Method and system for processing junk batteries by using agglomeration technology

A waste battery and treatment system technology, applied in the direction of solid waste removal, etc., can solve the problem that waste residue is difficult to reuse, and achieve the effects of short construction period, favorable resource utilization, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

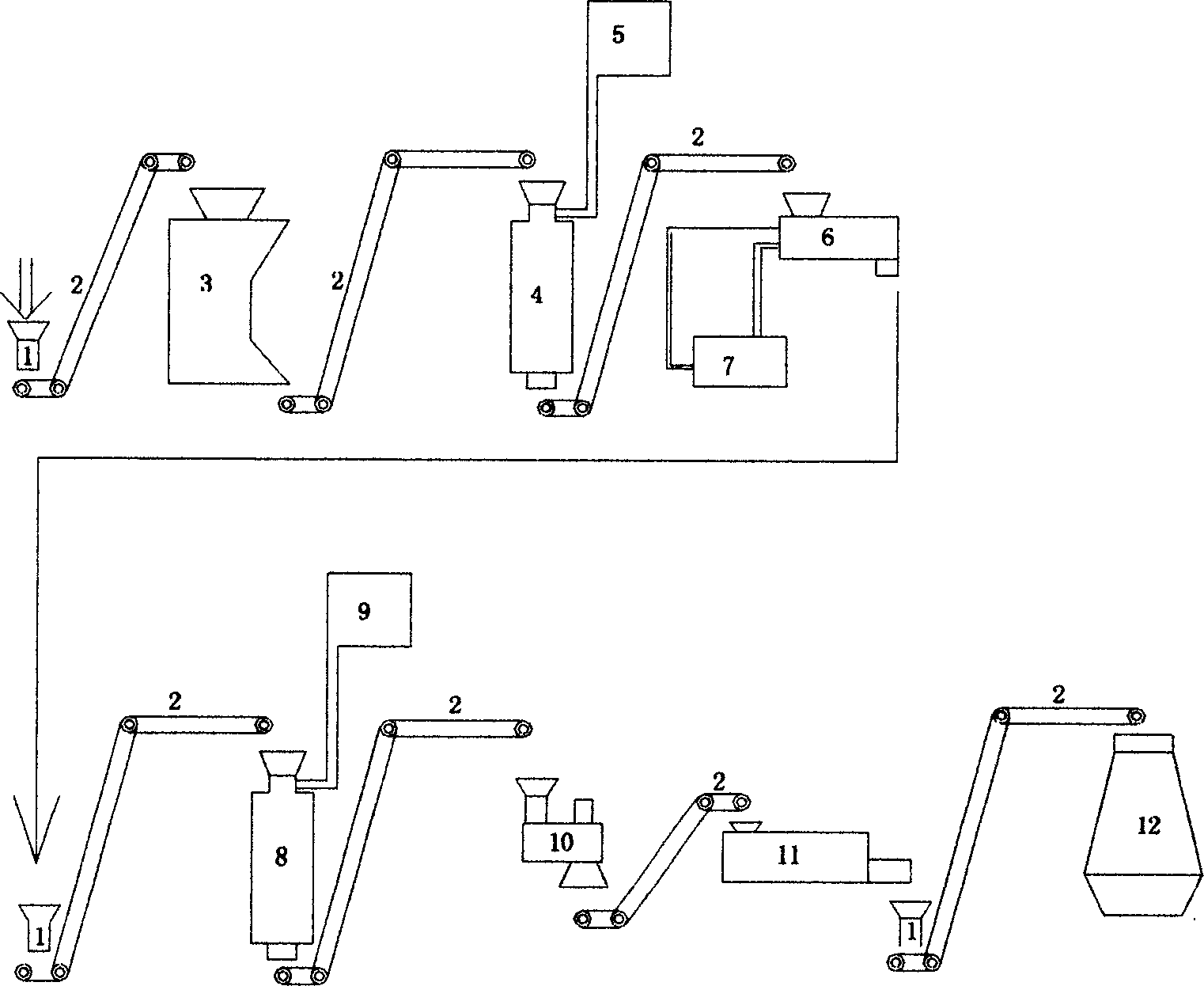

[0019] The waste battery is sent to the crusher 3 by the screw feeder 1 through the transmission belt 2 for crushing and screening, and then enters the low-temperature roasting furnace 4 and the Hg recovery device 5. After roasting, the sample enters the vibrating water washing and filtering system to remove K and Na device 6, After passing through the crystallization device 7, it enters the high-temperature roasting furnace 8 and the zinc recovery system 9, and finally the residue passes through the feeder 10, and is mixed into the sintering system 11, and the sintered ore enters the blast furnace 12 for smelting.

[0020] The system for processing waste batteries using the above-mentioned sintering process mainly includes a waste battery processing and crushing system, a low-temperature roasting and recycling system, a waste battery vibration washing and filtering system, a high-temperature roasting and recycling system, and a sintering system. Take advantage of the system: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com