Lithium ion secondary battery

A secondary battery and lithium-ion technology, applied in the direction of secondary batteries, battery pack components, non-aqueous electrolyte battery electrodes, etc., can solve problems such as insufficient movement channels, difficulty in porous membrane strength, etc., to ensure heat resistance, The effect of suppressing internal short circuit and suppressing falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

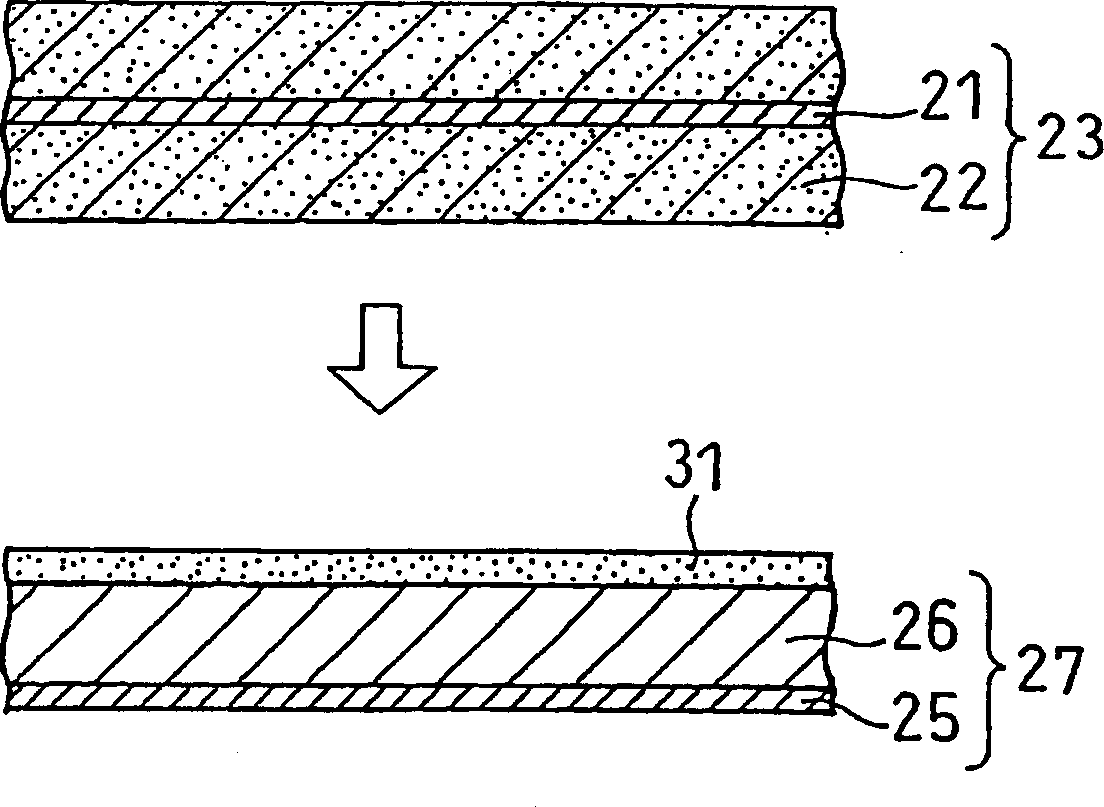

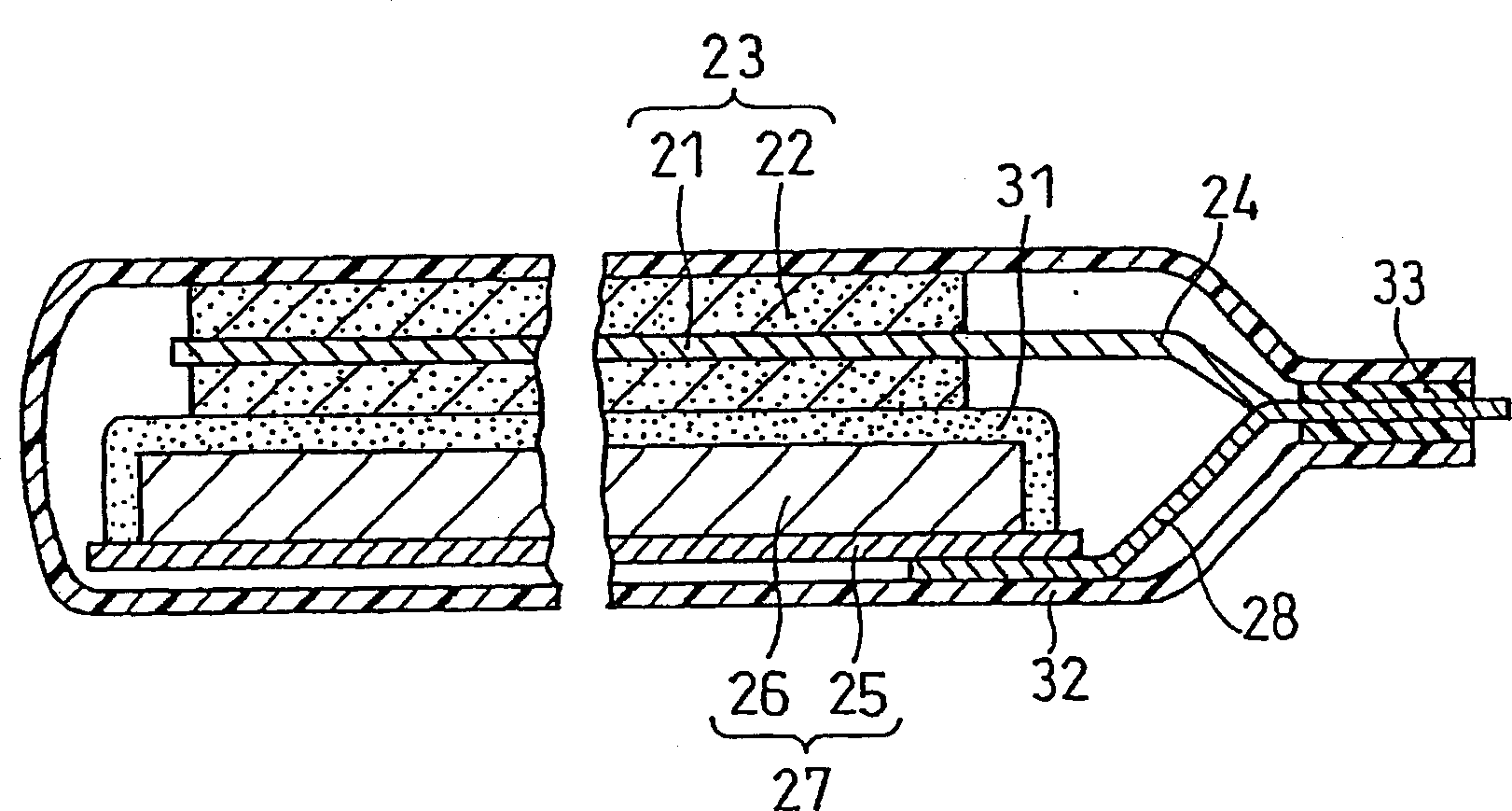

[0111] Refer below figure 2 versus image 3 Be explained.

[0112] (i) Production of positive electrode

[0113] Relative to 100 parts by weight of LiCoO 2 , Add 4 parts by weight of polyvinylidene fluoride (PVDF) as a binder and 3 parts by weight of acetylene carbon black as a conductive agent, and then add an appropriate amount of NMP (N-methyl-2-pyrrolidone) for mixing to prepare The positive electrode mixture paste is produced.

[0114] The obtained positive electrode mixture paste was coated on both sides of an aluminum foil core material 21 with a thickness of 20 μm, and rolled so that the active material density (LiCoO 2 The density) is 3.3 g / ml, which is used as the positive electrode 23. A positive electrode lead 24 made of aluminum is connected to the positive electrode 23.

[0115] (ii) Production of negative electrode

[0116] Relative to 100 parts by weight of spherical artificial graphite, add 1 part by weight of styrene-methacrylic acid-butadiene copolymer as a bin...

Embodiment 2

[0151] (i) Production of positive and negative electrodes

[0152] In the same manner as in Example 1, a positive electrode and a negative electrode were produced.

[0153] (ii) Formation of porous membrane

[0154] The raw material paste of the porous membrane was prepared in the same manner as in Example 1. Here, at the ratio shown in Table 3, the filler and the resin binder were dispersed in NMP and kneaded to prepare the raw material paste of the porous membrane. The content of the raw materials (the total amount of the filler and the resin binder) in the paste is set to 50% by weight in any case. The filler alone uses alumina (Al 2 O 3 ).

[0155]

Example

Relative to every 100 parts by weight of filler

Amount of resin binder (parts by weight)

Filler average

Particle size (μm)

Porous membrane micro

Average pore size

(μm)

Stripping

Characteristics

(%)

BM500B

PVDF

A...

Embodiment 3

[0177] (i) Production of positive electrode

[0178] A positive electrode was produced in the same manner as in Example 1, except that the size of the electrode plate was changed to a predetermined size.

[0179] (ii) Production of negative electrode

[0180] The negative electrode mixture was attached to both sides of the copper foil core material, and the active material density (the density of graphite) was rolled to 1.4 g / ml, and the size of the electrode plate was changed to a predetermined size, except that it was produced in the same manner as in Example 1. negative electrode.

[0181] (iii) Formation of porous membrane

[0182] According to the ratio shown in Table 4, the filler and the resin binder were dispersed in NMP and kneaded to prepare the raw material paste of the porous membrane. The content of the raw materials (the total amount of the filler and the resin binder) in the paste is set to 50% by weight in any case.

[0183] As in Example 1, the filler alone used a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com