Resist Composition

a composition and resist technology, applied in the field of resist composition, can solve the problems of reducing throughput, obstructing the full implementation of this technique in the semiconductor industry, and current photoresist technologies suffer from the “trade-off” between resolution and exposure speed/sensitivity, so as to achieve good balance between resolution and sensitivity, reduce scattering, and improve exposure control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

on of Anti-Scattering Compounds

[0622]In general, a resist composition of the invention (e.g. photoresist) may be produced by forming a composition that includes an anti-scattering compound as defined herein. Suitably the composition also comprises a coating solvent to enable the anti-scattering compound to be applied as a resist coating.

[0623]Since the anti-scattering compound suitably includes a low-density, high molecular weight polymetallic cage (since such structures produce less scattering owing to the amount of empty space within such cage structures), any polymetallic cage may be used to obtain the relevant beneficial effect. By way of guidance to the skilled person, suitable structures may include any polymetallic cage complexes the same or similar to those disclosed in G. F. S. Whitehead, F. Moro, G. A. Timco, W. Wernsdorfer, S. J. Teat and R. E. P. Winpenny, “A Ring of Rings and Other Multicomponent Assemblies of Clusters”, Angew. Chem. Int. Ed., 2013, 52, 9932-9935. This ...

example 2

on of Resist Compositions

[0632]The anti-scattering compounds of Examples 1A and 1B may be considered antiscattering-resist hybrid compounds, since they incorporate both an anti-scattering component (i.e. the overall low-density metal cage compound) and resist components (i.e. 2-Methyl-4-pentenoate resist ligands which bear terminal alkene groups which are cross-linkable).

[0633]As such, various resist compositions were formed and tested for effectiveness.

Cr7Ni base structure (see FIG. 13)

Example 2A(i) and (ii)—Formulation A (Cr7Ni / 2-Methyl-4-pentenoate Complex+Sulfoniumtriflate)

[0634]Formulations A(i) and (ii) were prepared using the antiscattering-resist hybrid compound of Example 1A, one without the Tris(4-tert-butylphenyl)sulfoniumtriflate (A(i)) and another with the Tris(4-tert-butylphenyl)sulfoniumtriflate (A(ii)).

[0635]To form the resist composition, 20 mg antiscattering-resist hybrid compound of Example 1A is dissolved in 1 g of tert butyl methyl ether (MTBE) and filtered thr...

example 3

on of Resist-Coated Substrates

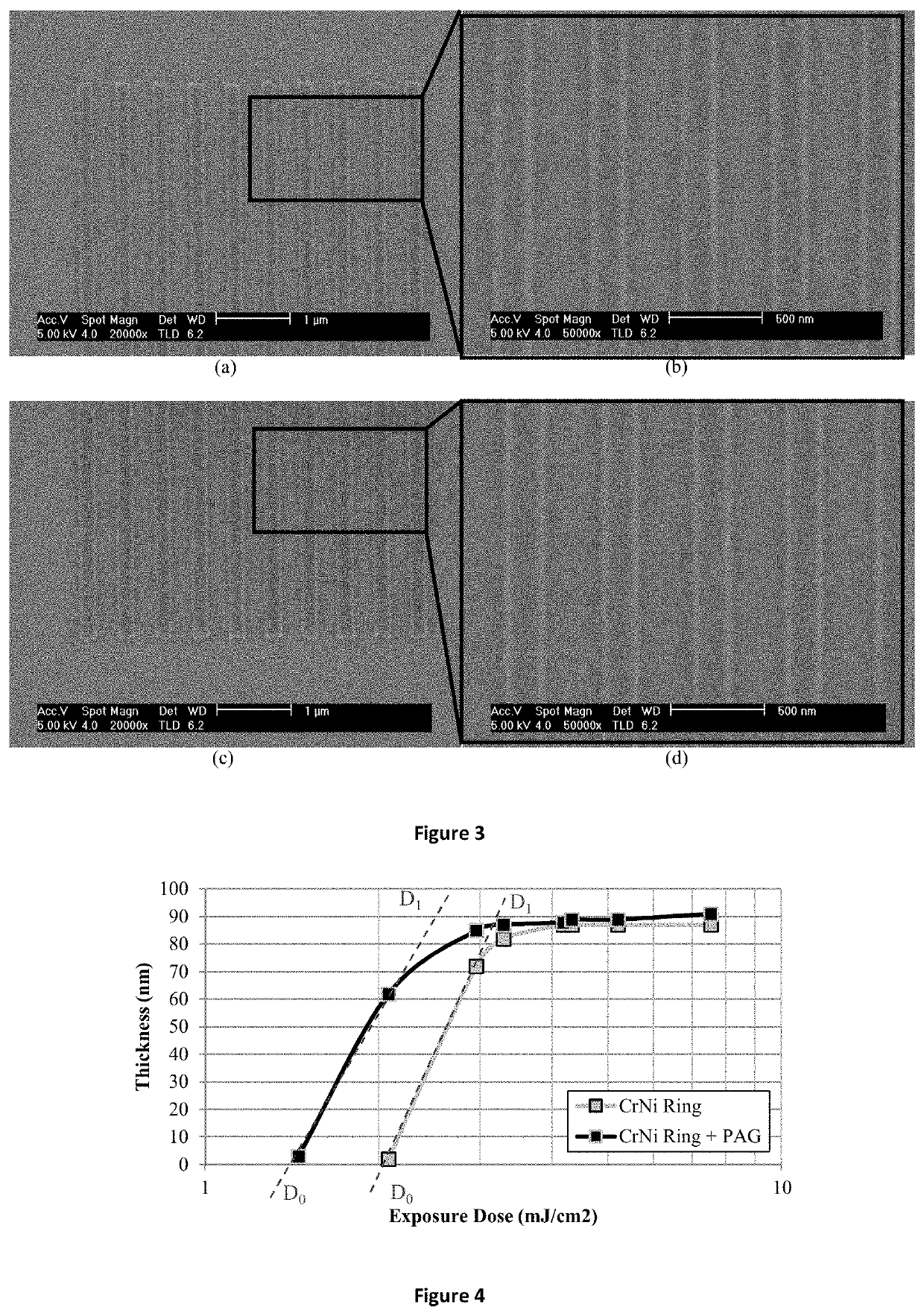

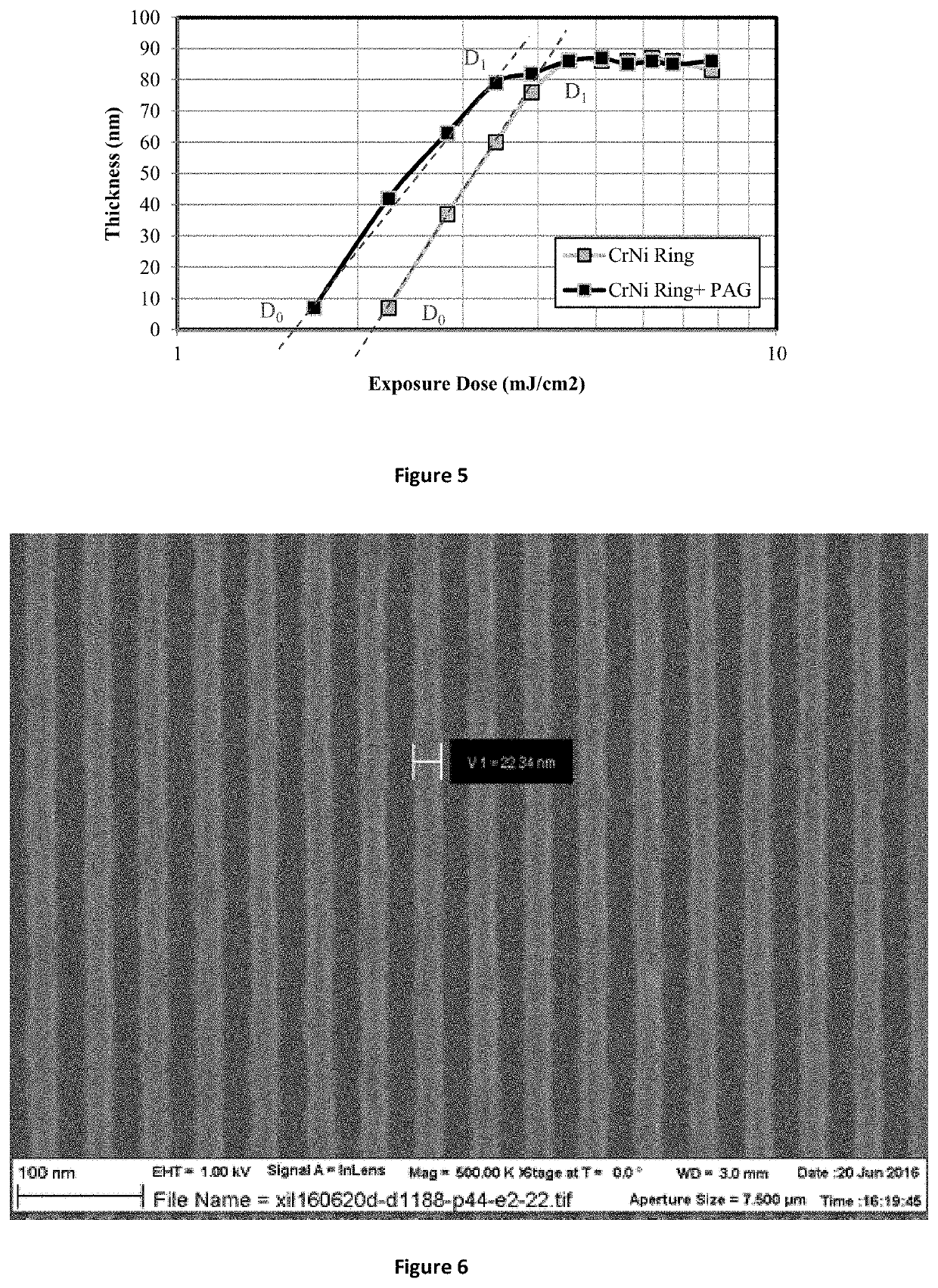

[0651]Each of the aforementioned Example resist compositions 2A-2H were spun onto 10 mm×10 mm silicon substrates. Each resist composition was spun using a spin cycle of 8000 rpm for 60 seconds, which was followed by a soft-bake at 100° C. for 2 minutes, allowing the cast solvent to evaporate. The resist film resulted with a thickness of 100 nm. The resist films were exposed with 248 and 193 nm radiation through a Silver optical mask which consisted of 250 and 200 nm features. Each material was developed using a solution of Hexane, for 30 s followed by an N2 blow dry.

Results and Discussion

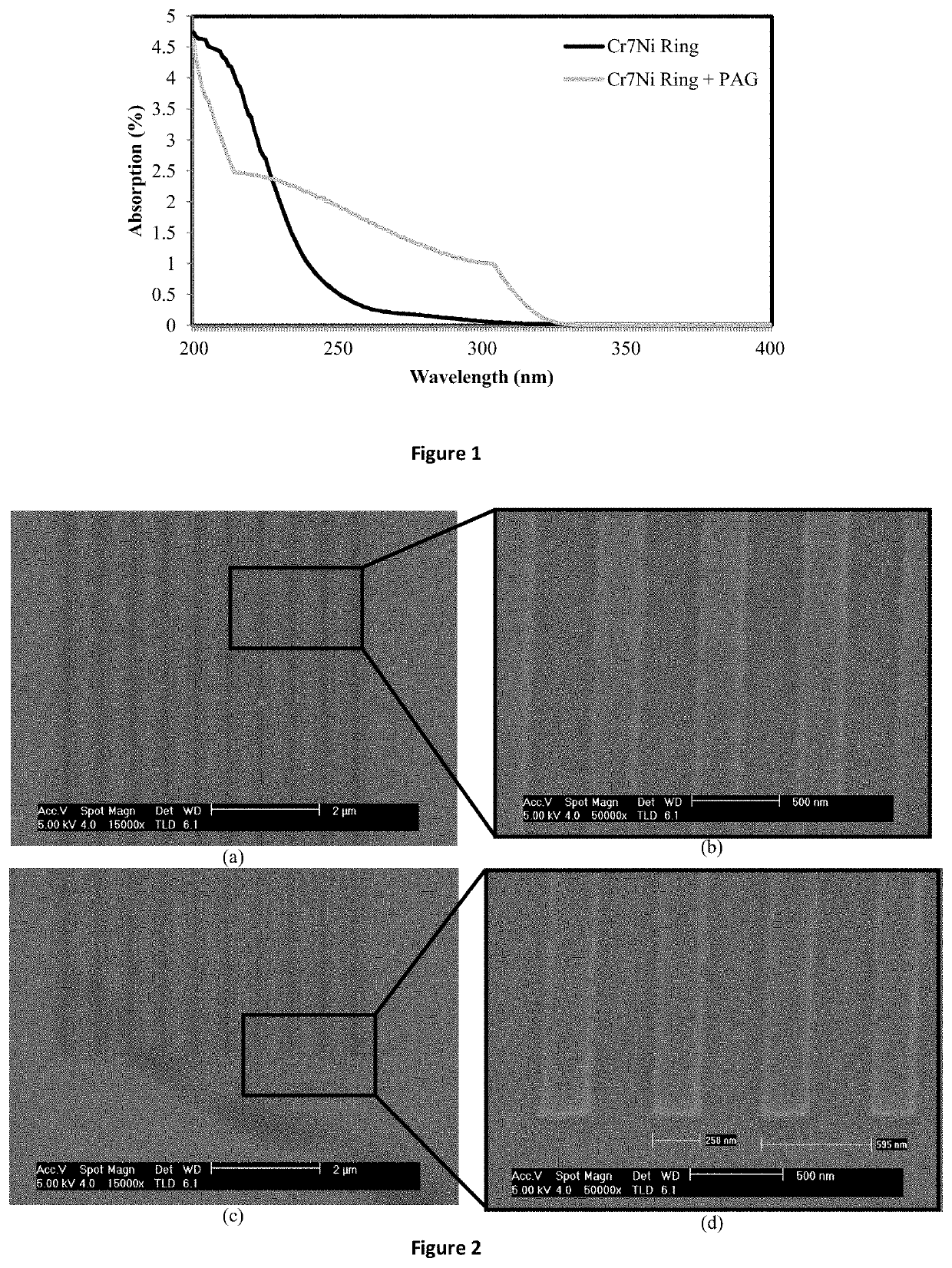

[0652]FIG. 1 shows a graph illustrating how radiation-absorption varies with incident wavelength for each of Formulations A(i) (i.e. Cr7Ni metal complex only) and Formulation A(ii) (Cr7Ni complex+photoacid generator).

[0653]It is evident from FIG. 1 that, at a wavelength of 248 nm (suitable for photolithography), the Cr7Ni ring molecule alone absorbs approximately 0.5% o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| atomic number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com