Normal-pressure low-temperature plasma treater for modifying fiber surface

A technology of low-temperature plasma and fiber modification, which is applied in fiber treatment, physical treatment, textile and paper making, etc., to achieve the effects of avoiding metal deposition pollution, appropriate temperature and energy, and improving wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

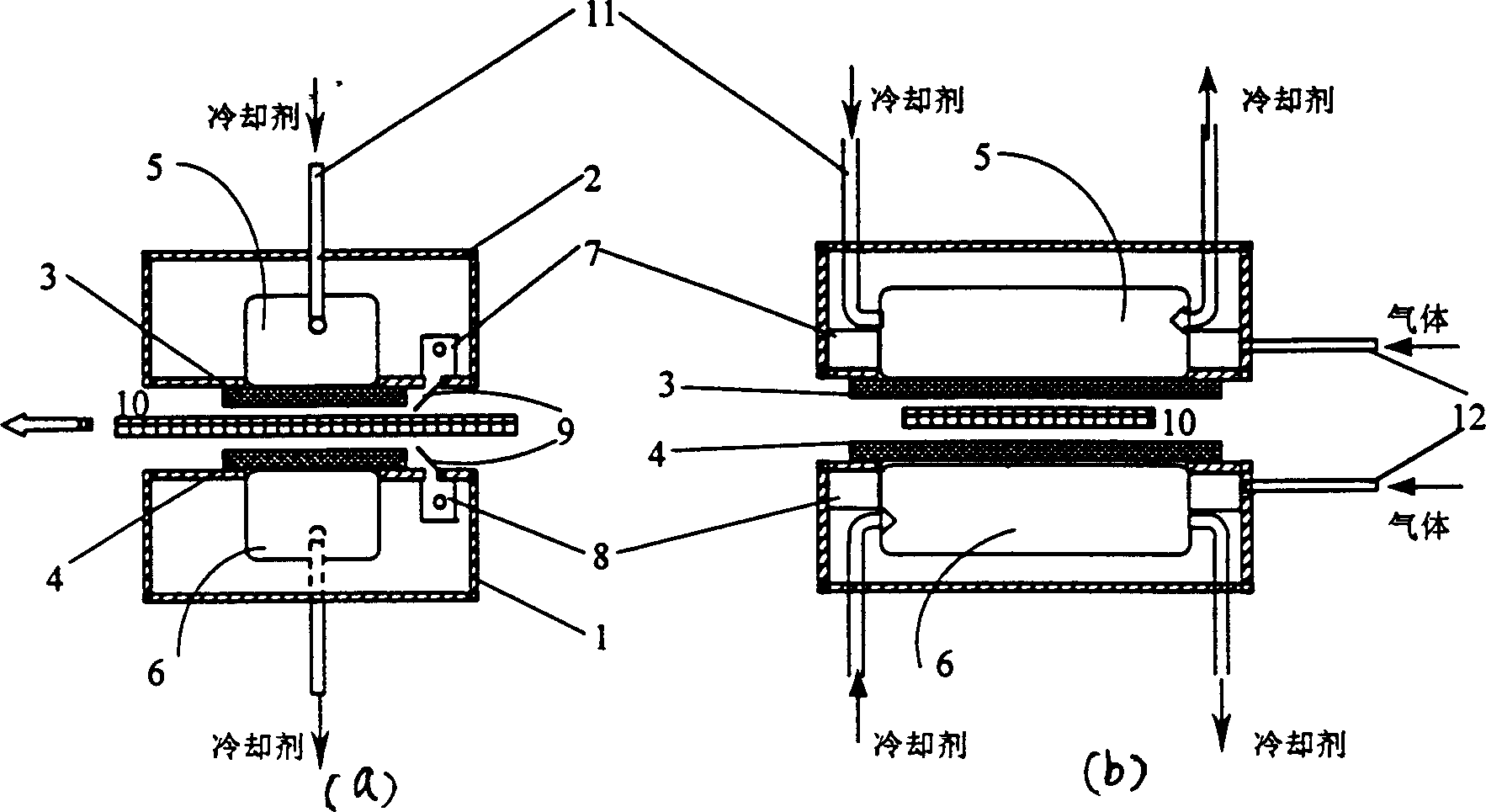

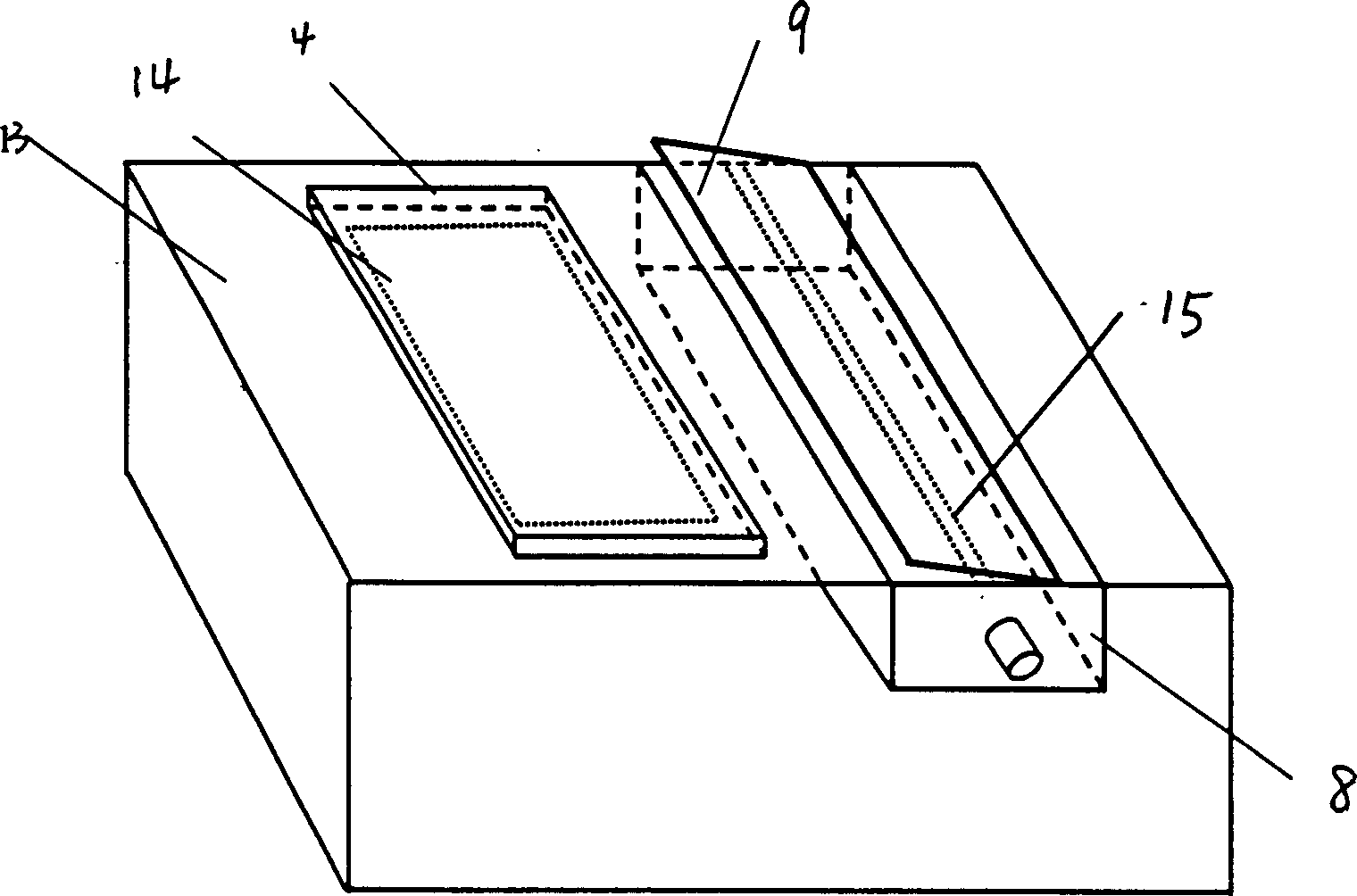

[0037] use figure 1 The atmospheric-pressure low-temperature plasma processor in the process continuously treats polyester (polyethylene terephthalate PET) woven fabrics. The two electrodes are brass, and the silicon oxide plate is used as the blocking medium. The upper and lower electrodes add about 10KHz AC high voltage, argon gas or argon gas mixed with air is passed into the discharge slit between the upper and lower parts of the processor as the discharge gas, and a blue-purple bright glow is produced in the discharge space, and the observation Less than arc flash and spark discharge. The larger the argon flow, the brighter the glow in the discharge space and the stronger the discharge. The distance between the slits is 3 mm.

[0038]The polyester cloth is placed statically in the discharge slit, or slowly passes through the discharge slit several times. Under the condition of stable discharge, regardless of static treatment or continuous treatment, under the same con...

Embodiment 2

[0044] use figure 1 The density of plasma generation and processor opposite is 170g / m 2 The PBT (polybutylene terephthalate) meltblown nonwovens (meltblown nonwovens) are processed statically or continuously. Roughly the same method as Example 1 is processed, but the processing conditions are different. In the case of stable discharge, there was no change in the appearance of the sample after treatment, and no thermal damage or ablation or perforation caused by arc and spark discharge was observed.

[0045] The PBT melt-blown non-woven fabric before and after treatment takes a sample with a diameter of 5 cm. Before the treatment, the non-woven fabric sample is flat on the surface of a yellow 5% potassium dichromate solution, and the non-woven fabric floats on the water surface without wetting within 20 seconds; The treated sample was immediately wetted in less than 1 second, and the white nonwoven turned yellow.

[0046] When the processing conditions are not good, the phe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com