Quantum carbon and its preparation method and implementation equipment

A technology of quantum carbon and equipment, applied in hybrid methods, chemical instruments and methods, nanotechnology for materials and surface science, etc., can solve problems such as complex equipment, difficulty in ensuring product quality, and limitations on the popularization and application of graphene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

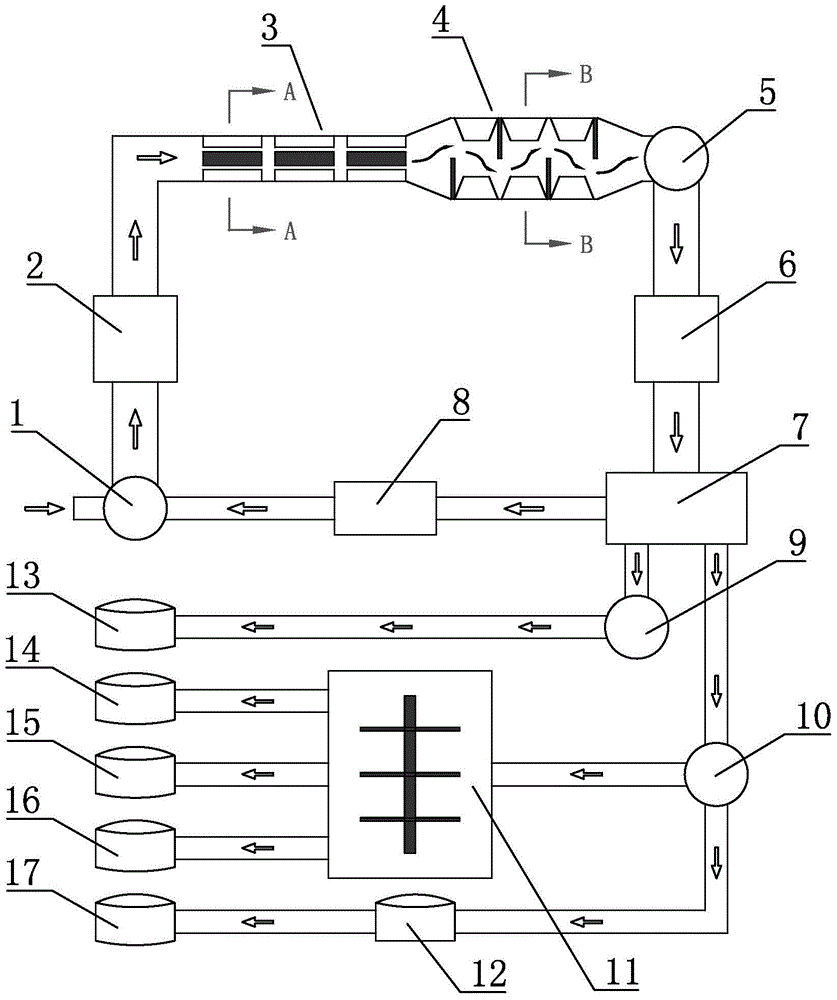

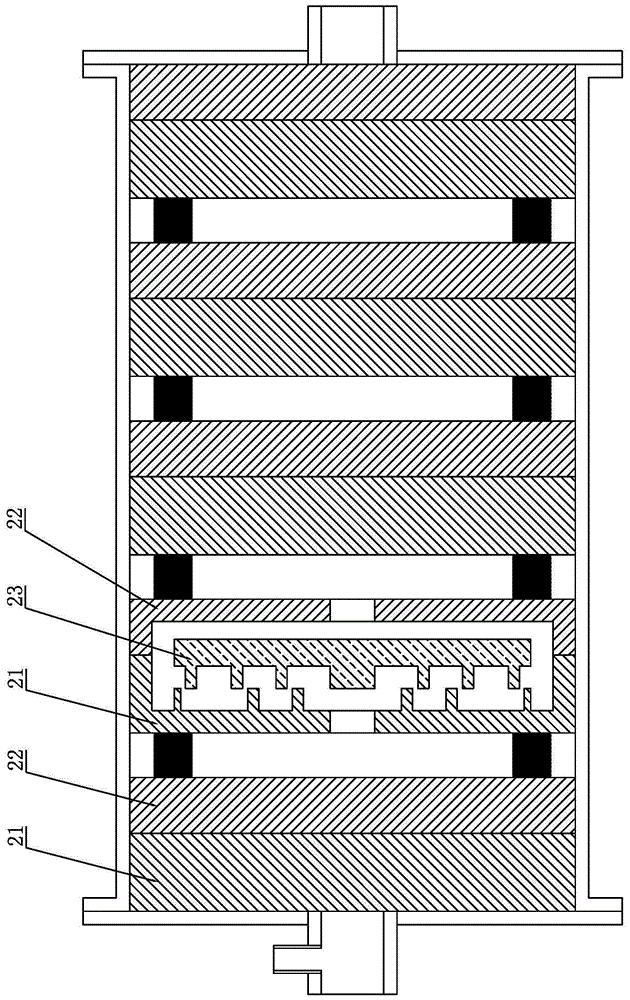

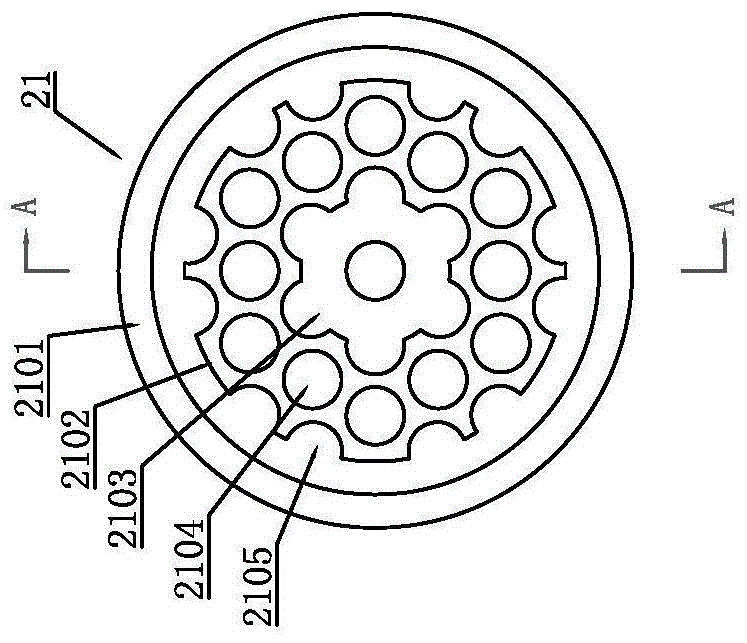

[0168] The microbubble generator 2 is used to purify the water with microbubble treatment, and obtain a pH value of 6.5 to 7.2, a resistance value of 120 MΩ, an average particle diameter of 100 nm containing nano microbubbles, and a density of 1 to 1.2 billion microbubbles / ml. Ionized water. The deionized water after the purified microbubble treatment enters the electrochemical anodizing device 3. The graphite carbon in the electrochemical anodizing device 3 has a purity of 99.9%, ash content of less than 50ppm, fineness of 200 mesh, and pressure above 60Mpa. Next, a graphite plate with geometric dimensions of length 100cm×width 100cm×thickness 10cm was processed as anode electrode plate, two metal plates (length 100cm×width 100cm×thickness 1cm) were made of 314# stainless steel and the surface was plated with Pt as cathode. The graphite plate anode is between the two metal plate cathodes, the distance between the anode and the cathode is 3cm, and the constant current density i...

Embodiment 2

[0170] The microbubble generator 2 is used to purify the water with microbubble treatment, and obtain deionized water with a pH value of 6.5-7.2, a resistance value of 120MΩ, an average particle diameter of 80nm containing nano-microbubbles, and a density of 1.2 billion microbubbles / ml . The deionized water after the purified microbubble treatment enters the electrochemical anodizing device 3. The graphite carbon in the electrochemical anodizing device 3 has a purity of 99.9%, ash content of less than 50ppm, fineness of 200 mesh, and pressure above 60Mpa. Next, a graphite plate with geometric dimensions of length 100cm×width 100cm×thickness 10cm was processed as anode electrode plate, two metal plates (length 100cm×width 100cm×thickness 1cm) were made of 314# stainless steel and the surface was plated with Pt as cathode. The graphite plate anode is between the two metal plate cathodes, the distance between the anode and the cathode is 3cm, and the constant current density is 0....

Embodiment 3

[0172] The microbubble generator 2 is used to purify the water with microbubble treatment, and obtain deionized water with a pH value of 6.5-7.2, a resistance value of 120MΩ, an average particle diameter of 80nm containing nano-microbubbles, and a density of 1.2 billion microbubbles / ml . The deionized water after the purified microbubble treatment enters the electrochemical anodizing device 3. The graphite carbon in the electrochemical anodizing device 3 has a purity of 99.9%, ash content of less than 50ppm, fineness of 200 mesh, and pressure above 60Mpa. Next, a graphite plate with geometric dimensions of length 100 cm × width 100 cm × thickness 10 cm was processed as the anode electrode plate, and the two metal plates (length 100 cm × width 100 cm × thickness 1 cm) were made of 314# stainless steel and the surface was plated with Ni as the cathode. The graphite plate anode is between the two metal plate cathodes, the distance between the anode and the cathode is 3cm, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| Ash content | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com