Polylactic resin composition

A technology of polylactic acid resin and composition, which is applied in the field of polylactic acid resin composition, can solve problems such as lowering the durable temperature, lowering the durable temperature of products, and limiting the use range of products, so as to reduce production costs, improve flame retardancy, and improve processing Effects on Performance and Productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] The thermoplastic elastomer is pretreated first. Take 80wt% styrene-ethylene-butadiene-styrene copolymer and 20wt% paraffin processing oil and place them in a high-speed mixer for high-speed mixing. After about 20 minutes, the processing oil and styrene-ethylene-butadiene - The styrene copolymer can reach a uniformly mixed state, take it out and let it stand for more than 8 hours for later use.

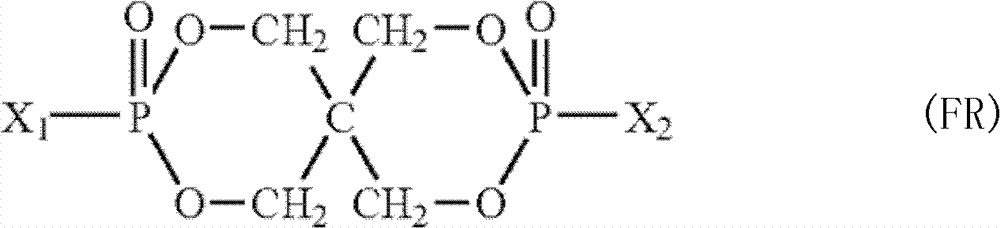

[0066] Get 100 mass parts of polylactic acid, 15 mass parts of new phosphorus flame retardant FR-1, 20 mass parts of pretreated styrene-ethylene-butadiene-styrene copolymer, 5 mass parts of talcum powder and 5 parts by mass of ethylene-butadiene-methyl methacrylate grafted maleic anhydride copolymer, first stir evenly in a dry mixing manner, and then introduce a volumetric feeder into a twin-screw extruder at 180-220 The melting and kneading process is carried out under the condition of ℃, and the extruded bar obtained after the melting and kneading process is cooled into a so...

Embodiment 2-16

[0069] Using the same melt kneading conditions and processing methods described in Example 1, according to the composition listed in Table 1 and Table 2, change the types and mixing ratios of different new phosphorus-based flame retardants in the composition to obtain poly The material particles of the lactic acid resin composition were made into standard test pieces conforming to standard test specifications for performance measurement, and the obtained measurement results are listed in Table 1 and Table 2 at the same time.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com