Self-lubricating heat-resistnat and wear-resistant materials

A self-lubricating material, heat-resistant technology, used in bearing components, shafts and bearings, mechanical equipment, etc., can solve problems such as short service life, wear clearance exceeding the design value, and wear-resistant parts crushing failure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

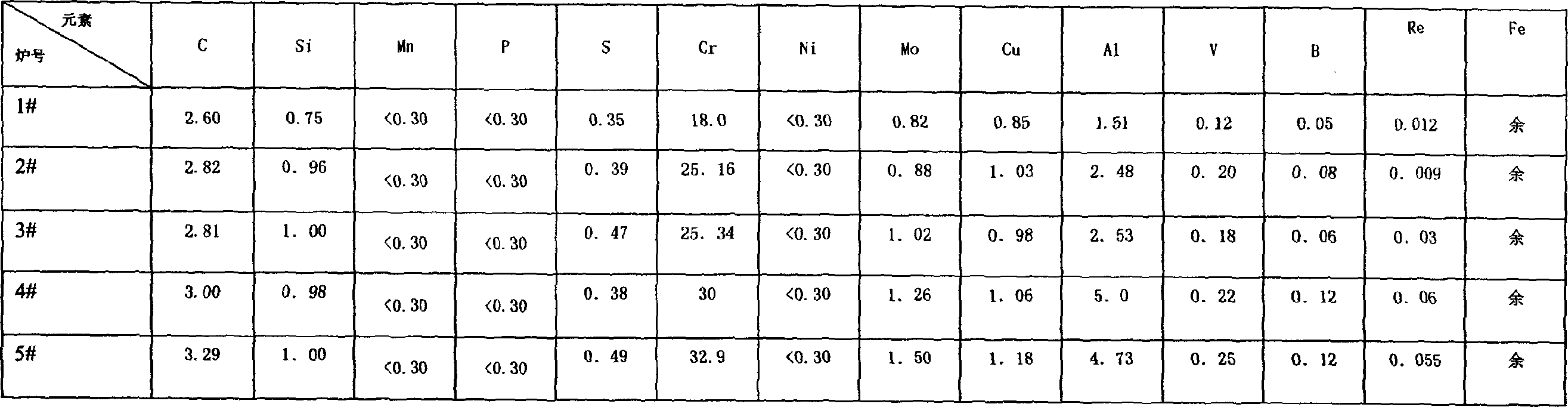

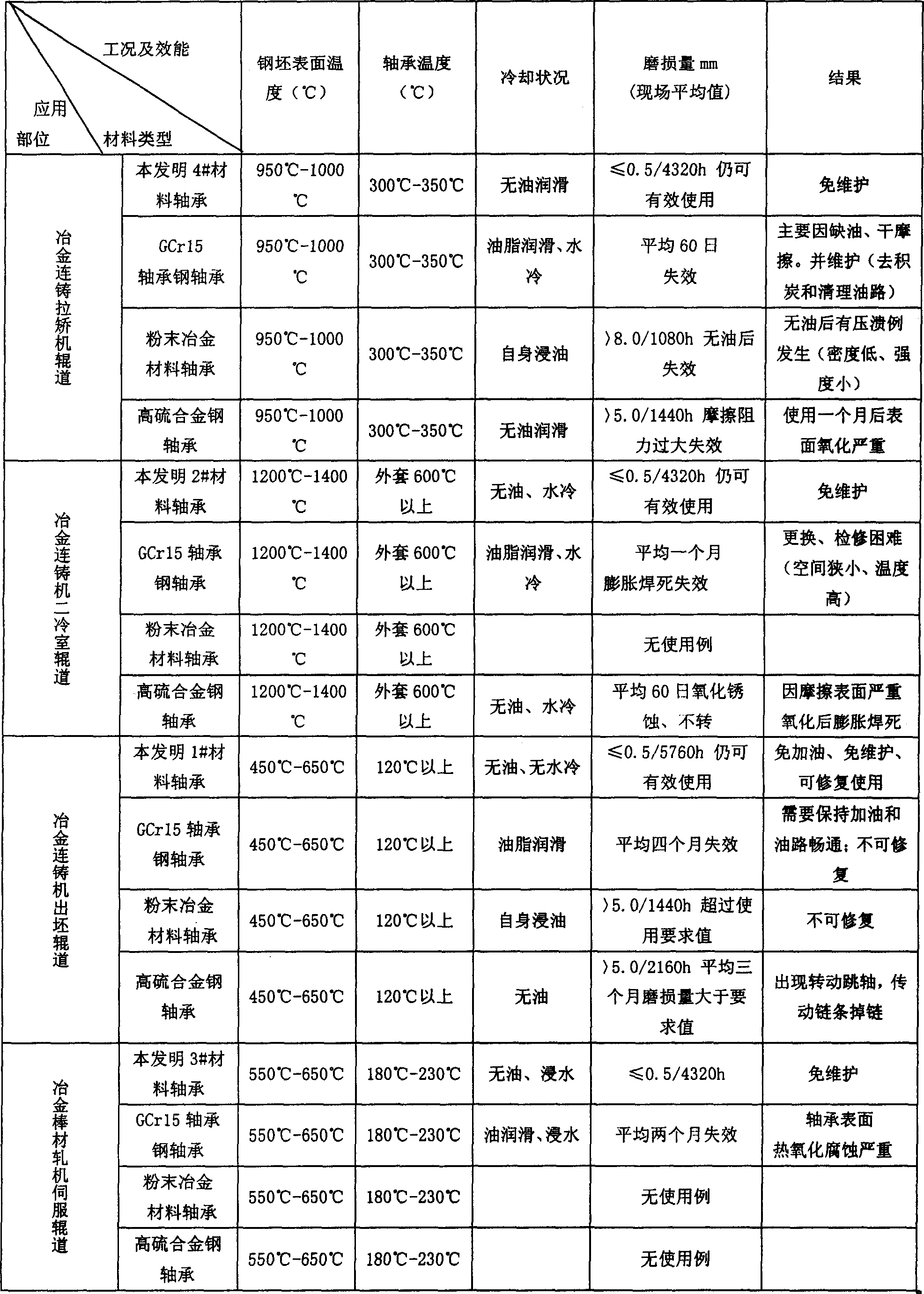

[0026] According to the chemical composition of the present invention and the smelting process similar to the conventional cast iron smelting process: it includes three parts: batching, smelting and casting. Material is smelted and cast in a 500 kg induction furnace. This material can be molded directly according to the design of bearings and wear-resistant parts. The main material sequence of smelting is: pig iron - scrap steel - ferrochrome - ferromolybdenum - electrolytic copper - ferrosilicon - electrolytic aluminum and aluminum insertion deoxidation, sulfur and rare earth treatment in the package. Baking temperature: 1550-1560°C; casting temperature: 1450-1460°C; control casting speed. After casting, the mold was opened after 5 to 8 hours of heat preservation (cast metallographic structure is martensite+carbide+retained austenite) to prepare 5 batches of self-lubricating materials. Simultaneously for the convenience of comparison, the bearings made of the material of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com