Preparation technology of titanium silicon molecular sieve catalyst

A titanium-silicon molecular sieve and catalyst technology, which is applied in the field of preparation of titanium-silicon molecular sieve catalysts, can solve the problems of decreased catalyst activity, unsatisfactory catalyst strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Add 400g of 12.5% tetrabutylammonium hydroxide aqueous solution into a 1000mL glass reactor, add 180g of tetraethyl silicate, stir vigorously for 15min, and raise the temperature to 50-60°C. Add 10 g of n-butyl titanate into 55 g of isopropanol, stir to dissolve, add the obtained n-butyl titanate isopropanol solution into the reactor dropwise, and stir at the same time. After the dropwise addition, continue to stir for 2 hours, and raise the temperature to At 85°C, remove the alcohol in the reaction system, add 200g of deionized water, stir for 1 hour, and let stand for one day to obtain raw gum.

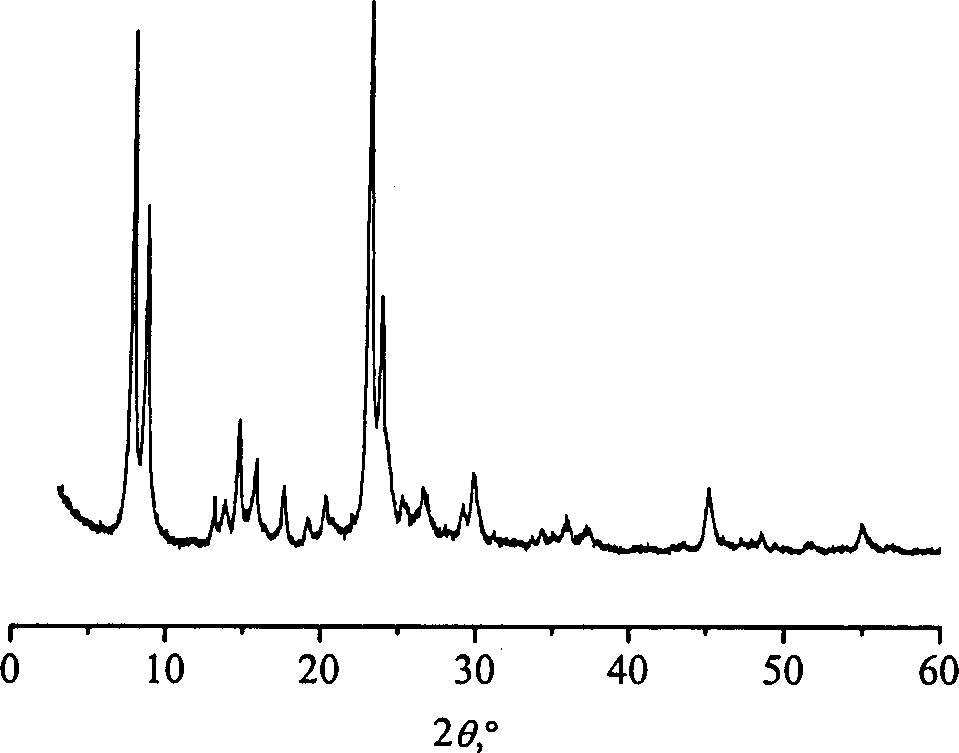

[0031] Put the original rubber into a 1L stainless steel autoclave, seal the reactor, start stirring, and control the heating rate of the reactor through a temperature program temperature controller. The heating curve of the reactor is as follows: figure 1 shown. After 120 hours, the temperature controller was turned off, the stirring was stopped, the temperature was natur...

Embodiment 2

[0037] The system of catechol and hydroquinone produced by hydroxylation of phenol was investigated. The reaction was carried out in a 1-liter four-neck flask, with 30% hydrogen peroxide as the oxidant and acetone as the solvent, the reaction temperature was 60°C, the hydrogen peroxide was added within 1 hour, and the reaction was continued for 10 hours after the dropwise addition. The ratio of reaction materials is: phenol: H 2 o 2 =3:1 (mol / mol), phenol:acetone=1:2 (v / v), phenol:catalyst=10:1 (mass ratio). Catalyst activity as H 2 o 2 The selectivity of forming quinone as an indicator:

[0038] λ = ( y CA + y HQ ) · w t / 110 w ...

Embodiment 3

[0042] The system of cyclohexane oxidation to cyclohexanone was investigated. Acetone was used as solvent and 30% hydrogen peroxide was used as oxidant, and the reaction was carried out in a stirred 100ml pressure reactor lined with polytetrafluoroethylene. 0.42g catalyst, 20ml acetone, 10.5ml 30% H 2 o 2 , 4ml cyclohexane was placed in a 100ml pressure vessel. The temperature was raised under stirring, the timing was started after the temperature reached 100° C., and the temperature was lowered after 8 hours of reaction. The catalyst in the product was filtered.

[0043] The composition of the sample is analyzed by gas chromatography. The chromatographic column is an OV-101 capillary column with a diameter of 0.2mm and a length of 60m. Hydrogen flame detection is carried out. The chromatographic analysis conditions are as follows:

[0044] Carrier gas (N 2 ) Reflux ratio: 35ml / min, FID temperature: 285°C, columnarity: 55°C.

[0045] The selectivity to H2O2 is λ=0.85.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com