Method for mfg. multilayer printed wiring board and multilayer printed wiring board thereby

A multi-layer printing and circuit board technology, which is applied in the fields of printed circuit manufacturing, multi-layer circuit manufacturing, printed circuit, etc., can solve problems such as difficulty in providing chips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

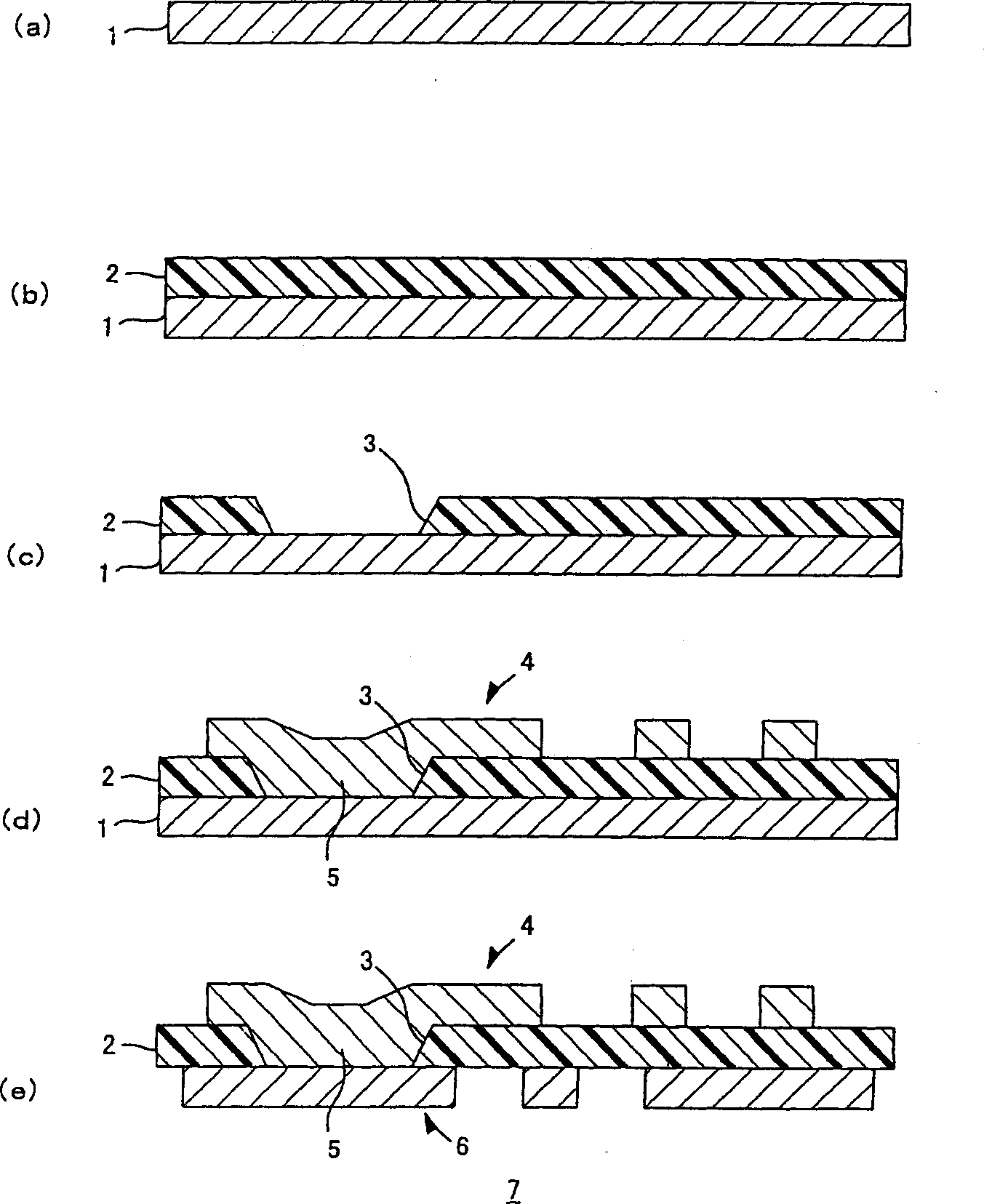

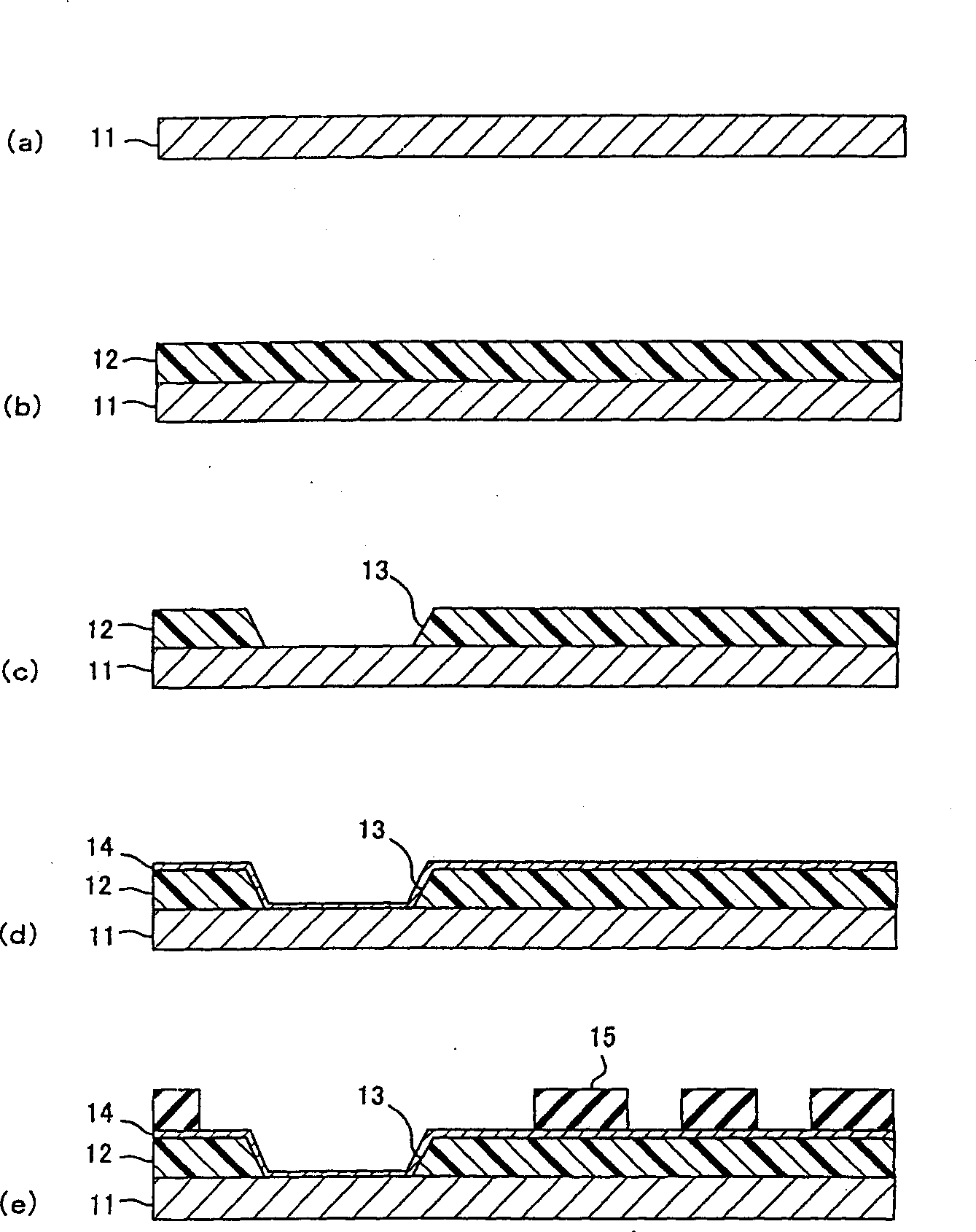

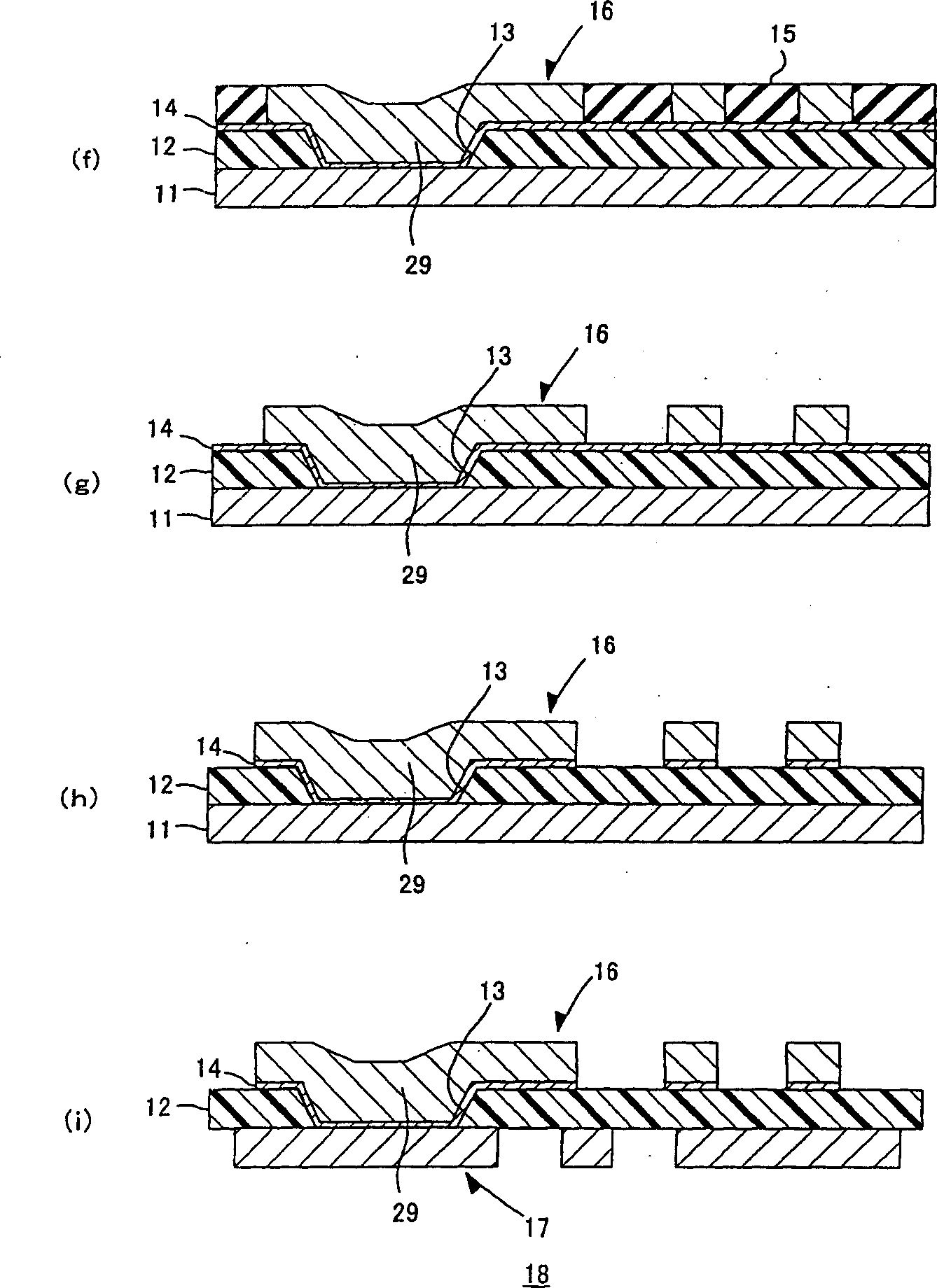

[0084] (manufacturing of double-sided substrates)

[0085] First, a rolled nickel foil (Ni-H available from Toyo Seihaku Co., Ltd.) with a thickness of 25 μm was cut to the desired size, and degreased (50ml / L-Metaclea CL-5513 available from Dai- ichiKogyo Seiyaku Co., Ltd.) at a temperature of 60°C for 2 minutes. Then rinse with water and dry. Through these steps, the nickel foil is ready, as figure 2 (a) shown. Subsequently, a photosensitive clear ink (BL-9700 available from Hitachi Chemical Co., Ltd.) was applied to one side of the nickel foil 11 by screen printing with a polyester mesh of 200 grids / inch. . Subsequently, it was placed in a desiccator at 80° C. for 40 minutes to dry. Through these steps, the insulating resin layer 12 with a thickness of about 30 microns is made, as figure 2 (b).

[0086] Next, after putting the mask in close contact with the insulating resin layer 12, use 2.7J / cm2 released from the ultra-high pressure mercury vapor lamp 2 of ultravi...

example 2

[0101] (Double-sided substrate manufacturing)

[0102] First, a rolled copper alloy foil (C-7025 available from Yamaha-Olin Metal Corporation) with a thickness of 35 micrometers was cut to the required size and degreased with a 60°C degreaser (200ml / L-OPC Acidclean 115 available from Okuno Chemical Industries Co., Ltd.) was treated for 2 minutes. Afterwards, wash with water and dry. Through these steps, the copper alloy foil 31 is prepared as Image 6 (a) shown.

[0103] Subsequently, the copper alloy foil 31 was immersed in 100 ml / L hydrochloric acid at 30° C. for 20 seconds, and then immersed in a palladium substitution plating solution (200 ml / L-ICP Accela available from Okuno Chemical Industries Co., Ltd.) at 30° C. for 3 minutes . Afterwards, wash with water. Again, it was immersed in a 60° C. electroless nickel plating solution (B-1 available from Meltex, Inc.) for 2 minutes, and then washed with water and dried. Through these steps, a nickel plating layer 32 with ...

example 3

[0118] In addition to the rolled nickel foil with a thickness of 25 microns (Ni-H is available from Toyo Seihaku Co., Ltd.), the rolled SUS304 foil with a thickness of 25 microns (SUS304H-TA is available from Toyo Seihaku Co., Ltd. .obtained) can also be used as a metal foil, the same method in Example 1 can be used to manufacture a double-sided substrate, and then the same method in Example 1 is used to manufacture a 4-layer printed wiring board by using the double-sided substrate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com