Structural building elements having pressure-sensitive adhesive

a technology of structural building elements and adhesives, applied in the direction of girders, walls, joists, etc., can solve the problems of affecting the formation of strong adhesive bonds between building materials, affecting the bond strength, so as to achieve low (or no) bond strength, easy placement and repositioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

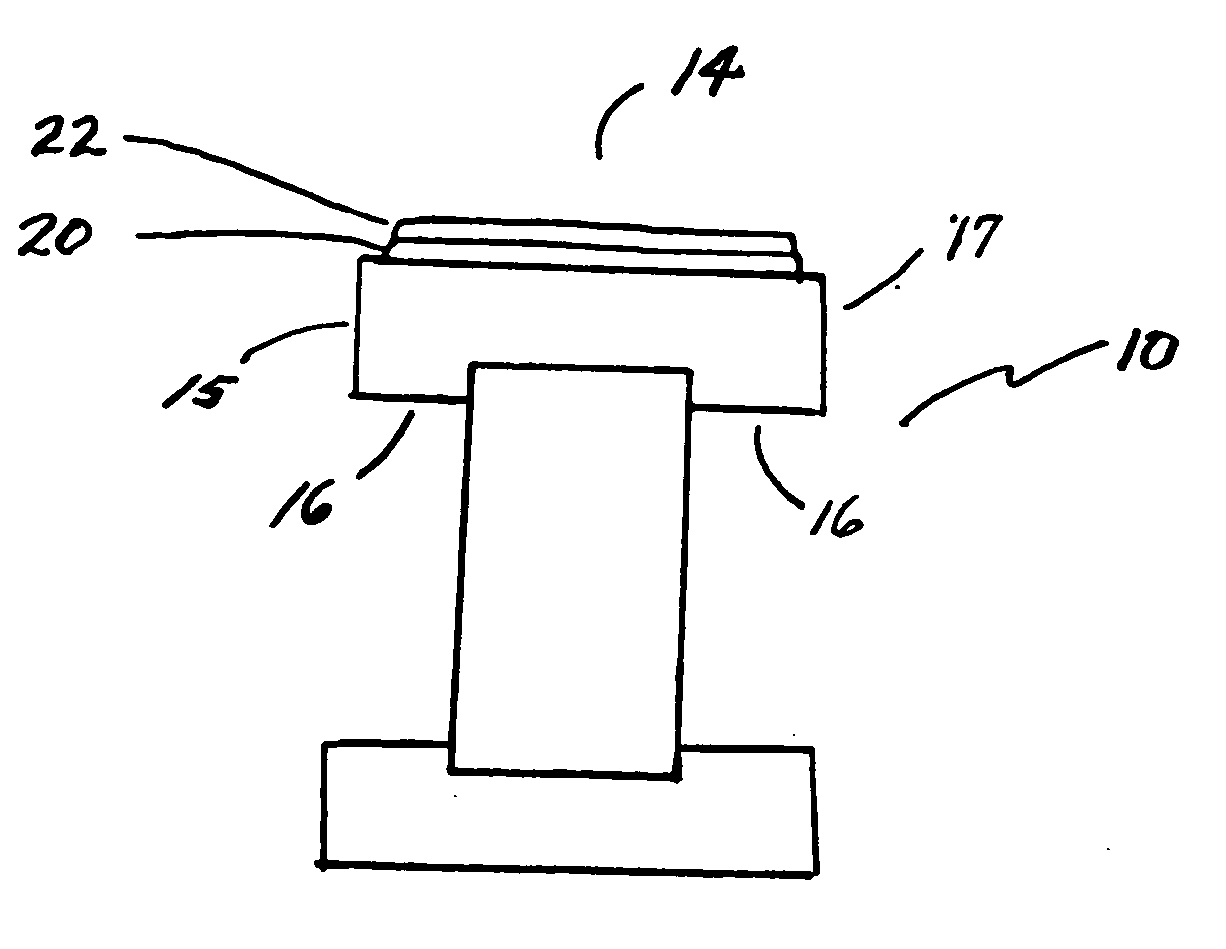

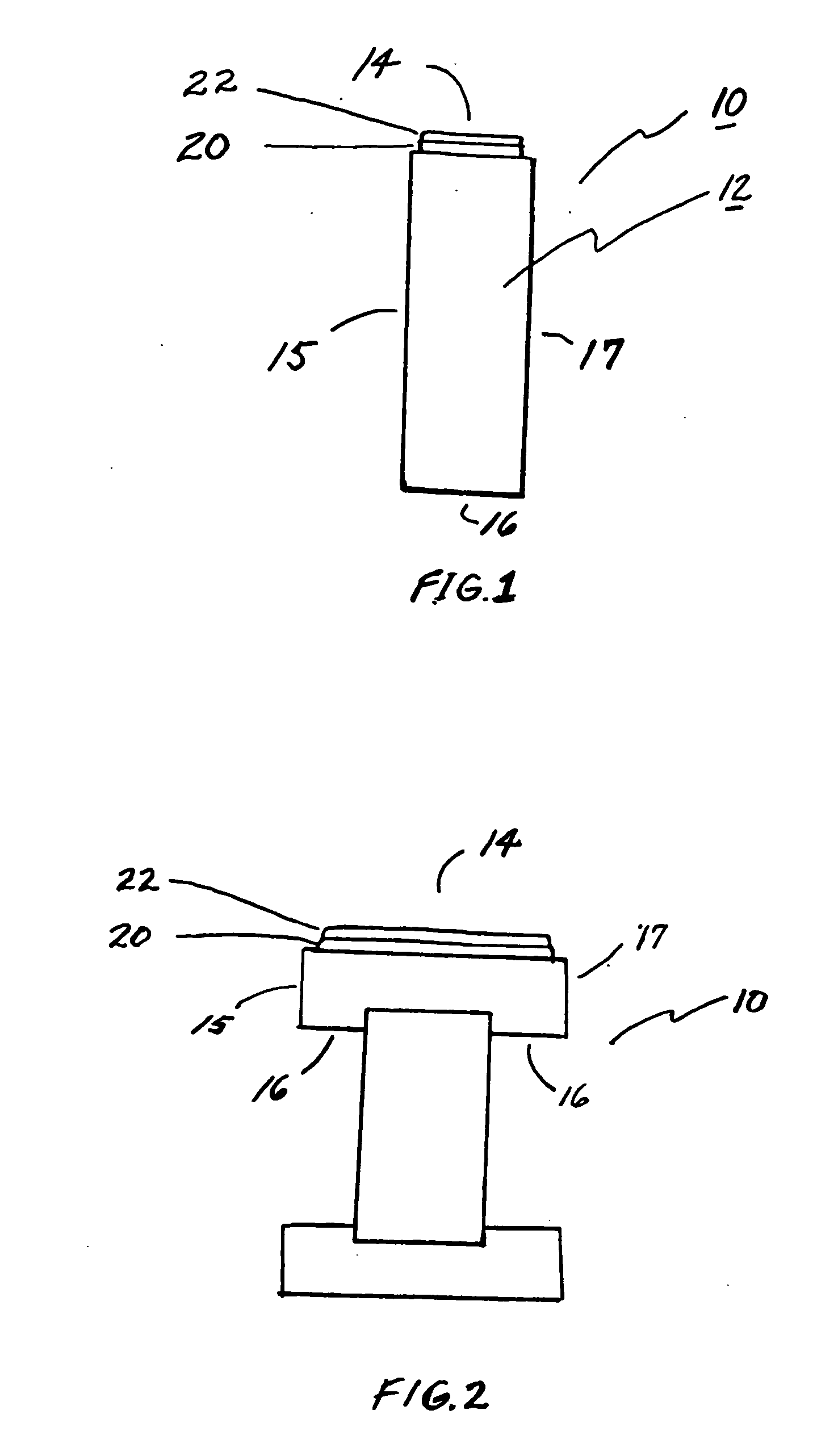

[0016] As shown in FIG. 1, an exemplary building element 10 of the present invention has a three-dimensional body 12 with at least four major faces 14, 15, 16, 17. Exemplary building materials are preferably selected from the group consisting of wood, plywood, oriented strand board, gypsum, concrete, mortar, brick, or tile. Such materials can be shaped in the form of a wall stud, floor joist, beam (e.g., rectangular or “I” shaped cross-section profile), a rafter (e.g., a beam for supporting roofing panels), floor decking, wall sheathing, gypsum board, and the like. Most preferred building elements 10 will have a beam shape, as shown in the cross-sectional profile illustration of FIG. 1, or an I-beam shape, as shown in FIG. 2.

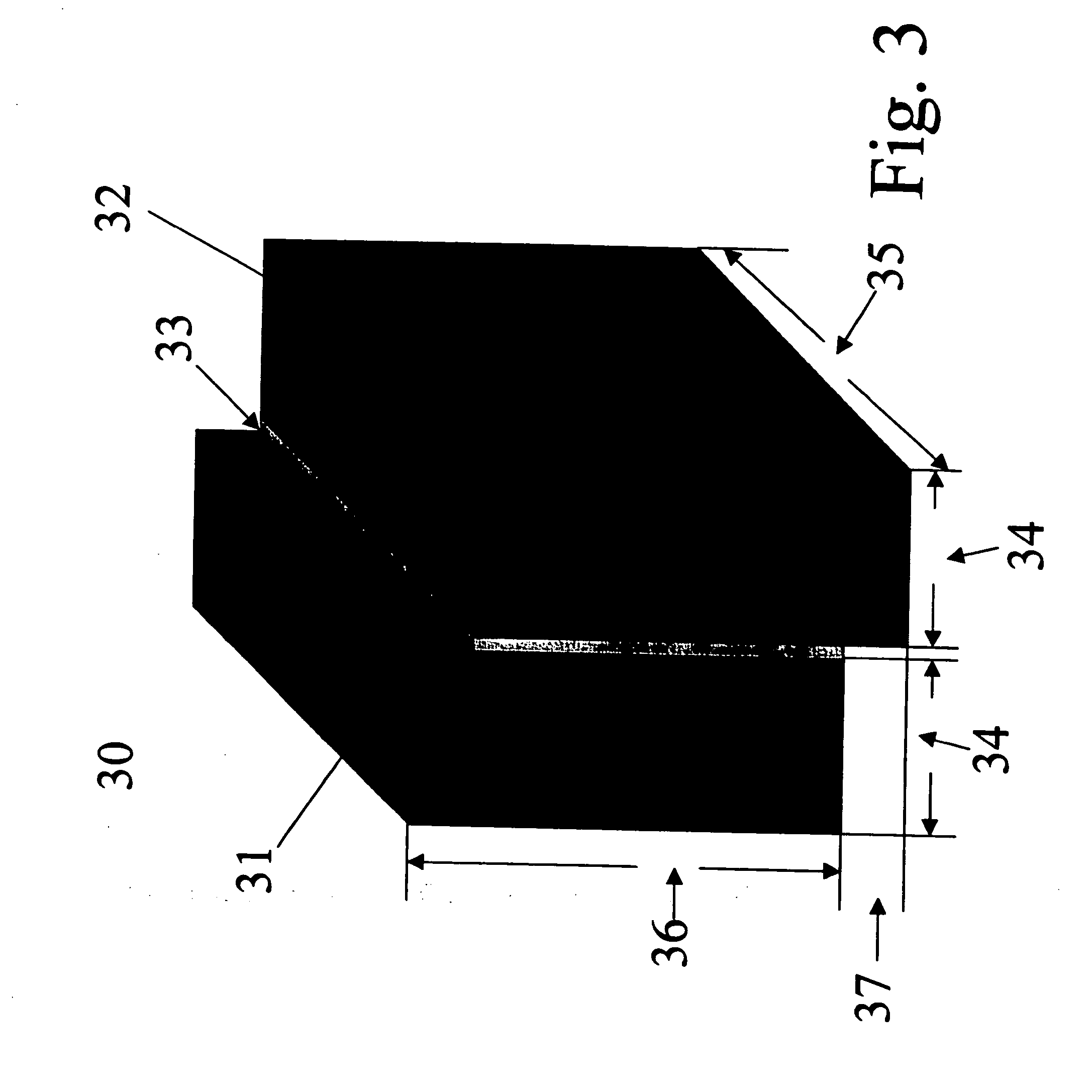

[0017] At least one face 14 of said at least four major faces has attached thereon a pre-formed, pressure-sensitive adhesive layer 20 comprising a polyolefin resin or a rubber adhesive having a minimum of 50% filler by total weight. The adhesive layer 20 has an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com