Method and system for preparing high polymer group biochip micro flow path structure adopting quasi molecule laser

A technology of excimer laser and biochip, which is applied in biochemical equipment and methods, measurement/inspection of microorganisms, biological testing, etc., can solve the problem that cannot meet the needs of rapid development of microfluidic biochips, and is difficult to adapt to large batches of chips Production and cost reduction, high degree of operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

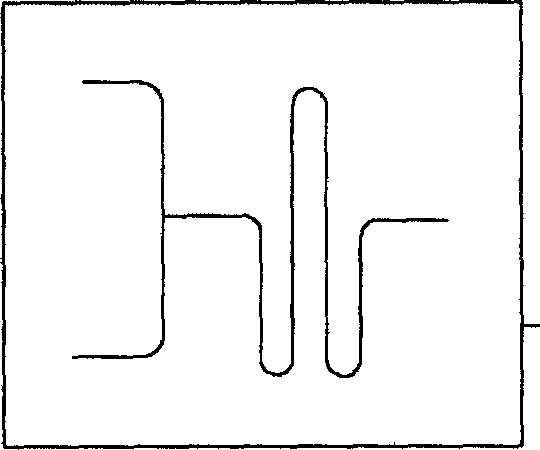

[0061] Utilize the technology of the present invention, can process the microfluidic circuit of biochip on high polymer materials such as COC (cycloolefin copolymer), PDMS (polydimethylsiloxane), polymethyl methacrylate (PMMA);

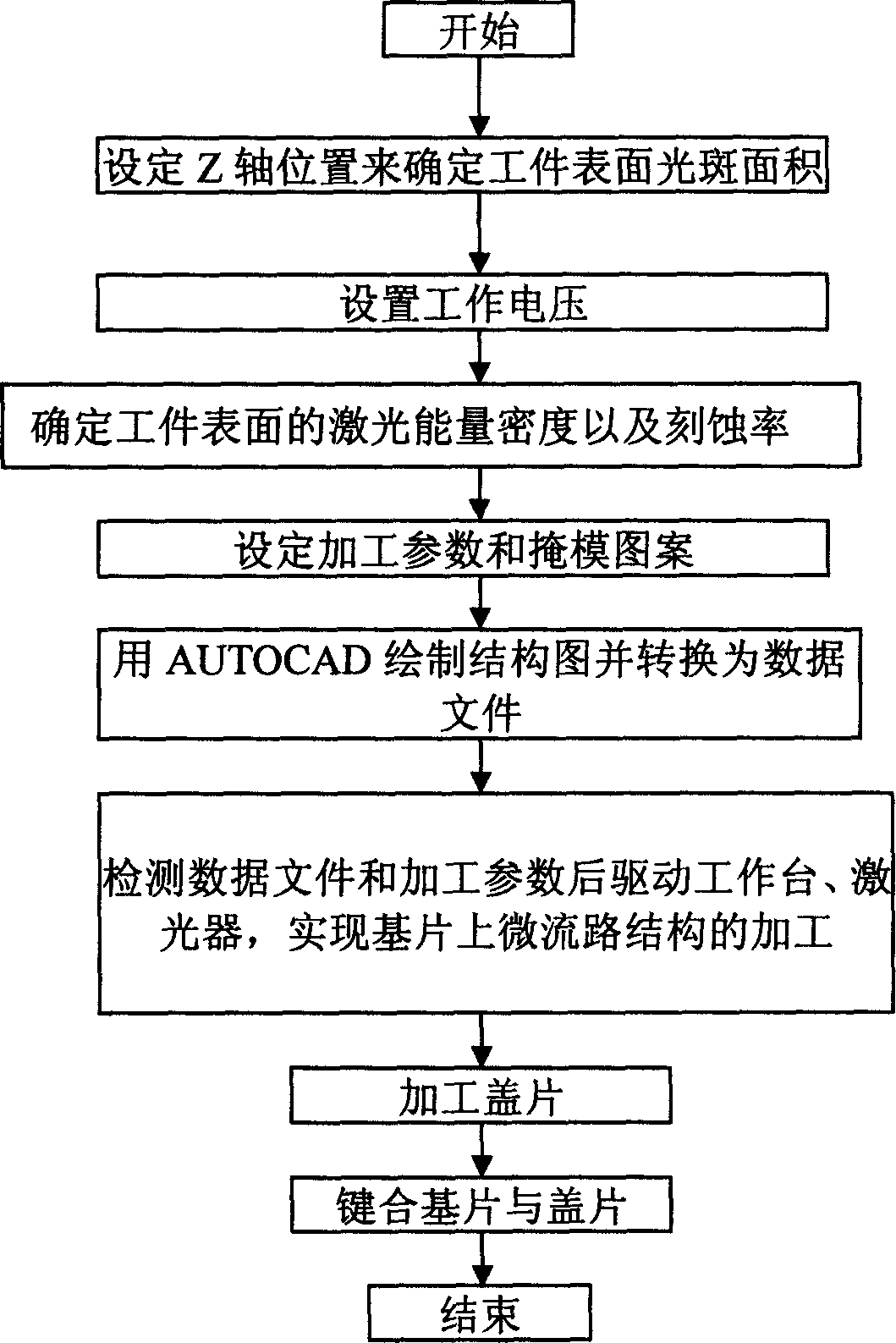

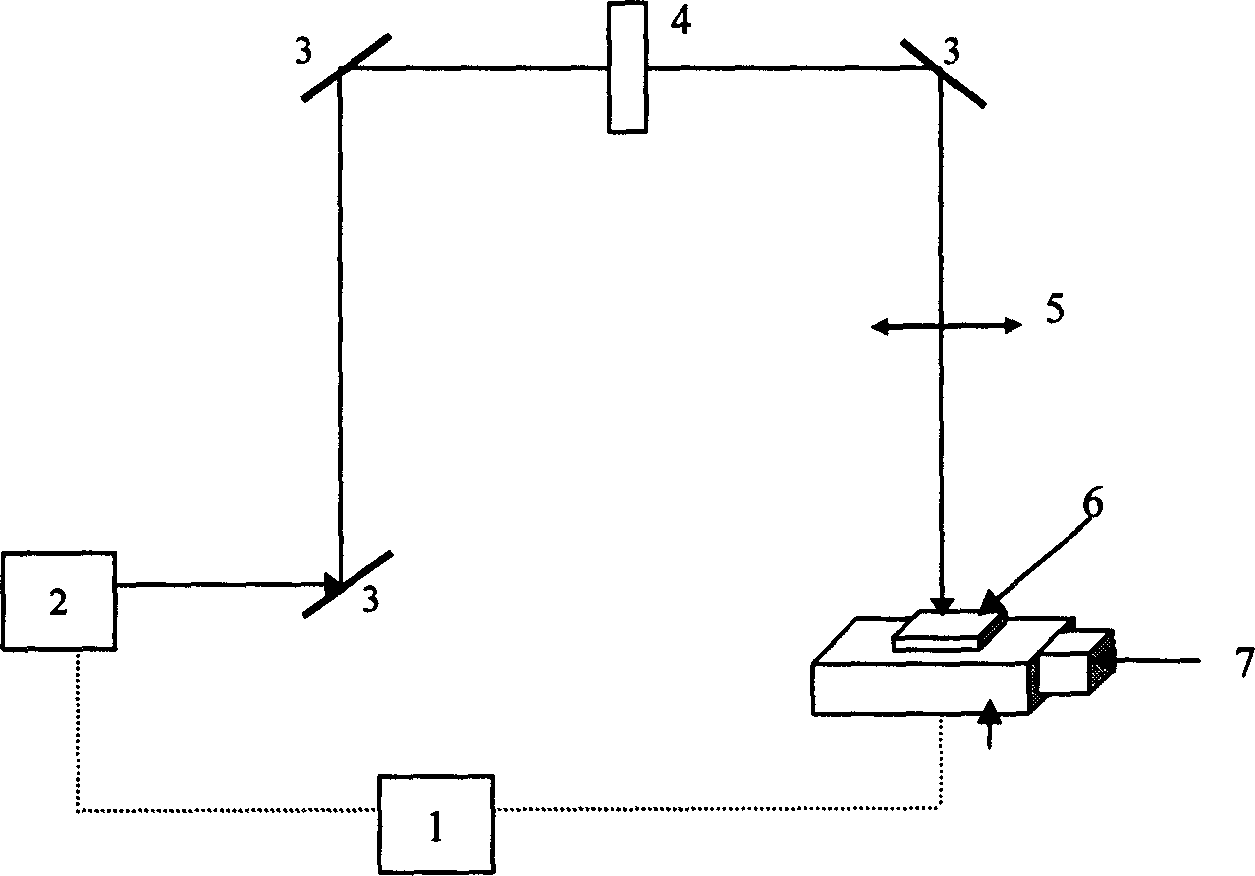

[0062] The present invention adopts embodiment to introduce that we have carried out the processing and the sampling experiment of CE (capillary electrophoresis) biochip microfluidic path on polymethyl methacrylate (PMMA) material; Processing system is made, installed and debugged by conventional method, wherein , the model of the excimer laser 2 is Lambda physik LPX305IF, and the laser wavelength is 248nm; the computer 1 is a Pentium 586PC machine; the computer 1 is equipped with sending signals to the excimer laser 2, the X-Y-Z three-dimensional displacement table drive motor 7 and from the drive motor 7 The built-in laser processing system control card of the universal input and output interface for receiving signals, and the drive motor 7 of the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com