Dual-vertical spin valve

A spin-valve, double-perpendicular technology, used in magnetic recording heads, instruments, measuring devices, etc., can solve the problems of loss of stored information, limit the development of high-level information storage technology, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Example 1: Two kinds of spin valve materials were prepared by using a magnetron sputtering apparatus: one of them is a common spin valve structure, and its multilayer film is metal tantalum (6nm) / nickel-iron alloy (7nm) from the bottom to the top. / metal copper (2.6nm) / nickel-iron alloy (4nm) / iron-manganese alloy (15nm) / metal tantalum (6nm) (the data in brackets is the thickness of the film, nm means nanometer), which is characterized by the current parallel to the plane configuration, And the magnetic anisotropy easy axis is parallel to the film surface; the other is the double vertical spin valve structure of the present invention, which is platinum metal (6nm) / [cobalt metal (0.4nm) / platinum metal (2nm)]5 / cobalt metal (0.8nm) / metallic copper (3nm) / Co(0.8nm)[Pt(2nm) / Co(0.4nm)]5 / FeMn(15nm) / Pt(2nm) (the subscript number is the number of repeated layers of the composite structure ), which is characterized by the current perpendicular to the plane configuration and the eas...

Embodiment 2

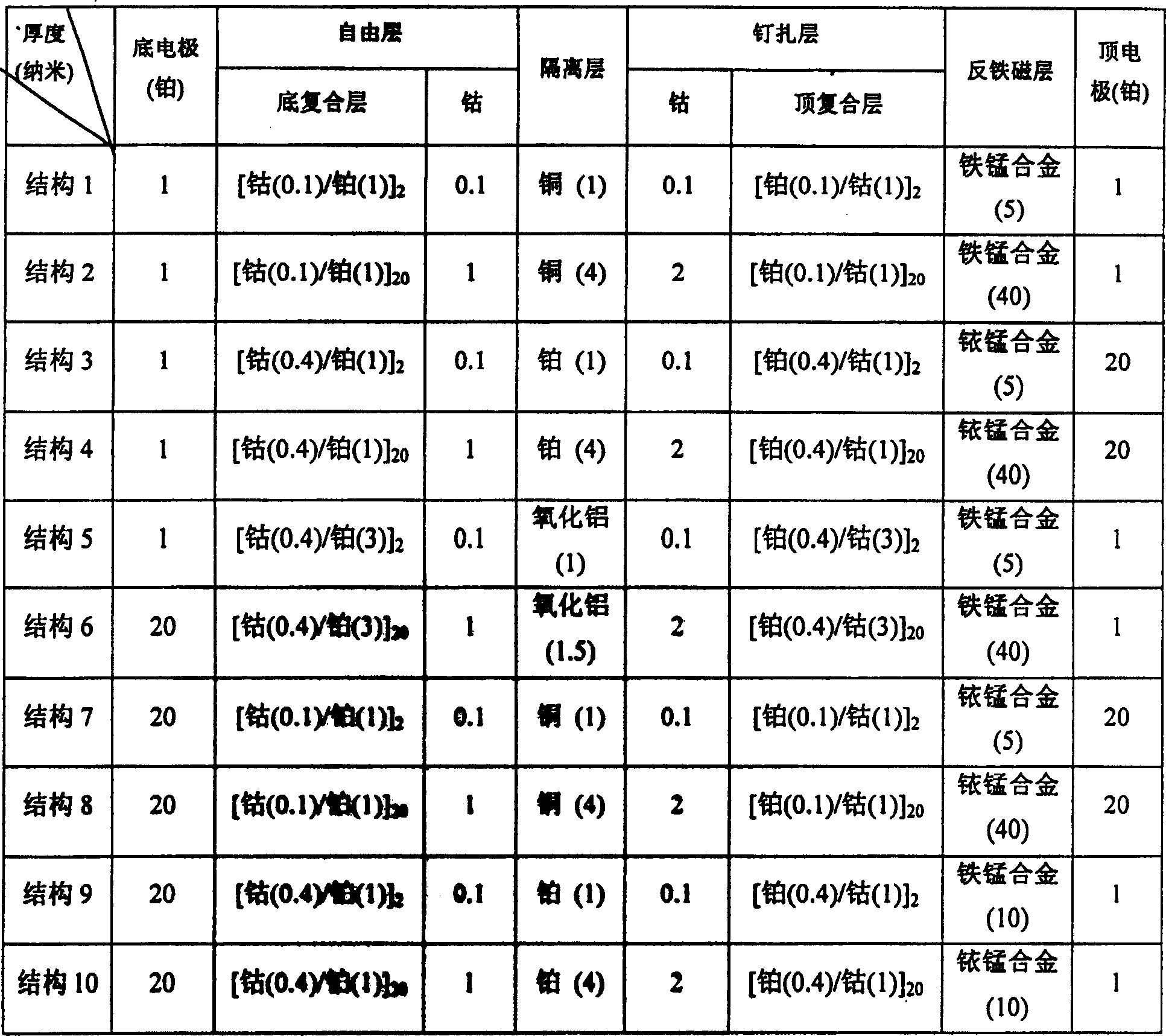

[0016] Example 2: Ten kinds of double vertical spin valve devices with structures were experimentally prepared, and the structures are shown in the following table:

[0017]

[0018] The present invention uses plasma sputtering, magnetron sputtering and molecular beam epitaxy to prepare a total of 30 double vertical spin valve devices with the above ten structures, and the size of the devices is 300 nanometers × 300 nanometers . Through testing, it is found that the magnetoresistance effect of all these spin valves at room temperature is more than 30% higher than that of spin valves with conventional structures. Magnetic force microscopy tests revealed that these dual vertical spin-valve devices all exhibit good single magnetic domain characteristics.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com