Method for preparing CaO-P2O5-MgO glass reinforced porous beta-tricalcium phosphate bioceramics

A cao-p2o5-na2o-mgo, glass-reinforced technology, applied in the direction of ceramic products, applications, home appliances, etc., can solve the problems that are not enough to meet clinical applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

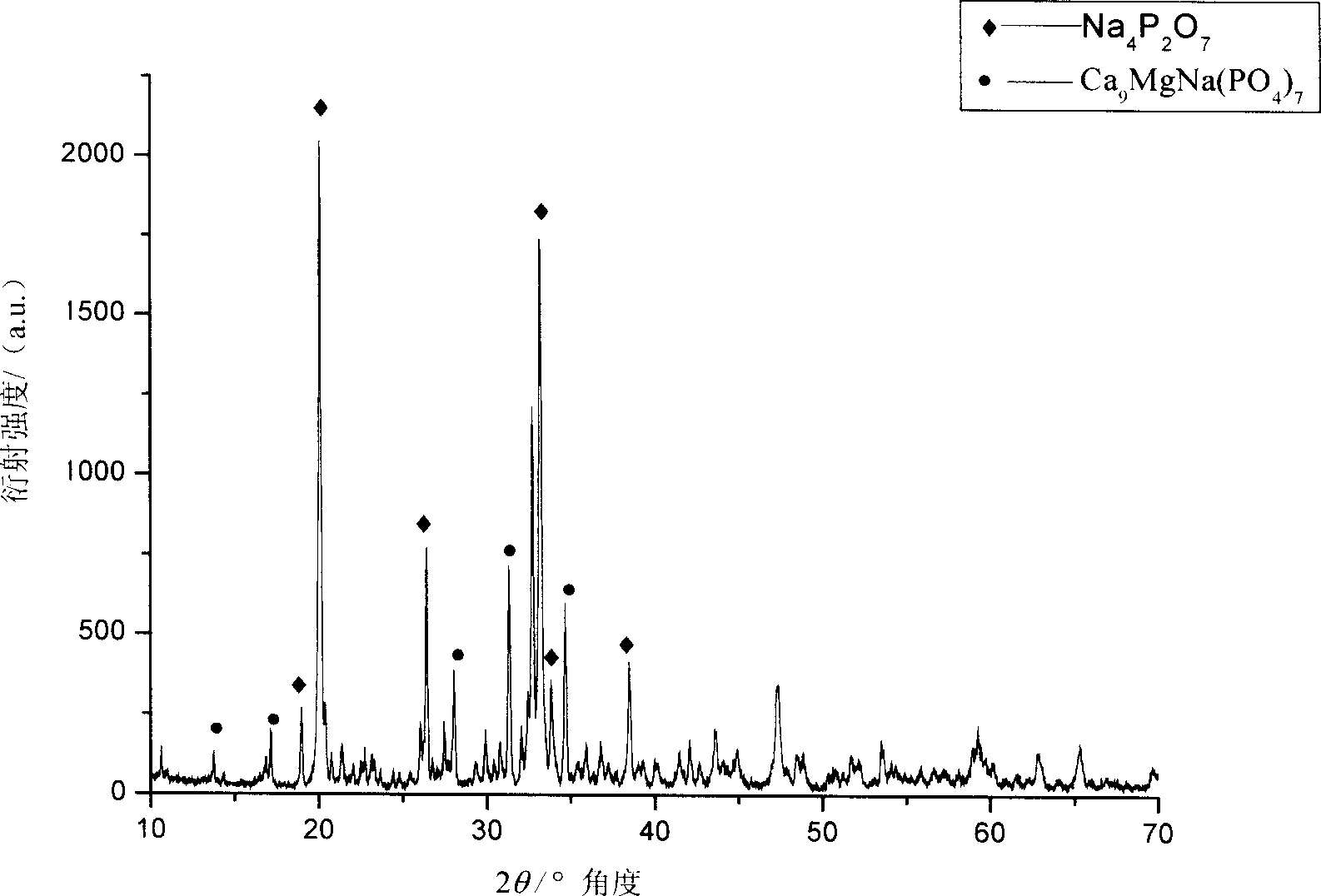

[0020] Example 1: CaO-P 2 o 5 -Na 2 O-MgO bioglass

[0021] Take NH 4 h 2 PO 4 , Ca(OH) 2 、Na 2 CO 3 , (MgCO 3 ) 4 Mg(OH) 2 ·5H 2 O is the raw material, according to the P in the raw material 2 o 5 :CaO:Na 2 The mass percentage of O:MgO is 62:14.7:18:5.30, the total mass is 100 grams, and 47.12 grams of NH 4 h 2 PO 4 , 19.45 g Ca(OH) 2 , 30.19 g Na2 CO 3 and 63.69 g (MgCO 3 ) 4 Mg(OH) 2 ·5H 2 O. Grind the said raw material evenly, pour it into a beaker, slowly add deionized water, and keep stirring until no bubbles come out. The mixture is dried in an oven at a constant temperature of 80°C, and then calcined and melted. In the temperature range from ℃ to 910℃, the heating rate is 3.5℃ / minute, and the temperature is raised to 910℃ for 1 hour. The molten glass is naturally cooled, ground and sieved with the furnace temperature. The ground glass powder is heat treated at 700°C for half an hour, cooled to room temperature, then heated to 740°C for 1 hour...

Embodiment 2

[0022] Example 2: CaO-P 2 o 5 -Na 2 O-MgO bioglass

[0023] to (NH 4 ) 2 HPO 4 , CaCO 3 、Na 2 CO 3 , MgCO 3 as the raw material, according to the P in the raw material 2 o 5 :CaO:Na 2 The mass percentage of O:MgO is 41.4:9.80:12:3.50, the total mass is 50 grams, and 26.98 grams (NH 4 ) 2 HPO 4 , 13.06 g CaCO 3 , 15.40 g Na 2 CO 3 and 5.46 g MgCO 3 . Grind the said raw material evenly, pour it into a beaker, slowly add deionized water, and keep stirring until no bubbles come out. The mixture is dried in an oven at a constant temperature of 80°C, and then calcined and melted. ℃~980℃ temperature range, the heating rate is 3.5℃ / min, and the temperature is raised to 980℃ for 2 hours. The molten glass is naturally cooled with the furnace, ground and sieved. The ground glass fine powder is heat treated at 720°C for half an hour, cooled to room temperature, then heated to 750°C for 1 hour, then heat treated at 800°C for 2 hours, and naturally cooled with the furn...

Embodiment 3

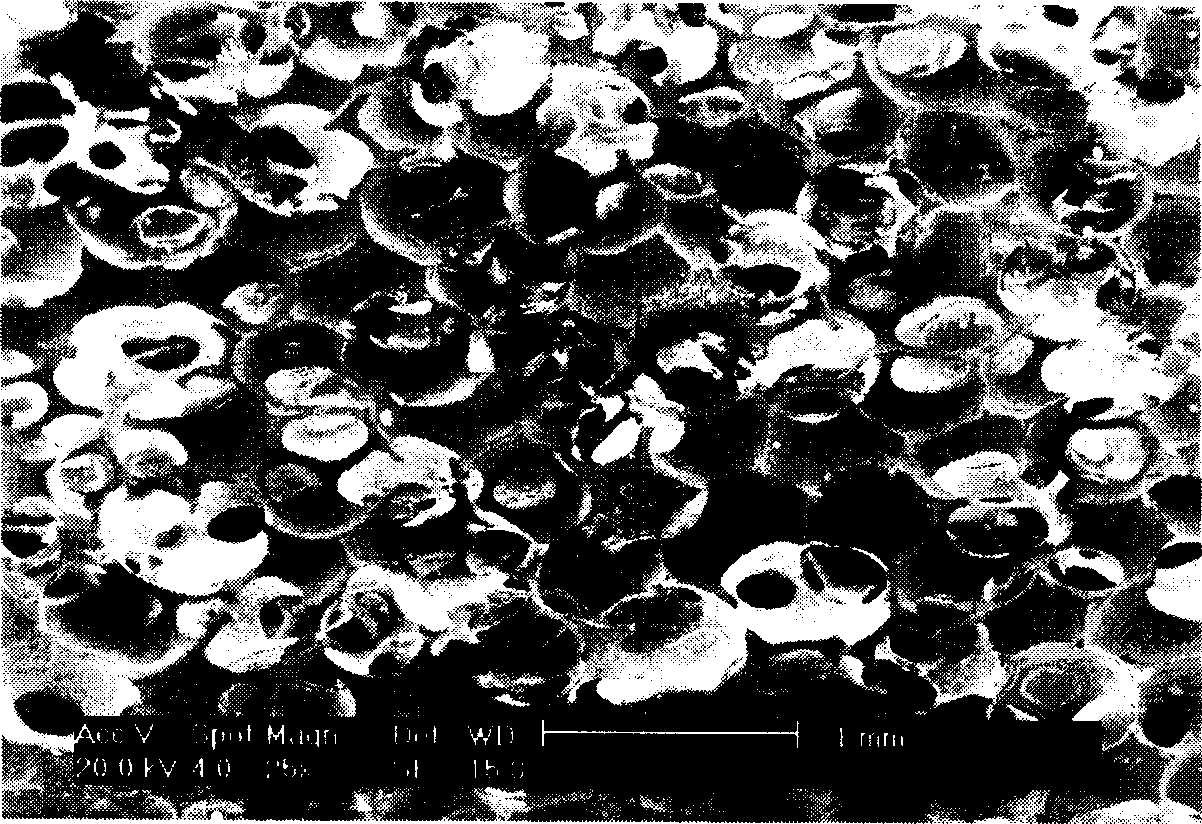

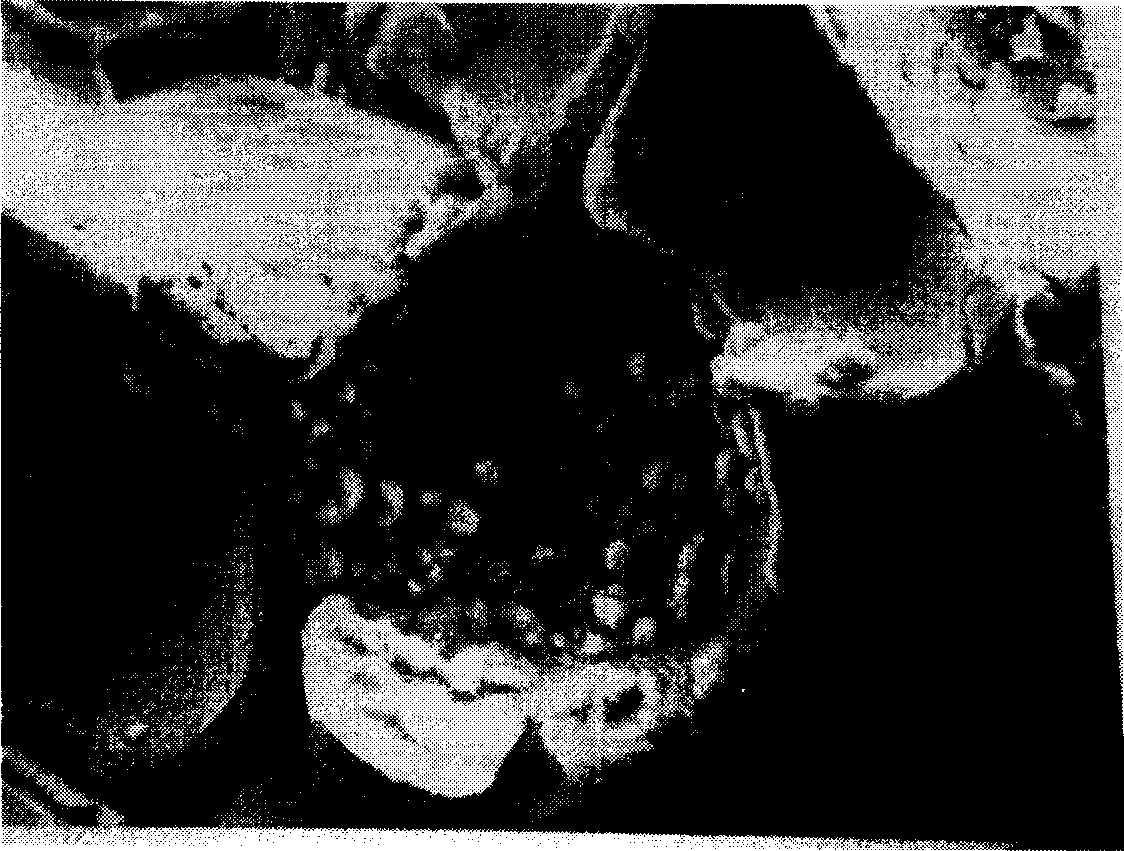

[0024] Example 3: Glass Reinforced Tricalcium Phosphate Porous Ceramics

[0025] Raw materials: medical grade calcium carbonate (CaCO 3 ) and calcium hydrogen phosphate dihydrate (CaHPO 4 2H 2 O) is a raw material, and it is 1.5 to accurately weigh 171.1 grams of CaHPO by Ca / P mol ratio 4 2H 2 O and 50.0 g CaCO 3 , Pour the weighed material into a ball mill jar, add deionized water and zirconia balls. According to the ratio of material: grinding ball: water, the mass ratio is 1:3:2.2, the mixture is high-speed ball milled for 16 hours, dried at a constant temperature of 85°C in an oven, and calcined at 830°C after drying to obtain an average particle size of 380nm. Beta-calcium phosphate powder.

[0026] Process: β-tricalcium phosphate and the bioglass prepared in Example 1 are 80:20 by mass percentage, weigh the mixed powder with a total weight of 50 grams, measure 33 milliliters of deionized water, and add molar concentration to the deionized water 4 milliliters of am...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average compressive strength | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Average compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com