Lead frame for semiconductor device

A lead frame and semiconductor technology, used in semiconductor devices, semiconductor/solid-state device components, electric solid-state devices, etc., can solve problems such as damage to appearance, inability to meet corrosion resistance, moisture resistance, and impracticality of lead frames. Appearance, good appearance, effect to ensure snug fit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0070] Hereinafter, preferred embodiments of the present invention will be described with reference to the drawings.

[0071] [plan 1]

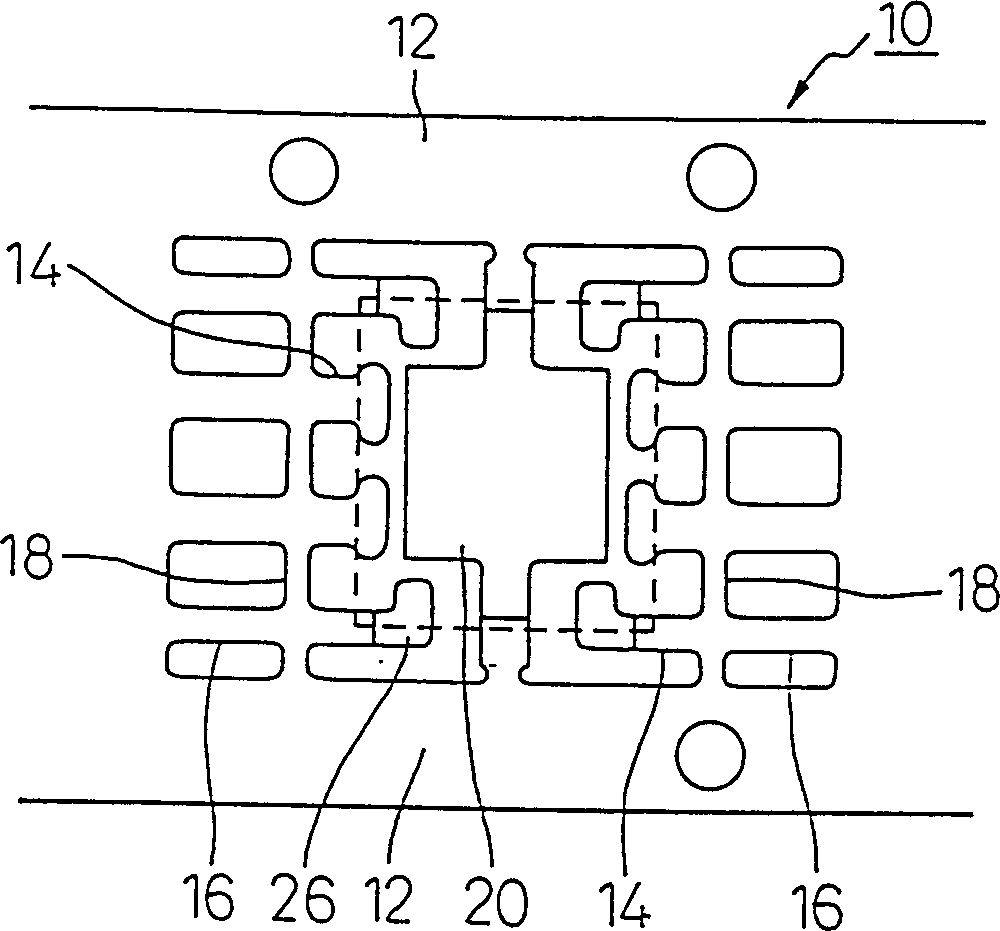

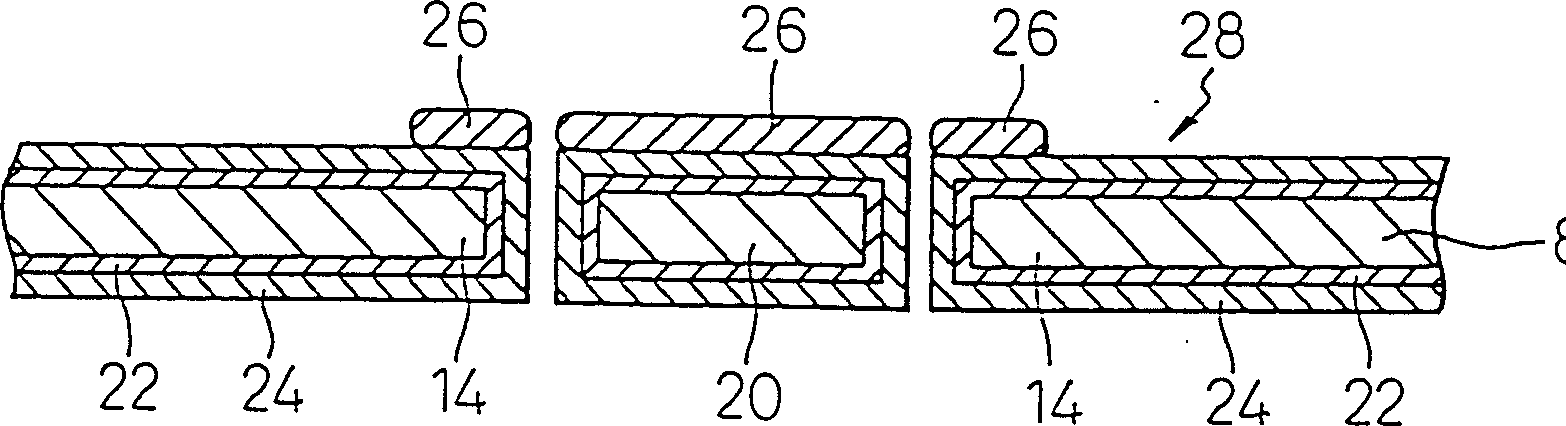

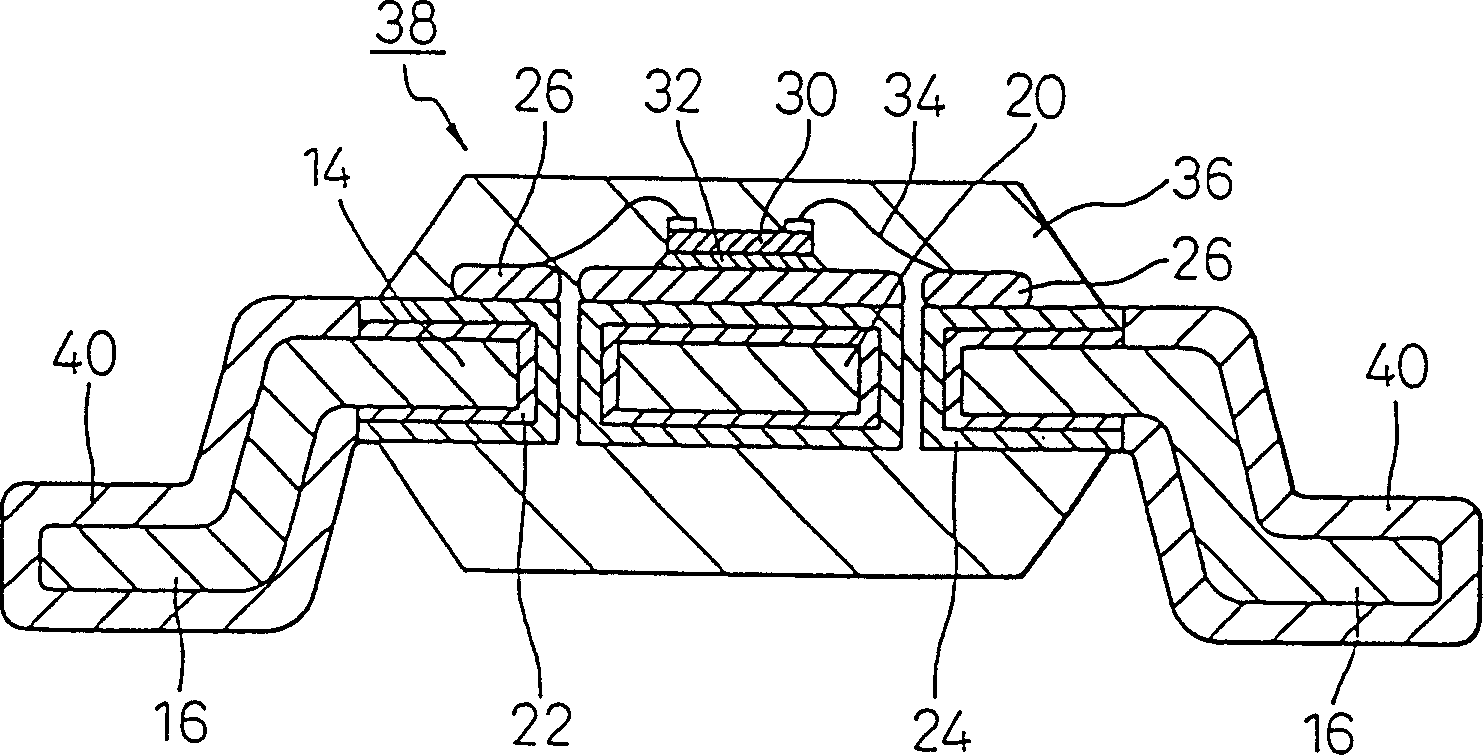

[0072] According to the first invention, such as figure 1 and figure 2 As shown, the copper-based material 8 is stamped or etched to form a lead frame body 10 having a frame 12, an inner lead 14, an outer lead 16, a tie-bar 18, and a chip pad 20. The copper-based material can be Various materials such as pure copper, copper-tin alloy, copper-zinc alloy, copper-iron alloy, and copper-chrome alloy are used.

[0073] Next, the galvanized film 22 is formed on the entire surface of the lead frame body 10 . The thickness of the galvanized film 22 is formed to be about 0.001 to 0.5 micron, preferably a strike plating film of about 0.01 micron.

[0074] Next, a copper-plated film 24 having a thickness of 0.02 to 0.4 microns is formed on the zinc-plated film 22 . The thickness of the copper plating film 24 is more preferably 0.1 to 0.3 microns. ...

Embodiment 1、2、3

[0093] On the copper alloy material (Cu-1 ~ 3wt% Sn alloy. The same below), use the above electroplating solution to form a 0.01 micron galvanized film, and use the above electroplating solution to form a thickness of 0.1 micron, 0.3 micron, 0.4 micron on the galvanized film. Micron copper plating film.

[0094] [Scenario 2]

[0095] According to the first invention, the copper-zinc alloy plating film 22 is formed on the lead frame body 10 instead of the zinc plating film 22 . The copper-zinc plating film is also formed to a thickness of about 0.001 to 0.5 micron, and it is desirable to form a strike plating film of about 0.01 micron.

[0096] The composition of the copper-zinc electroplating film is: the ratio of copper is 10-90wt%, and the rest is zinc.

[0097] Next, a copper plating film 24 is formed on the copper-zinc alloy plating film 22 . The thickness of the copper plating film 24 is 0.02 to 0.4 microns, preferably 0.1 to 0.3 microns to strike the plating film. Adhe...

Embodiment 4、5、6

[0109] On the copper alloy material, form a 0.01 micron copper-zinc (copper 50-zinc 50) alloy electroplating film with the above-mentioned electroplating solution, and use the above-mentioned electroplating solution on the copper-zinc alloy electroplating film to form a thickness of 0.1 micron, 0.3 micron, 0.4 micron copper plating film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com