Lead accumulator

A lead-acid battery and electrode technology, applied in lead-acid batteries, lead-acid battery electrodes, lead-acid battery construction, etc., can solve the problems of liquid depletion, inability to inhibit the falling of active substances, and difficulty in effectively filling silica fine powder, etc. Achieve the effect of improving flexibility and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] (i) Manufacture of negative electrode

[0065] A lead-tin-calcium alloy sheet composed of 0.08% by weight of calcium, 0.8% by weight of tin, and the rest of which is lead is cut with fine slits, expanded to form a large number of mesh holes, and made into an expanded grid with tabs 1a Body 1.

[0066] Lead powder, water, sulfuric acid with a specific gravity of 1.41, carbon powder (electric card black), barium sulfate, woody derivatives and polyester short fibers are prepared in a weight ratio of 1000:115:70:4.1:21:4.1:1 , by making negative electrode paste in this way.

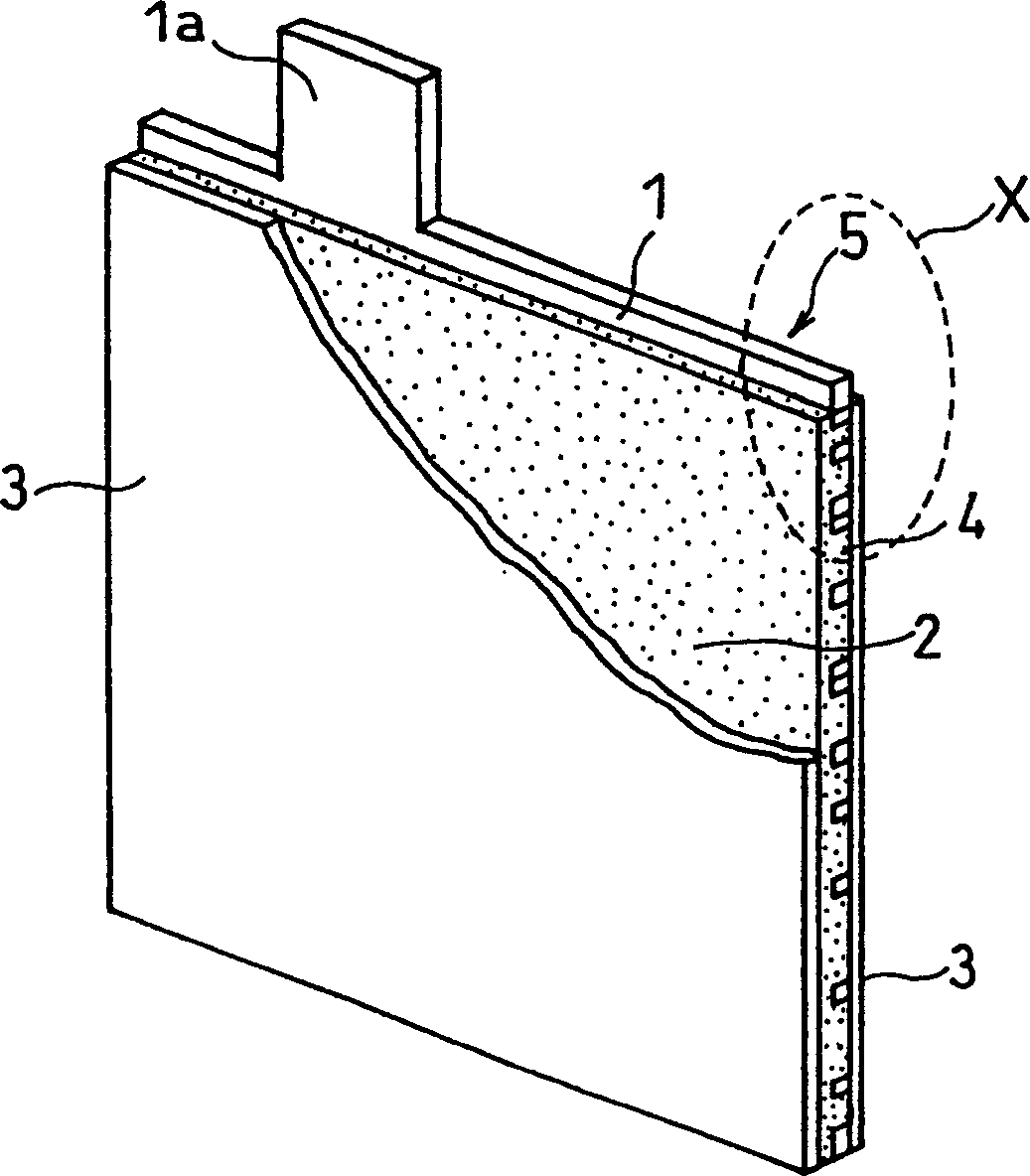

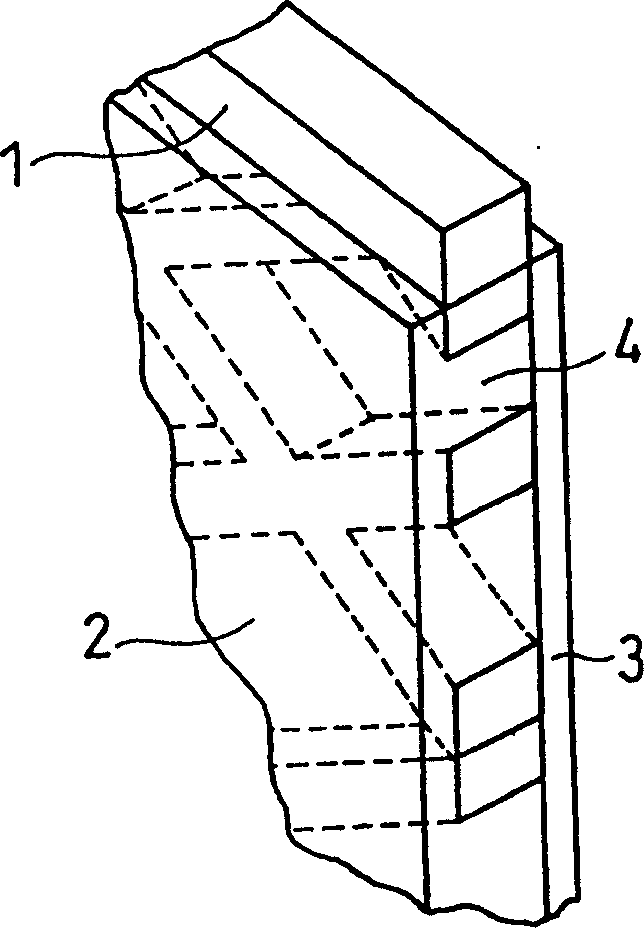

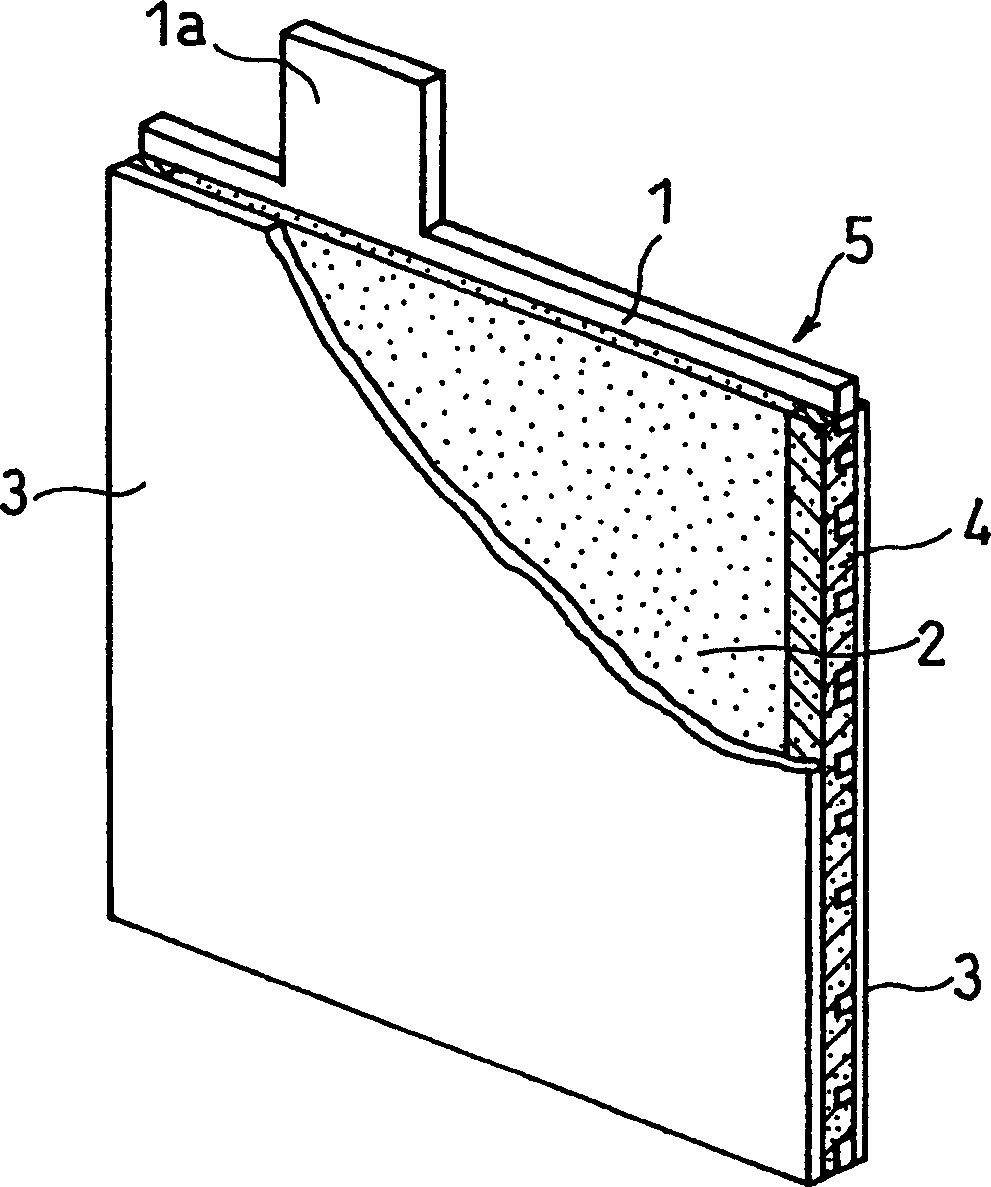

[0067] Fill the negative electrode paste into the expanded grid body 1 obtained above, after forming the active material layer 2, paste the paste paper 3 made of kraft pulp and water-resistant enhancer to prevent the active material from falling off on both sides, and carry out chemical conversion and drying ,get figure 1 and figure 2 Negative terminal shown.

[0068] (ii) Add an organic binder t...

Embodiment 2

[0077] The active material layer on the edge of the left and right ends of the negative electrode does not contain an organic binder, and the same method as in Example 1 is adopted to make the active material layer on the edge of the left and right ends of the positive electrode contain an organic binder. In the same way, a sealed lead-acid storage battery with a rated voltage of 12V and a nominal capacity of 65Ah was made. Take it as battery B.

Embodiment 3

[0089] Figure 6 A transverse cross-sectional view of main parts of the lead acid storage battery of this embodiment is shown.

[0090]After the negative electrode 5 was produced by the same method as in Example 1, the porous resin layer 10 having through holes was formed on the surface of the active material layer 2 on the left and right end edges 4 of the negative electrode 5 as follows.

[0091] Isobutylene rubber was mixed with styrene rubber in a weight ratio of 97.3. A resin solution was obtained by adding 70 parts by mass of toluene to 30 parts by mass of this mixed resin and dissolving it. Adipic dihydroxyamide was dispersed in this resin solution as a foaming agent, and the left and right end edges 4 of the aforementioned negative electrode 5 were immersed in this dispersion liquid. Then, toluene which is a solvent was removed while making it foam at 210 degreeC. At this time, a portion of the resin component is impregnated in the vicinity of the surface of the act...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com