Multilayer thin film hydrogen getter

a hydrogen getter and thin film technology, applied in the field of thin film hydrogen getters, can solve the problems of reducing the performance and reliability of gallium arsenide (gaas) integrated circuits which are hermetically packaged, unable to re-work the assembly, and unable to return false results, etc., to achieve excellent high electrical conductance metals, enhance circuit performance, and cost benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

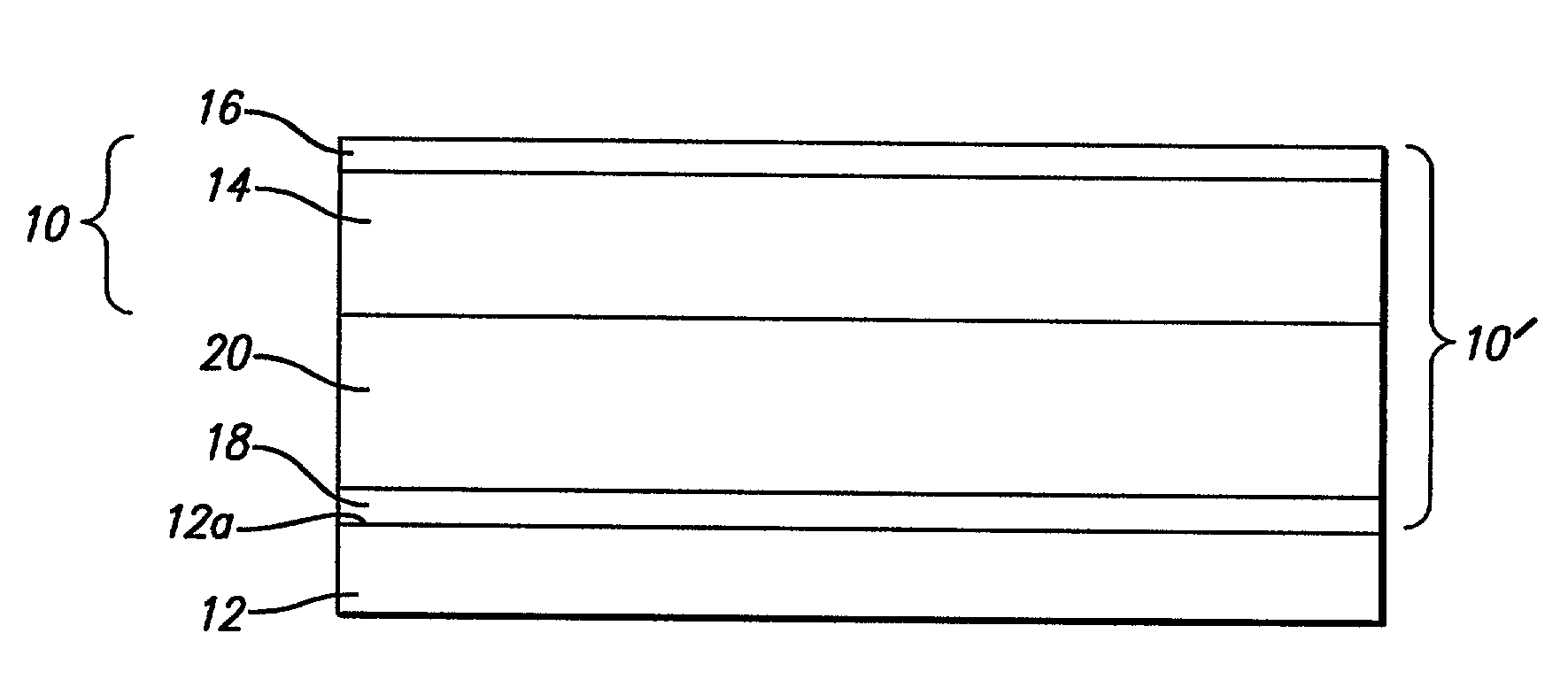

[0020] In a first embodiment, the thin film hydrogen getter 10 of the present invention consists of a vacuum-deposited multilayer film as shown in FIG. 1a, deposited on top of a surface 12a of substrate 12. A titanium (Ti) layer 14 is first vacuum-deposited, followed by a palladium (Pd) layer 16.

[0021] The titanium layer 14 has a thickness that is related to the expected generation of hydrogen over the lifetime of the package and the total area of the thin film, plus some safety margin. For example, for an expected hydrogen generation of about 75 Torr.multidot.cm.sup.3 from the package, only 0.56 mg of titanium would be required to absorb this amount of hydrogen. Factoring in a safety factor of 10, the required amount of titanium would still only be 5.6 mg.

[0022] The thickness of the palladium layer 16 must be thick enough to avoid pinholes (which would allow unwanted oxidation of the underlying titanium layer), but not so thick as to adversely affect the diffusion of hydrogen there...

second embodiment

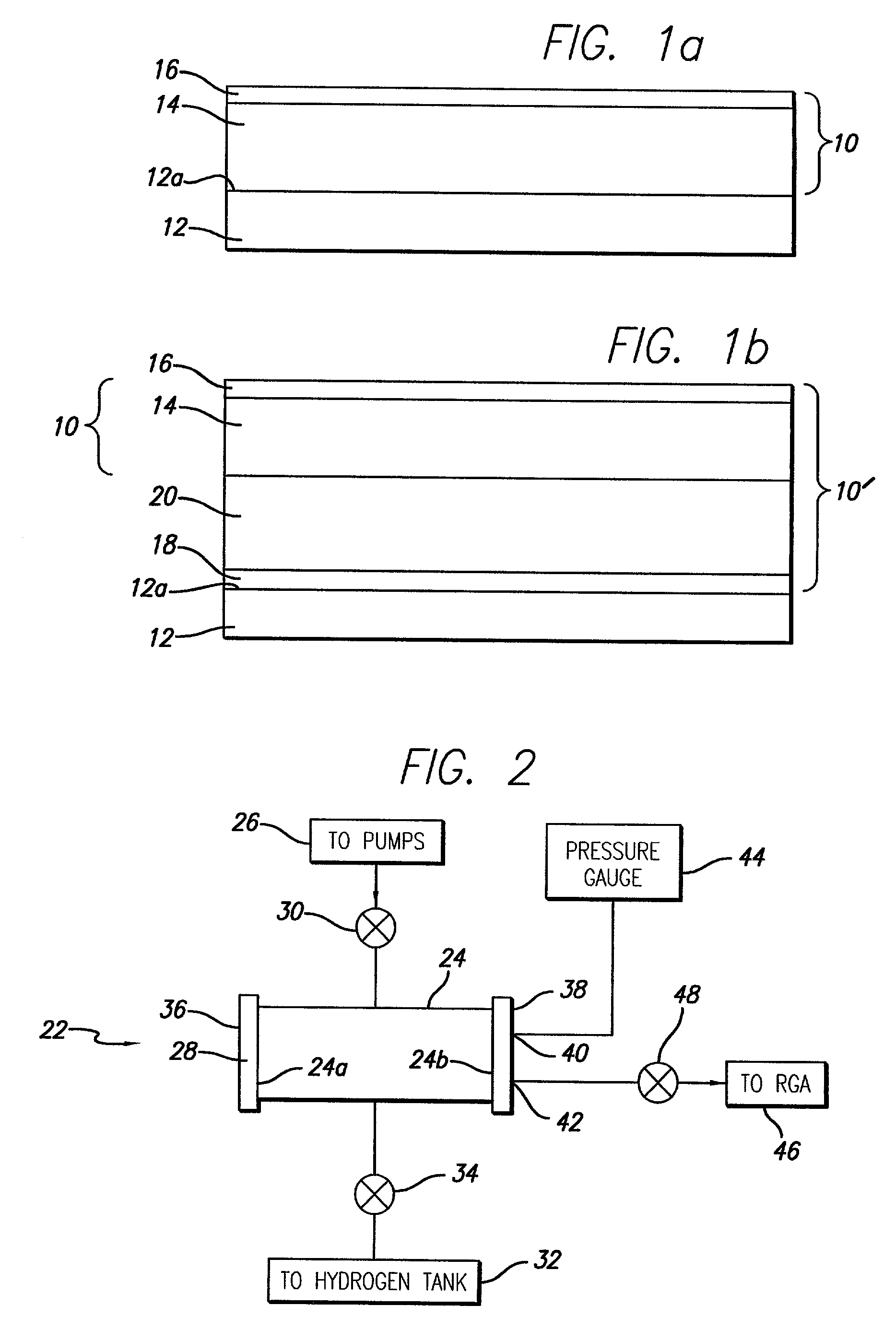

[0030] In a second embodiment, the thin film hydrogen getter / EMI shield 10' of the present invention consists of a vacuum-deposited multilayer film as shown in FIG. 1b, deposited on top of the surface 12a of substrate 12. The EMI film comprises a thin (100 to 250 .ANG.) electrically conductive metal, for example, a Ti adhesion layer 18 followed by an aluminum 20, 100 to 200 microinch in thickness, thereby providing 5 to 6 skin depths thickness at 10 GHz. As above, the getter portion comprises the Ti layer 14, followed by the palladium Pd layer 16. Again, the titanium layer 14 has a thickness of about 40 to 80 microinch, while the palladium layer 16 has a thickness of about 8 microinch. All of the four layers 14, 16, 18, 20 are deposited during the same processing run at a vacuum of about 10.sup.-6 Torr. Alternatively, the Ti adhesion layer 18 may be omitted, and instead, a copper or nickel layer, deposited by electroless deposition, may be deposited directly on the dielectric substr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Molar density | aaaaa | aaaaa |

| Molar density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com