Method for preparing Ti3 AlC2 powder

A technology of powder and process method, which is applied in the field of chemical synthesis material preparation, and can solve the problems of restricting widespread use and high preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Weigh 6.9434g of Ti powder with a purity greater than 99wt% and 1.6954g of Al powder with a purity greater than 99.99wt% in a molar ratio of 3:1.3:2; Al powder has been included in the 30mol% portion of Al as an additive; % C powder 1.1611g. Then add WC balls according to the ball-to-material ratio of 20:1, and put them into a stainless steel ball mill jar; then seal it, fill it with argon gas, and carry out mechanical alloying; the ball milling time is 60 hours, and the rotation speed is 225rpm. Then put the mechanically alloyed powder into a crucible, and anneal it under the protection of argon. The annealing temperature is 950°C, and the annealing time is 2 hours; 3 AlC 2 Powder.

Embodiment 2

[0015] Weigh 7.0294 g of Ti powder with a purity greater than 99 wt%, 1.3203 g of Al powder with a purity greater than 99.99 wt%, 1.1755 g of C powder with a purity greater than 99.99% in a molar ratio of 3:1:2, and then add Si powder with a purity greater than 99 wt%. Powder 0.2748g. Then add WC balls according to the ball-to-material ratio of 20:1, and put them into a stainless steel ball mill tank; then seal it, fill it with argon gas, and carry out mechanical alloying; the ball milling time is 60 hours, and the rotation speed is 250 rpm. Then transfer the mechanically alloyed powder into a crucible, and perform annealing treatment under the protection of argon. The annealing temperature is 950°C, and the annealing time is 2 hours; then it is cooled to room temperature with the furnace, and the obtained product is Ti 3 AlC 2 Powder.

Embodiment 3

[0017] Weigh 6.7462g of Ti powder with a purity greater than 99wt% and 1.9007g of Al powder with a purity greater than 99.99wt% in a molar ratio of 3:1.5:2; Al powder has been included in the 50mol% portion of Al as an additive; there is also a purity greater than 99.99g % C powder 1.1281g. Then add WC balls according to the ball-to-material ratio of 30:1, and put them into a stainless steel ball mill jar; then seal it, fill it with argon gas, and carry out mechanical alloying; the ball milling time is 60 hours, and the rotation speed is 250rpm. Then put the mechanically alloyed powder into a crucible, and anneal it under the protection of argon. The annealing temperature is 900°C, and the annealing time is 2 hours; then it is cooled to room temperature with the furnace, and the obtained product is Ti 3 AlC 2 Powder.

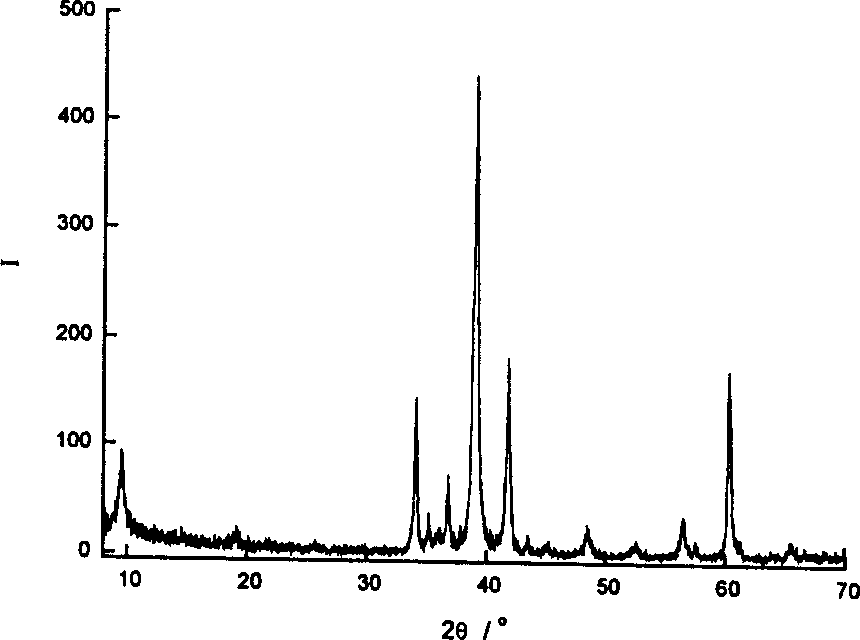

[0018] The resulting product is detected by X-ray diffraction analysis, in the X-ray diffraction spectrum, see figure 1 , it was found that a characteristic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com