Method for preparing light-weight wallboard by using fly ash

A light-weight wallboard and fly ash technology, applied in the field of light-weight wallboards, can solve problems such as inability to form light-weight wallboards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

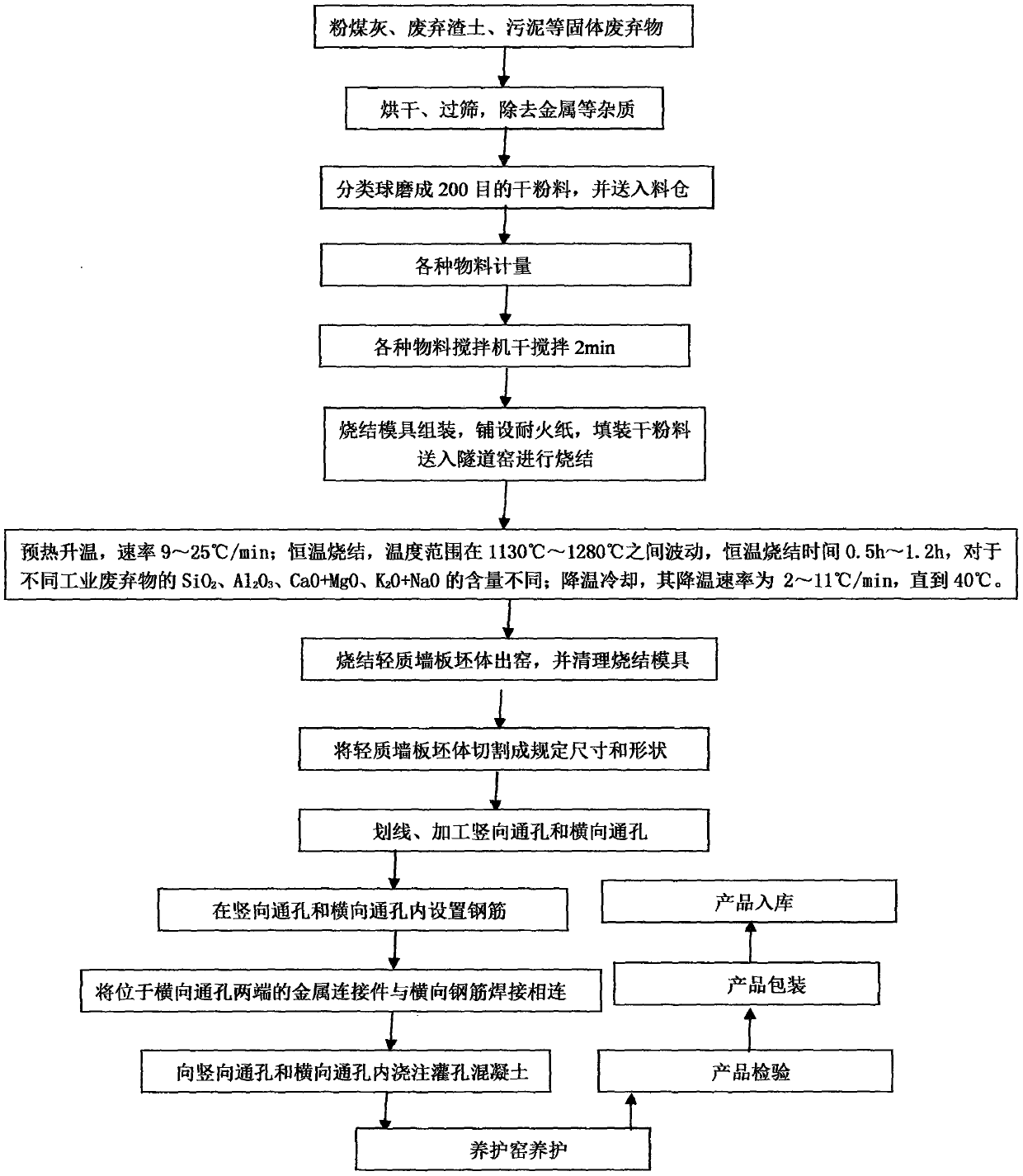

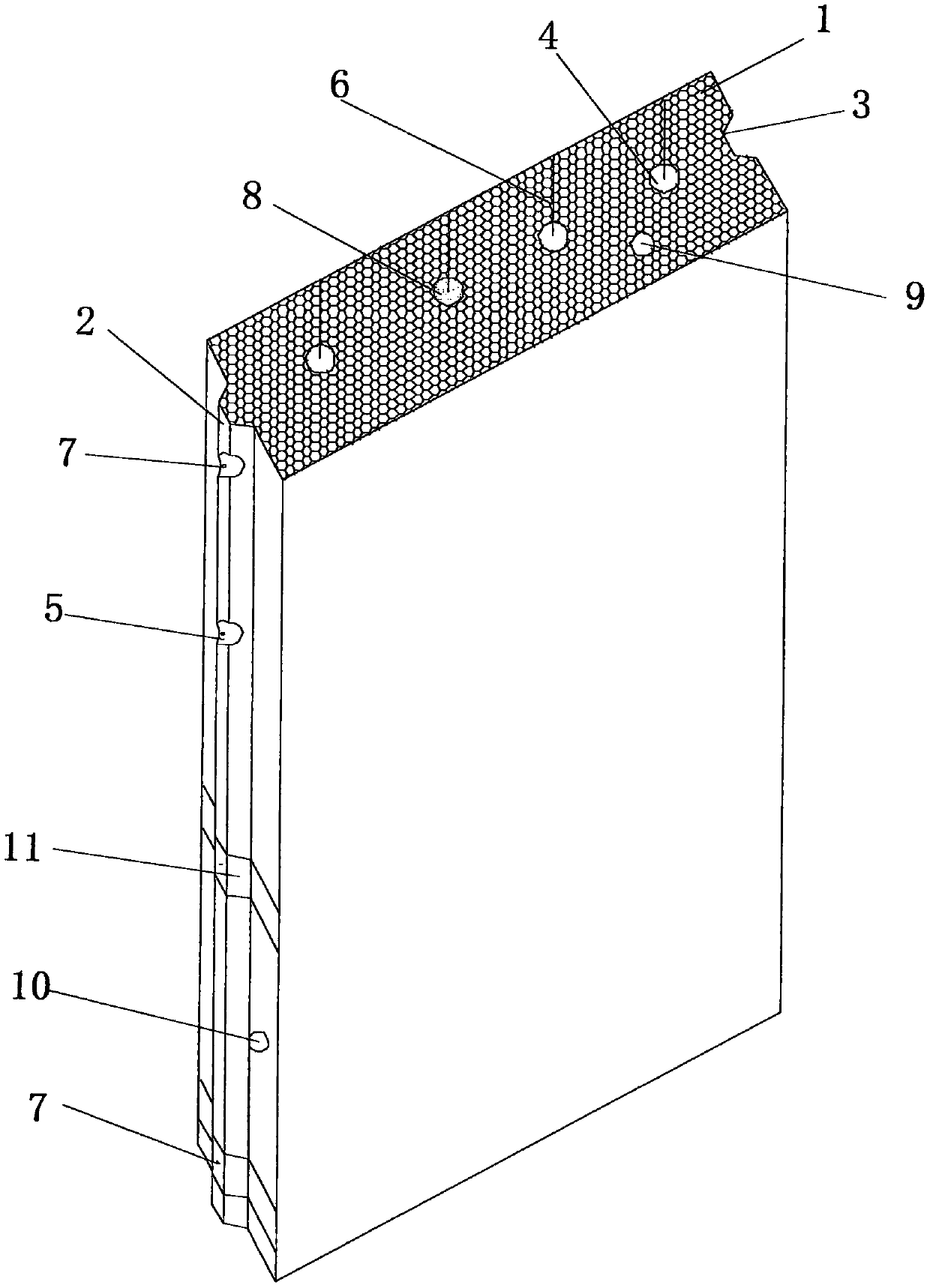

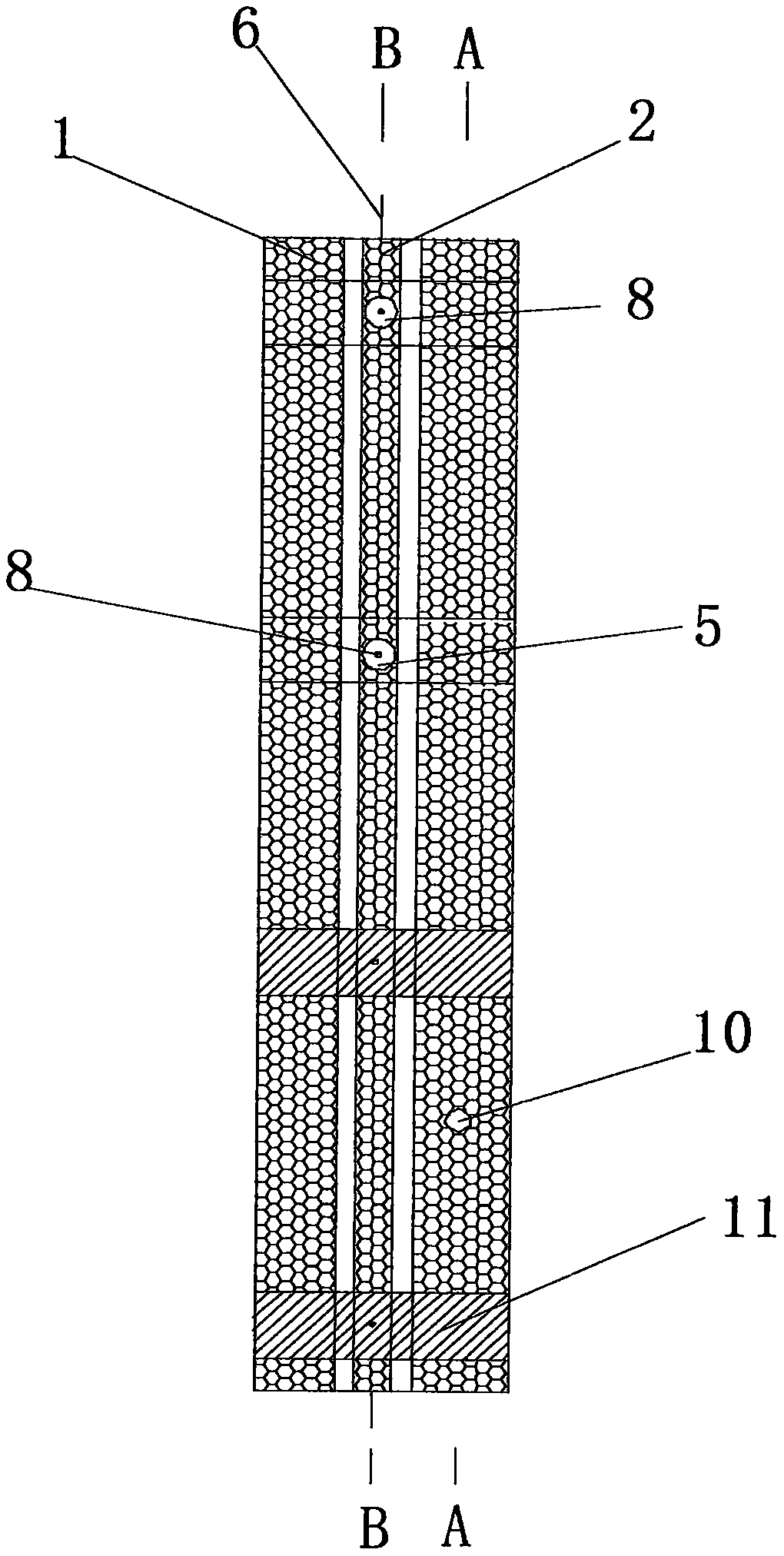

[0047] The present invention is achieved like this, below in conjunction with appendix Figure 1 to Figure 8 For further explanation: a method for preparing lightweight wallboards using fly ash, including materials and proportions and a manufacturing process, the proportion of materials is: 70-80% of fly ash, 10-15% of waste muck, Sludge 10-15%, foaming agent 0.2-0.8% of the total material; the process flow is:

[0048] 1) Dry the fly ash, waste slag and sludge first and then sieve to remove impurities such as metals;

[0049] 2) Ball mill the fly ash, waste slag and sludge respectively, the fineness of the dry powder is 200 mesh, and send the dry powder into the warehousing for preparation and stand-by;

[0050] 3) Measure the fly ash, waste residue, sludge and foaming agent according to the ratio;

[0051] 4) Put the measured material into the mixer and dry mix for 2 minutes;

[0052] 5) Assembling the sintering mold, laying fire-resistant paper on the bottom plate of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com