Fast preparation of titanium or titanium alloy surface biological active coating

A biologically active, titanium alloy technology, applied in metal material coating process, coating, superimposed layer plating, etc., can solve problems such as long production cycle, achieve easy operation, simple equipment, and increased coating formation rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The Ti-28Nb-8Zr-2Sn sample was polished by 100#, 400#, 800#, and 1000# silicon carbide sandpaper respectively, then soaked in 60°C, 5M KOH solution for 24 hours, and then blown in air at 0-30°C. Dry.

[0040] The alkali-treated Ti-28Nb-8Zr-2Sn sample was heated to 600°C in a box-type resistance furnace, kept for 1 hour and then cooled with the furnace. The heating rate was 5°C / min.

[0041] Prepare a high ion concentration calcium and phosphorus solution according to Table 1, and use 10mM NaHCO 3 The pH of the solution was adjusted to 6.5.

[0042] Reagent

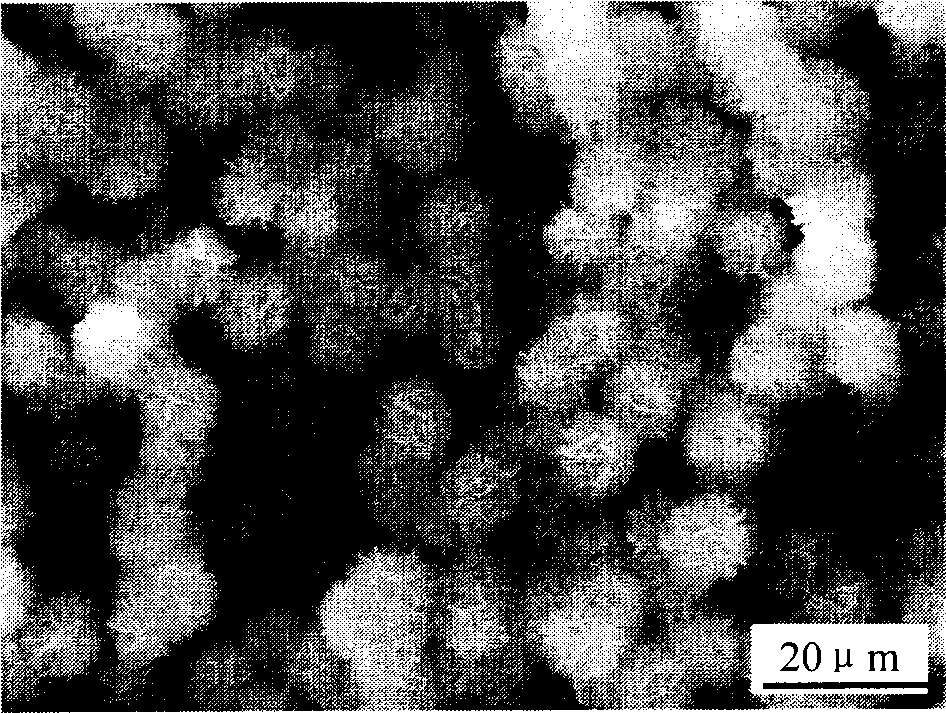

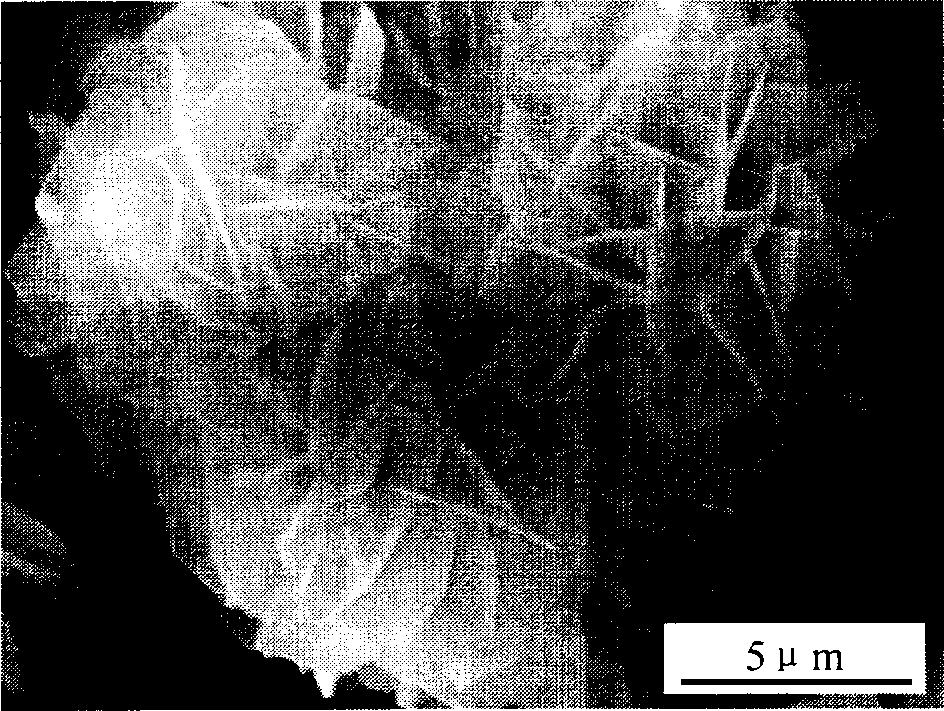

[0043] Soak the alkali-treated and heat-treated Ti-28Nb-8Zr-2Sn sample in the above solution at room temperature (18±8°C) for 2 to 24 hours to obtain a spherical hydroxyapatite layer (see figure 1 , figure 2 ), the thickness of the coating is 2-100 μm, and the X-ray diffraction pattern of the spherical hydroxyapatite coating is shown in Figure 8 .

Embodiment 2

[0045] The Ti-6Al-4V samples were polished by 100#, 400#, 800#, and 1000# silicon carbide sandpaper respectively, then soaked in 3M KOH solution at 30°C for 24 hours, and then dried in air at 0-30°C.

[0046] The alkali-treated Ti-6Al-4V sample was heated to 600°C in a box-type resistance furnace, kept for 1 hour and then cooled with the furnace. The heating rate was 5°C / min.

[0047] Prepare a high ion concentration calcium and phosphorus solution according to Table 1, and use 10mM NaHCO 3 The pH of the solution was adjusted to 6.5.

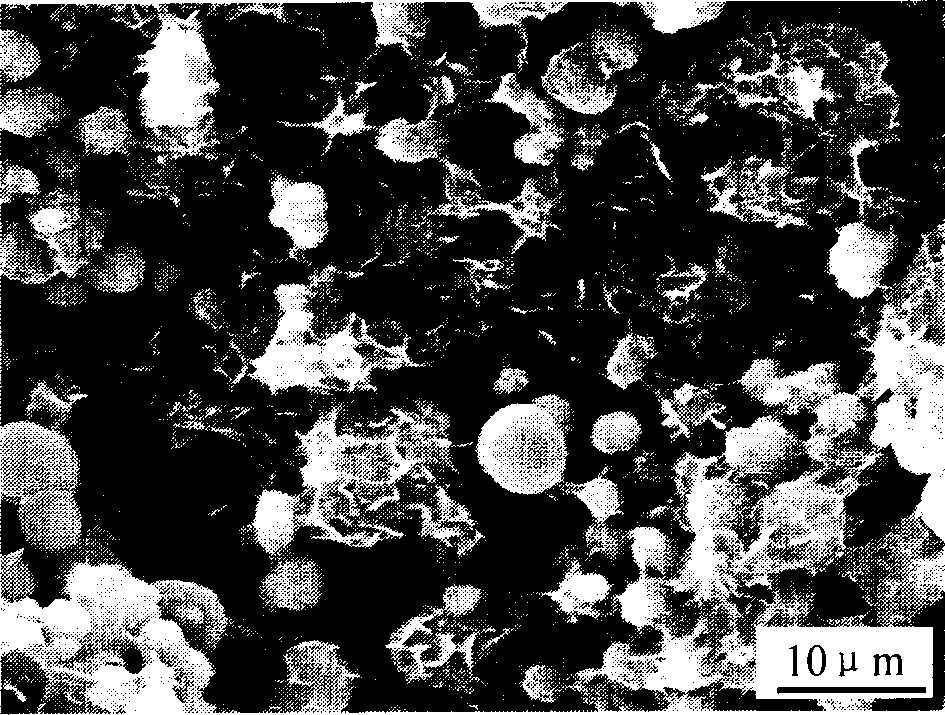

[0048] Soak the Ti-6Al-4V sample after alkali treatment and heat treatment in the above solution at 37°C for 2-24h. Soak for 6h to get spherical hydroxyapatite layer see image 3 , the thickness of the coating is about 50μm, soaked for 24h to get a spherical hydroxyapatite layer see Figure 4 , Figure 5 , and its coating thickness is 50-100 μm. The X-ray diffraction pattern of the spherical hydroxyapatite coating is shown in Figure 8 . ...

Embodiment 3

[0050] The commercial pure titanium samples were polished by 100#, 400#, 800#, and 1000# silicon carbide sandpaper respectively, then soaked in 1M KOH solution at 80°C for 2 hours, and then dried in air at 0-30°C.

[0051] The commercially pure titanium sample after alkali treatment was heated to 600°C in a box-type resistance furnace, kept for 0.5 hours and then cooled with the furnace. The heating rate is 3°C / min.

[0052] Prepare a high ion concentration calcium and phosphorus solution according to Table 1, and use 10mM NaHCO 3 The pH of the solution was adjusted to 7.

[0053] Soak the commercially pure titanium sample after alkali treatment and heat treatment in the above solution at room temperature for 2 to 24 hours. Soaked for 24h to obtain spherical hydroxyapatite layer figure 1 Similarly, its coating thickness is about 100 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| coating thickness | aaaaa | aaaaa |

| coating thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com