Powder stainless steel reinforcing and sintering method

A technology for strengthening sintering and stainless steel, applied in the field of powder metallurgy, it can solve the problems of many pre-alloyed elements, reduce the plasticity and ductility of materials, etc., and achieve the effect of improving corrosion resistance, improving thermoplasticity and hot workability, and increasing density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 4

[0022] Example 4: The dense austenitic 316L stainless steel powder product has good plasticity, and the elongation rate reaches 30%, while the general powder sintered steel is below 3-5%, which is a brittle material. Whether the material formed by powder sintered stainless steel high-density pressing and sintering with activator is plastic or brittle is very important for structural parts and has an important impact on subsequent processing performance.

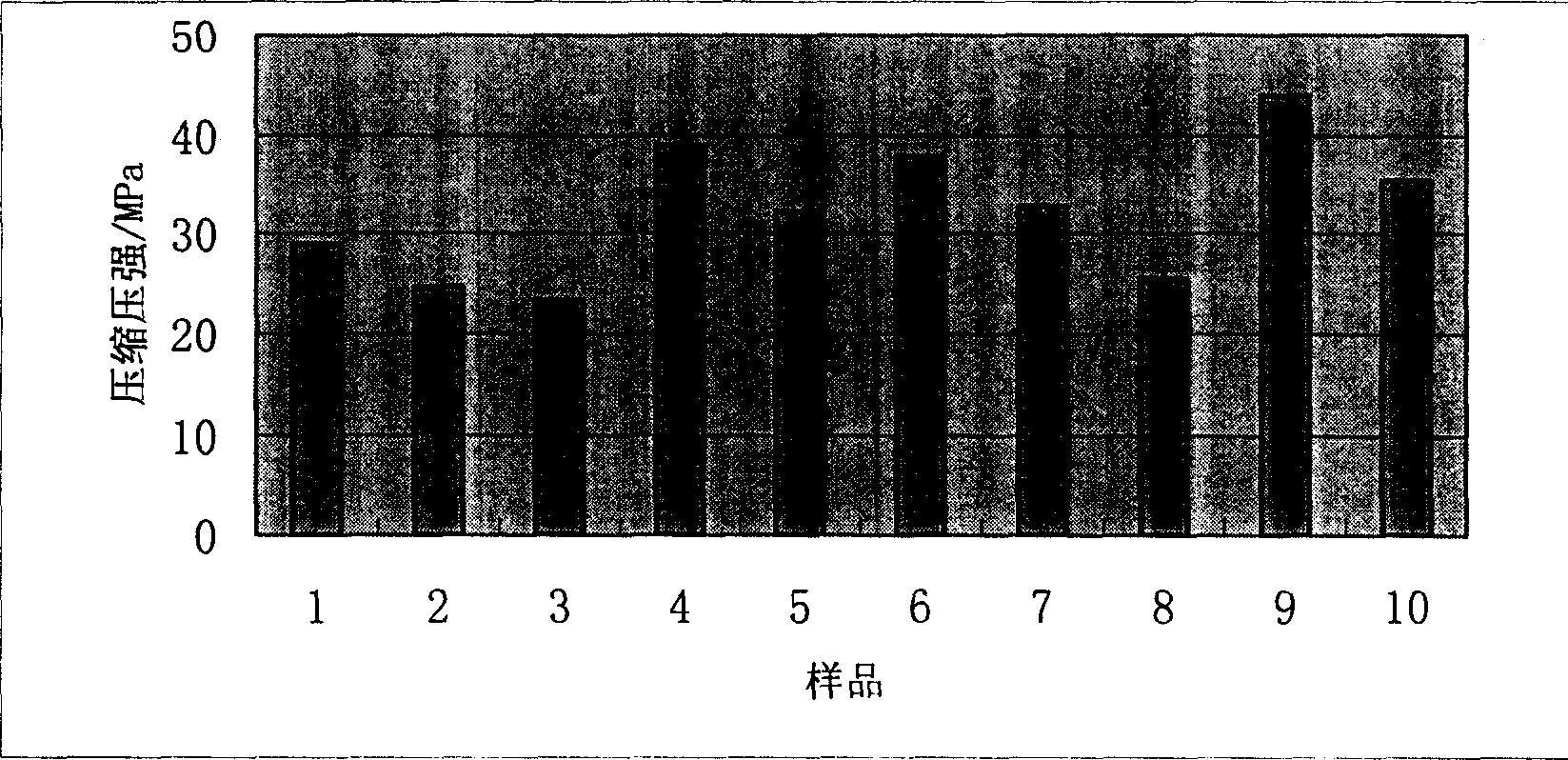

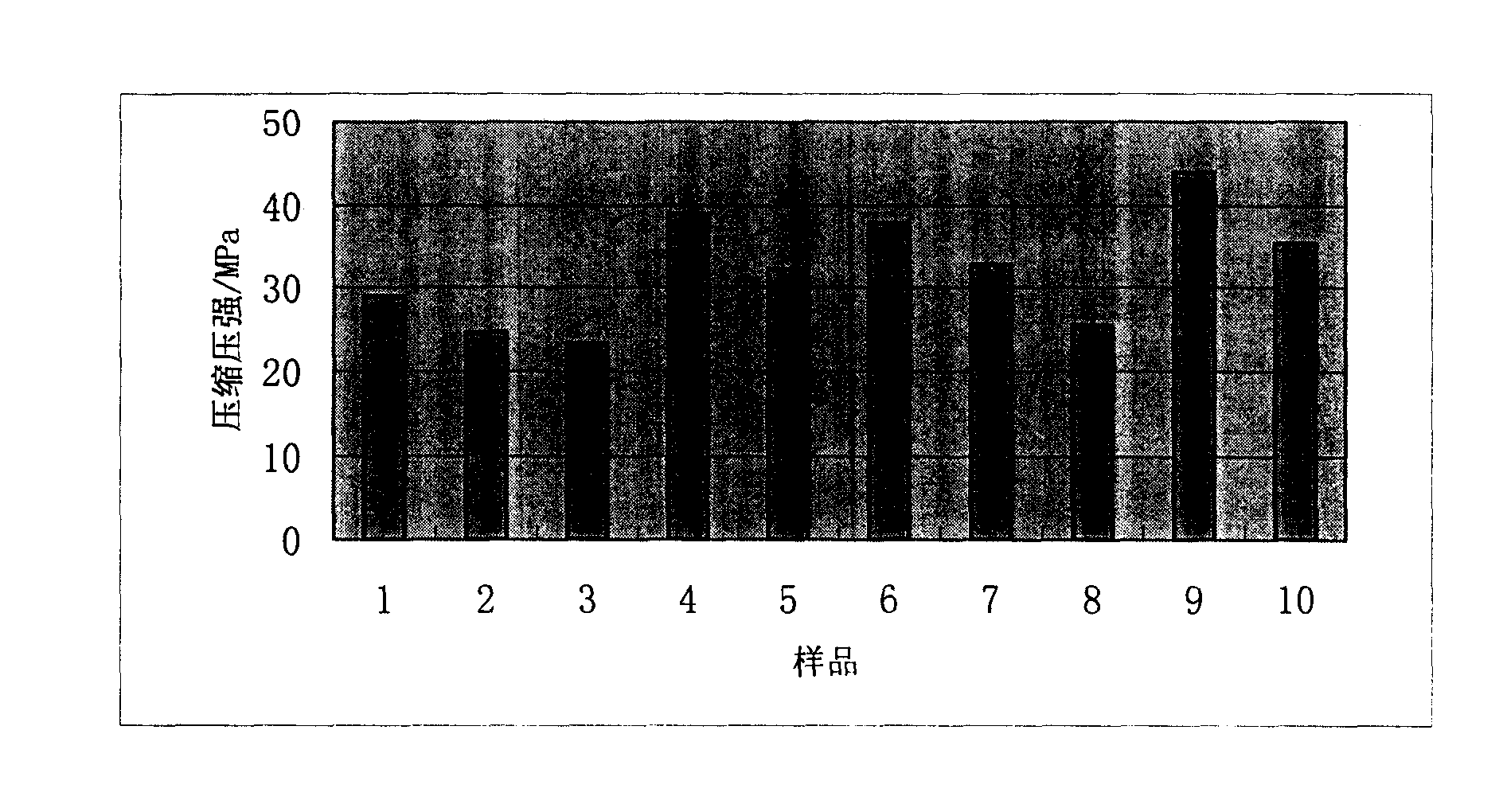

[0023] The invention uses compression deformation to judge whether the plasticity of the powder sintered stainless steel is high-density pressed and sintered with the addition of an activator is good or bad. Depress the sample to a certain height (about 40% of the total height of the sample) to see if there are macroscopic cracks. The compression pressure required for each sample at 40% reduction is as follows figure 1 shown.

[0024] From figure 1 Look, when the reduction is the same, 4# sample, 6# sample, and 9# sample r...

example 5

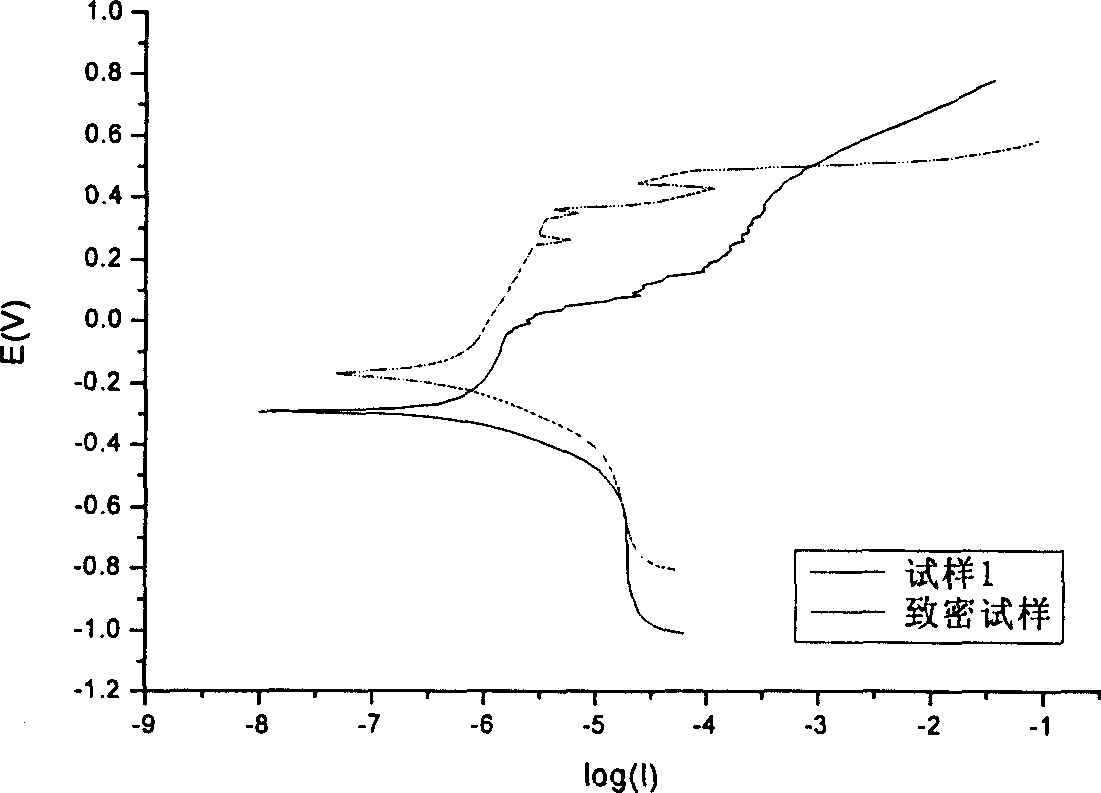

[0026] Example 5: An important indicator for evaluating the performance of powdered stainless steel parts is to determine the quality of its corrosion resistance. Usually in a certain concentration of NaCl or various acidic media such as H 2 SO 4 、HNO 3 and HCl to determine the corrosion type of stainless steel.

[0027] An important factor restricting the development of powder stainless steel structural parts is the low density of the parts, which means that there are a large number of residual pores inside the parts. These residual pores, especially the interconnected pores, not only significantly reduce the mechanical properties of the material, but also deteriorate the corrosion resistance of the parts. Since the present invention aims to make stainless steel products that can be well applied to watches and some medical instruments, it requires samples to have good corrosion resistance in environments similar to sweat, body fluids, and the like. A self-prepared solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com