Directional film and liquid crystal display device using the same directional film

A liquid crystal display, directional film technology, applied in the direction of instruments, optics, nonlinear optics, etc., can solve problems such as failure to degrade, and achieve the effects of excellent operating characteristics, improved retention characteristics, and prevention of charge retention rate reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0051] (1) Prepare a glass substrate for forming a predetermined circuit or the pixel electrode 16 of the liquid crystal display 10 .

[0052] (2) Mixing a low molecular weight thermosetting resin with polyimide and / or polyamic acid to prepare a resin composition. The mixing ratio is 99.9:0.1 to 5:95 by weight.

[0053] (3) Coat the resin composition uniformly on the said glass substrate. Coating can be performed by general coating methods such as spin coating, printing, brush coating, spraying, and the like.

[0054] (4) The solvent of the polyimide resin mixed with the low-molecular-weight thermosetting resin is evaporated in a relatively low-temperature atmosphere, and then baked in a relatively high-temperature atmosphere. In addition, the low-temperature atmosphere used for solvent evaporation is appropriately selected according to the solvent mixed in the resin composition, and the baking temperature is determined according to the polyimide and / or polyamic acid and low...

Embodiment 1

[0066] A resin composition in which double F-type epoxy resin (Yepicot 806 manufactured by Nippon Epoxy Resin Co., Ltd.) and polyimide resin wax (Nissan Chemical Co., Ltd. SE7492 6% solid content concentration) were directly dissolved was adjusted. An average of 2 samples of 0%, 1%, 10%, and 50% by weight of the epoxy resin ratio to the mixed solution of the epoxy resin and the polyimide resin wax was prepared individually. Then, after the adjusted resin composition is coated with a spinner on a glass substrate equipped with an indium tin oxide (ITO) transparent electrode, it is pre-baked in an atmosphere of about 85°C, and heat-cured at about 220°C for 30 minutes. A film of about 60 to 100 nm is formed. In addition, grinding|polishing was performed on the conditions of the pushing amount of 0.3 mm, the number of revolutions of 700 rpm, and the conveying speed of 1000 mm / min. Print epoxy-based thermosetting sealant, spread 5.25μm-diameter spacer balls and bond them with therm...

Embodiment 2

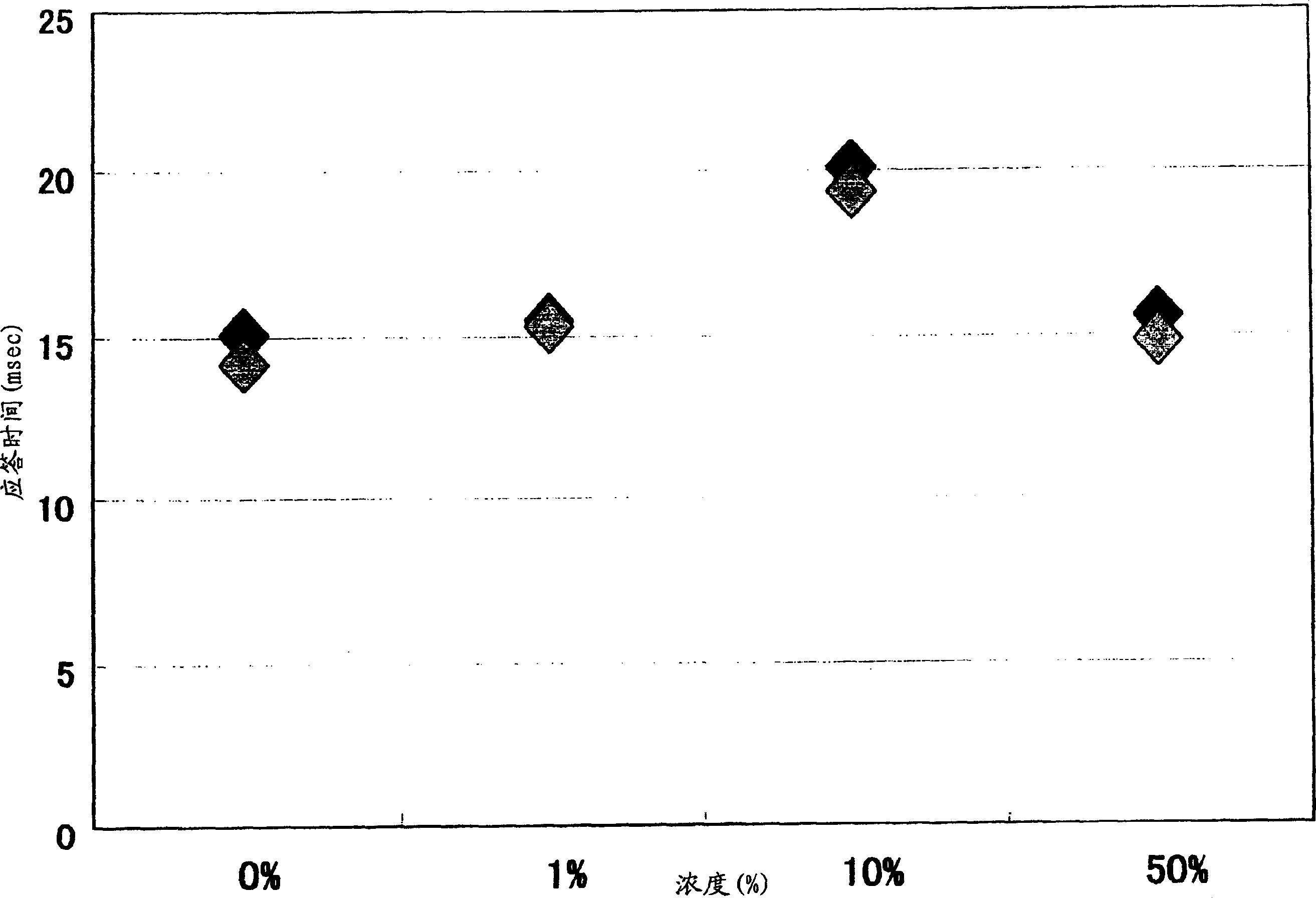

[0073] The liquid crystal 12 is a fluorine-based liquid crystal (model ZLI4792, +5.3 dielectric anisotropy) restrained by magnesium ear. A liquid crystal display was fabricated in the same manner as in Example 1. An average of two samples were prepared in which the ratio of the epoxy resin to the mixed solution of the epoxy resin and the polyimide resin wax was 0%, 1%, 10%, and 50% by weight. Experiments were conducted with respect to the response time (ON+OFF) of the liquid crystal display. The results are shown in Table 2 and image 3 . Using an alignment film composed of double F-type epoxy resin mixed with 1%, 10%, and 50% by weight of epoxy resin and polyimide resin wax mixed solution, the response time of liquid crystal 12 was approximately stable.

[0074] Table 2

[0075] epoxy resin

mix ratio

Microsecond (msec)

0% by weight

15.1

0% by weight

14.2

1% by weight

15.5

1% by weight

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com