Process for preparing antibacterial stainless steel using ion-implantation method

A technology of antibacterial stainless steel and ion implantation equipment, which is applied in the direction of ion implantation plating, metal material coating process, coating, etc., can solve the problems of low yield rate, high rolling process requirements, high labor intensity, etc., and achieve production Simple process, avoid high copper content, good antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

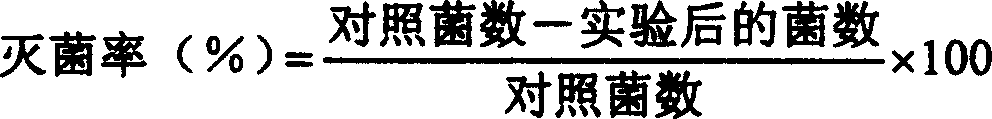

Method used

Image

Examples

Embodiment approach ( 1

[0013] Embodiment (1) Preparation of martensitic antibacterial stainless steel by ion implantation

[0014] 1. The specific process steps for preparing martensitic Cu-containing antibacterial stainless steel by ion implantation are as follows:

[0015] (1) The matrix material is martensitic stainless steel, and its weight percentage composition is as follows: C: 0.08-0.45, Cr: 12-14, Si: ≤0.60, Mn: ≤0.80, Cu: ≤0.10, and the rest is Fe;

[0016] (2) Perform Cu ion implantation on the stainless steel base material on the ion implanter, and the pressure of the vacuum chamber is 1.33×10 -4 Pa is about, the Cu ion implantation energy is 60-80keV, and the Cu ion implantation dose is 1.0×10 17 cm -2 , the ion beam current density is 35μA / cm 2 , the injection time is 30-60 minutes;

[0017] (3) Antibacterial treatment (vacuum aging treatment), the treatment temperature is 450-900° C., and the time is 1-10 hours.

[0018] 2. The specific process steps for preparing martensitic Ag-...

Embodiment approach

[0021] (3) Antibacterial treatment (vacuum aging treatment), the treatment temperature is 450-900° C., and the time is 1-10 hours. Embodiment (2) Preparation of Austenitic Antibacterial Stainless Steel by Ion Implantation

[0022] 1. The specific process steps for preparing austenitic Cu-containing antibacterial stainless steel by ion implantation are as follows:

[0023] (1) The base material is austenitic stainless steel, and its weight percentage composition is as follows: C: 0.01~0.15, Cr: 16~20, Ni: 8~10, Si: ≤1.00, Mn: ≤2.00, Cu: ≤0.10, The rest is Fe;

[0024] (2) Perform Cu ion implantation on the stainless steel base material on the ion implanter, and the pressure of the vacuum chamber is 1.33×10 -4 Pa is about, Cu ion implantation energy is 100~120keV, Cu ion implantation dose is 2.0×10 17 cm -2 , the ion beam current density is 50μA / cm 2 , the injection time is 30-60 minutes;

[0025] (3) Antibacterial treatment (vacuum aging treatment), the treatment temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com