Highly selective chemical and biological sensors

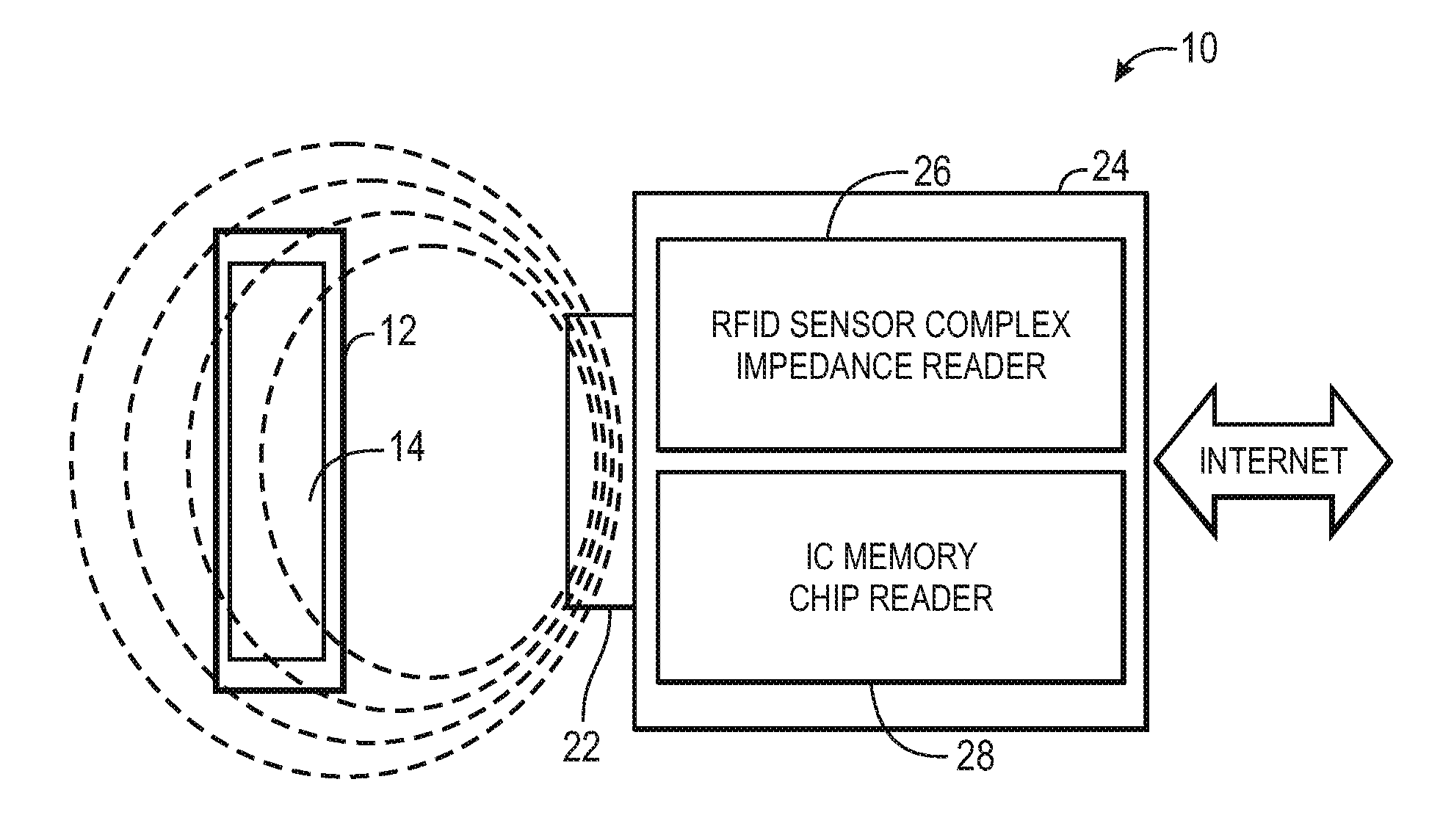

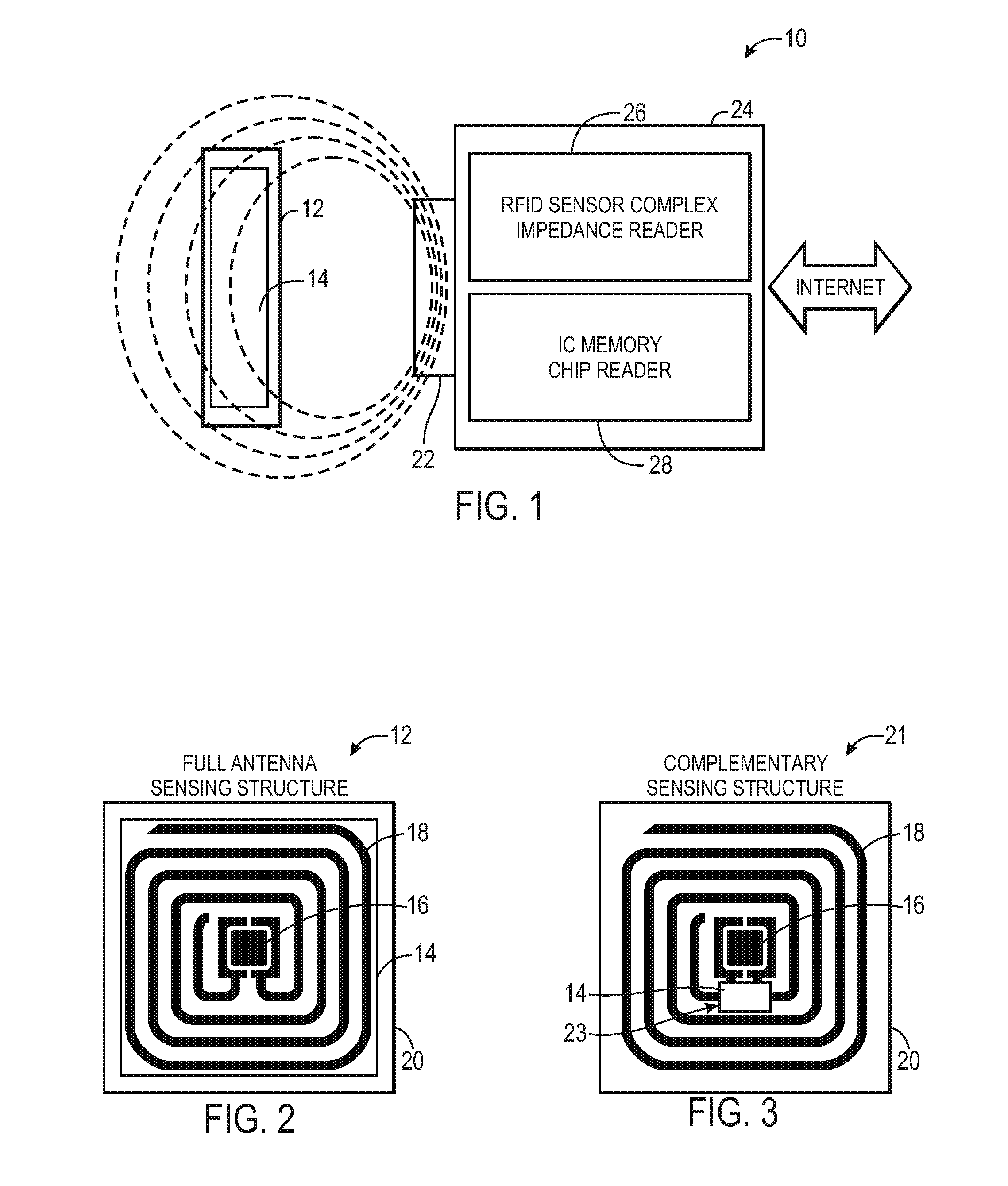

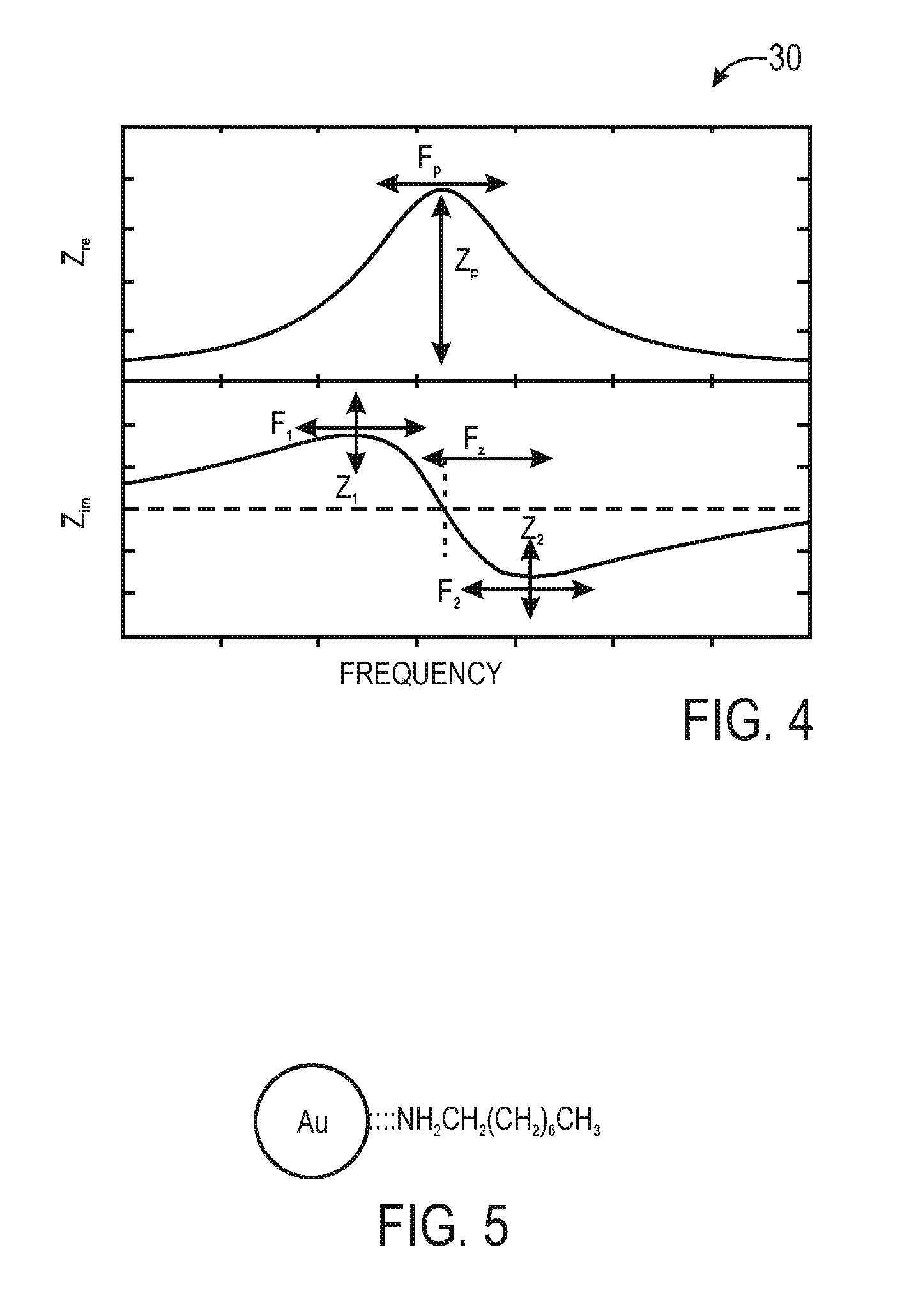

a biological sensor, high-selective technology, applied in the direction of resistance/reactance/impedence, instruments, chemical methods analysis, etc., can solve the problem of difficult to accurately sense and discern a specific type of vapor or vapor mixture being sensed, limited array capability for sensing only a single response, etc. problem, to achieve the effect of reducing the impedance spectrum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

Selective Detection of Individual Nine Alcohols with a Single Sensor

[0064]As illustrated in FIGS. 6 and 7, test results were obtained to demonstrate the selective detection of individual, closely related vapors, such as alcohols from their homologous series and water vapor as an interferent, using a single sensor, such as the sensor 12 described above. As illustrated in FIG. 6, the sensor was exposed to the following 10 vapors over a period of time:

1water2methanol3ethanol41-propanol51-butanol61-pentanol71-hexanol81-heptanol91-octanol101-nonanol

The structures of the alcohols 60 are illustrated in FIG. 7.

[0065]The sensing material used to coat the RFID tag was carefully chosen and provided the ability to selectively detect the listed vapors. In the present experiment, the chosen sensing material was octylamine-capped C8 ligand attached to gold nanoparticles, which was applied as a sensing film onto an RFID sensor chip by drop casting. Specifically, the nanoparticles of the sensing mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com