Production and its apparatus for organic coated metal nanometer powdery

A technology of metal nanometer and preparation device, applied in the direction of coating, can solve the problems of affecting the coating effect and quality, and the coating layer is easy to peel off, and achieve the effect of large-scale production, small volume, and improved dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1 online organic coated metal nanopowder

[0017] All metal nanopowders in this embodiment are copper nanopowders.

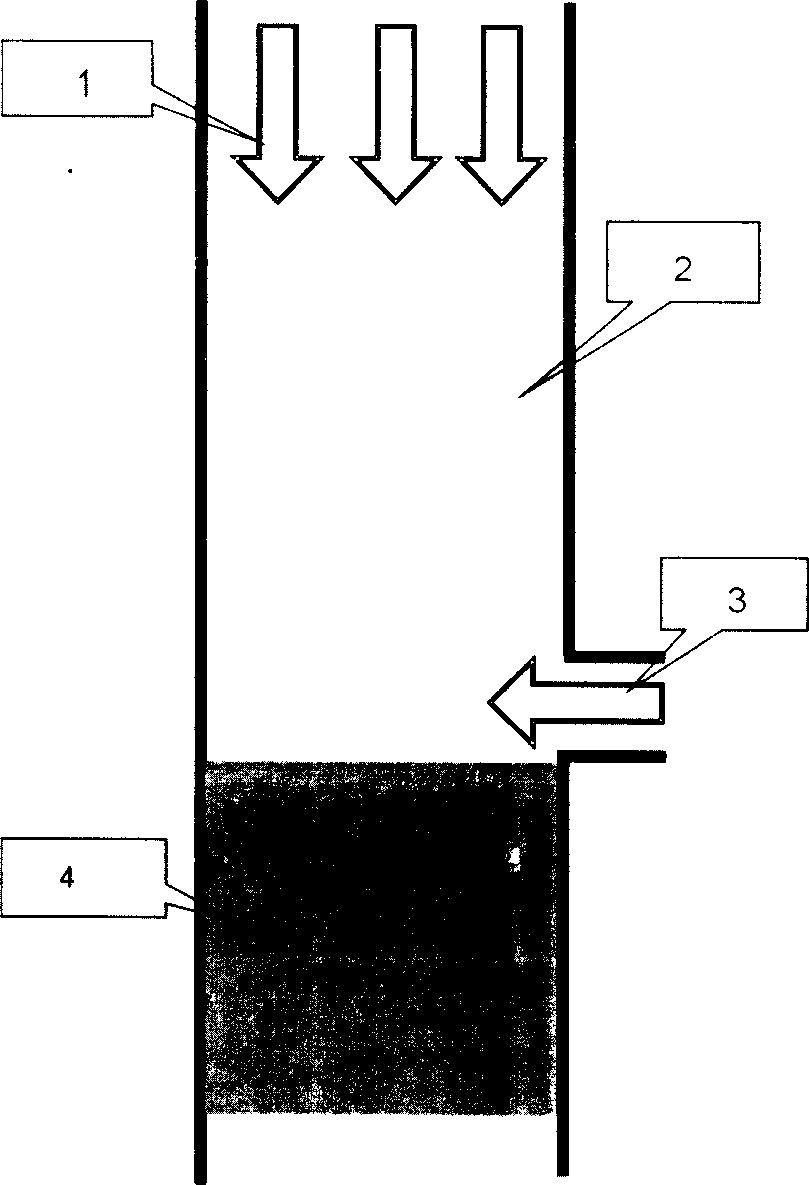

[0018] figure 1 In the process, the inert gas 1 is passed into the metal nanomaterial 2, and driven by the flowing inert gas 1, the metal nanomaterial 2, the inert gas 1, and the organic gas and hydrogen gas 3 that are introduced later form a gas flow and enter the high-pressure plasma area together. 4. Reaction to generate organic coated metal nanopowder.

[0019] The metal nano powder raw material enters part 10 using the device structure in another patent application "Preparation method of metal nano powder material and its preparation device" (patent application number 200410040125.3) submitted by the Laser Fusion Research Center of China Academy of Engineering Physics in 2004. Get online metal nanopowder.

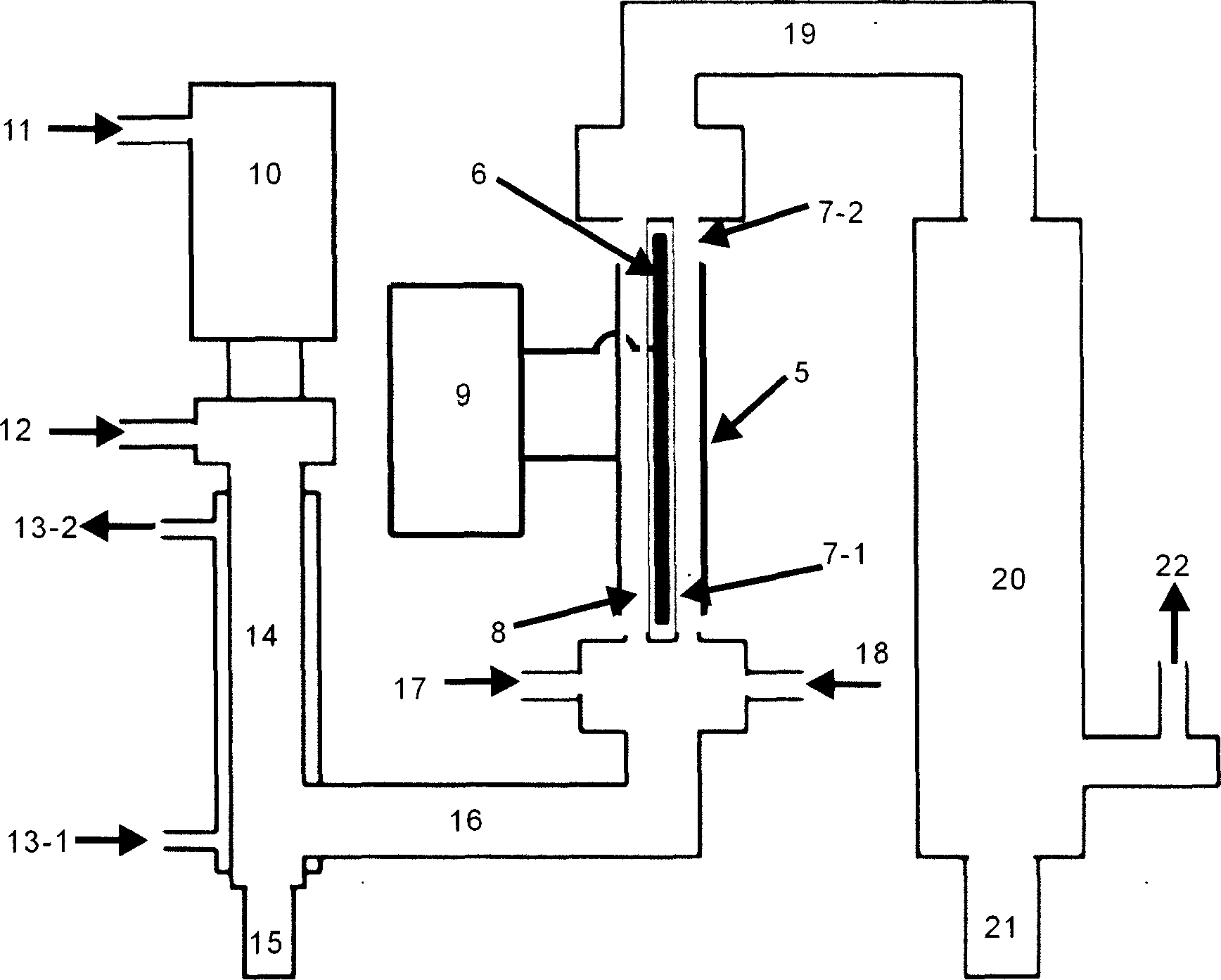

[0020] image 3 Shown, the preparation device of the organic coated metal nanopowder of the present invention is: the metal nanopo...

Embodiment 2

[0025] Embodiment 2 off-line organic coated metal nanopowder

[0026] All metal nanopowders in this embodiment are copper nanopowders.

[0027] Metal nano powder raw material enters part 10 as metal nano powder storage area.

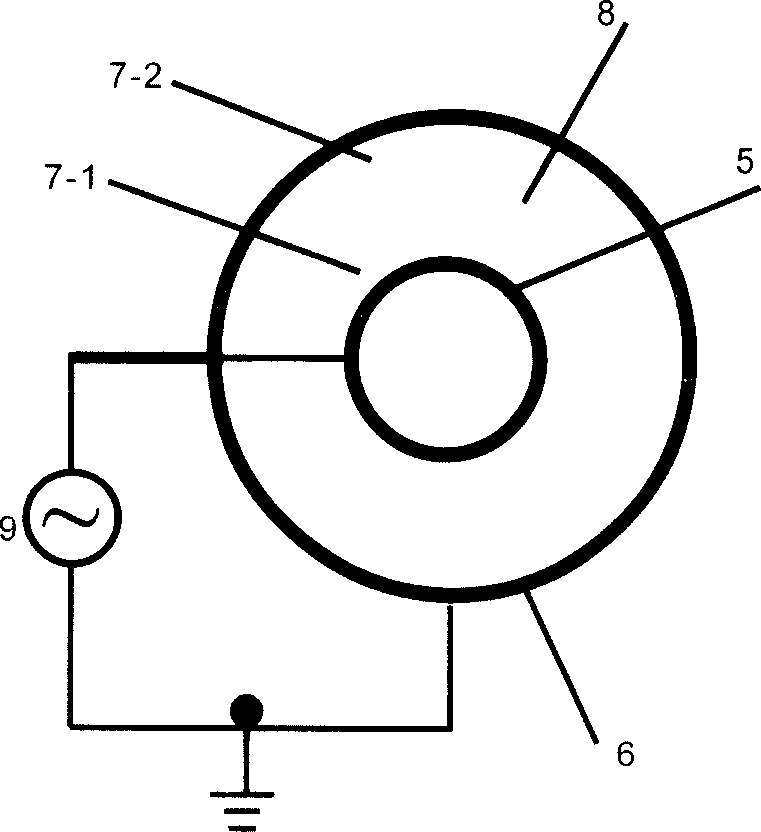

[0028] figure 2 , image 3 Shown, the preparation device of organic coated metal nanopowder of the present invention is: metal nanopowder raw material enters part 10 through metal nanopowder grading pipeline 14, connecting pipeline I 16 and is used to produce uniform, continuous, stable high pressure plasma generation The discharge tube of the device is connected, and a water cooling device is arranged outside the metal nano powder classification pipeline 14, 13-1 is a cooling water inlet, and 13-2 is a cooling water outlet, and an unreacted Metal nano powder collecting container 15; discharge tube lower end is provided with organic gas inlet 17 and hydrogen gas inlet 18 respectively; discharge tube connects pipeline II 19 with organic coated metal n...

Embodiment 3

[0033] The metal nanopowders in this embodiment are all nickel nanopowders.

[0034] The high-frequency high-voltage power supply 9 for generating high-voltage plasma has an operating voltage of about 20kV and an operating frequency of about 40kHz.

[0035] All the other are with embodiment 1.

[0036] The metal nanopowder in the embodiment of the present invention can be replaced by metal iron, cobalt, aluminum, silver, gold, lead, manganese, titanium, vanadium, chromium, zinc, tungsten, magnesium, etc. in addition to metal copper and nickel. , to prepare the corresponding organic-coated metal nanopowder material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com