Process for solid phase synthesis of lithium iron phosphate anode materials under high pressure

A technology of lithium iron phosphate and cathode material, applied in chemical instruments and methods, phosphorus compounds, battery electrodes, etc., can solve the problems of low charge and discharge current density, low diffusion speed of lithium ions, and limitations of coarse particles, so as to reduce the reaction Time, small grain size, effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Will Li 2 CO 3 , FeC 2 o 4 2H 2 O and NH 4 h 2 PO 4 Weigh 45g according to the stoichiometric ratio of Li:Fe:P=1:1:1, mix evenly, and ball mill on a planetary ball mill for 6h; then pretreat at 300°C for 5h under air atmosphere, and after natural cooling, the powder is obtained Shape product; Add low molecular weight phenolic resin 5g as carbon source in above-mentioned powdery product, ball mill 6h again in planetary ball mill, in N 2 Sintering was carried out at 550° C. for 6 hours under a pressure of 10 MPa in an air atmosphere to obtain a carbon-coated lithium iron phosphate cathode material.

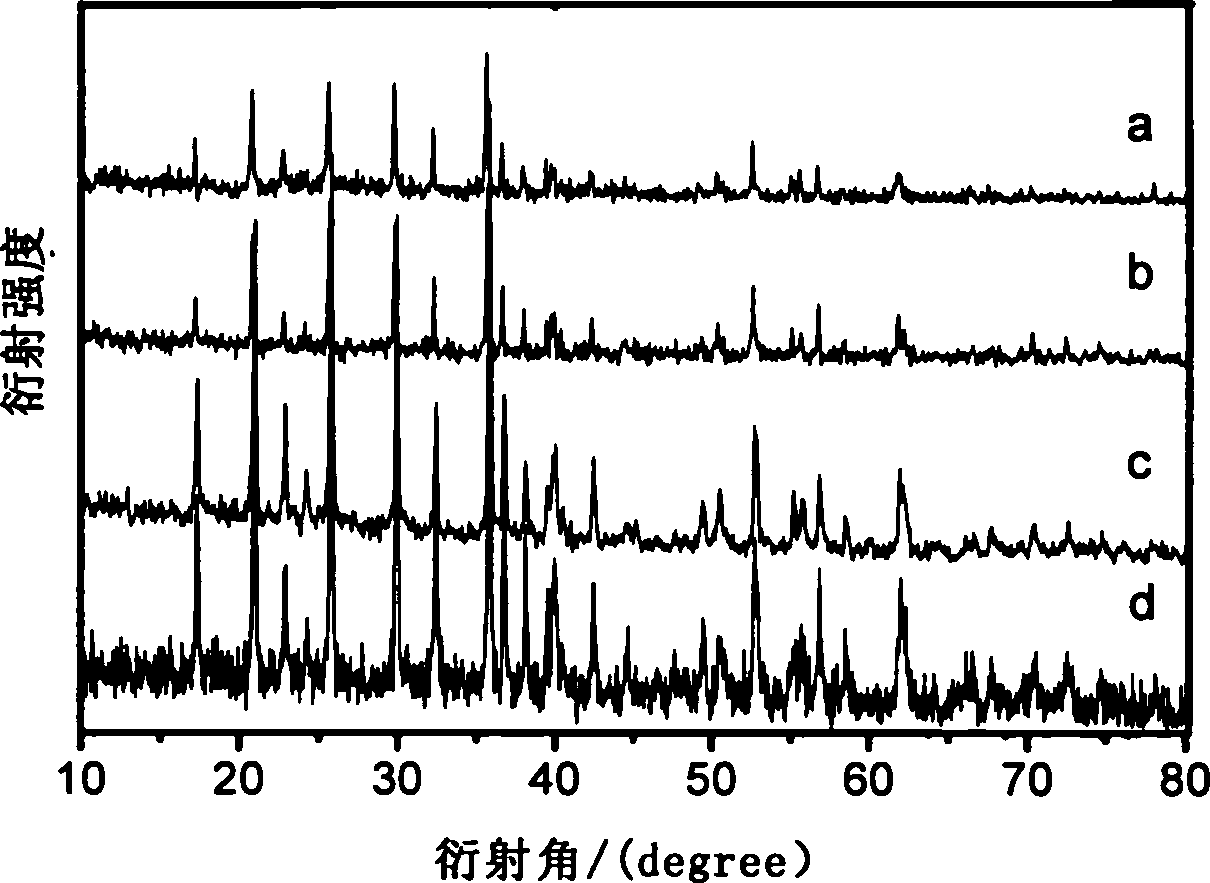

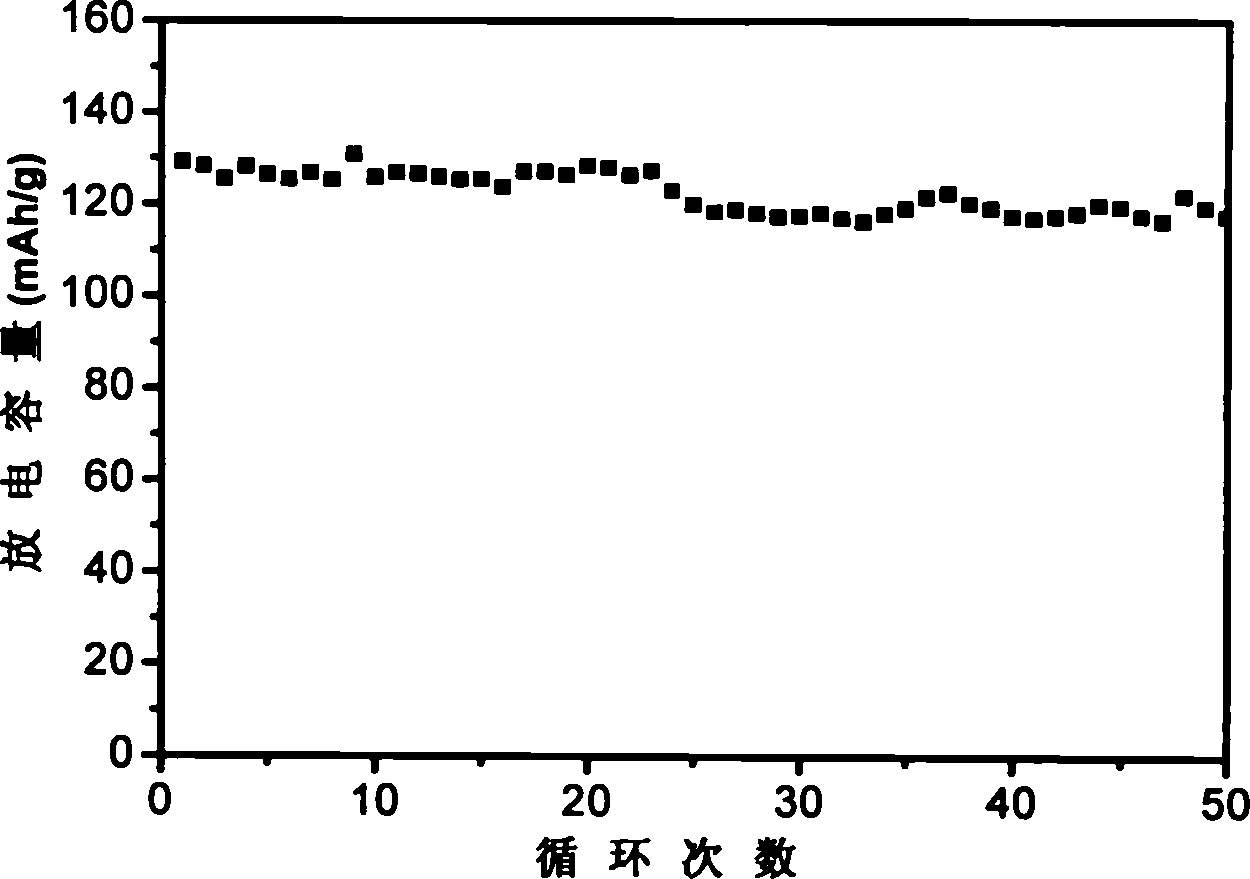

[0024] The XRD pattern of the product is shown in figure 1 As shown in the middle a curve, it can be seen from the figure that a lithium iron phosphate cathode material with a pure phase olivine structure was synthesized by using this high-temperature solid-state sintering method. There is no impurity peak in the spectrogram, and the product has high purity. The cyc...

Embodiment 2

[0026] LiNO 3 , FeC 2 o 4 2H 2 O and (NH 4 ) 2 HPO 4 Weigh 50g according to the stoichiometric ratio of Li:Fe:P=1:1:1, mix evenly, and ball mill on a planetary ball mill for 12h; then under air atmosphere, carry out pretreatment at 200°C for 8h, after natural cooling, to obtain Powdered product; then add 1 g of acetylene black as a carbon source to the above powdered product, ball mill it again in a planetary ball mill for 10 h, and sinter at 560 ° C for 6 h in an Ar gas atmosphere to obtain a carbon package Coated lithium iron phosphate cathode material.

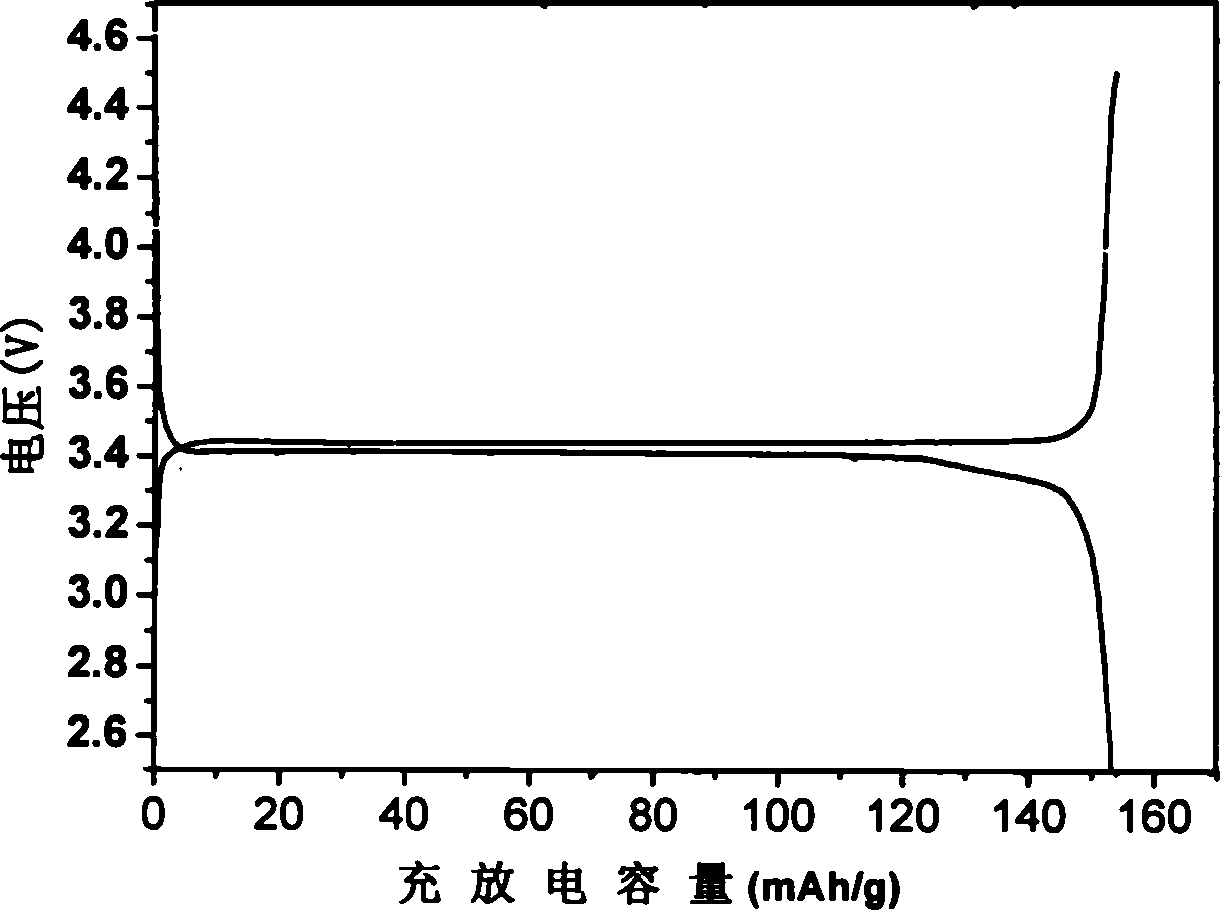

[0027] The XRD pattern of the product is shown in figure 1 As shown in the middle b curve, it can be seen from the figure that there is no impurity in the product, and it is a lithium iron phosphate positive electrode material with a pure-phase olivine structure. The first charge and discharge curve of the lithium iron phosphate cathode material at a rate of 0.1C is shown in image 3, the charge and discharge capac...

Embodiment 3

[0029] LiCH 3 COO, FeC 2 o 4 2H 2 O and (NH 4 ) 3 PO 4 Weigh 99g according to the stoichiometric ratio of Li:Fe:P=1:1:1, mix uniformly, and ball mill on a planetary ball mill for 20h; then under air atmosphere, carry out pretreatment at 300°C for 12h, after natural cooling, to obtain powdered product; then add graphite 1g as a carbon source in the above powdered product, and ball mill for 10 h again in the planetary ball mill, in CO 2 Sintering was carried out at 550° C. for 6 hours under a pressure of 15 MPa in an air atmosphere to obtain a lithium iron phosphate cathode material.

[0030] The XRD pattern of the product is shown in figure 1 As shown in the middle c curve, it can be seen from the figure that there is no impurity in the product, and it is a lithium iron phosphate positive electrode material with a pure-phase olivine structure. The first charge and discharge curves of the lithium iron phosphate cathode material at different rates are shown in Figure 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com