Solid electrolyte including layered metal oxide, fuel cell including thereof, production method for solid electrolyte, and production method for electrode catalyst

a production method and metal oxide technology, applied in the direction of physical/chemical process catalysts, non-aqueous electrolyte cells, sustainable manufacturing/processing, etc., can solve the problem of not being able to obtain open-circuit voltage, etc., to achieve high electromotive force, shorten the time, and achieve sufficient current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0060]A preferred first embodiment of the present invention will now be described in more detail while, on occasion, referring to the drawings.

[0061]

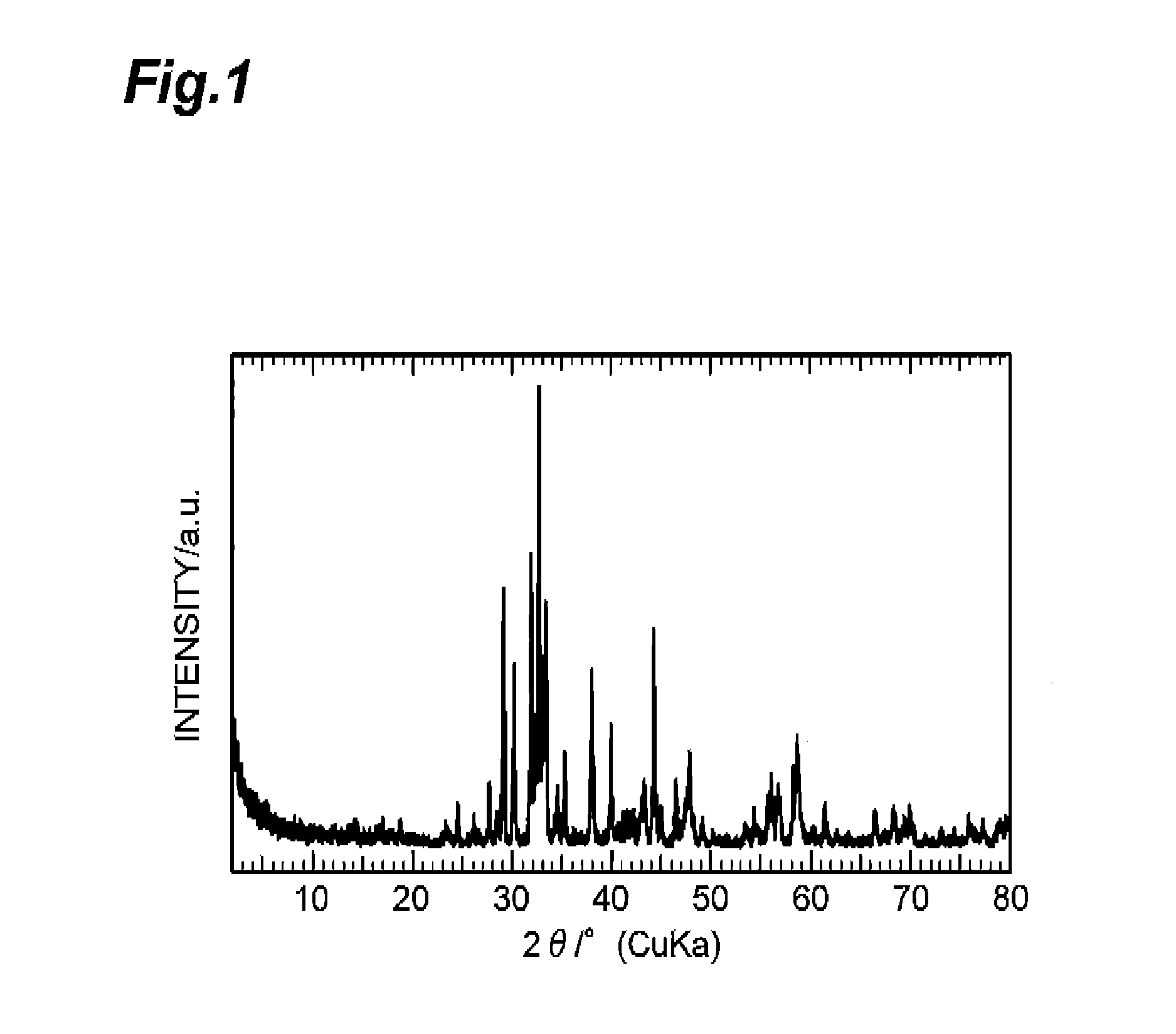

[0062]The layered metal oxide included in the solid electrolyte according to the present invention is a perovskite type layered metal oxide having LaSr3Co3O10 as a basic structure, which has a composition represented by the formula (1). The term “layered” refereed to here means a crystal structure that forms a sheet structure in which atoms or atom groups are especially aligned in a plane, in which repetition of the sheet structure can be seen in a perpendicular direction to this plane.

(La1-xAx)(Sr1-yBy)3(Co1-zCz)3O10-δ (1)

[0063]In the formula (1), A represents the element included in the La site, and is a rare earth element other than La (lanthanum). Examples of A include Sc (scandium), Y (yttrium), Ce (cerium), Pr (praseodymium), Nd (neodymium), Pm (promethium), Sm (samarium), Eu (europium), Gd (gadolinium), Tb (terbium), Dy (dyspros...

second embodiment

[0096]A preferred second embodiment of the present invention will now be described in more detail while, on occasion, referring to the drawings.

[0097](Fuel Cell)

[0098]FIG. 5 is a schematic cross-sectional view illustrating a preferred embodiment of a fuel cell according to the present invention. A fuel cell 210 in FIG. 5 includes a solid electrolyte layer 201, and an anode electrode 202 and a cathode electrode 203, which are arranged so as to sandwich the solid electrolyte layer 201. In addition, the fuel cell 210 has a cell body part 204, whose internal space is separated into a first region R1 and a second region R2 by the solid electrolyte layer 201.

[0099]The cell body part 204 houses the anode electrode 202, the cathode electrode 203, and the solid electrolyte layer 201. The internal space of the cell body part 204 is separated into the first region R1 and the second region R2 by the solid electrolyte layer 201. The cell body part 204 has a gas supply port 205a for supplying, as...

third embodiment

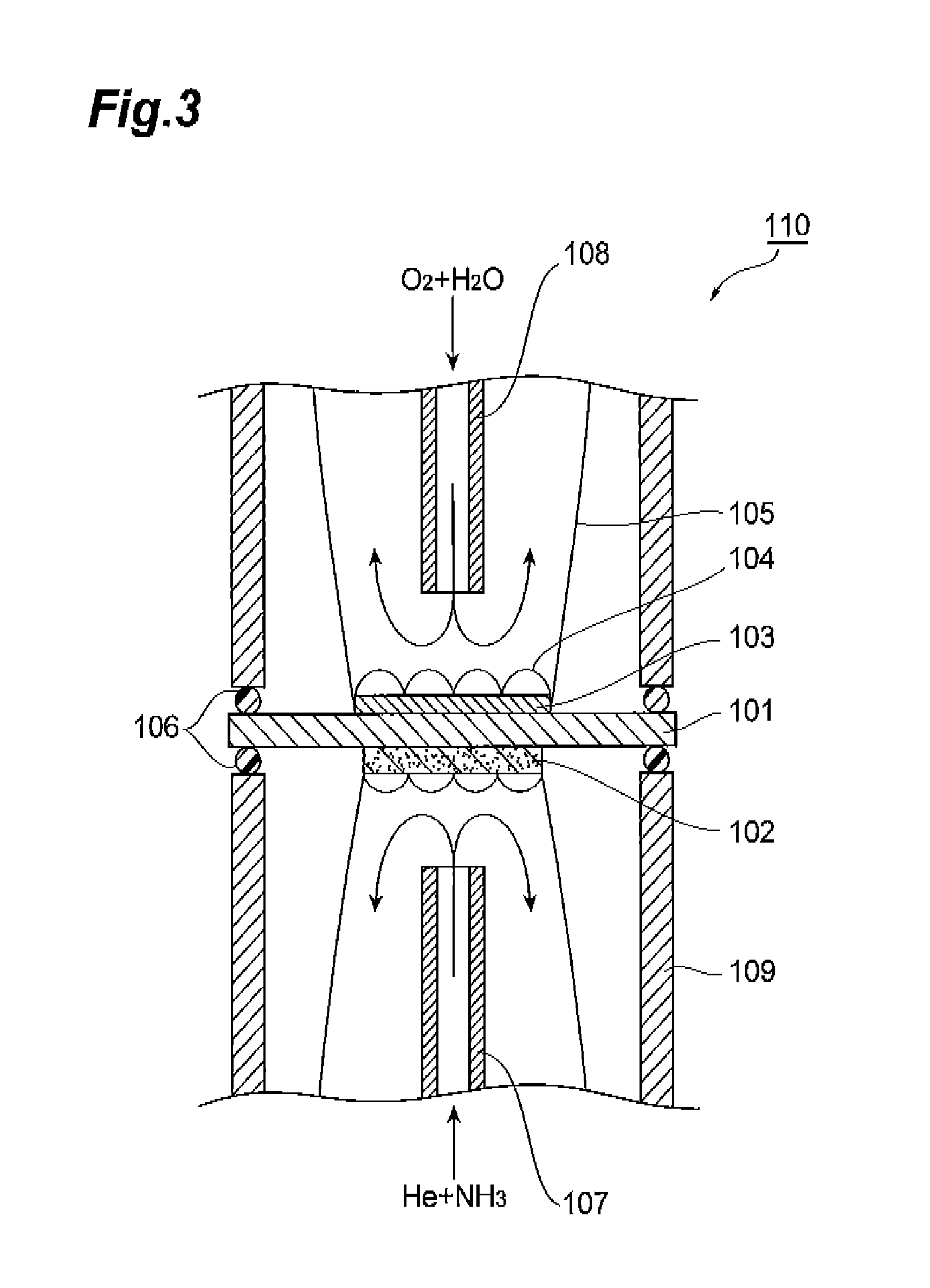

[0138]A preferred third embodiment of the present invention will now be described in more detail while, on occasion, referring to the drawings.

[0139]Electrode Catalyst Including Fe, Co, and Ni>

[0140]The electrode catalyst according to the present invention has an alloy material that includes an alloy portion containing Fe, Co, and Ni, and an Fe portion in which the alloy portion is not formed. The phrase “alloy portion containing Fe, Co, and Ni” refers to, for example, a portion in which Fe, Co, and Ni form a ternary alloy. The alloy portion containing Fe, Co, and Ni may also include components such as other metals, within a range that does not harm its function as this alloy portion. Further, the phrase “Fe portion in which the alloy portion is not formed” refers to a portion in which some of the Fe has precipitated from the ternary alloy of Fe, Co, and Ni. This Fe portion in which the alloy portion is not formed exists, for example, outside of the region of the alloy portion conta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com