Multi-cavity concrete column and construction method thereof

A concrete column and concrete technology, applied in the direction of columns, pier columns, pillars, etc., can solve the problems of accelerated corrosion of wall decoration materials, many construction procedures, and difficult construction, etc., to achieve easy construction and installation, good mechanical performance, and simple construction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

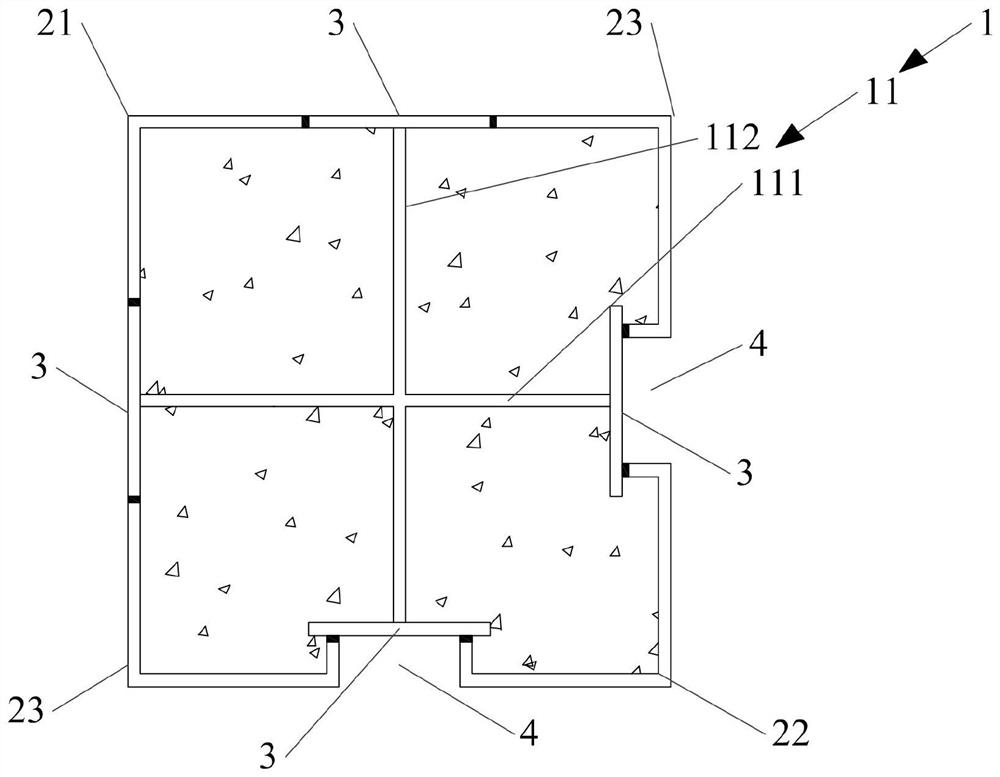

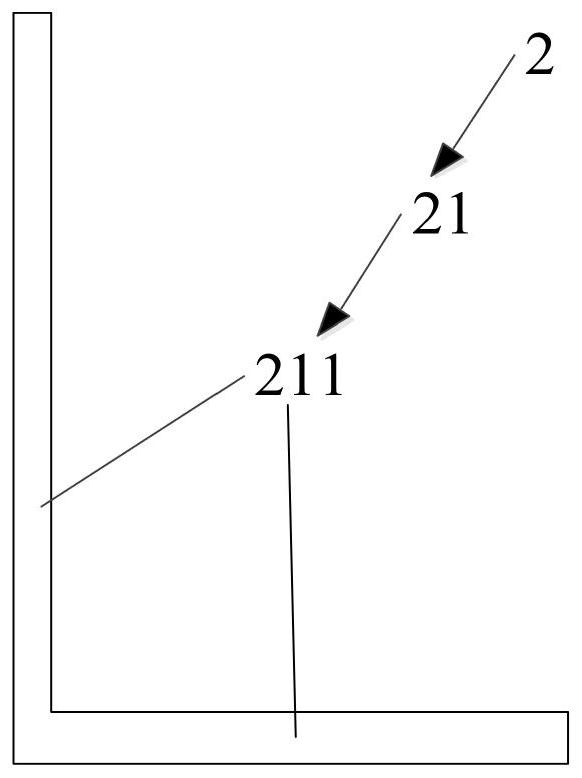

[0031] This embodiment provides a multi-cavity concrete column, please refer to figure 1 , including a support 1, at least one external plate 2 and at least one flange 3, the support 1 includes at least one plate, each side end of the plate is fixedly provided with a flange 3, two adjacent wings The flange plates 3 are fixedly connected by an external plate 2; the support member 1, the flange plate 3 and the external plate 2 form a cavity column with at least two cavities, and each cavity is used to be filled with concrete. And at least one outer cavity wall of the cavity column has a groove 4 for embedding with the filling wall.

[0032]The support member 1, the flange plate 3 and the outer plate 2 form a cavity column with at least two cavities, and then the cavity is filled with concrete to be cooled to form a concrete column. Setting multiple cavities can effectively restrain the core concrete shrinkage and joint cracking, and the plate body of support 1 can act as an inn...

Embodiment 2

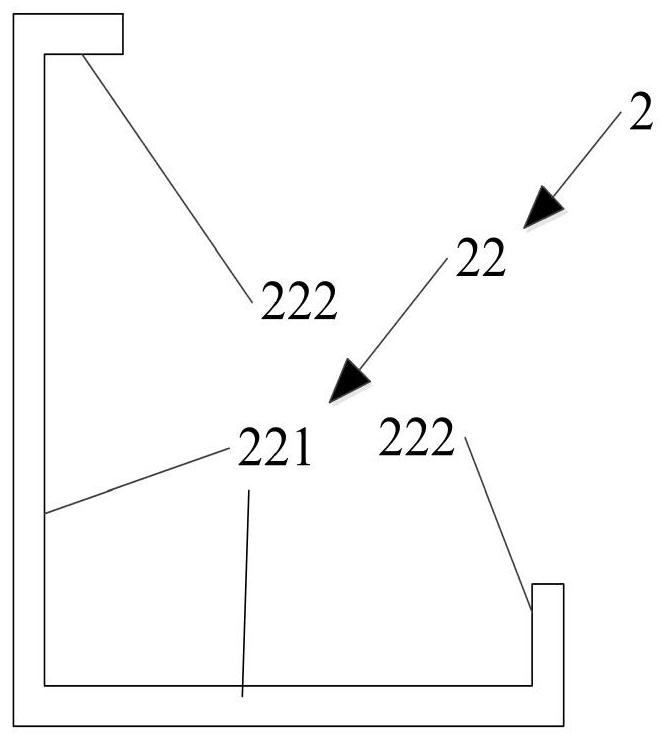

[0039] This embodiment provides another multi-cavity concrete column, see Figure 5 , the difference between this embodiment and Embodiment 1 is that: the four outer connecting plates 2 are all set as second outer connecting plates 22; a second outer connecting plate 22 is connected between adjacent flange plates 3, and each second The two second outer plates 222 of the outer connecting plate 22 are fixedly connected to the two adjacent flange plates 3 respectively, and the two second outer plates 222 close to each other between the adjacent second outer connecting plates 2 are connected to the same wing The edge plate 3 also forms a groove 4, that is, the number of grooves 4 is four in total, and the four grooves 4 are respectively located on the four outer side walls of the multi-cavity concrete column; so set, the multi-cavity concrete provided by this embodiment The column can be used as the column in the inner cavity, and the four outer walls of the multi-cavity concrete ...

Embodiment 3

[0041] This embodiment also provides a multi-cavity concrete column, see Figure 6 , the difference between this embodiment and Embodiment 1 is that: the four external plates 2 are all set as the third external plate 23; a third external plate 23 is connected between adjacent flange plates 3, and the first plate body 111 Or the flange plate 3 connected to both ends of the second plate body 112 is fixedly connected to the third outer plate 232 and forms two opposite grooves 4, and the two grooves 4 are located on the two opposite outer walls of the multi-cavity concrete column Above; set up in this way, the multi-cavity concrete column provided by this embodiment can be used as the middle column of the outer wall, and the opposite outer wall of the multi-cavity concrete column is embedded and connected with two filling walls through two grooves 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com