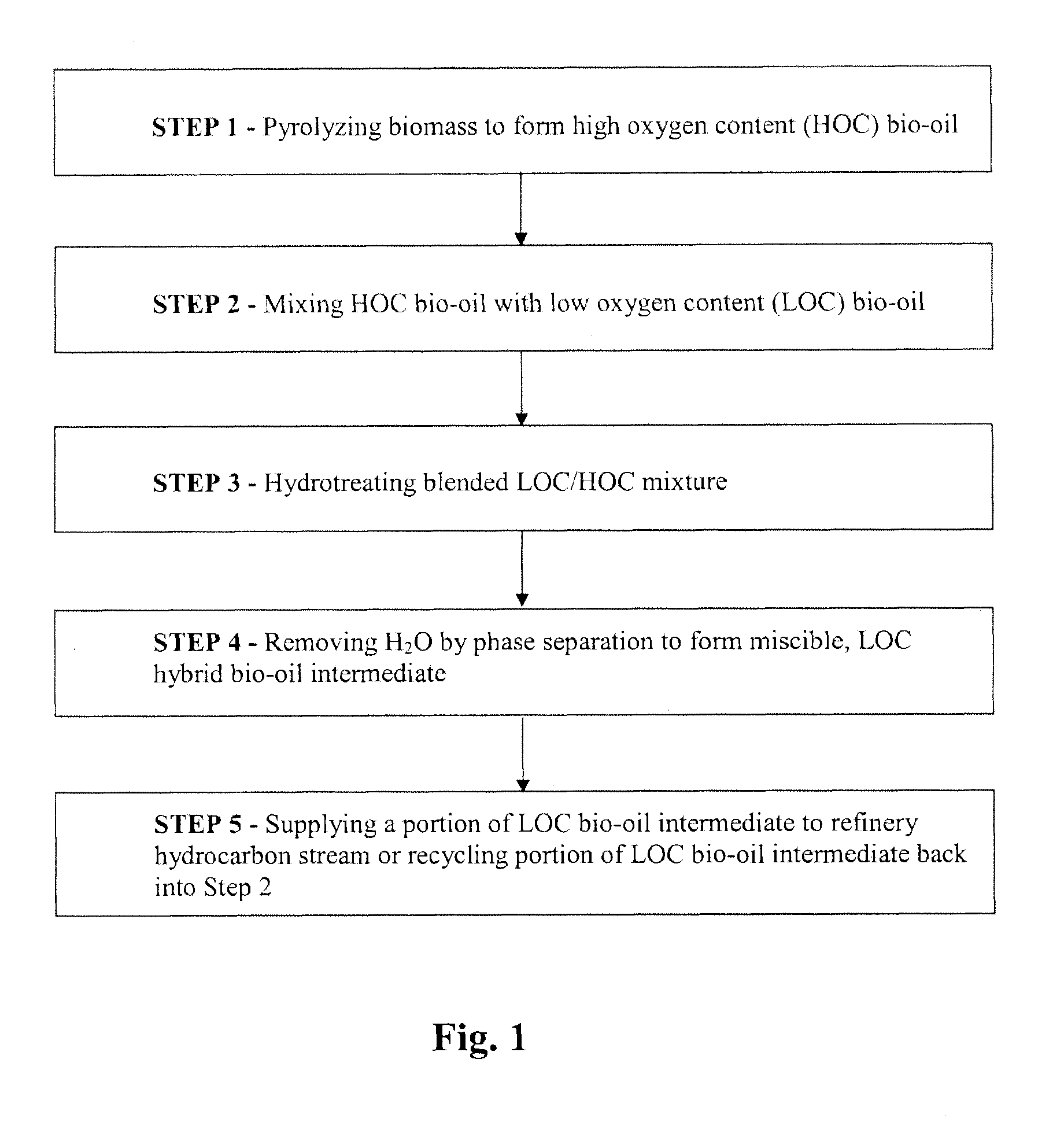

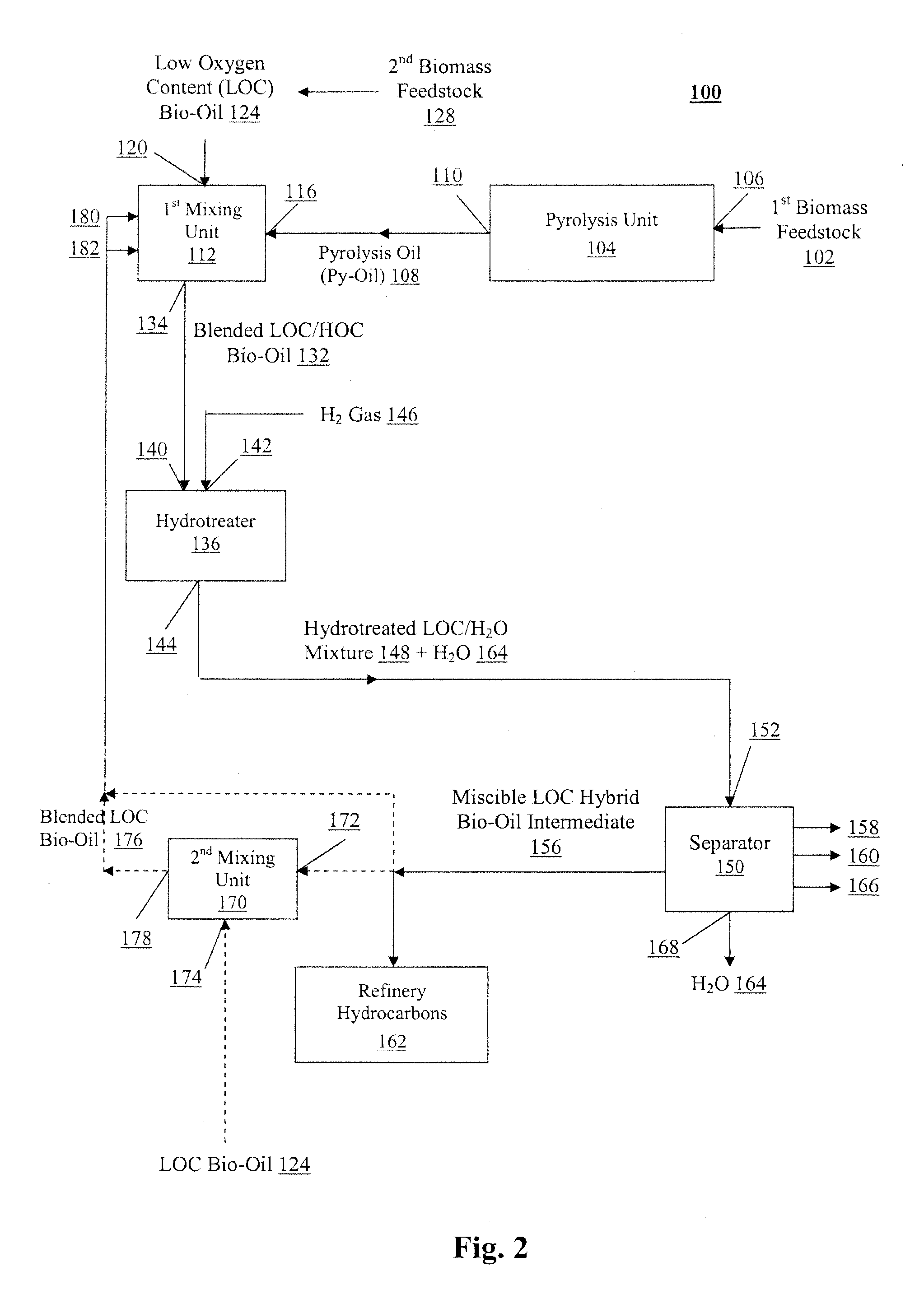

Process for producing a refinery stream-compatible bio-oil from a lignocellulosic feedstock

a technology of lignocellulosic feedstock and bio-oil, which is applied in the field of compositions and methods for preparing bio-oil, can solve the problems of unnecessary addition of solvents, and achieve the effect of reducing oxygen content and reducing molecular weigh

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Pyrolysis Oil

[0071]A pyrolysis oil was produced from pine sawdust by a fast pyrolysis method. Chemical analysis of the pyrolysis oil showed 21% water content, and elemental analyses of 48.72% carbon, 5.97% hydrogen, <0.05% nitrogen, and 44.64% oxygen (by difference) on a moisture and ash free basis (MAF). The total acid number (TAN) of the Pyrolysis Oil was 331 mg KOH / g.

[0072]This resulting Py-Oil was immiscible with n-dodecane. The low solubility of the Py-Oil in an aromatic solvent was demonstrated using toluene as a solvent. The Py-Oil was mixed with five-to-ten times the volume of toluene. The mixture was heated to boiling and the water removed by azeotropic distillation (Dean Stark method). The resulting Py-Oil / toluene mixture was allowed to cool and two phases resulted: a thin, light colored toluene rich phase and a thick, viscous Py-Oil phase immiscible in toluene. The toluene-insoluble Py-Oil accounted for 38% of the original Py-Oil.

[0073]The elemental composition of the tol...

example 2

Lignin Bio-Oil

[0074]A lignin bio-oil was produced by hydrotreating a purified pine Kraft lignin with hydrogen at 2000 psig and 420° C. and a suspended iron based catalyst. The chemical analysis of the resultant lignin oil showed <0.34% water content, and an elemental analyses of 83.47% carbon, 9.23% hydrogen, 1.19% nitrogen, 0.40% sulfur, and 5.71% oxygen (by difference). The TAN of lignin bio-oil was 7 mg KOH / g. The number average molecular weight of the lignin bio-oil was 229 g / mol.

[0075]The solubility of the lignin bio-oil in toluene was determined. The bio-oil was mixed with nine times the volume of toluene. The mixture was heated to reflux, and then allowed to cool to room temperature. A single organic phase resulted, with the lignin bio-oil being miscible with the toluene. The lignin bio-oil was miscible with the toluene due to its low oxygen content, molecular weight, and TAN value, as compared to the toluene-insoluble Py-Oil in Example 1.

example 3

Mild Hydrotreating of Py-Oil+Lignin Oil

[0076]A Py-Oil, as described in Example 1, was blended in line with a lignin bio-oil, described in Example 2, to yield a 1:3 mixture and directly fed into a hydrotreating, down flow reactor containing a sulfided NiO / MoO3 supported catalyst (ICR181). The process pressure was 800 psig of hydrogen. A temperature gradient was applied across the catalyst bed, with the inlet temperature at 140° C., and an outlet temperature of 245° C. The product bio-oil was homogeneous and the water phase could be separated. Chemical analysis of the bio-oil product was 80.93% carbon, 9.90% hydrogen, 1.11% nitrogen, and 8.07% oxygen (by difference). The TAN of the product bio-oil was 17 mg KOH / g. Simple dilution of the Py-Oil by the lignin oil produced a TAN value of 88 mg KOH / g.

[0077]The product bio-oil was mixed with about ten times the volume of toluene. The mixture was heated to boiling and residual water entrained in the oil was removed by azeotropic distillatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com