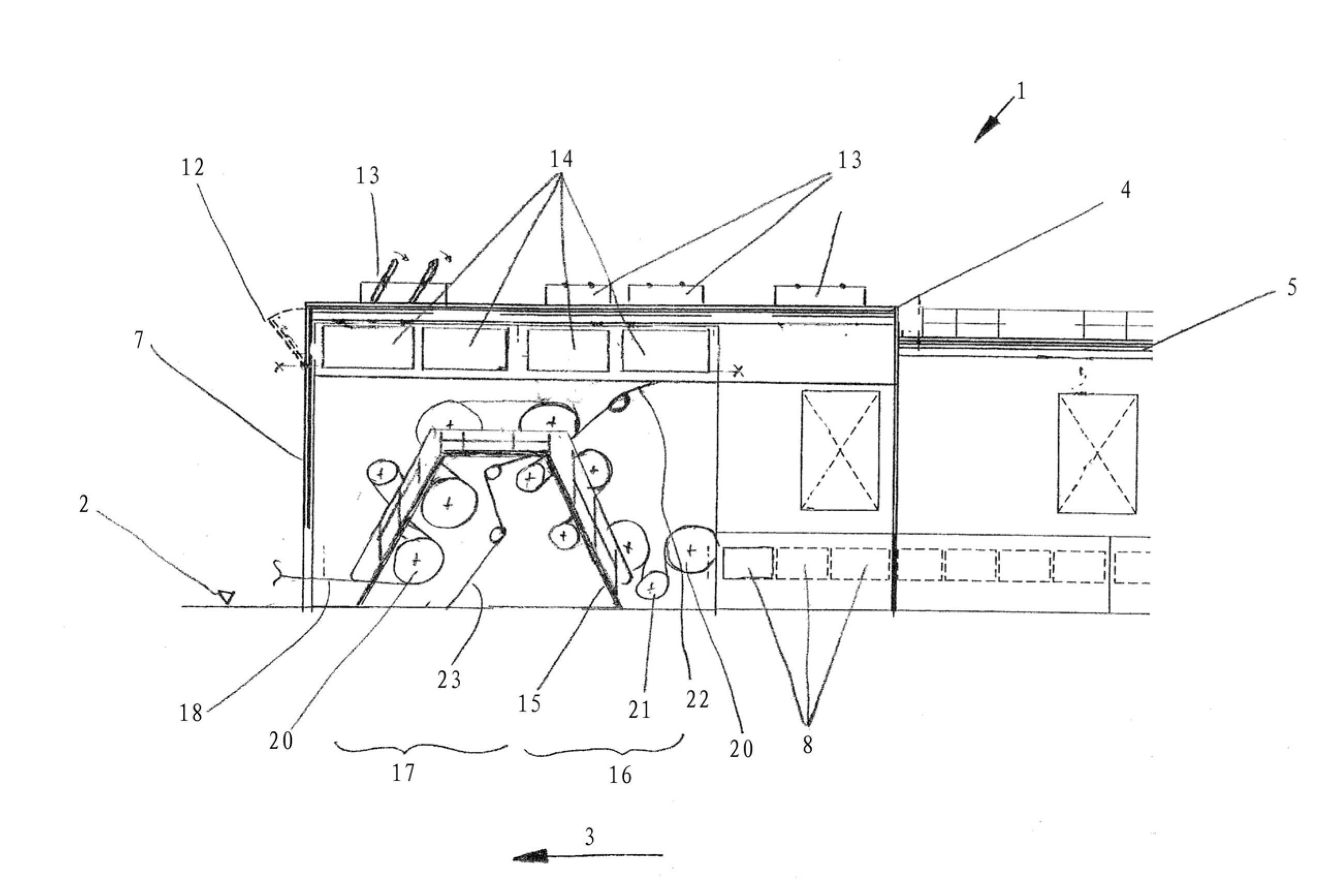

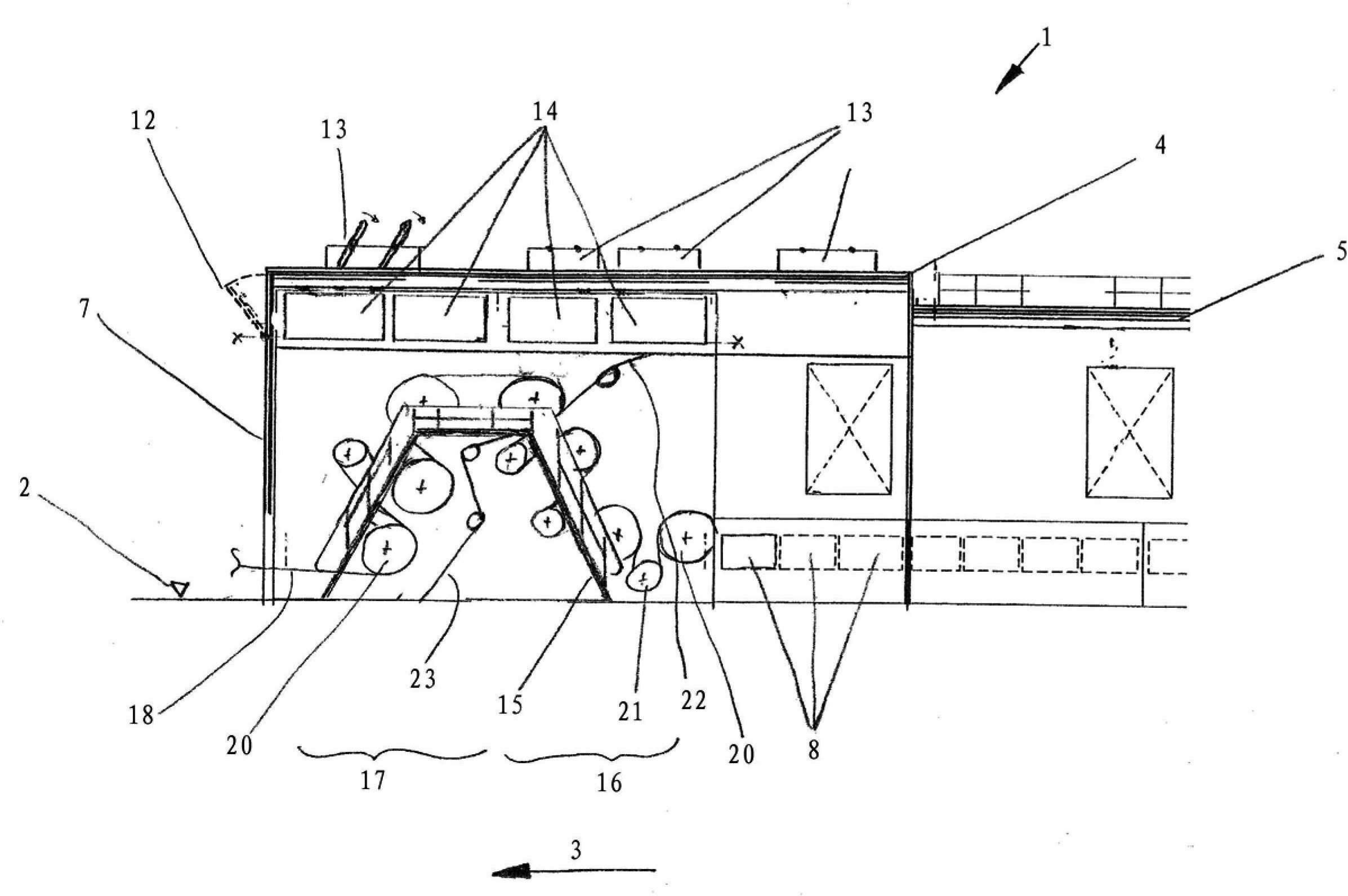

[0031] figure 1 An embodiment of the hoods 4 , 5 of the drying device 1 according to the invention is shown. The hood 4 here surrounds the last drying group of the drying plant 1 according to the invention, and the hood 5 surrounds the penultimate drying group of the drying plant 1 according to the invention. The other hoods 4 equipped with higher drying devices have a higher height than the hoods 5 of the first drying group. The hood 4 preferably has hood doors 10 , 11 on the operator's side, which do not extend over the entire height of the hood 4 . A window 8 and a door 9 are provided in the hood doors 10 , 11 . This enables, on the one hand, an external visual inspection from the operator level 2 and, on the other hand, access to the lower region of the drying group for inspection purposes without interfering with the production run. For quick opening of the hood 4 and thus quick ventilation, a movable flap opening 14 is provided above the hood doors 10 , 11 and in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com