Non-phosphate alkaliproof highly effective chelating dispersion stabilizer, preparation process and use thereof

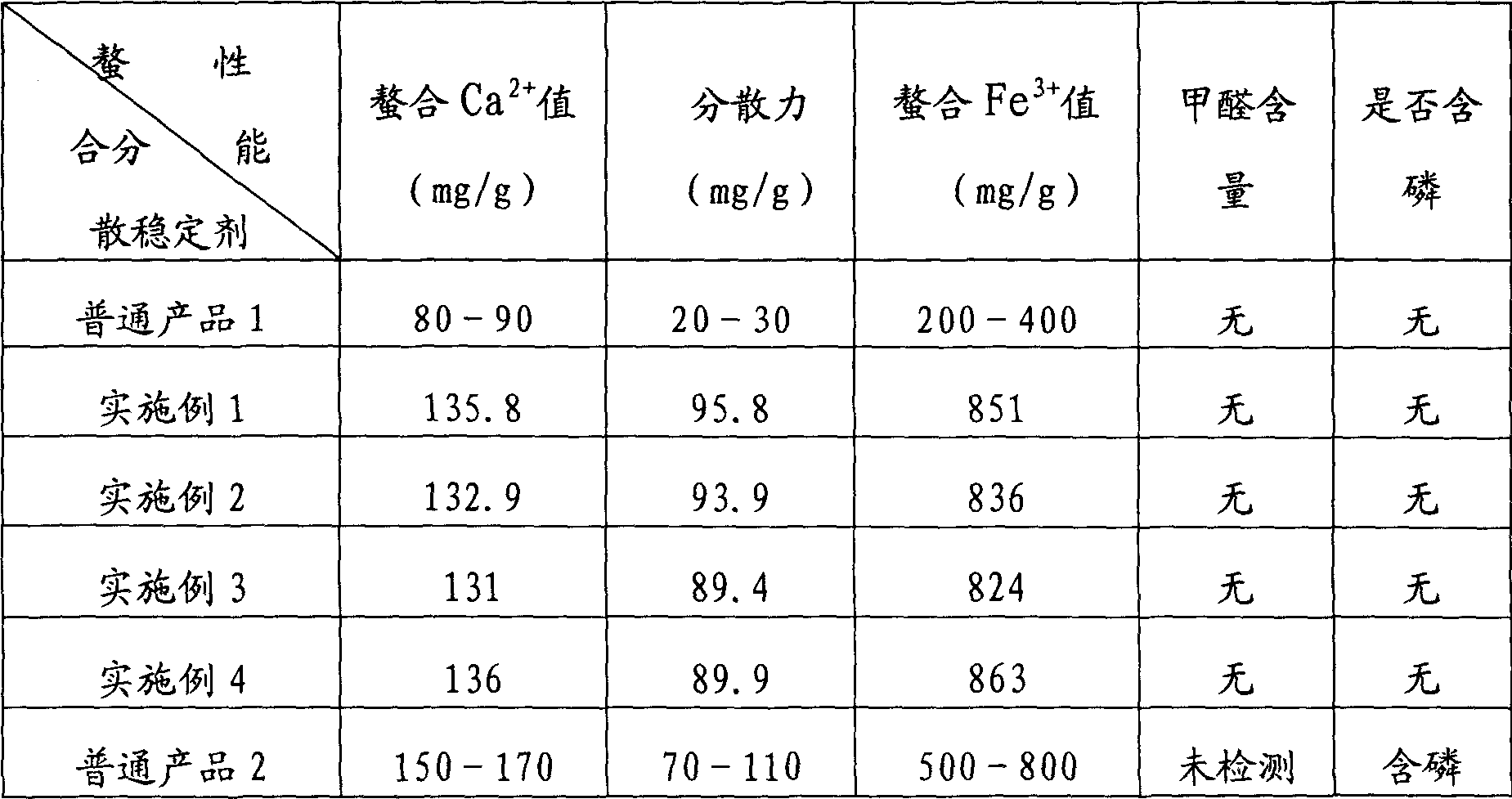

A chelating dispersing and stabilizing agent technology, which is applied in the field of phosphorus-free and alkali-resistant high-efficiency chelating dispersing stabilizer and its preparation, can solve problems such as pollution, eutrophication of waters, and ecological imbalance of aquatic organisms, and achieve superior dispersing performance and biological Good degradability and strong chelating ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0193] 1. Preparation of α-hydroxyacrylic acid

[0194] Add 72 grams of acrylic acid, 0.15 g of catalyst-red phosphorus and 0.1 g of polymerization inhibitor-phenol into a three-necked flask equipped with a stirrer, a thermometer and a condensing tube, and pass it for 5-10 hours at 0-20 ° C under the protection of nitrogen. Add 71 grams of chlorine gas, react at 0-20°C for 24-48 hours after passing through, then add 40 grams of sodium hydroxide, heat up to 50-70°C for 2-3 hours, and finally add 98 grams of concentrated sulfuric acid for neutralization, filter , Refined to obtain α-hydroxyacrylic acid.

[0195] 2. Preparation of phosphorus-free alkali-resistant high-efficiency chelating dispersion stabilizer

[0196] Preparation of polymers:

[0197] A, preparation of initiator aqueous solution: add 10 grams of water to 1.5 grams of potassium persulfate and make initiator aqueous solution;

[0198] B. Synthesis of high molecular polymer: add 20 grams of itaconic acid, 3.0 gr...

Embodiment 2

[0201] The compounding process of the preparation of α-hydroxyacrylic acid, the synthetic of polymer and chelating dispersion stabilizer is the same as embodiment 1, and its each composition is respectively as follows:

[0202] A, initiator aqueous solution: potassium persulfate 2.0g, water 10g;

[0203] B, the synthesis of polymer: 24 grams of itaconic acid, 2.0 grams of α-hydroxyacrylic acid, 35 grams of water, 1.3 grams of acrylic acid and 0.6 grams of methacrylic acid, 0.8 grams of dodecanethiol, 0.5 grams of sodium bisulfite, Potassium persulfate aqueous solution 3.0 grams; Dropping solution: 2.5 grams of peracetic acid, 1.0 grams of α-olefin sulfonate, 2.7 grams of acrylic acid, 1.4 grams of methacrylic acid, 15 grams of water;

[0204] C, compounding of chelating dispersion stabilizer: 90 grams of high molecular polymer prepared above, 6 grams of alkyl polyglycoside (APG-0810 or 1214) hydrolyzate and 4 grams of water.

Embodiment 3

[0206] The compounding process of the preparation of α-hydroxyacrylic acid, the synthetic of polymer and chelating dispersion stabilizer is the same as embodiment 1, and its each composition is respectively as follows:

[0207] A, initiator aqueous solution: potassium persulfate 1.8g, water 10g;

[0208] B, synthesis of polymer: 18 grams of itaconic acid, 4.0 grams of α-hydroxyacrylic acid, 35 grams of water, 1.8 grams of acrylic acid and 0.5 grams of methacrylic acid, 1.2 grams of dodecanethiol, 1.0 grams of sodium bisulfite, Potassium persulfate aqueous solution 3.0 grams; Dropping liquid: 2.8 grams of peracetic acid, 1.2 grams of α-olefin sulfonate, 3.7 grams of acrylic acid, 1.0 grams of methacrylic acid, 15 grams of water;

[0209] C, compounding of chelating dispersion stabilizer: 88 grams of high molecular polymer prepared above, alkyl polyglucoside (available APG-0810 or 1214 produced by Shanghai Jinling Petrochemical Company) hydrolyzate 5 grams and water 7 grams.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com