Making process of compound wood-plastic material product

A technology of composite materials and manufacturing methods, which is applied in the field of manufacturing wood-plastic blended composite products, can solve the problems that consumers cannot feel the natural quality of wood, the filling amount of wood powder is not very high, and the appearance of wood-plastic products is not good. , to achieve the effect of high impact strength and tensile strength, high filling content and clear wood grain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

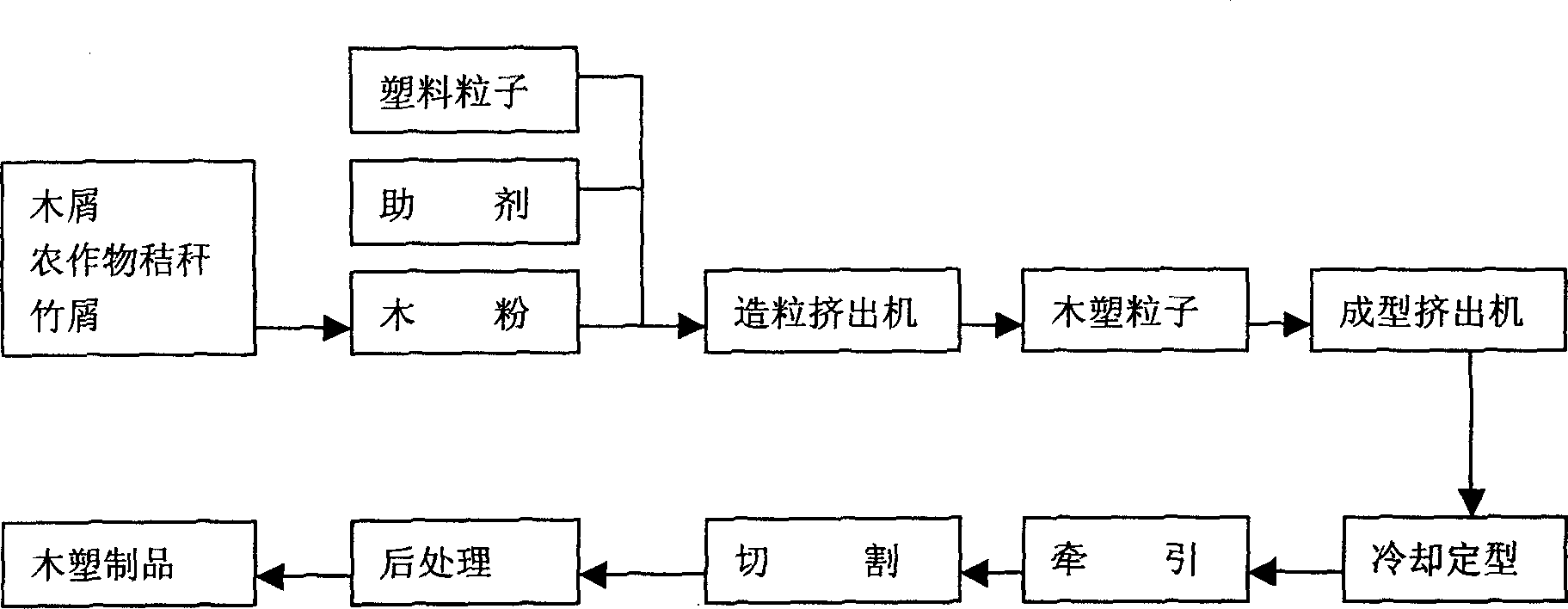

Method used

Image

Examples

Embodiment 1

[0023] The formula of wood-plastic blended composite particles is as follows:

[0024] Wood flour (80 mesh): 100 parts

[0025] Polypropylene: 50 parts

[0026] Polypropylene-maleic anhydride graft copolymer: 3 parts

[0027] Coupling agent A-174: 1 part

[0028] Antioxidant 1010: 0.6 parts

[0029] Fiberglass: 8 parts

[0030] Toner: 0.2 parts

[0031] Stearic acid: 1 part

[0032] According to the above ratio, add the pelletizing extruder at the same time. The granulation extruder adopts a counter-rotating non-intermeshing twin-screw extruder connected in series with a single-screw extruder. Extruder screw diameter 65mm, L / D=28. The prepared pellets are extruded on a single-screw extruder, cooled and shaped, pulled, cut, and modified, and finally made into various wood-plastic products.

Embodiment 2

[0034] The formula of wood-plastic blended composite particles is as follows:

[0035] Bamboo powder (60 mesh): 100 parts

[0036] Polypropylene: 60 parts

[0037] Polypropylene-maleic anhydride graft copolymer: 3 parts

[0038] Dicumyl peroxide: 0.3 parts

[0039] Antioxidant 1010: 1 serving

[0040] Superfine Calcium Carbonate: 15 parts

[0041] Toner: 0.2 parts

[0042] Zinc stearate: 0.5 parts

[0043] Bamboo powder is processed and pulverized from the leftovers of ordinary bamboo processing, and the moisture content is 10%. According to the above ratio, add the pelletizing extruder at the same time. The granulation extruder adopts a counter-rotating non-intermeshing twin-screw extruder connected in series with a single-screw extruder. Extruder screw diameter 65mm, L / D=28. The produced pellets are extruded in a single-screw extruder, cooled and shaped, drawn, cut, modified, and finally made into various wood-plastic products.

Embodiment 3

[0045] The formula of wood-plastic blended composite particles is as follows:

[0046] Wood flour (80 mesh): 100 parts

[0047] HDPE: 70 parts

[0048] Ethylene-vinyl acetate copolymer: 3 parts

[0049]Stearic acid: 1 part

[0050] Titanate coupling agent: 2 parts

[0051] Talc powder: 15 parts

[0052] Toner: 0.2 parts

[0053] Polyoxyethylene wax: 0.5 parts

[0054] Paraffin: 0.5 parts

[0055] According to the above ratio, add the pelletizing extruder at the same time. The granulation extruder adopts a co-rotating meshing twin-screw extruder with a screw diameter of 36 mm, L / D=36, and a rotational speed of 200 rpm. The produced pellets are extruded in a twin-screw extruder, cooled and shaped, drawn, cut, modified, and finally made into various wood-plastic products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com