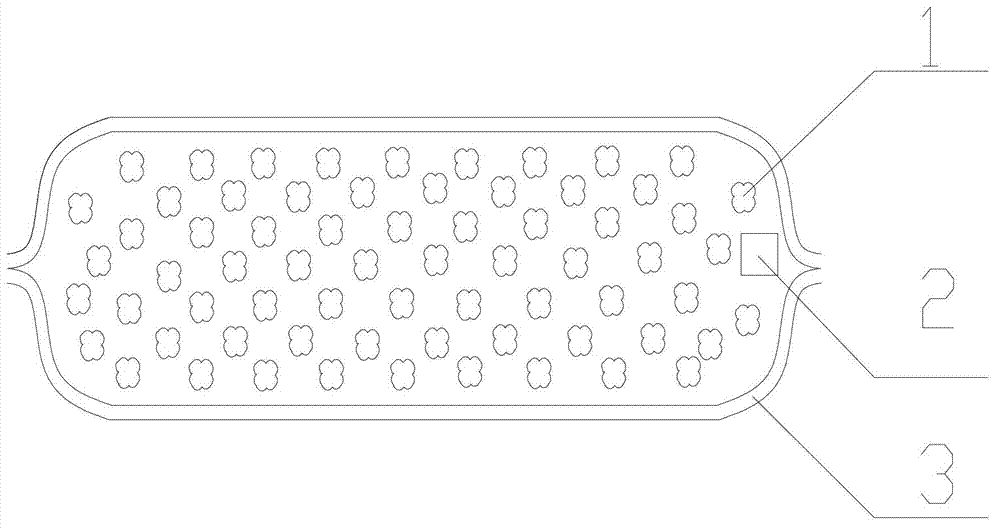

Vacuum insulation panel of phase change material and glass fiber composite core material and preparation method thereof

A technology of vacuum insulation panels and phase change materials, which is applied to heat exchange equipment, mechanical equipment, and pipelines through thermal insulation protection, etc., can solve the problem of not using vacuum insulation panels, etc. The effect of thermal barrier action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

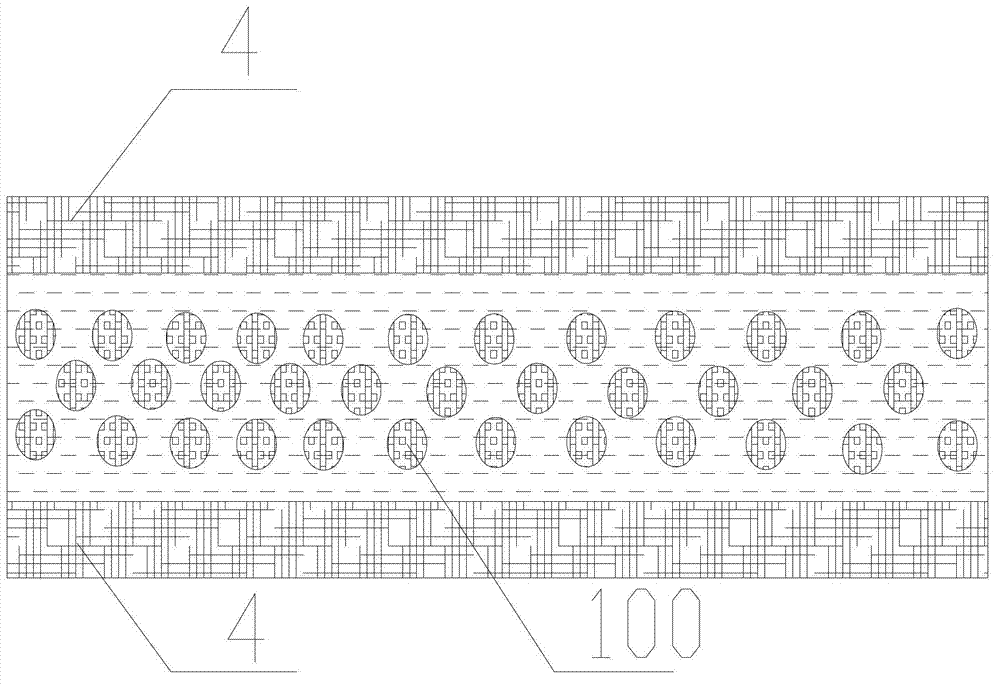

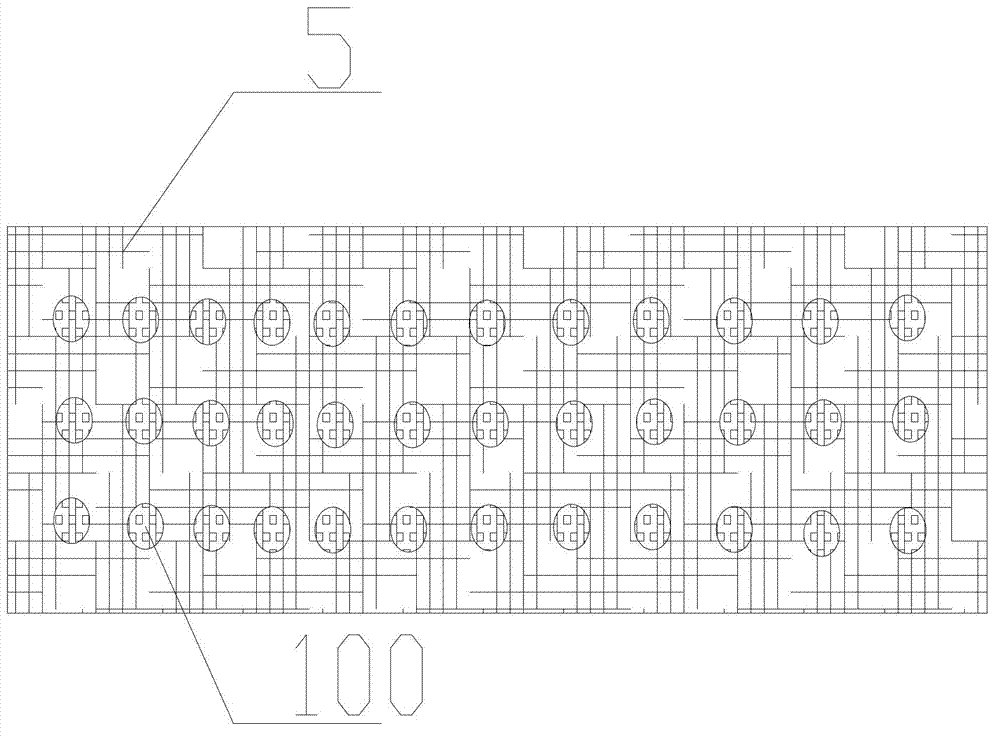

[0066] The paraffin wax is a binary mixed system of 17-alkane and 18-alkane. Under different mixing ratios, the phase transition temperature of the paraffin wax can be obtained by mixing between 20°C and 28°C. Silica molecular sieve is a composite phase change energy storage material with a carrier. Paraffin wax and silica molecular sieve are in a simple chimera relationship, and the composite material has good thermal stability and compatibility.

[0067] The above-mentioned composite phase change energy storage material with a phase change temperature of 20°C is selected and wrapped with a high polyester-based capsule with a diameter of 50 nanometers, and then the nanocapsules are combined with a glass fiber with a diameter of 30 μm to form a sandwich structure. The mass of the phase change material The percentage is 12%, and the vacuum insulation panel using this core material is evacuated to a final pressure of 0.6Pa, and the thermal conductivity value measured by GB / T3399-...

example 2

[0233] The calcium chloride hexahydrate nanocapsule phase change material with a phase transition temperature of 29°C is wrapped with a high polyester-based capsule with a diameter of 50 nanometers, and then the nanocapsules are composited with glass fibers with a diameter of 30 μm to form a sandwich structure. The mass percentage of the core material is 12%, and the vacuum insulation panel using this core material is evacuated to a final pressure of 0.6Pa. The thermal conductivity value measured by GB / T3399-2009 plastic thermal conductivity test method-protected hot plate method is 0.00351W (m · K). Choose a vacuum insulation panel composed of calcium chloride hexahydrate nanocapsule phase change material and glass fiber with a diameter of 30 μm, and the labels are G, H, and I. Select a vacuum insulation panel with a diameter of 30 μm glass fiber as the core material, and evacuate to a final pressure of 0.6Pa in the same way, labeled A 2 , B 2 、C 2 , this group was set as ...

example 3

[0292] The nanocapsule phase change material made of capric acid and lauric acid binary compound has a phase change temperature between 25-30°C, and the phase change temperature can be determined according to the molar concentration of capric acid in the capric acid-lauric acid binary compound system.

[0293] The above-mentioned phase-change energy storage material with a phase-change temperature of 25°C is selected and wrapped with a high-polyester-based capsule with a diameter of 50 nanometers, and then the nanocapsules are composited with glass fibers with a diameter of 30 μm to form a sandwich structure. The mass percentage of the phase-change material The vacuum insulation panel using this core material is evacuated to a final pressure of 0.6Pa, and the thermal conductivity value measured by GB / T3399-2009 plastic thermal conductivity test method-protected hot plate method is 0.00347W (m K) Choose a vacuum insulation panel made of capric acid-lauric acid binary composite n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com