Dark ultraviolet negative photoresist and filming resin

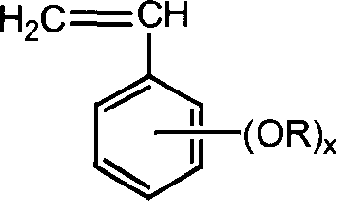

A film-forming resin, C1-C20 technology, used in optics, optomechanical equipment, photosensitive materials for optomechanical equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0164] A copolymer film-forming resin containing a silicon coupling agent, prepared from the following comonomers and their contents, in the presence of a free radical initiator, by heating for copolymerization:

[0165] 120 grams of m-hydroxystyrene;

[0166] Styrene 11 grams;

[0167] Propyltrimethoxysilyl methacrylate (KH570) 22 grams.

[0168] The preparation method is: in a 1000ml three-neck flask equipped with an electric stirrer, condenser, thermometer, temperature controller, heating mantle and nitrogen inlet, add 120 grams of m-hydroxystyrene, 11 grams of styrene, and propyl methacrylate 8 grams of trimethoxysilyl ester (KH570), 500 grams of tetrahydrofuran, nitrogen gas flow for 10 minutes under stirring, then heated to 60-70 ° C, and a solution of 9.5 grams of azobisisobutyronitrile (AIBN) in 100 grams of tetrahydrofuran was added , continue to reflux the reaction for 6-24 hours, and then cool to room temperature. The polymer solution was extracted three times wi...

Embodiment 2

[0170] A copolymer film-forming resin containing a silicon coupling agent, prepared from the following comonomers and their contents, in the presence of a free radical initiator, by heating for copolymerization:

[0171] 160 grams of p-acetoxystyrene;

[0172] 12 grams of methyl methacrylate;

[0173] Propyltrimethoxysilyl methacrylate (KH570) 9 grams.

[0174] The preparation method is: in a 1000ml three-neck flask equipped with an electric stirrer, a condenser, a thermometer, a temperature controller, a heating mantle and a nitrogen inlet, add 160 grams of p-acetoxystyrene and 12 grams of methyl methacrylate, Propyltrimethoxysilyl methacrylate (KH570) 9 grams, tetrahydrofuran 500 grams, under stirring nitrogen gas for 10 minutes, then heated to 60 ~ 70 ° C, add azobisisobutylnitrile (AIBN) 14 grams in 100 The solution in the gram tetrahydrofuran, after continuing to react and reflux for 8-28 hours, add 80 gram A-15 (Rohm&Haas, Amberlyst 15) ion exchange resin and 200 gram ...

Embodiment 3

[0176] A copolymer film-forming resin containing a silicon coupling agent, prepared from the following comonomers and their contents, in the presence of a free radical initiator, by heating for copolymerization:

[0177] 160 grams of p-acetoxystyrene;

[0178] 10 grams of p-tert-butylstyrene;

[0179] Cyclopentyl acrylate 14 grams;

[0180] Ethyltrimethoxysilyl methacrylate 7 g.

[0181] The preparation method is: in a 1000ml three-neck flask equipped with an electric stirrer, condenser, thermometer, temperature controller, heating mantle and nitrogen inlet, add 160 grams of p-acetoxystyrene and 10 grams of p-tert-butylstyrene , 14 grams of cyclopentyl acrylate, 7 grams of ethyltrimethoxysilane methacrylate, 500 grams of tetrahydrofuran, nitrogen gas flow for 10 minutes under stirring, then heated to 60 ~ 70 ° C, added azobisisobutyronitrile (AIBN ) 11 grams of solution in 100 grams of tetrahydrofuran, after continuing to reflux for 8-18 hours, add 4.2 sodium ethylate, add ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resolution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com