Treating material for polluted water, method for production thereof and use thereof

A technology of sewage treatment and manufacturing method, applied in the direction of water/sewage treatment, biological water/sewage treatment, adsorption water/sewage treatment, etc., can solve problems such as waste water treatment and achieve high water permeability and good reactivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] 75 g of stone wool (manufactured by Shinnichiwa Stone Wool Co., Ltd., S-Fiber granular cotton, with an average particle diameter of 30 mm), nickel slag wool (manufactured by Pacific Metal Co., Ltd., granular wool, with an average particle diameter of 30 mm), glass wool (without resin short fibers), carbon fibers (pitch-based short fibers), or quartz fibers (tissue culture short fibers) as the inorganic fibers. Use the reagents ferrous sulfate, gypsum and sulfuric acid, add them to 5L of acidic solution with pH 2, total iron ion 340mg / l, calcium ion 250mg / l, sulfate ion 2000mg / l, and let it react for 28 days at room temperature.

[0059] At this time, the adhesion rate of the iron component to each inorganic fiber and the pH of the solution after the reaction were measured. In order to observe the adhesion of the iron component to the surface of the fiber, the solution was stirred for 5 minutes, and the separation state of the fiber and the reaction product was confirmed...

Embodiment 2

[0061] The same experiment was carried out as in Example 1, except that 15 g of biological material containing iron-oxidizing bacteria-Thiobacillus ferrooxidans was added.

[0062] Table 1 shows the adhesion rate of the iron component to the fiber and the pH of the solution. In addition, in Table 1, RW is stone wool, NW is nickel slag wool, GW is glass wool, CF is carbon fiber, SF is quartz fiber, S+G is a mixture of low crystallinity hydrous iron sulfate mineral and goethite, - indicates that the product is too small to be measured.

[0063] Example 1

Embodiment 3

[0065] Using stone wool (S-Fiber granular cotton, average particle size 30 mm), slag cement (manufactured by Nippon Steel Slag Cement Co., Ltd., type B slag cement), 60% by weight of stone wool and 40% by weight of slag cement were mixed with a ribbon mixer. % Stir and mix to obtain a granular mixture with an average particle diameter of 20mm, a volume specific gravity of 0.15, and a void ratio of 94%. The chemical composition of the granular mixture is SiO 2 : 33.0%, Al 2 o 3 : 10.2%, CaO: 47.8%, MgO: 4.2%, Fe 2 o 3 : 1.4%, TiO 2 : 0.5%, MnO: 0.2%, SO 3 : 0.7%, Ig.loss: 1.2%.

[0066] Separately, ferrous sulfate, gypsum, and sulfuric acid were used to prepare an acidic solution at pH 2.5 containing 1,080 mg / l of sulfate ions, 137 mg / l of total iron ions, and 250 mg / l of calcium ions.

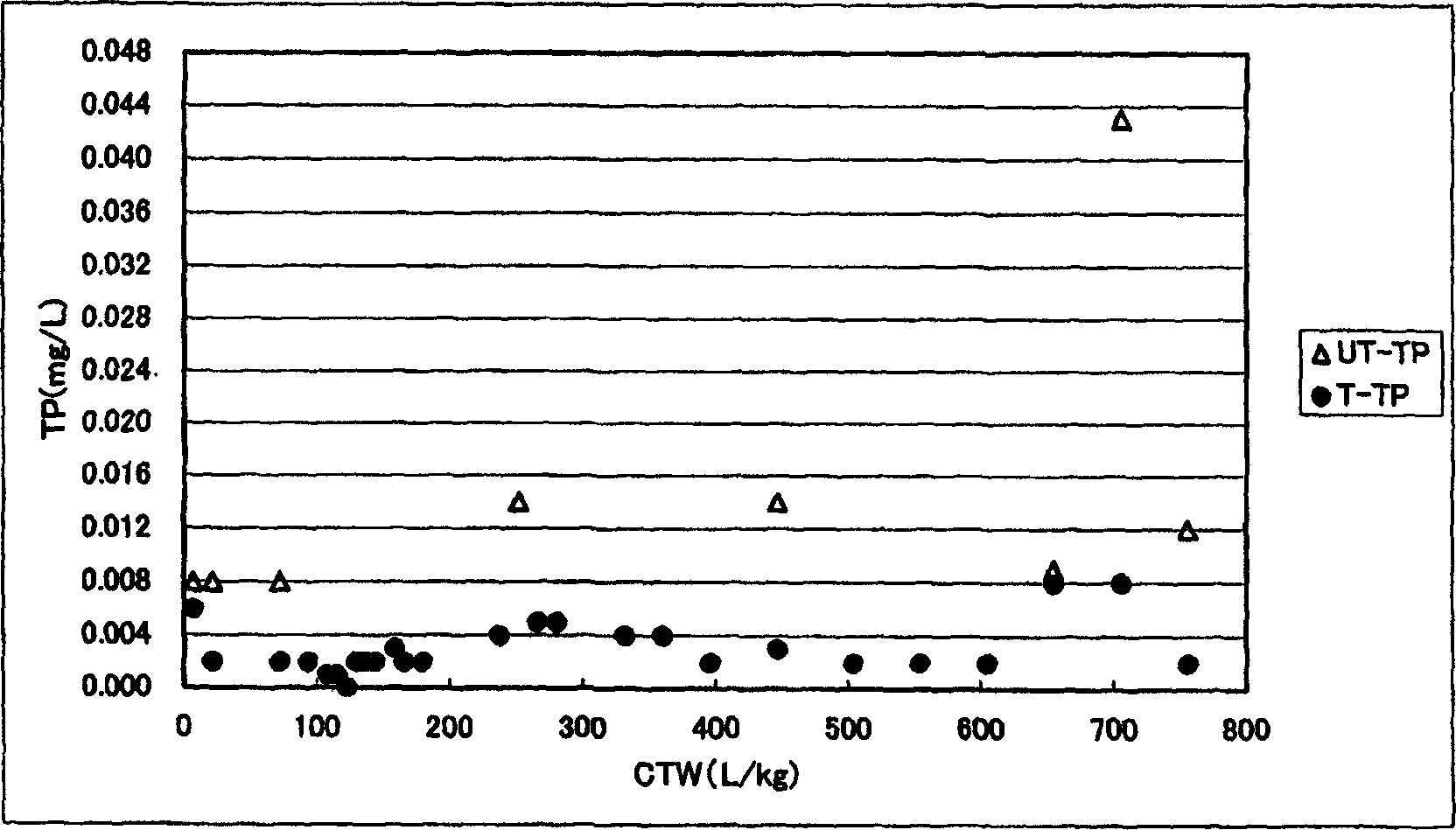

[0067] 100 g of the granular mixture was packed into a synthetic resin column with a diameter of 10.4 cm to have a thickness of 6.8 cm and a volume specific gravity of 0.174, and the aci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Water permeability coefficient | aaaaa | aaaaa |

| Water permeability coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com