Radiator with uniform temperature hot cavity

A heat dissipation device and cavity technology, applied in the cooling of instruments, components of instruments, cooling/ventilation/heating transformation, etc., can solve the problems of drying out at heating points and damage to plate heat pipes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

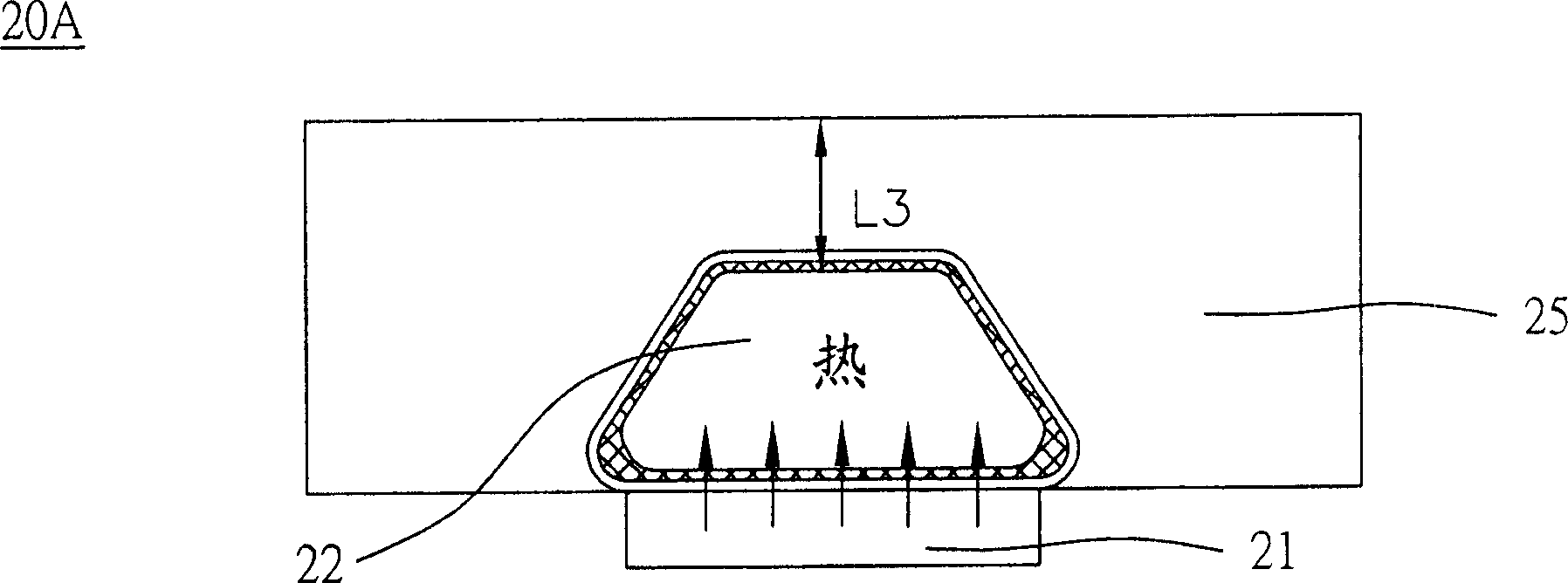

[0032] Please refer to Figure 2A , which shows a schematic diagram of a heat dissipation device according to a preferred embodiment of the present invention. The heat dissipation device 20A is applied to a heat source 21 , that is, a heat-generating electronic component 21 . The heat dissipation device 20A includes a vapor chamber 22 and a heat sink 25 . The heat uniform chamber 22 is directly attached to a heat source 21 to transfer heat from the heat-generating electronic component 21 to the radiator 25, and the radiator 25 is covered on and around the heat uniform chamber 22, The heat of the electronic component 21 can be quickly transferred to other places through the heat equalization cavity 22 and the heat sink 25 . The heat source 21 is, for example, a heating electronic component 21, such as CPU, transistor, server, high-end graphics card, hard disk, power supply, driving control system, multimedia electronic mechanism, wireless communication base station, high-end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com