Hollow fiber medicine carrier and its preparing method and use

A hollow fiber technology, applied in hollow fiber drug carrier and its preparation and application field, can solve the problems of compression resistance, poor bending resistance, poor plasticity, brittle quality, etc., to reduce dosage, improve therapeutic effect and improve utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

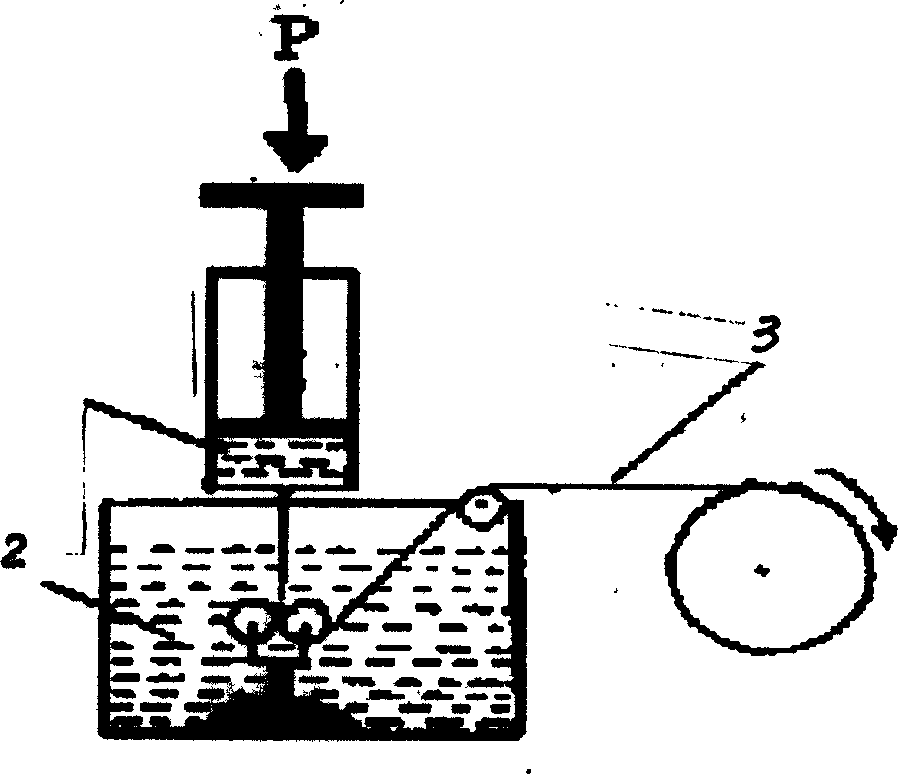

[0030] Embodiment 1: see figure 1

[0031] The hollow bio-inorganic fiber drug carrier and filling material for root canal filling were prepared by precursor wire drawing method and drug vacuum adsorption method. The specific process is as follows:

[0032] 1. Sodium alginate (Na-Alg) and sodium pyrophosphate (Na-Alg) with a mass ratio of 2.3:1 4 P 2 o 7 ) was dissolved in hot water and stirred to completely dissolve into a sol, and the pH value of the sol was adjusted to 7 with acetic acid, and then stood in a constant temperature tank at 75°C for 1.5 hours to obtain a uniform phosphorus-containing sol without bubbles. (2) Phosphorus-containing sol in 0.4mol / L CaCl 2 drawing in solution, such as figure 1 , and then washed with water and dried to obtain dry precursor fibers. (3) The precursor fiber is treated at high temperature in air, the heat treatment temperature is 900° C., and the heat treatment time is 0.5 hour. A hollow bioinorganic fiber is obtained.

[0033]...

Embodiment 2

[0035] The inorganic hollow fiber is prepared by electrophoretic deposition method, and after filling the hollow fiber with medicine, the bone filling material is prepared with bio-inorganic bone cement, which is used for bone tuberculosis and bone defect repair. The specific process is as follows:

[0036] 1. Select the hydroxyapatite suspension as the electrophoretic deposition medium, alcohol as the suspension, the solid content of the suspension: 25g / L, and add 0.5% magnetic glass.

[0037] 2. Select carbon fiber as the precursor, and prepare bioactive calcium phosphate coating on its surface by electrophoretic deposition. Electrophoretic deposition pulse voltage: 30V, pulse current: 50mA, deposition time: 30s

[0038] 3. Treat the precursor fibers at high temperature in the air, the heat treatment temperature: 1000°C, and the heat treatment time: 0.5 hours.

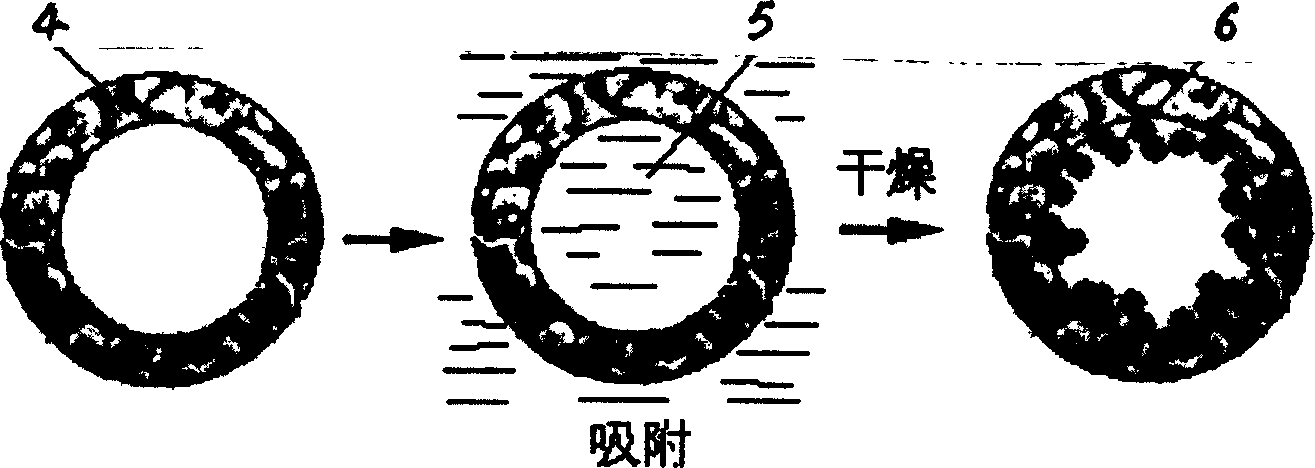

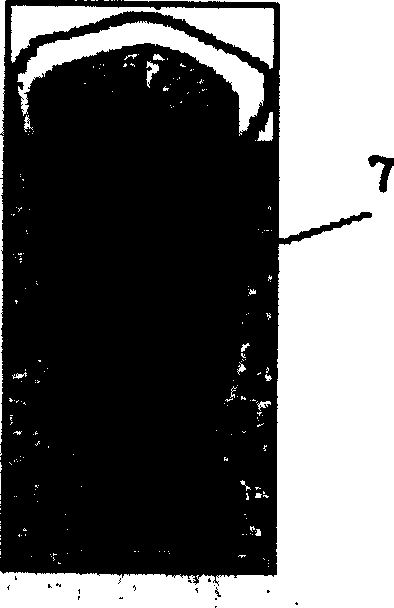

[0039] 4. Add rifampicin to the mixer cup and dissolve it in a water bath at 50°C; use rifampicin vacuum adsorpt...

Embodiment 3

[0041] The biodegradable polymer hollow fiber is prepared by melt stretching method, and after the drug is filled in the hollow fiber, the bone filling material is prepared with bio-inorganic bone cement for tumor treatment. The specific process is as follows:

[0042] 1. Melt the degradable polylactic acid at a temperature of 115° C. using a melt rheometer. The melt is passed through a hollow blowing spinneret to form a hollow fiber, and the required hollow degradable polymer fiber is obtained through drawing and stretching.

[0043] 2. Add doxorubicin into the mixer cup to dissolve, and use vacuum adsorption method in the prepared hollow fiber, then take out the composite carrier, freeze-dry several times at low temperature to realize the drug deposition in the hollow fiber; use calcium phosphate bone cement to The hollow fiber carrier is modulated into a drug-loaded filling material to obtain the required hollow fiber drug carrier for tumor treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com