Coaxial flexible piezoelectric cable polarizer, polarizing method, defect detector, and defect detecting method

A defect detection and piezoelectric technology, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, measuring devices, etc. Flexible piezoelectric body 2, can not be polarized, can not complete the cable and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

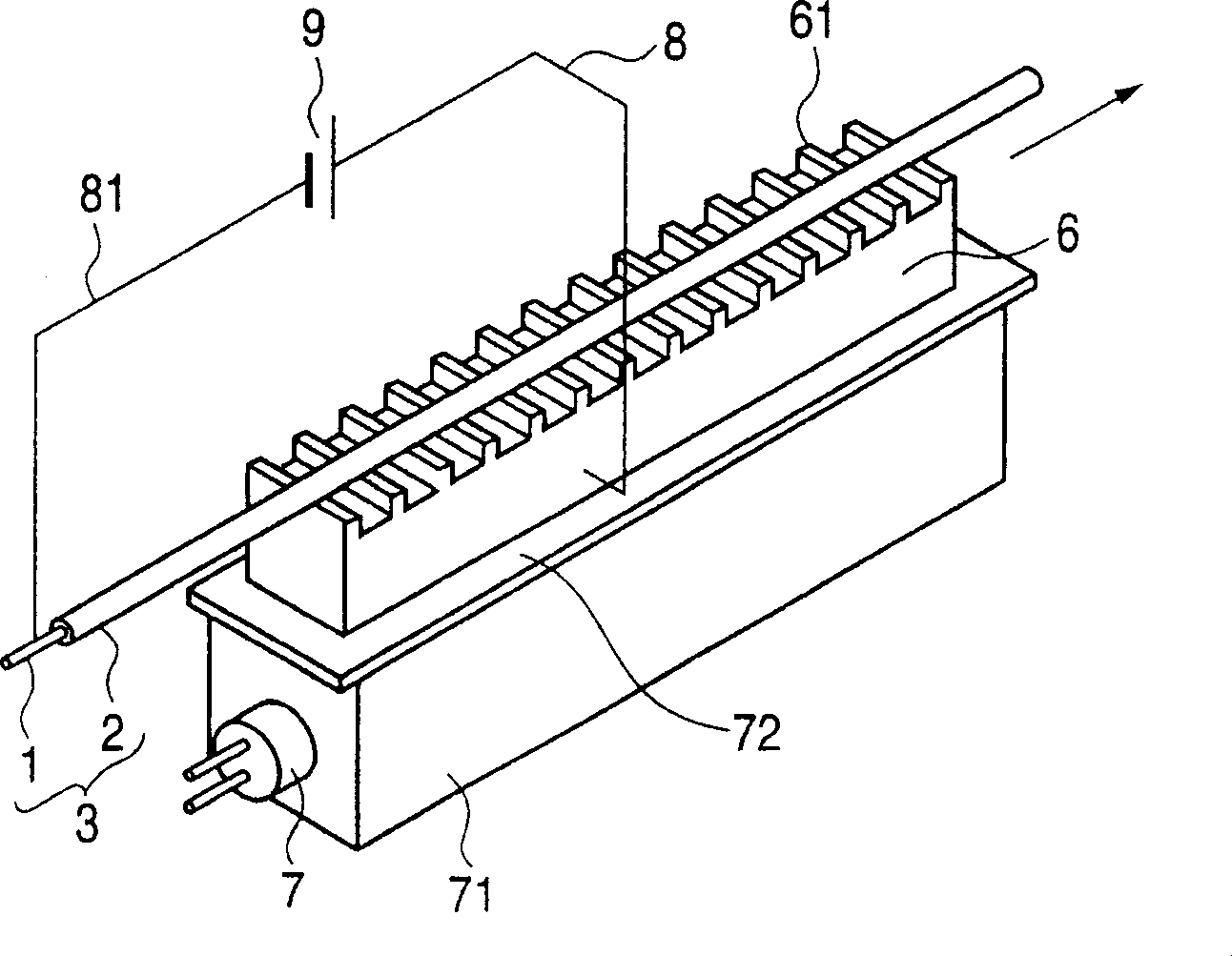

[0063] figure 1 It is a schematic appearance diagram showing the configuration of the polarizing device in Example 1 of the present invention. A coaxial flexible piezoelectric body is formed facing the core electrode 1 . This molded body is referred to as a piezoelectric tube 3, and a helical metal wire or a bundle of thin metal wires is used as the core electrode 1. Used in polymer masterbatches such as epoxy resin, amino resin, chloroprene rubber, chlorinated polyethylene resin, etc., which are filled with ceramic piezoelectric body powder such as lead zirconate titanate or composite piezoelectric body or macromolecule such as PVDF The piezoelectric body serves as a flexible piezoelectric body.

[0064] The piezoelectric tube 3 is arranged on the piezoelectric tube passage portion 61 provided on the bulk conductor 6, and the piezoelectric tube 3 is moved by moving means (not shown in the figure). The piezoelectric tube passage portion 61 is formed in a concavo-convex sha...

Embodiment 2

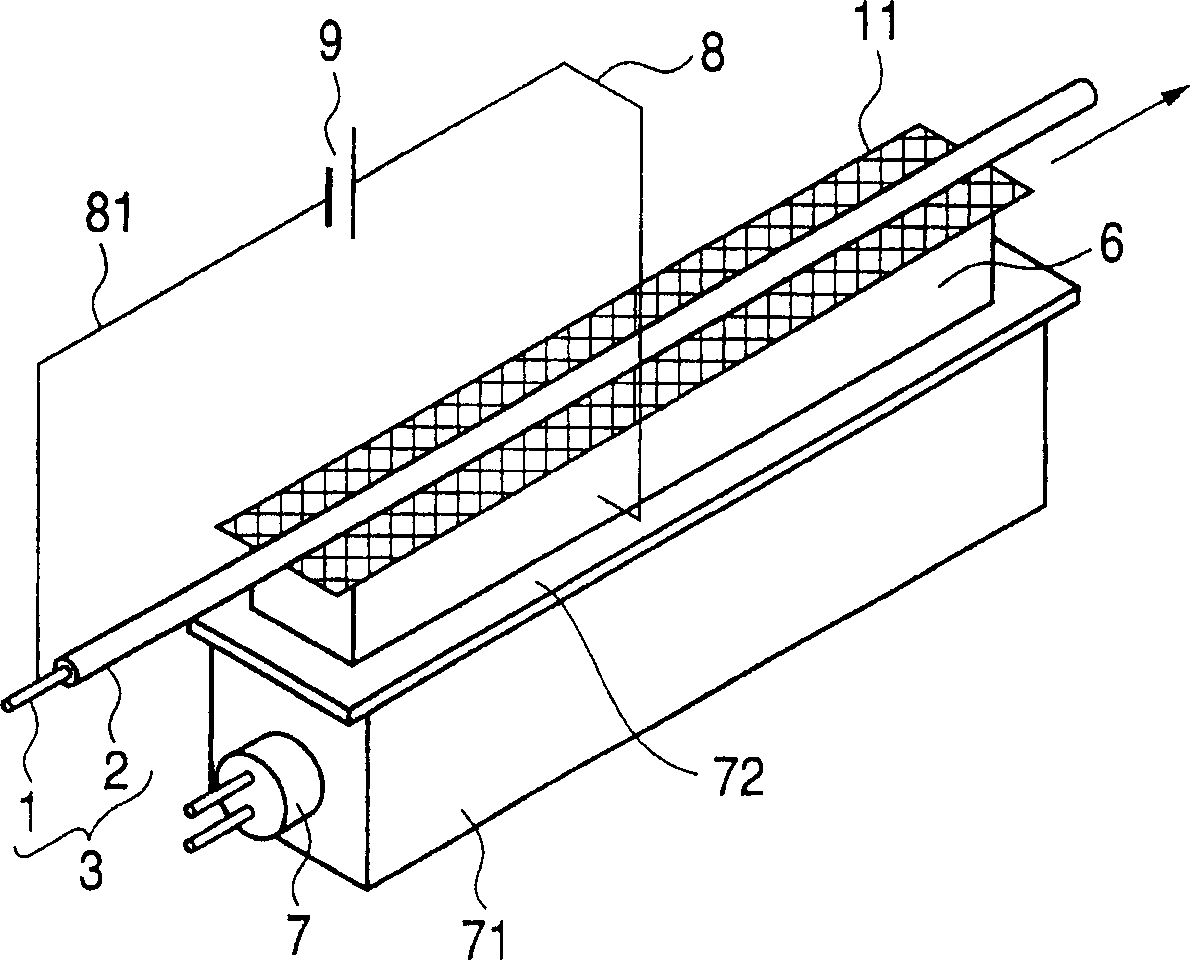

[0068] figure 2 It is a schematic appearance diagram showing the configuration of the coaxial flexible piezoelectric body polarizer in the second embodiment of the present invention. In the second embodiment, the metal mesh 10 is used as the piezoelectric body tube passage portion. The piezoelectric tube 3 is arranged on the metal mesh 10 provided on the surface of the bulk conductor 6, and moved by moving means (not shown). The surface of the metal mesh 10 is formed in a concave-convex shape. Since the metal mesh 10 is used to form the unevenness, it is not necessary to process the arrangement surface of the piezoelectric tube 3 into a concave-convex shape, so the gap between the piezoelectric tube 3 and the piezoelectric tube passage portion (in the embodiment, the metal mesh 10) can be reduced. Friction, so that the piezoelectric tube 3 can be moved with a very small picture.

[0069] Conductors such as iron, stainless steel, copper, brass, and aluminum are used as the ...

Embodiment 3

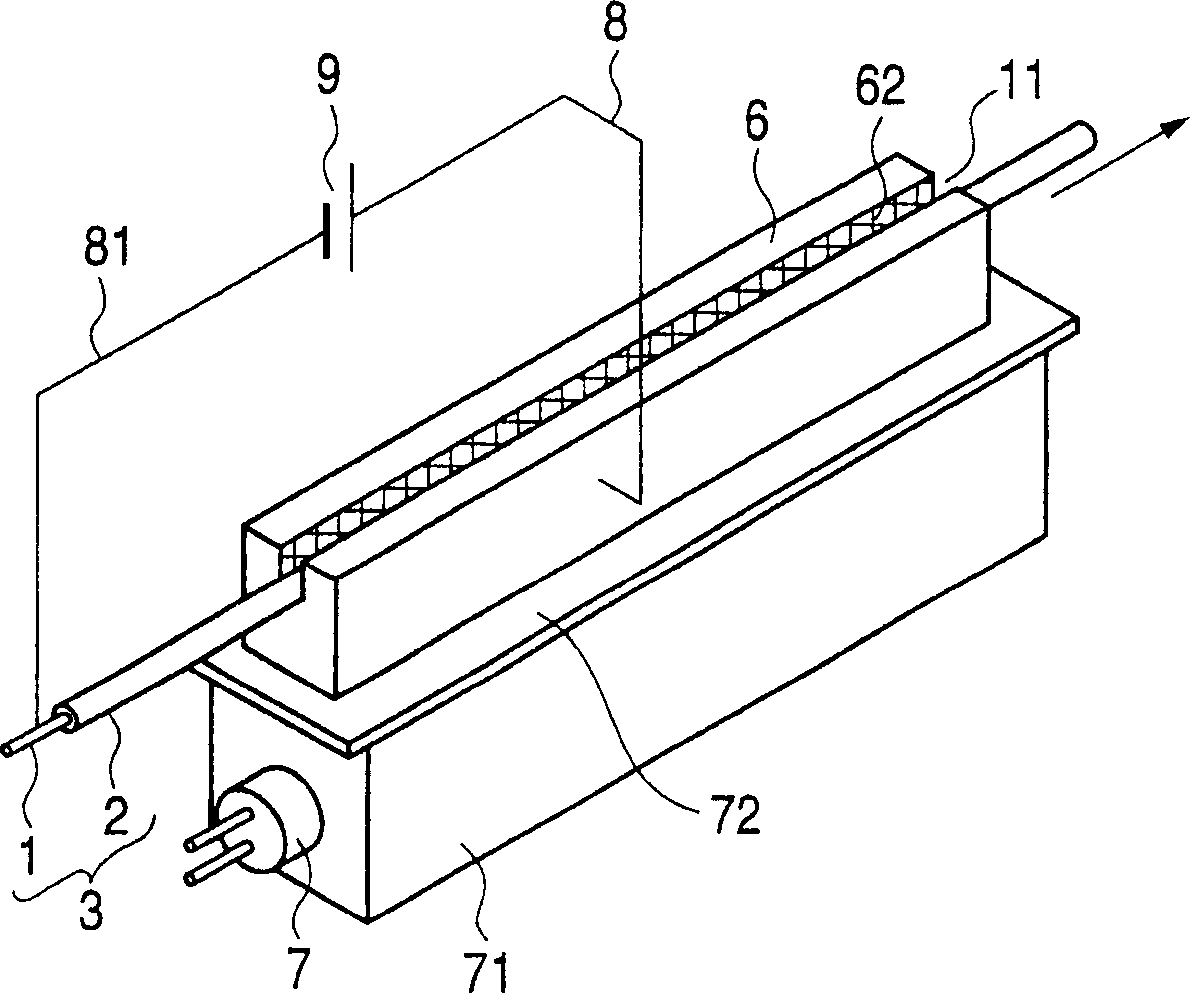

[0071] image 3 It is a schematic appearance diagram showing the configuration of the coaxial flexible piezoelectric body polarizer in Example 3 of the present invention. Grooves 11 are provided in the bulk conductor 6 , the passage portion of the piezoelectric tube 3 is changed to the groove 11 , and the inner surface of the groove 11 is formed into a concavo-convex shape 62 . When the bulk conductor 6 is heated to heat the piezoelectric tube 3 arranged in the groove 11 of the bulk conductor 6 , the piezoelectric tube 3 is heated by the bottom and both walls of the groove 11 . Since the piezoelectric body tube 3 is heated more uniformly, it is possible to polarize the coaxial flexible piezoelectric body 2 at a necessary temperature. In addition, the upper part is opened in advance, and the piezoelectric tube 3 can be easily arranged from the upper part of the tank 11 . In addition, since the inner surface of the groove 11 serving as the passage portion of the piezoelectric ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com