Nano light-screen zinc-cerium composite oxide and its preparing method

A composite oxide and nano-light technology, applied in nano-materials and fields, can solve the problems of affecting performance, deterioration of light transmittance, particle agglomeration size, etc., and achieve the effects of high absorption rate, loose powder and low material cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0043] According to the zinc / cerium molar ratio = 0.1, dissolve zinc nitrate and cerium nitrate in deionized water at room temperature (such as 25 ° C), adjust the acidity to pH = 1 with a 30% nitric acid solution, and then press the nitrate : Fuel (molar ratio)=1:2 Add urea, obtain mixed solution after mechanical dispersion; Control inlet temperature is 80 ℃, dry air volume 300m 3 / h, material flow 2L / h, to obtain dry gel particles; gel particles in the air flow in the muffle furnace, controlled at 600 ° C, burned for 2 hours to obtain a body color of light yellow zinc cerium composite oxide; according to zinc cerium Composite oxide: methyl acrylate = 1:1, add 0.1% (volume) hydrogen peroxide, ultrasonically disperse for 60 minutes, at an inlet temperature of 110°C and a dry air volume of 100m 3 / h, material flow 1L / h, atomization to obtain coated zinc cerium composite oxide particle product, the average particle size of the particles is 5 nanometers.

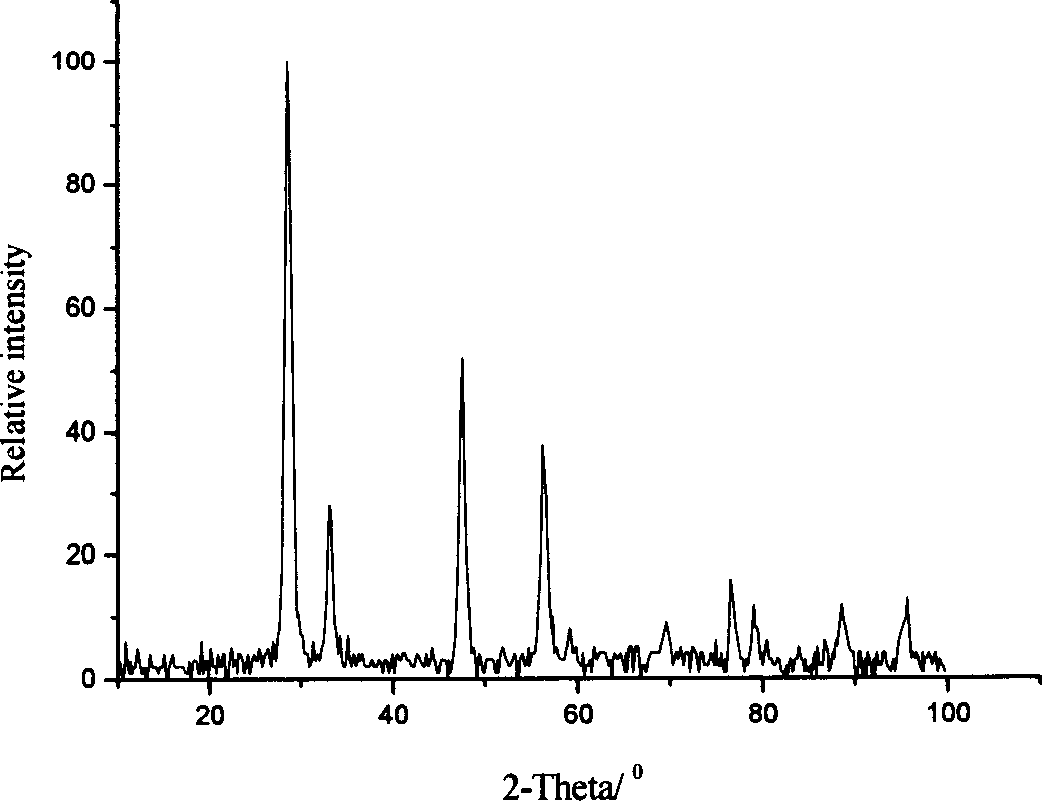

[0044] attached figur...

example 2

[0046] According to the zinc / cerium molar ratio = 0.3, dissolve zinc nitrate and cerium nitrate in deionized water at room temperature (such as 25 ° C), adjust the acidity to pH = 2 with a 30% nitric acid solution, and then press the nitrate : Fuel (molar ratio)=1: 2.5 add carbama, obtain mixed solution after mechanical dispersion; Control entrance temperature is 85 ℃, dry air volume 200m 3 / h, material flow 1L / h, to obtain dry gel particles; gel particles in the air flow in the muffle furnace, controlled at 700 ° C, burning for 1 hour to obtain a body color of light yellow zinc-cerium composite oxide; according to zinc-cerium Composite oxide: methyl acrylate = 1:2, add 0.05% (volume) hydrogen peroxide, ultrasonically disperse for 10 minutes, at an inlet temperature of 120°C and a dry air volume of 200m 3 / h, material flow 1.5L / h, atomization to obtain coated zinc cerium composite oxide particle product, the average particle size of the particles is 30 nanometers. The XRD pat...

example 3

[0048] According to zinc / cerium molar ratio = 0.5, zinc nitrate and cerium nitrate are dissolved in deionized water at room temperature (such as 25 ° C), and the acidity is adjusted to pH = 3 with a 30% nitric acid solution, and then press the nitrate : Fuel (molar ratio) = 1: 2.5 Add dihydrazine oxalate to obtain a mixed solution after mechanical dispersion; control the inlet temperature to be 110°C, and the dry air volume to be 300m 3 / h, material flow 2L / h, obtain dry gel granule; Gel granule is in the air flow in the microwave oven, burns 1 hour and obtains the zinc cerium composite oxide that body color is pale yellow; Press zinc cerium composite oxide: Methyl acrylate = 1:1.5, add 2% (volume) hydrogen peroxide, ultrasonically disperse for 10 minutes, control the inlet temperature to 110°C, and dry air volume to 150m 3 / h, material flow 1L / h, atomization to obtain coated zinc cerium composite oxide particle product, the average particle size of the particles is 50 nanomete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com