Composite coating material for high temperature heat barrier and ablation barrier, and its uses

A composite coating and warming technology, applied in coatings, fireproof coatings, polyester coatings, etc., can solve the problems of surface thermal barrier coating loss of attachment foundation, thermal barrier protection failure, surface coating collapse and cracking, etc., to achieve The process parameters are easy to control, the effect of heat insulation is good, and the equipment is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

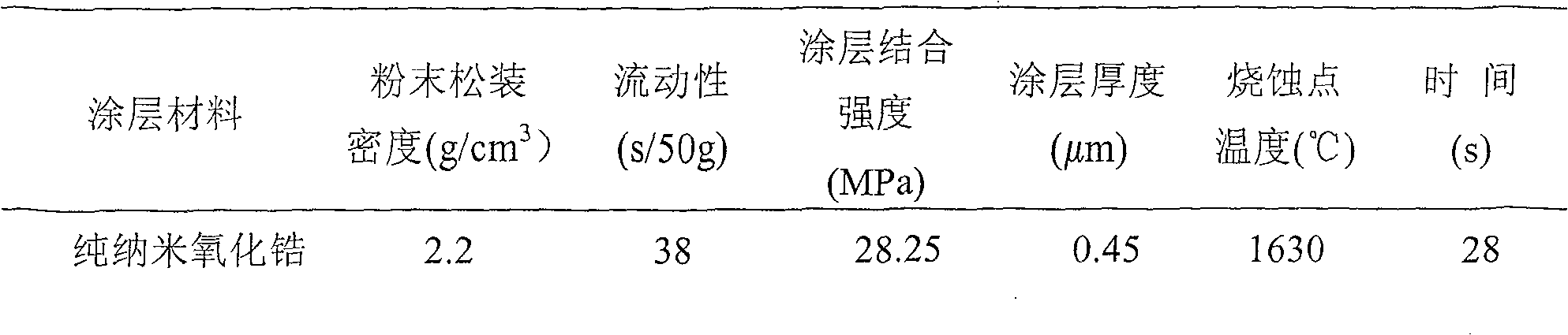

Embodiment 1

[0037] Take 8.5 kg of partially stabilized ZrO with a particle size of 10-100nm 2 / Y 2 o 3 powder (yttrium oxide partially stabilized zirconia powder), add 1.5 kg of nano-silicon oxide, and 0.2 kg of polyvinyl alcohol binder, after mixing fully, add 11 kg of clean water and stir to form a uniformly dispersed and suspended slurry. use. The partially stabilized ZrO 2 / Y 2 o 3 Y in powder 2 o 3 The content is 5-7wt%.

[0038] Dry and pure compressed air is used as the carrying gas, the gas pressure is controlled at 0.8Mpa, and the slurry is sprayed into the drying tower by a two-flow nozzle. The atomized slurry shrinks into a reunited hollow sphere depending on its own surface tension. In medium drying, the heating temperature of the drying tower heater is controlled between 150-280°C, and the adjustment of the temperature is limited to the sufficient drying of the powder. The dried agglomerated powder is then drawn into a cyclone for collection by means of an aspirator....

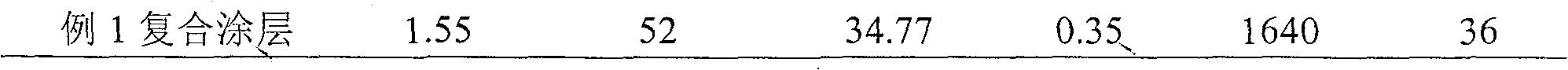

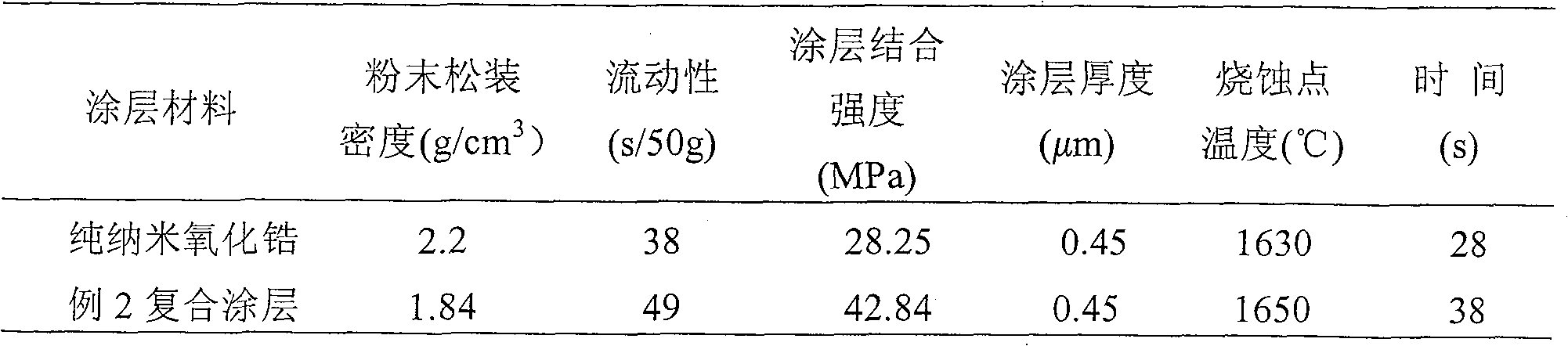

Embodiment 2

[0045] Take 7.0 kg of partially stabilized ZrO with a particle size of 10-100nm 2 / Y 2 o 3 Powder, 1.0 kg of nano-silicon nitride and 2.0 kg of copper powder with a particle size of 0.5 μm, add 0.2 kg of polyvinyl alcohol adhesive, after thorough mixing, add 11 kg of clean water and stir to form a uniformly dispersed and suspended material pulp for later use. The partially stabilized ZrO 2 / Y 2 o 3 Y in powder 2 o 3 The content is 5-7wt%.

[0046] Spray the slurry into the drying tower with a centrifugal atomizing nozzle. The rotational speed of the centrifugal atomizer is 800-2000r / min. The atomized slurry particles shrink into agglomerated solid spheres by their own surface tension and are dried in the hot wind. , The heating temperature of the drying tower heater is controlled between 150-280 ° C, and the adjustment of the temperature is limited to the sufficient drying of the powder. The dried agglomerated powder is then drawn into a cyclone for collection by mean...

Embodiment 3

[0052] Take 7.0 kg of partially stabilized ZrO with a particle size of 10-100nm 2 / Y 2 o 3 Powder, 2.0 kg of 10-30 μm copper powder and 1.0 kg of 10-30 μm organic polymer (phenolic resin) powder, add 0.2 kg of polyvinyl alcohol adhesive, mix well, and then add 11 kg of clean water Stir to form a uniformly dispersed and suspended slurry for later use. The partially stabilized ZrO 2 / Y 2 o 3 Y in powder 2 o 3 The content is 5-7wt%.

[0053] Dry and pure compressed air is used as the carrying gas, the gas pressure is controlled at 0.8Mpa, and the slurry is sprayed into the drying tower by a two-flow nozzle. The atomized slurry shrinks into a reunited hollow sphere depending on its own surface tension. In medium drying, the heating temperature of the drying tower heater is controlled between 150-280°C, and the adjustment of the temperature is limited to the sufficient drying of the powder. The dried agglomerated powder is then drawn into a cyclone for collection by means ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com