Fastening method for heating electronic device and radiating device

A technology of electronic devices and heat dissipation devices, which is applied in the field of device production technology for instant heat dissipation, can solve problems such as difficulties, high requirements for spring clip design and manufacturing, and high cost, and achieve the effects of reducing production costs, good stability, and convenient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

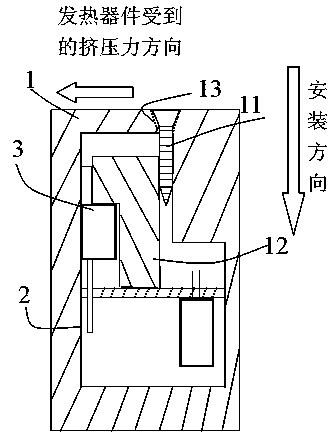

[0033] Example 1: If image 3 As shown, a deformable filler 12 is arranged on the outside of the heat-generating electronic device 3 opposite to the contact surface 2 of the heat dissipation device 1, and a threaded part 11 is fixed on the back of the filler 12. The contact surfaces 2 are parallel.

[0034] The threaded part 11 above can be a self-tapping screw, and the deformable filler 12 can be a plastic part.

[0035] Through the above method, the use of the deformable filler 12 to cooperate with the progress of the threaded part 11 in the fastening direction is achieved, so that the filler 12 is deformed when the threaded part 11 reaches the predetermined installation position, and the heat-generating electronic device 3 and the screw thread The part 11 forms a force component perpendicular to the traveling direction that presses the heat-generating electronic device 3 onto the heat-dissipating device 1 .

[0036] Wherein the threads of the threaded parts 11 are threade...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com